Turning CNC Siemens Sinumerik 840D sl: creating a cutting tool [shot 02]

Good day to all!

This is a project of Open Technical Education "Polytech 2.0".

Here is our history and ideology .

Well, after a short pause, we continued to upload video on the CNC and here is another introductory shot.

Please write off in the comments right away whether it is worth duplicating textual training material here on Habr, or is it better to write off new and events of the stages of development of our project. We just have in our blanks materials on CAD / CAM systems that are not worthy of a separate video, but perhaps would be interesting to you!

In this video, I would like to talk about how to create the cutting tool necessary for programming turning in the Siemens Sinumerik 840D Sl CNC system:

This article will somewhat supplement the video itself and its content, so if you have questions, you are welcome to tackle it.

So! You have already seen how the CNC window and its main function keys are arranged, and now we will move on to the process of creating the tool.

When you press the Offset button , the window of the cutting tool manager installed on your machine opens. In my case, this is a lathe emulator with a 12-position turret into which a cutting tool is installed. An example of such a head is shown in the figure:

The tool itself is installed in blocks that are correctly called snap-ins. Blocks are different: from the usual tool holders for fixing them to drive ones, in which you can install a rotating tool, for example, a drill or a mill. In conventional blocks for cutters there is a groove width equal to the width of the holder (the most common sizes: 20x20 mm and 25x25 mm). The cutter assembly itself is installed in this groove. A carbide plate is attached to the cutter, which carries out the cutting process.

The difference between conventional blocks is that they use the rotation of the lathe spindle of the machine for processing, while the tool is rigidly fixed to the block. And for drive units, the tool itself rotates and the workpiece can be firmly clamped in a turning chuck. There are cases when the tool rotates in the drive unit and the turning chuck rotates - this happens, for example, when milling any contours. In the figure you can see the tail of the block with a gear at the end - this is the axis through which rotation is transmitted to the cutting tool. The block in the figure is for vertical machining (the axis of rotation of the tool is perpendicular to the axis of rotation of the part), and there are also horizontal blocks where the axis of rotation of the tool and the part are parallel.

An example of using a drive unit of a vertical layout is milling a keyway on the outer diameter of the part, and horizontal - getting a hexagon on the end of the part (such as a bolt).

So, we will create the simplest tool - a turning tool, which we will use when machining the end face of a part and turning its outer diameter. To do this, go to the Offset window if you were in some other window, press the " Instr . List " key and go to the bottom of the list (after the numbered lines). When you select an empty line at the bottom of the list, the “ New tool ” button in the right column of the function keys becomes active .

The tool type selection window opens. As you can see, a lot of different cutting tools can be installed on a CNC lathe. For us, for the concept of the principle and the algorithm of action, it’s enough to create a rough turning tool. We select the “ Draft tool ” and one of the four squares with the display of the position of the cutting edge is highlighted. What is the difference between these four pictures?

CNC lathes come with one or two turning spindles. For machining a part, each of the spindles uses its own type of tool position. If you visually look at the machine, then the left spindle is usually the main or first, and the right one is additional or second.

The part that we will process during the entire course will be installed in the first spindle, and accordingly the position of the tool will be described by the first and third boxes. I won’t describe the difference between them yet. Now we will create a tool with the first type of position, and in the next lessons we will create a tool in the third. In a nutshell - the first type is used for external processing:

and the second for internal processing :

After selecting the desired position, click on the OK button. The CNC system will ask us to enter the corresponding tool name. You can enter any word there so that you understand which tool you created, but if not only you are working on the machine, then it is worth using a description of the tool to be created by another person. In our case, it will be of the form: O_ROUGH_80_08 .

This is what it means:

О - Outside (external processing)

ROUGH - roughing (roughing)

80 - angle between the edges of the plate

08 - radius of rounding off the plate 0.8 mm

Our tool has been successfully created, now it must be described by a set of appropriate parameters. The length X is the position of the cutting edge in the X coordinate, the length Z in the Z coordinate, and the length Y in the Y coordinate. Both of these values are obtained by measuring the tool on the machine.

We work in a simulator, so in our case it is enough to indicate approximate values.

Radius is the radius of the rounding of the cutting edge of the cutter. For rough cutters, it usually ranges from 0.8 to 1.6. Install 0.8.

The arrow indicates the direction of installation of the cutter. By default, it coincides with our direction of the cutter mounted on the machine.

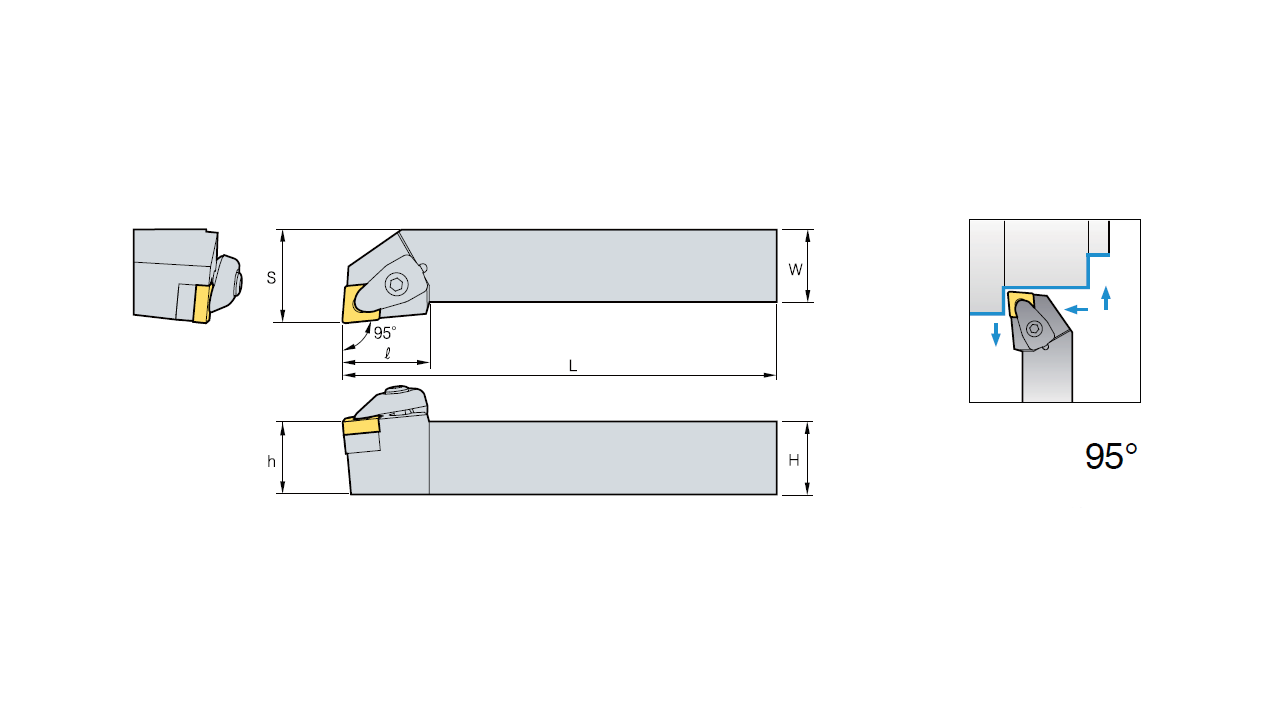

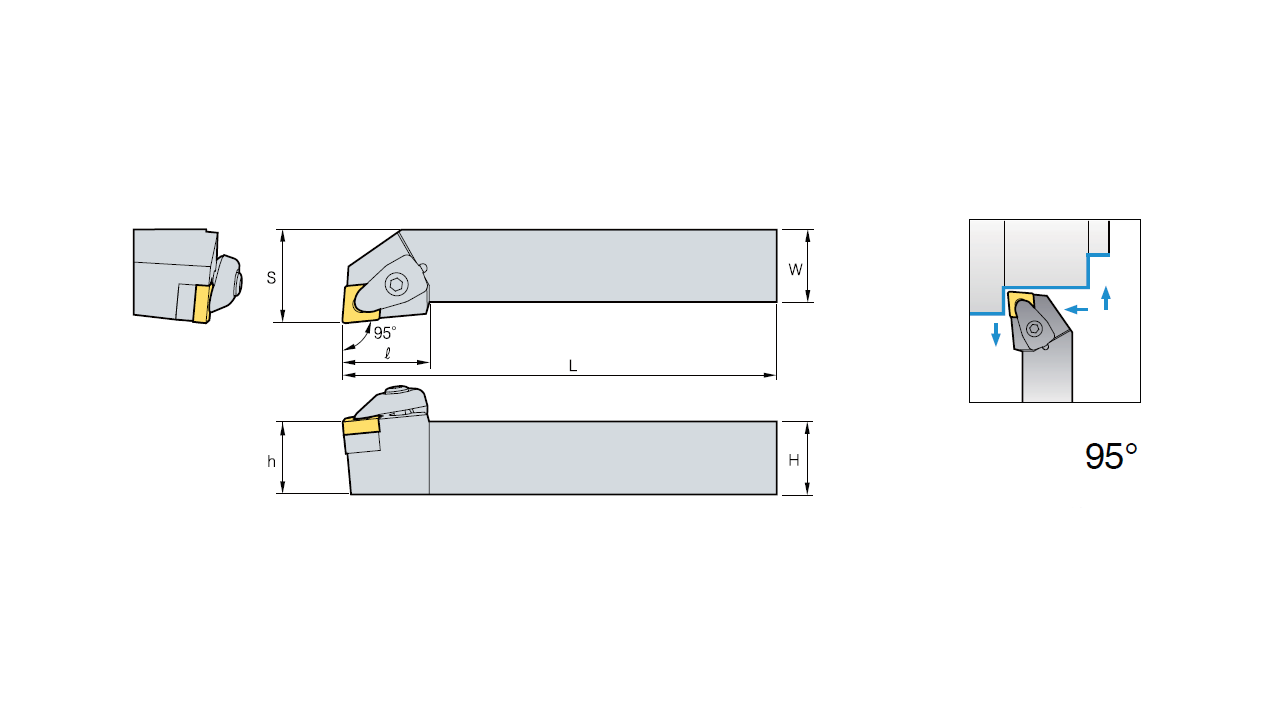

The holder angle is the main angle in the plan and it has its own on each cutter - therefore, I advise you to first study the catalog of the supplier of the cutting tool - there it is shown clearly. In our case, you can leave 95 degrees.

Number 80 - means the angle between the cutting edges on the cutter plate. For roughing, the most commonly used is a diamond-shaped plate with an angle between the sides of 80 degrees. In the figure you can see which plate geometries are available. It is worth noting that the dumber the edge, the higher the tool life (i.e., it will last longer). However, dumber - does not mean that the tool will not cut the workpiece material. Blunt edges are called edges with a fillet radius of 0.8 or higher, as well as, for example, round plates. Such a tool is used for roughing, and in turn a tool with a sharp edge - for finishing. The difference in these treatments is the plate load. When roughing, you can shoot more material at a time (pass),

The length of the insert that we have set to 11 mm is equal to the length of the cutting edge. You can directly measure the plate itself or also see the catalog.

The clockwise or counterclockwise arrow corresponds to the cutting direction. It depends on the type of holder installed and has only two meanings - left or right. In our case, the installed counterclockwise arrow corresponds to the left rotation of the spindle, and clockwise - corresponding to its right rotation. Here it’s worth looking at which holder is installed for processing - if the letter R is at the end of the holder designation according to ISO, then this holder is right, and if L - then the holder is left. The direction of rotation will depend, but there is one golden rule: "the direction of rotation of the workpiece should always be on the edge of the plate"

Two faucets and fields for installing checkmarks are responsible for turning on cooling when cutting with our tool. As a rule, the first checkmark is responsible for supplying fluid from the outside (by irrigation), and the second through the tool. However, it is better to check this point with the machine manufacturer.

That's it! We have successfully created the first cutting tool with which we will process our part in subsequent lessons.

Subscribe to the channel and like.

Good knowledge to you! Waiting for your suggestions and criticism!

This is a project of Open Technical Education "Polytech 2.0".

Here is our history and ideology .

Well, after a short pause, we continued to upload video on the CNC and here is another introductory shot.

Please write off in the comments right away whether it is worth duplicating textual training material here on Habr, or is it better to write off new and events of the stages of development of our project. We just have in our blanks materials on CAD / CAM systems that are not worthy of a separate video, but perhaps would be interesting to you!

In this video, I would like to talk about how to create the cutting tool necessary for programming turning in the Siemens Sinumerik 840D Sl CNC system:

This article will somewhat supplement the video itself and its content, so if you have questions, you are welcome to tackle it.

So! You have already seen how the CNC window and its main function keys are arranged, and now we will move on to the process of creating the tool.

When you press the Offset button , the window of the cutting tool manager installed on your machine opens. In my case, this is a lathe emulator with a 12-position turret into which a cutting tool is installed. An example of such a head is shown in the figure:

The tool itself is installed in blocks that are correctly called snap-ins. Blocks are different: from the usual tool holders for fixing them to drive ones, in which you can install a rotating tool, for example, a drill or a mill. In conventional blocks for cutters there is a groove width equal to the width of the holder (the most common sizes: 20x20 mm and 25x25 mm). The cutter assembly itself is installed in this groove. A carbide plate is attached to the cutter, which carries out the cutting process.

The difference between conventional blocks is that they use the rotation of the lathe spindle of the machine for processing, while the tool is rigidly fixed to the block. And for drive units, the tool itself rotates and the workpiece can be firmly clamped in a turning chuck. There are cases when the tool rotates in the drive unit and the turning chuck rotates - this happens, for example, when milling any contours. In the figure you can see the tail of the block with a gear at the end - this is the axis through which rotation is transmitted to the cutting tool. The block in the figure is for vertical machining (the axis of rotation of the tool is perpendicular to the axis of rotation of the part), and there are also horizontal blocks where the axis of rotation of the tool and the part are parallel.

An example of using a drive unit of a vertical layout is milling a keyway on the outer diameter of the part, and horizontal - getting a hexagon on the end of the part (such as a bolt).

So, we will create the simplest tool - a turning tool, which we will use when machining the end face of a part and turning its outer diameter. To do this, go to the Offset window if you were in some other window, press the " Instr . List " key and go to the bottom of the list (after the numbered lines). When you select an empty line at the bottom of the list, the “ New tool ” button in the right column of the function keys becomes active .

The tool type selection window opens. As you can see, a lot of different cutting tools can be installed on a CNC lathe. For us, for the concept of the principle and the algorithm of action, it’s enough to create a rough turning tool. We select the “ Draft tool ” and one of the four squares with the display of the position of the cutting edge is highlighted. What is the difference between these four pictures?

CNC lathes come with one or two turning spindles. For machining a part, each of the spindles uses its own type of tool position. If you visually look at the machine, then the left spindle is usually the main or first, and the right one is additional or second.

The part that we will process during the entire course will be installed in the first spindle, and accordingly the position of the tool will be described by the first and third boxes. I won’t describe the difference between them yet. Now we will create a tool with the first type of position, and in the next lessons we will create a tool in the third. In a nutshell - the first type is used for external processing:

and the second for internal processing :

After selecting the desired position, click on the OK button. The CNC system will ask us to enter the corresponding tool name. You can enter any word there so that you understand which tool you created, but if not only you are working on the machine, then it is worth using a description of the tool to be created by another person. In our case, it will be of the form: O_ROUGH_80_08 .

This is what it means:

О - Outside (external processing)

ROUGH - roughing (roughing)

80 - angle between the edges of the plate

08 - radius of rounding off the plate 0.8 mm

Our tool has been successfully created, now it must be described by a set of appropriate parameters. The length X is the position of the cutting edge in the X coordinate, the length Z in the Z coordinate, and the length Y in the Y coordinate. Both of these values are obtained by measuring the tool on the machine.

We work in a simulator, so in our case it is enough to indicate approximate values.

Radius is the radius of the rounding of the cutting edge of the cutter. For rough cutters, it usually ranges from 0.8 to 1.6. Install 0.8.

The arrow indicates the direction of installation of the cutter. By default, it coincides with our direction of the cutter mounted on the machine.

The holder angle is the main angle in the plan and it has its own on each cutter - therefore, I advise you to first study the catalog of the supplier of the cutting tool - there it is shown clearly. In our case, you can leave 95 degrees.

Number 80 - means the angle between the cutting edges on the cutter plate. For roughing, the most commonly used is a diamond-shaped plate with an angle between the sides of 80 degrees. In the figure you can see which plate geometries are available. It is worth noting that the dumber the edge, the higher the tool life (i.e., it will last longer). However, dumber - does not mean that the tool will not cut the workpiece material. Blunt edges are called edges with a fillet radius of 0.8 or higher, as well as, for example, round plates. Such a tool is used for roughing, and in turn a tool with a sharp edge - for finishing. The difference in these treatments is the plate load. When roughing, you can shoot more material at a time (pass),

The length of the insert that we have set to 11 mm is equal to the length of the cutting edge. You can directly measure the plate itself or also see the catalog.

The clockwise or counterclockwise arrow corresponds to the cutting direction. It depends on the type of holder installed and has only two meanings - left or right. In our case, the installed counterclockwise arrow corresponds to the left rotation of the spindle, and clockwise - corresponding to its right rotation. Here it’s worth looking at which holder is installed for processing - if the letter R is at the end of the holder designation according to ISO, then this holder is right, and if L - then the holder is left. The direction of rotation will depend, but there is one golden rule: "the direction of rotation of the workpiece should always be on the edge of the plate"

Two faucets and fields for installing checkmarks are responsible for turning on cooling when cutting with our tool. As a rule, the first checkmark is responsible for supplying fluid from the outside (by irrigation), and the second through the tool. However, it is better to check this point with the machine manufacturer.

That's it! We have successfully created the first cutting tool with which we will process our part in subsequent lessons.

Subscribe to the channel and like.

Good knowledge to you! Waiting for your suggestions and criticism!