3D-systems - a selection of great ways to mess with content

3D-systems are used to visualize engineering solutions (such as training for NPP operators, monitoring there), in oil and gas exploration (the most expensive immersion systems go there), to demonstrate various products (from custom designs of car interiors to the type of packing goods in trucks), training of repairmen (you can disassemble a Boeing engine), in medicine for training, as well as for practicing evacuations and emergency situations at various critical facilities.

The main problem of content preparation is that there are many companies on the market that say "We can do this," but do not have their own hardware in fact. Without a two-week test, without a clear understanding of the limitations of iron and just knowing the special features of a rake, this is not “we can and can”, but “we want, but it won’t work out”.

Why the market exploded

The Occluses and other similar cheap 3D content display systems are to blame. They give a good presence effect, but are absolutely not suitable for the above engineering and technical needs, because working for more than 10-15 minutes already hurts the eyes and head. Well, the detailing is, alas, insufficient yet - pixels in the face are clearly visible. But - cheaply, and even very cheaply. Hence the ideas of many companies to make decisions in this spirit in the spirit of "cool and innovation." Yes, it is an innovation, but in most cases it is not cool. Cool is a cluster in your basement.

At our school, both customers and their contractors regularly apply to the 3D school. Regularly for training our specialists, often for direct orders, sometimes - so that we do at least something for the remaining two weeks of two months of development. We save projects.

I’ll tell you about the typical rake of such "rescued" and generally about what is most often found on the market.

Rake

- The very first children's rake is initially the choice of such visualization software (cheaper), which works with some kind of its own format. It sounds a little strange, but support for different CADs is the basis for the content to display normally. That's why we love Eon very much - it grinds everything out of the box, from 3ds, FBX and OBJ to the STL, IGES, SolidWorks and Inventor formats. Why is it important? Because sooner or later they will bring you a model from Compass, 3D Max, something Siemens and so on. In a couple of years, thousands of people went through the center and they brought about two dozen different formats from the strangest sources. Everything was converted without problems.

- The second part is the choice of iron for a specific task.As a rule, the most frequent ones are training, education, presentation. There are systems that are cheap, but not suitable for a particular task. For example, we have a 3D table that makes architecture and mechanisms cool. But with him it is very problematic to train to look into the turbines. But in a 3D cube, you can suspend the turbine in the air in front of the user so that he bypasses it, sticks his head inward, almost licks the blade, etc. Tables are not suitable for such tasks. Or, for presentation, you need a good wow effect (this often applies to museums and sellers of VIPs) - there is a holographic system that shows an object floating in the air. In the dark. Experience and settings allows you to correctly recommend and select a specific system. Naturally, when a company does not have the full range of options, it’s done on what the staff knows or what is more profitable to sell. The result is not always optimal.

- A lot of rakes are collected at the stage of collecting the terms of reference. Perhaps this is the most difficult stage. It is necessary to understand for the customer what kind of content he needs, how he will use it and under which systems. It is necessary to clearly state all the details. It happens that the customer sets the task to do one system, after two months he looks at the preliminary run and says: “Listen, something is not impressive, let's do it under the holographic projector”. You can redo it, but it's time. Even at the stage of negotiations, you need to carefully listen and study all aspects.

- At the same stage of identifying technical requirements, it is important to understand the algorithm and storyboard.Ideally - again, first draw everything at least on napkins and take the same training steps with the teacher in steps. Why is it important? Well, for example, this removes the questions of how to properly create a model. Here is a keyboard: you can create it as one solid model, if it will be used as a dumb light object in the simulator of emergency and evacuation. You can do it as a collection of keys, if you plan to click on them. And you can do the insides, if they are supposed for training analysis. What objects, what detail, what control - all this needs to be understood more “on the shore”.

Multipliers are kidding

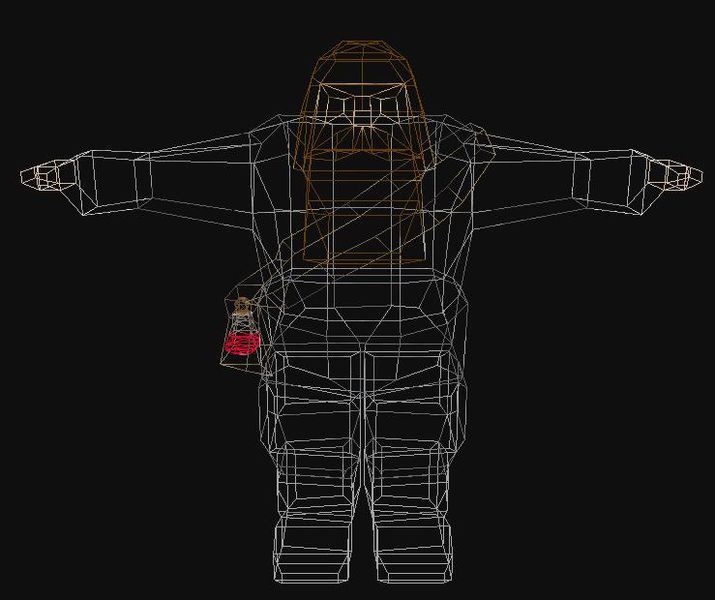

- Then optimization.As a rule, this is a common problem for those with insufficiently professional specialists. For example, for oil refineries, most of the rendering is in real time, and only important objects need to be detailed. The same library tubes look great close by, even the bumps are visible on them. But this is not necessary - every extra polygon on the pipe will slow down the process. But, on the contrary, shut-off valves - they need perfectly detailed. And immediately you need to think about the fact that with further content modernization, the architecture did not cause any brakes. Often a project comes right up to the capabilities of the system, and then after a month it starts to lag, because the customer has added models of new equipment. In general, you can thoughtlessly simulate it in a high-poly, or you can approach it wisely.

Here is a gnome with a bottle. The bottle is not visible. And there are more polygons in it than in the whole gnome.

- The final part of the optimization is usually like a repair - “why align the walls, they will fix them on the finish with wallpaper”. It is immediately known that the project for phones including - but they think about optimization only at the very end.

- The approach to modeling is important. You need to immediately know how the interactive will work, what will be uploaded to the software environment, how the objects will interact, what exactly will happen. You need to be able to document it right away, otherwise then a sea of surprises awaits.

- The second point where the most problems are interfaces and interaction with control devices.In terms of compatibility, it’s relatively calm - Eon itself supports a lot of manipulators from joysticks and gloves to kinekt and 3D mice, there are drivers for everything. No need to write anything yourself. There are also many ready-made modules such as menus in the air, various systems for interacting with the user. There are typical modules like “explosion-schemes” that make it easy and simple to disassemble an object. Many drivers for ready-made 3D systems. We take any cube and directly in the environment indicate that it is there. And all the settings of cameras, angles and so on are already optimal. In another environment, you would have to spend more time.

- The accuracy of 3D control is important.There is a driver, it describes how to work with the device. But you need to think for the user. To try to take an object does not turn into pixel hunting, you need auto-aiming. Often, a magnet module is required that allows you to place the details of an object at some distance so that they "click" converge and assemble. Understanding the convenience of the interface for the final system greatly affects the level of immersion, so you can’t dismiss this (as is often done on enterprise software for engineers).

“Mouse”

“Gamepad”

- With regards to iron, there are a lot of nuances in terms of 3D types- vertical layout, horizontal, synchronization, alternation. Depending on the system, this may mean a half-resolution drop. For ourselves, we came to the conclusion that it makes sense to use only 120 Hz (quad buffer or Full3D) saves the resolution. You have probably seen this smearing effect on home 3D TVs due to line rotation.

- Themselves regularly stepped on a rake with the correct selection of points - for different audiences need different models. For example, there are three main technologies now - synchronization using the projector’s DLP chip (DLP glasses will fit any projector), infrared and radio signals. The air interface is expensive but effective. IR is quite functional. DLP is cheap and angry. It’s also important to consider the drop in brightness due to active glasses to 70%.

- Another link is computers for rendering . They must be with the correct graphics card. Not everyone gives out a quad buffer, not everyone gives out a mosaic system for different screens. Again, Eon works with the nVidea mosaic system - many screens are combined into one panoramic. And this requires a certain iron. Wrong laptop for rendering on the road or a wrong video card - garbage at the exit.

- Transmitters-receivers must support 120 Hz- if factors are not taken into account, the signal will not reach itself completely. Not everyone knows how to transmit 4K 120 Hz purely in physics. While Extron works without jambs for us, others have not grown together 100% qualitatively. The signal is sent via optics or twisted pair. The quality of the connection matters: if the same optics are stuck a little incorrectly - at the time of maximum load, the screen may begin to flicker, which is often attributed to software flaws, rather than the physical properties of the channel. Of course, there are traditional problems when the specification for the device shows one thing, but in real life everything looks a little different. There was, for example, a cable that, at the slightest bend, exceeded the declared parameters. Often, customers buy a new laptop for demonstrations, and then face the fact that you need to get an amplifier to it. We use externally powered boosters for such cases, if something is shown on other people's equipment. There are still nuances, without knowing which you can launch a presentation for a very long time.

- A lot of difficulties during transportation - it is important to assemble and disassemble very carefully. If mounted carelessly, the structure loosens. In our youth, the projector fell, crashed - during installation on a point they hung it for tests, but forgot to tighten it. Once arrived - the IR emitter did not work for 100 bucks. And no one has it in Moscow, only messes with the order for two months. As a result, they established their spare parts warehouse.

- In 3D, many components that can kill the whole effect. If the glasses are not charged or the cable doesn’t pass 3D, all the other components for tons of dollars are no longer important. Many points of failure. For example, we had a case when one person - let's call him Colonel - looked closely at the product model, and then said: “It’s something muddy.” We figured out 10 minutes until we realized that his radio interface to the glasses had fallen off. Changed the "frame" - then it went fine. Therefore, it is good practice to tightly monitor the lamp operating hours, always recharge your glasses even after five seconds of use, check emitters. In the demo center we turn on the system an hour before the presentations always, there is even a special person for this. An hour before the end of the working day, this same special person puts everything on charge, checks the iron, changes components.

It's about such glasses.

- Well, the traditional development problems - code style, general architecture, comments - all this is familiar, but still relevant.

Something like that. If you're interested in more about the 3D center, then here's a tour . Well, here is my mail, if you have a question that is not suitable for comments - PPochtennov@croc.ru.