A corporation that DIY challenges you to a duel

This story began simply: the office multifunction printer broke. Multi Functional Device means a copier, printer and fax. The piece of iron did not break for the first time, and it was possible to simply replace an unreliable device. But "no money." Warranty is also long over. Anyway, the repair on my own is not my first time. Challenge accepted!

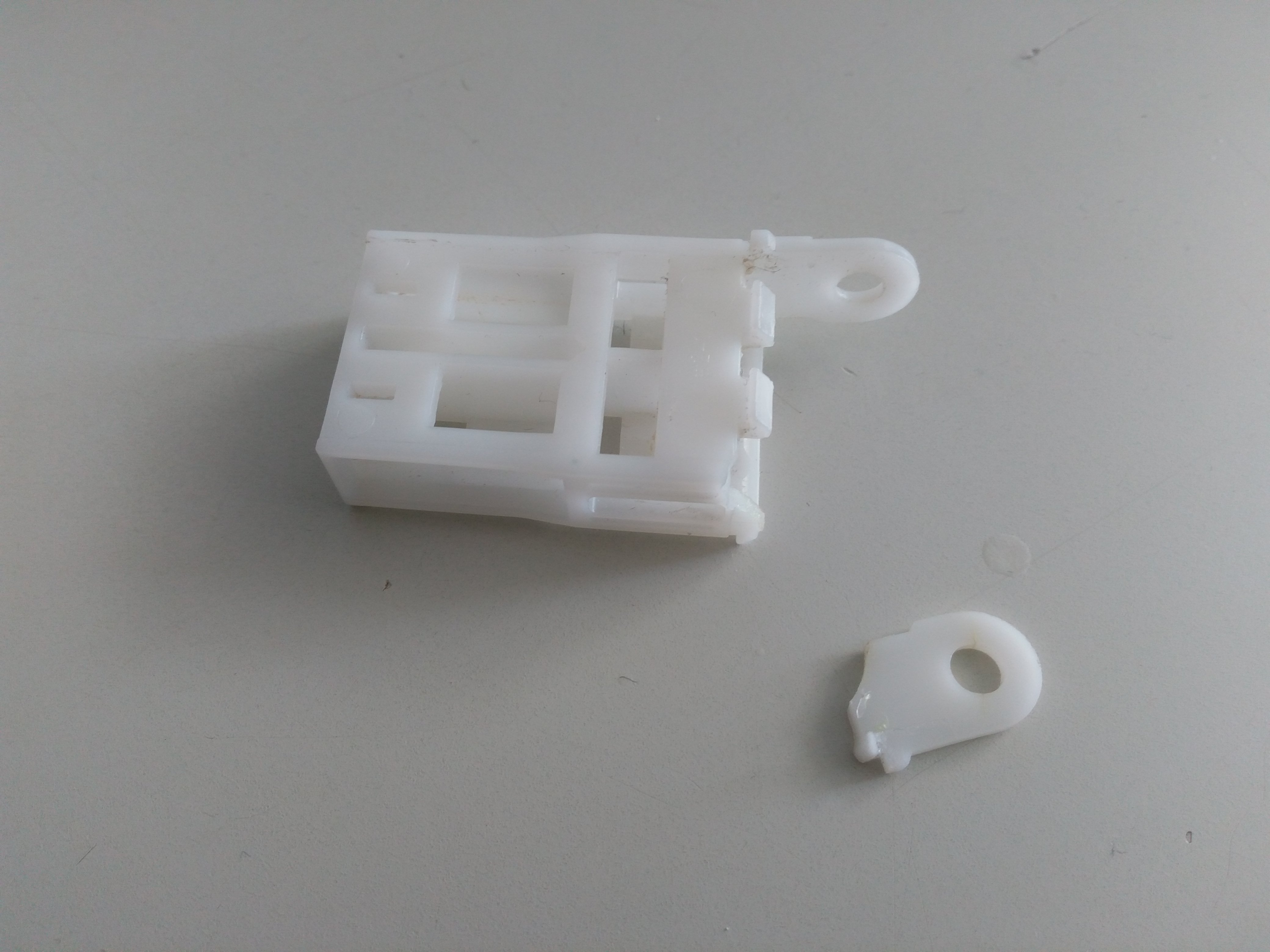

The cause of the breakdown was discovered without difficulty. The small plastic part in the cover was broken. At the same time, due to the design features, the part remained in place, and the failure was almost imperceptible.

Detail can be found and ordered. But it seemed to me that there is a cheaper and faster way. There is a 3D printer standing idle, I'll draw it once, and then I can print at least a hundred in reserve.

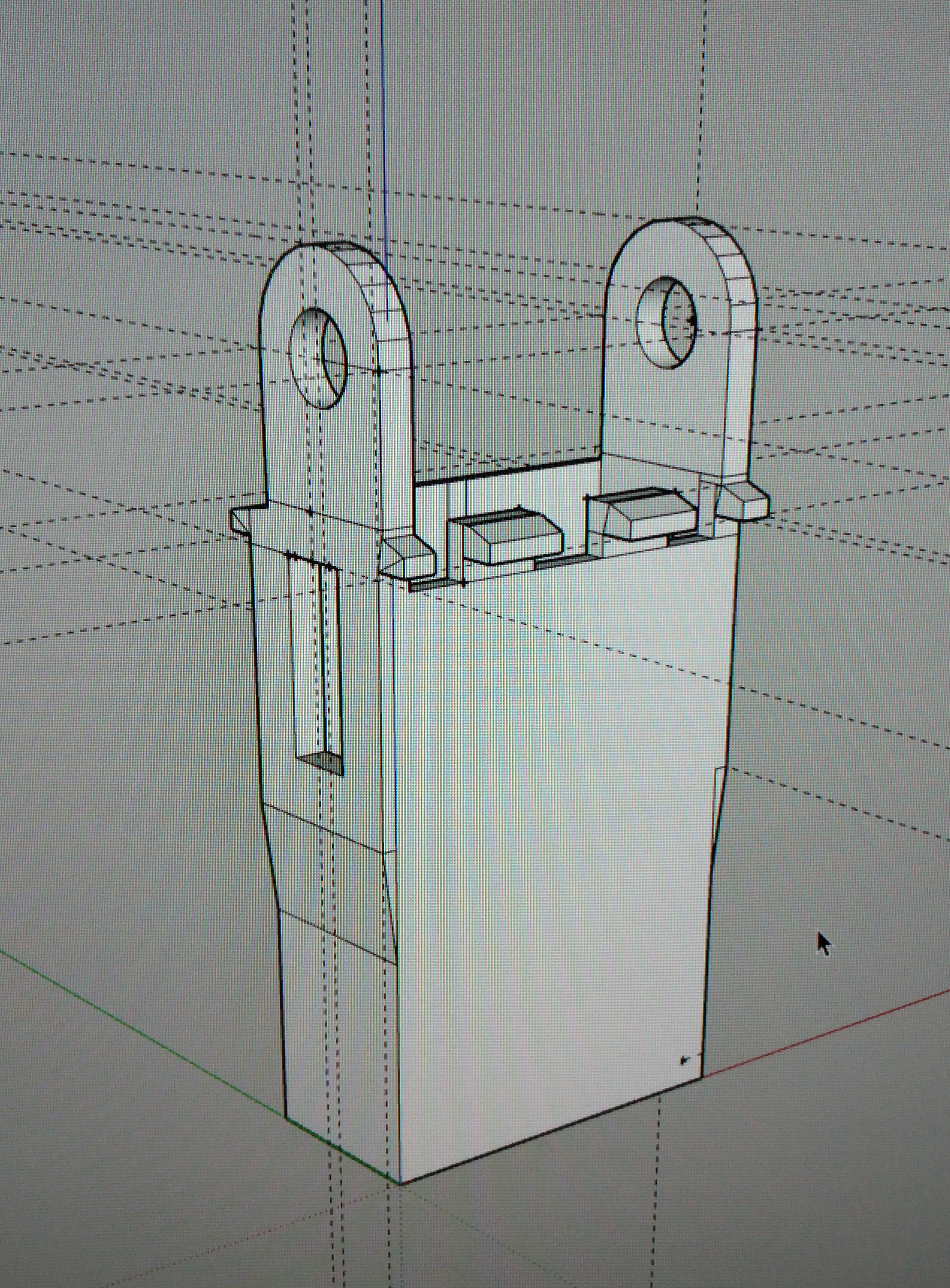

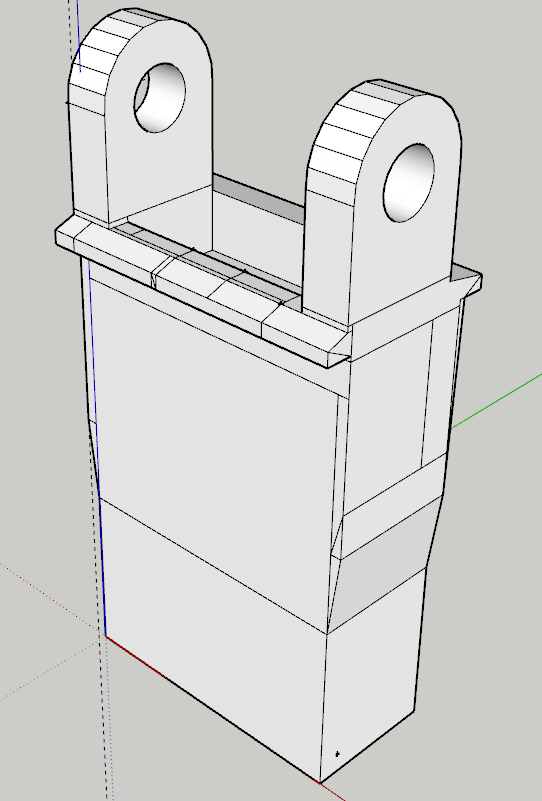

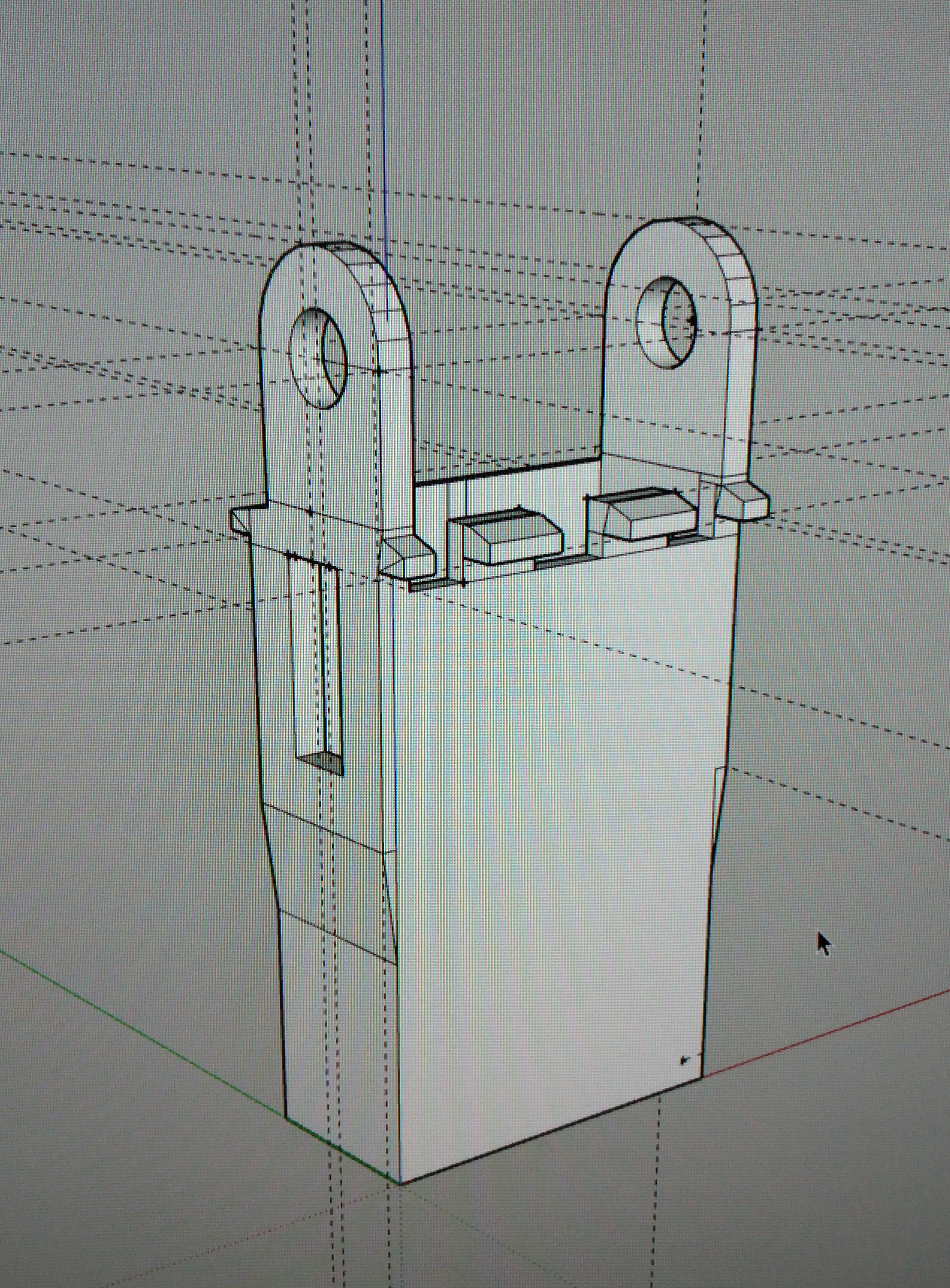

When I first met, I studied the problem detail inattentively. The essence of the detail is a loop on which the device lid is held. And what is there, a loop: two holes and a pin. There is nothing to wise and even harmful.

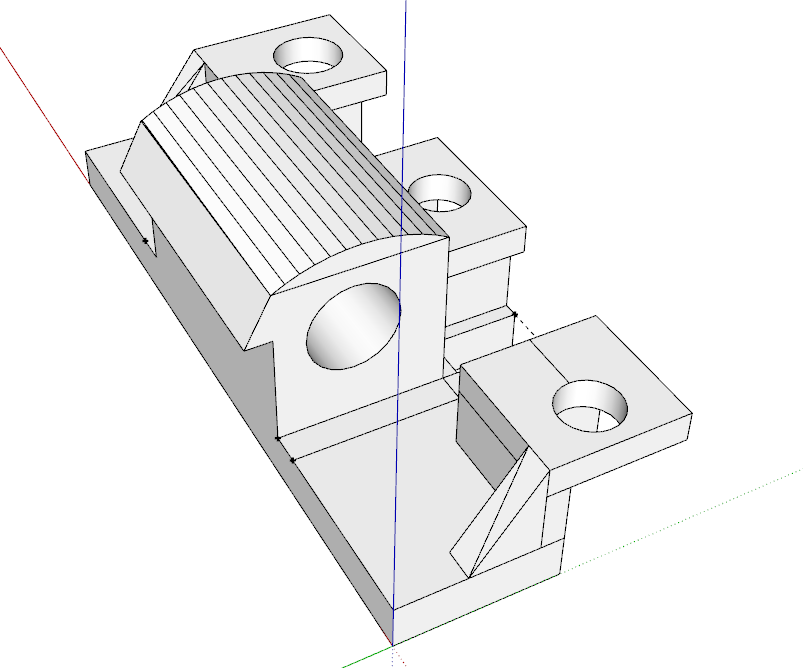

Quickly measuring the original, he marveled. I added strength in some places according to my understanding,

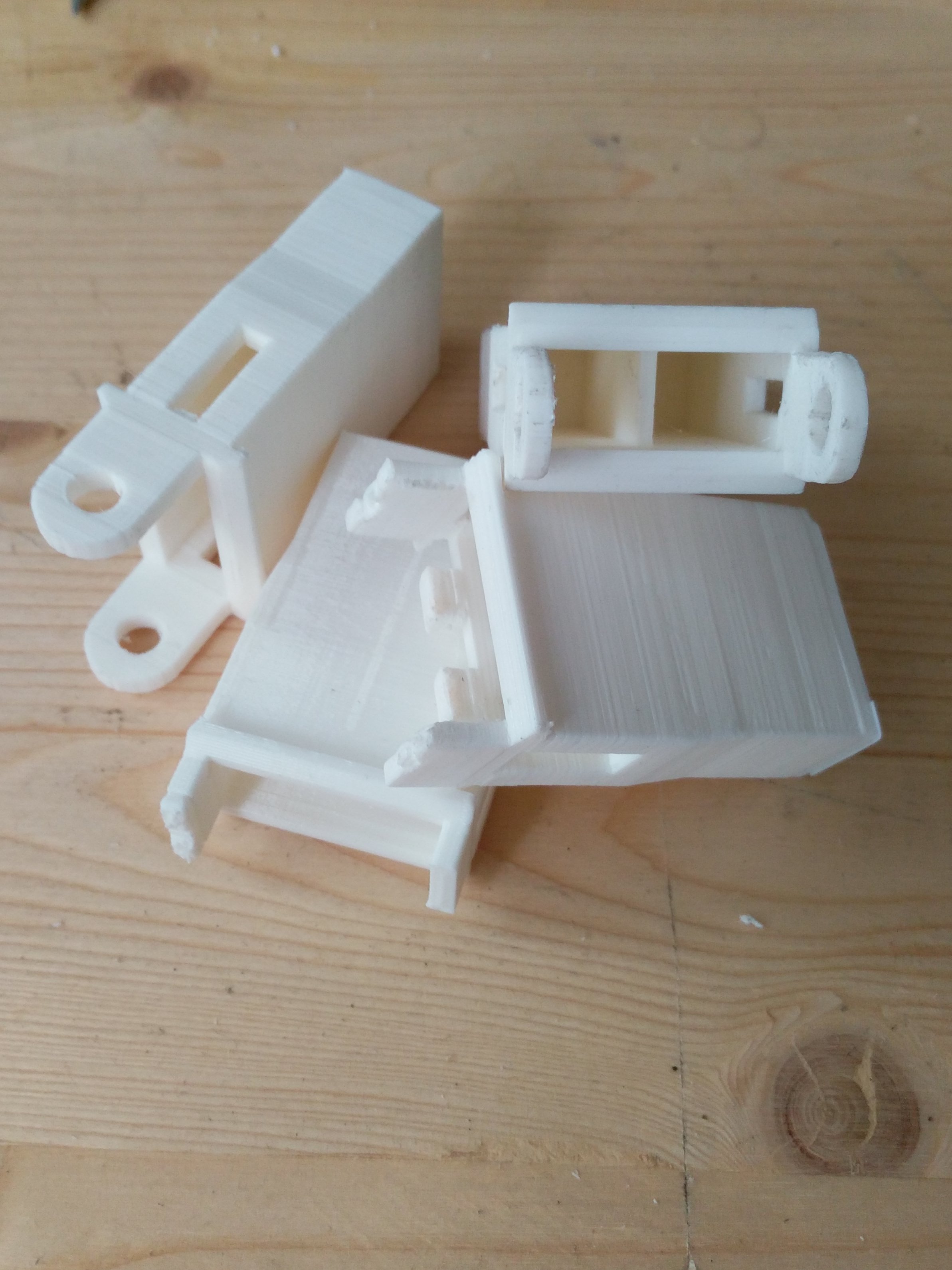

printed:

Share it.

Not without a file - but found:

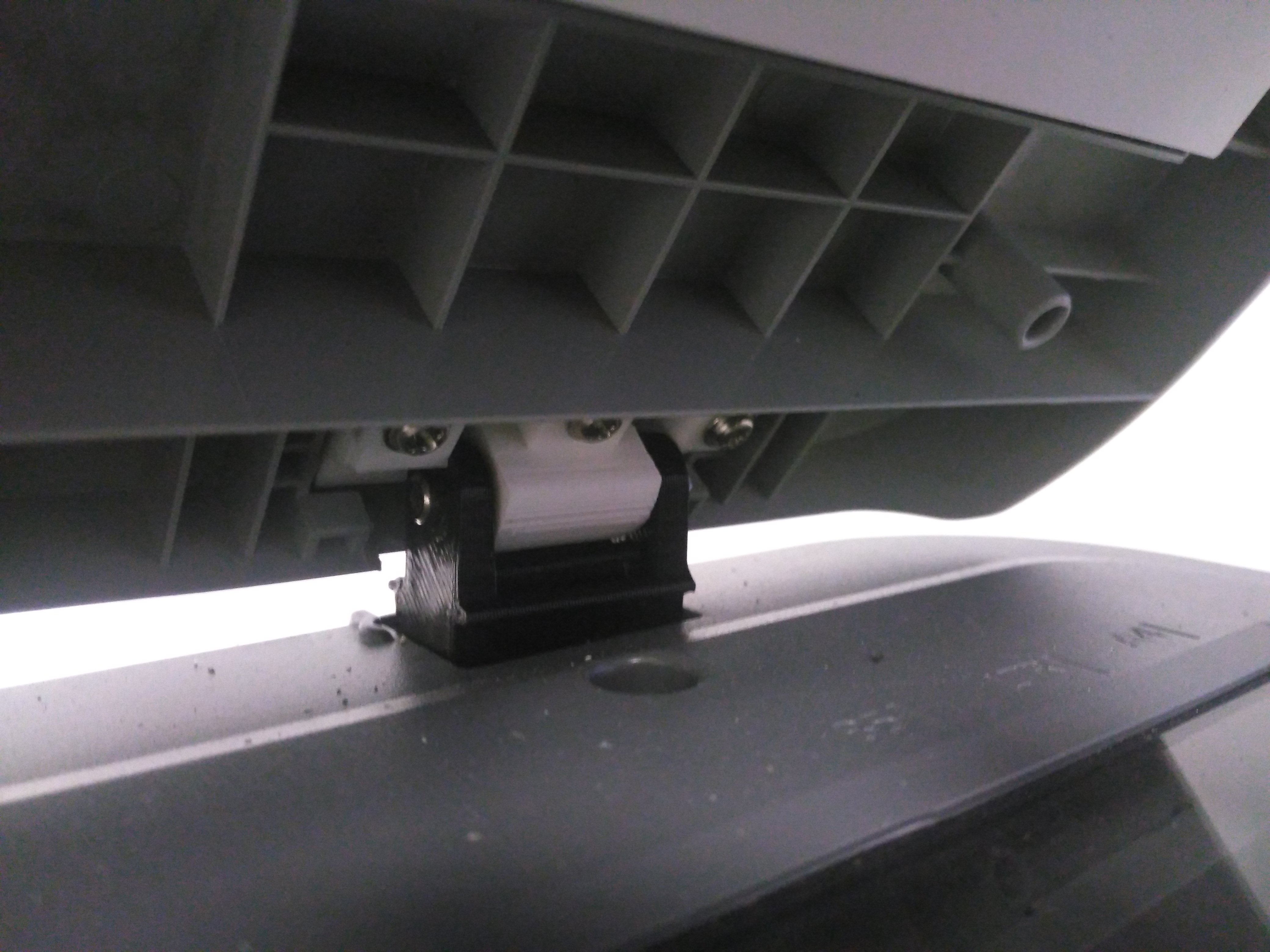

The copy lasted three days and was again broken.

"Along the same", say sophisticated printers. “And in general, of what is there, the detail was painted and printed, it’s a big deal.” And they will be partly right (survived, three-dimensional design and printing at home is not new).

However, let's continue and look at our item more closely. This is interesting, I promise.

Let's start with the fact that the loop is made of plastic with a thickness of two millimeters. The very thing that embarrassed me in the first place, and that I tried to improve in my copy. On the unfortunate two millimeters hanging lid weighing at least a kilogram. Pin, at the same time, - iron. I do not have the appropriate education, but even to me it is clear: the decision is strange. The margin of safety is clearly insufficient even for a static connection. And even more so for a heavy cover.

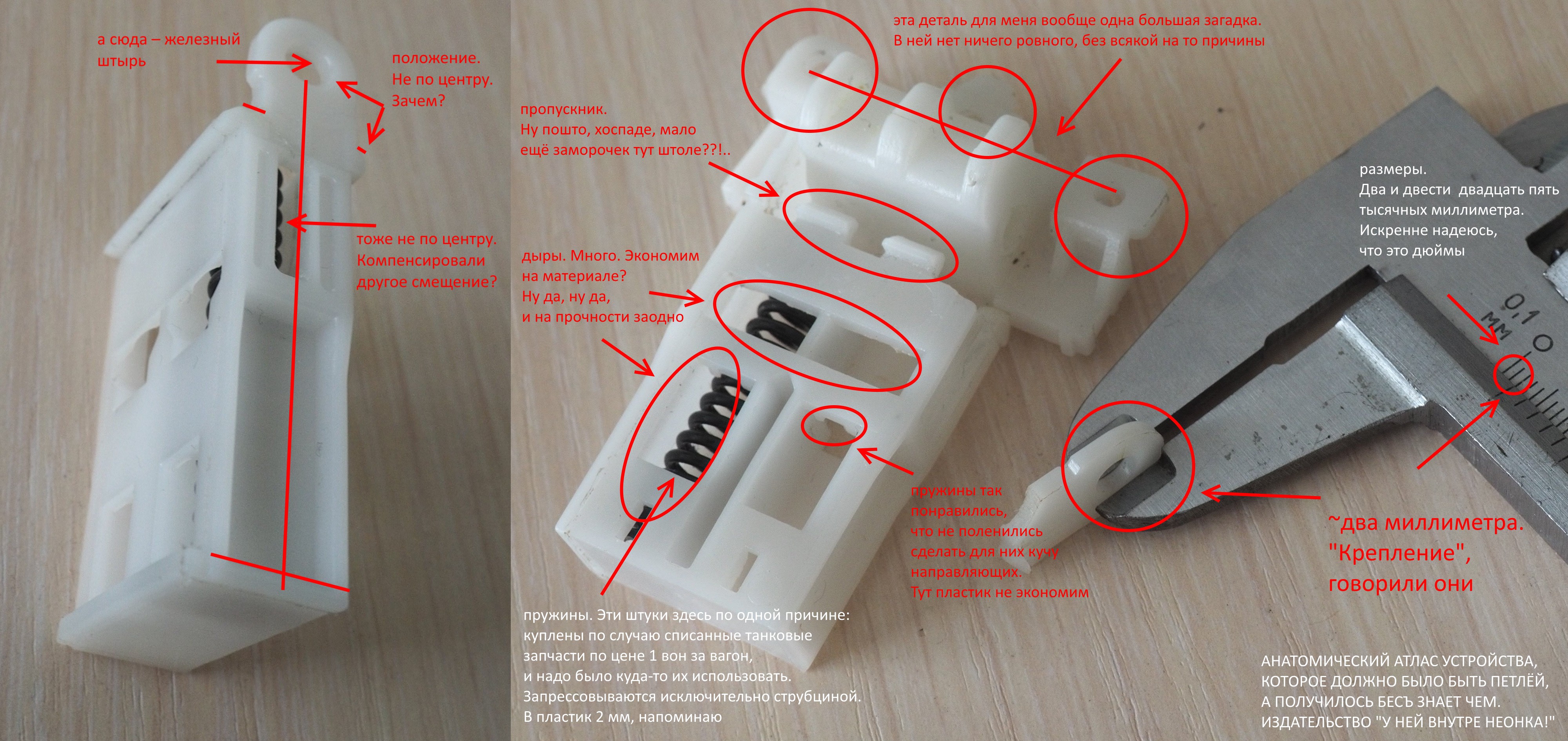

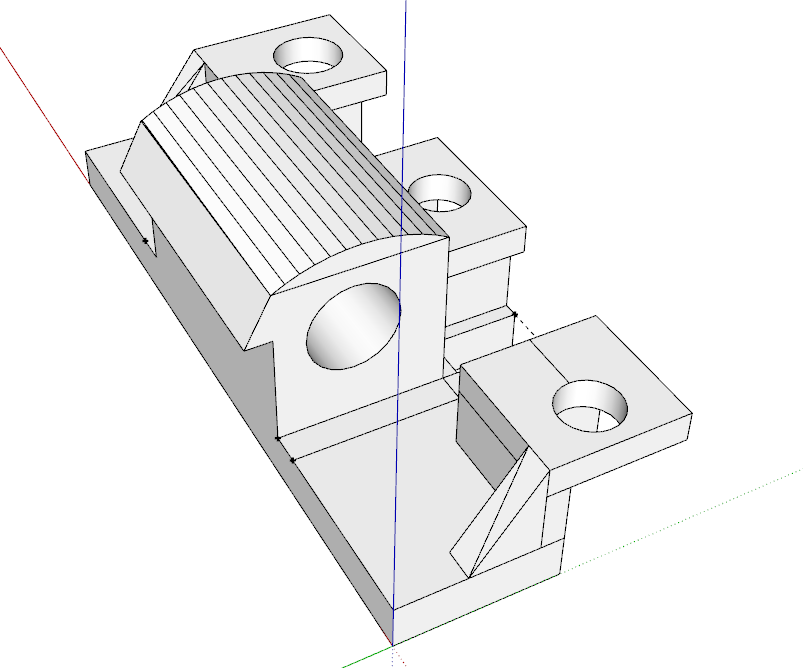

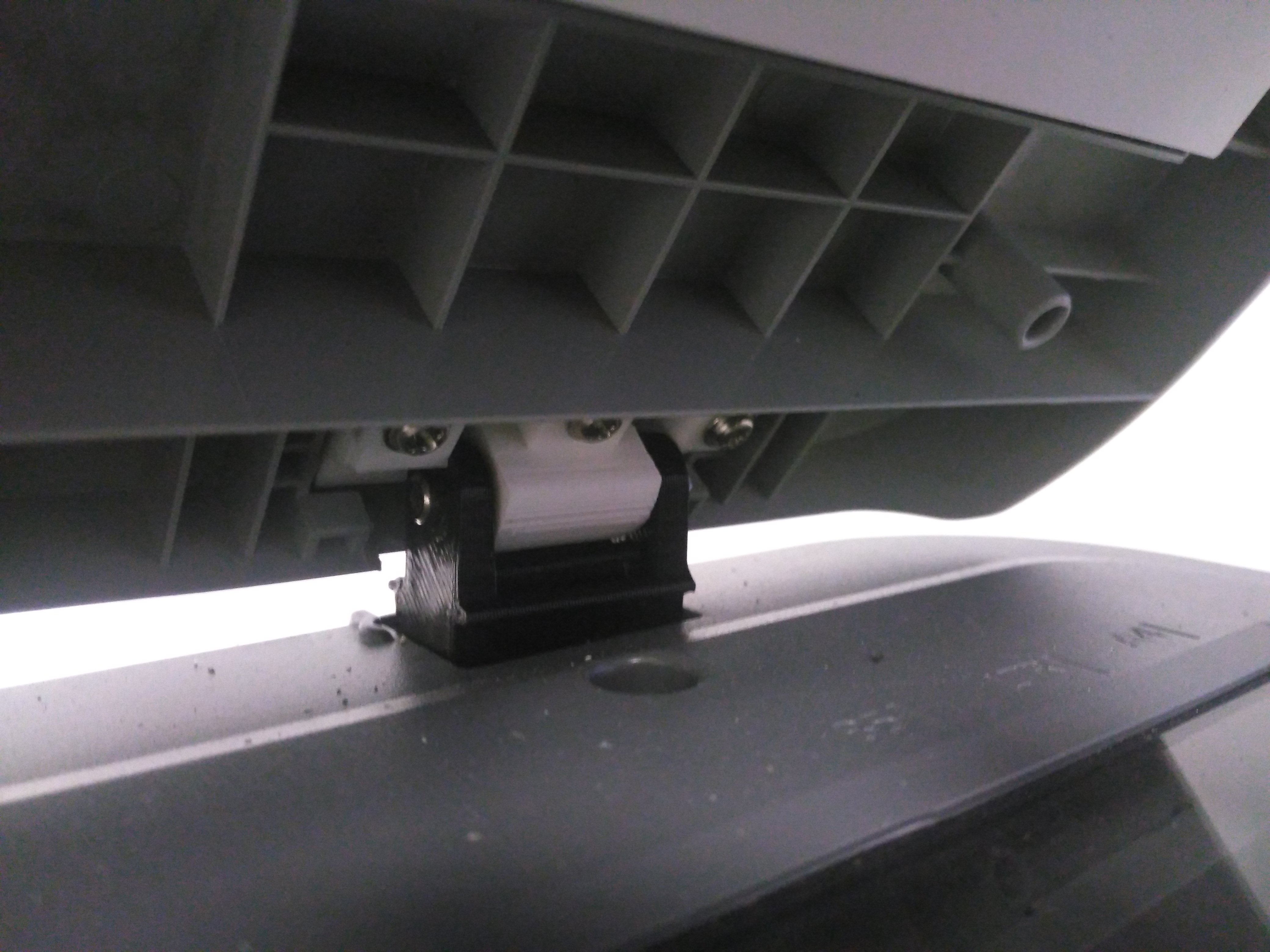

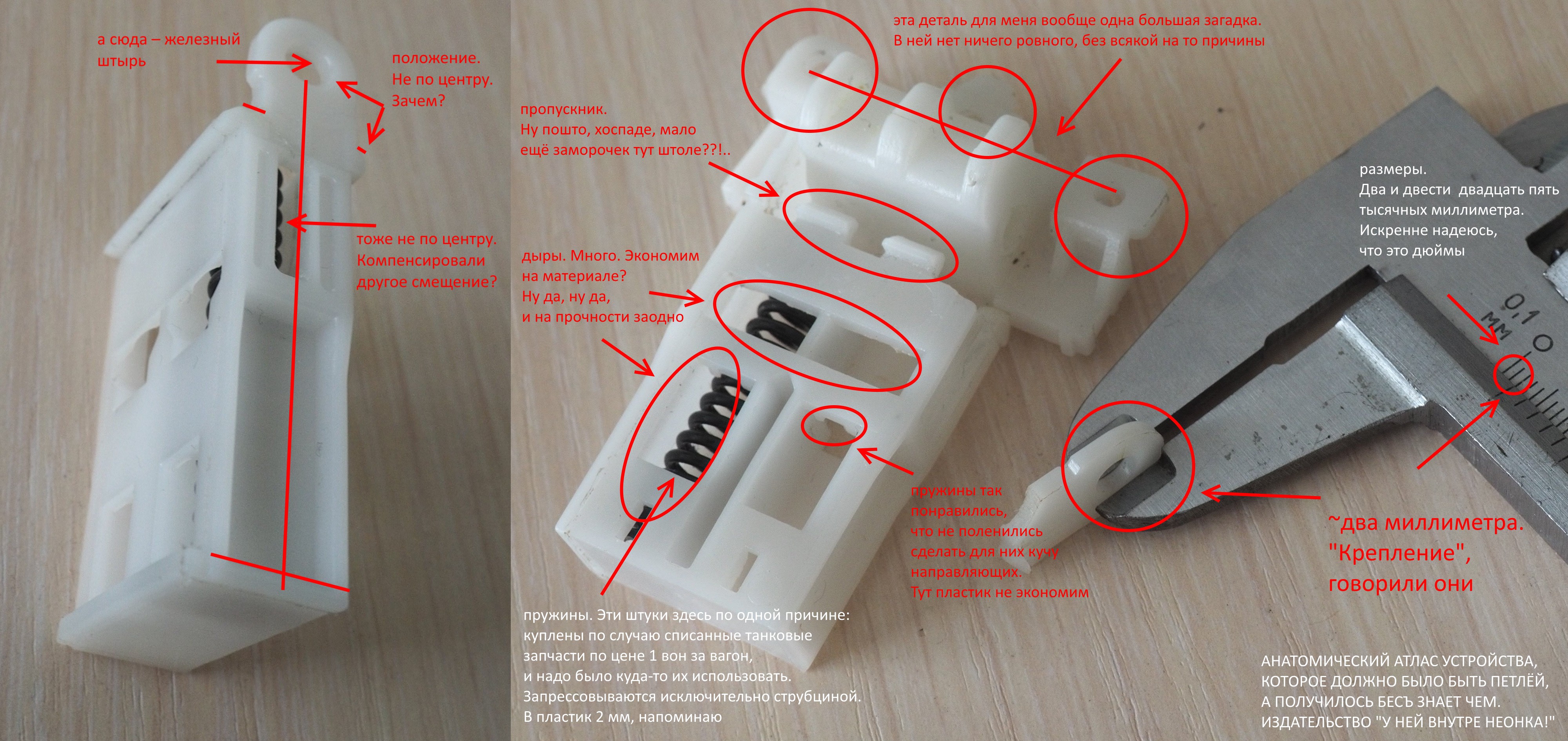

The original turned out to be more than one detail. Disassembly, research and subsequent assembly made me experience a whole range of feelings. In order not to be unsubstantiated and not spread out, I submit to your attention the anatomical atlas:

The general idea of an engineering miracle: a smooth course of the lid and reliable fixation in extreme positions.

As you can see, with the reliability of the pad.

And speaking quite simply: the part is doomed to break. With high probability in the first months of intensive use.

Mechanical damage in the service will fall on the client, which means a non-warranty case and part for the money for the order. I don’t even want to think about the time and cost.

The wisdom and obvious shoals of the details made me think: after all, they probably have a whole department of engineers, or even a division. And quality control service. And just control. And statistics on warranty repairs. How did this product get into production? What did the company do when it discovered the problem? And did you even find it?

In this particular case, the breakdown of this detail also means the disruption of the automatic feeding system of the original scanner. The automatic feed mechanism is built into the cover, and its exact position and good pressure are critical. Otherwise the mechanism starts - attention - to tear the originals. As already mentioned, it is difficult to detect a broken ear due to the design features. Everything looks working, only it is shifted to millimeters.

Hell with them even, with all these holes, springs and other wisdoms. But hang the weight of two millimeters thick, and even pull the weight as a lever - anyone who did something at least a couple of times with his hands, without any matan and mat, obviously: it will break. Who are you, corporation engineers? The consumer must know their heroes! Tell me, what are you doing at work? And what is your education? Let's hope it's benign.

And now, of course, the moral of the fable. More precisely, a few. And also the disclosure of intrigue.

Moral 1:

for enthusiasts, 3D printers, repairmen and other users. Carefully inspect the part and think carefully before messing with it. It is possible that the detail was designed by the legendary Drunken Master. His kung fu is stronger and you have to sweat.

Moral 2:

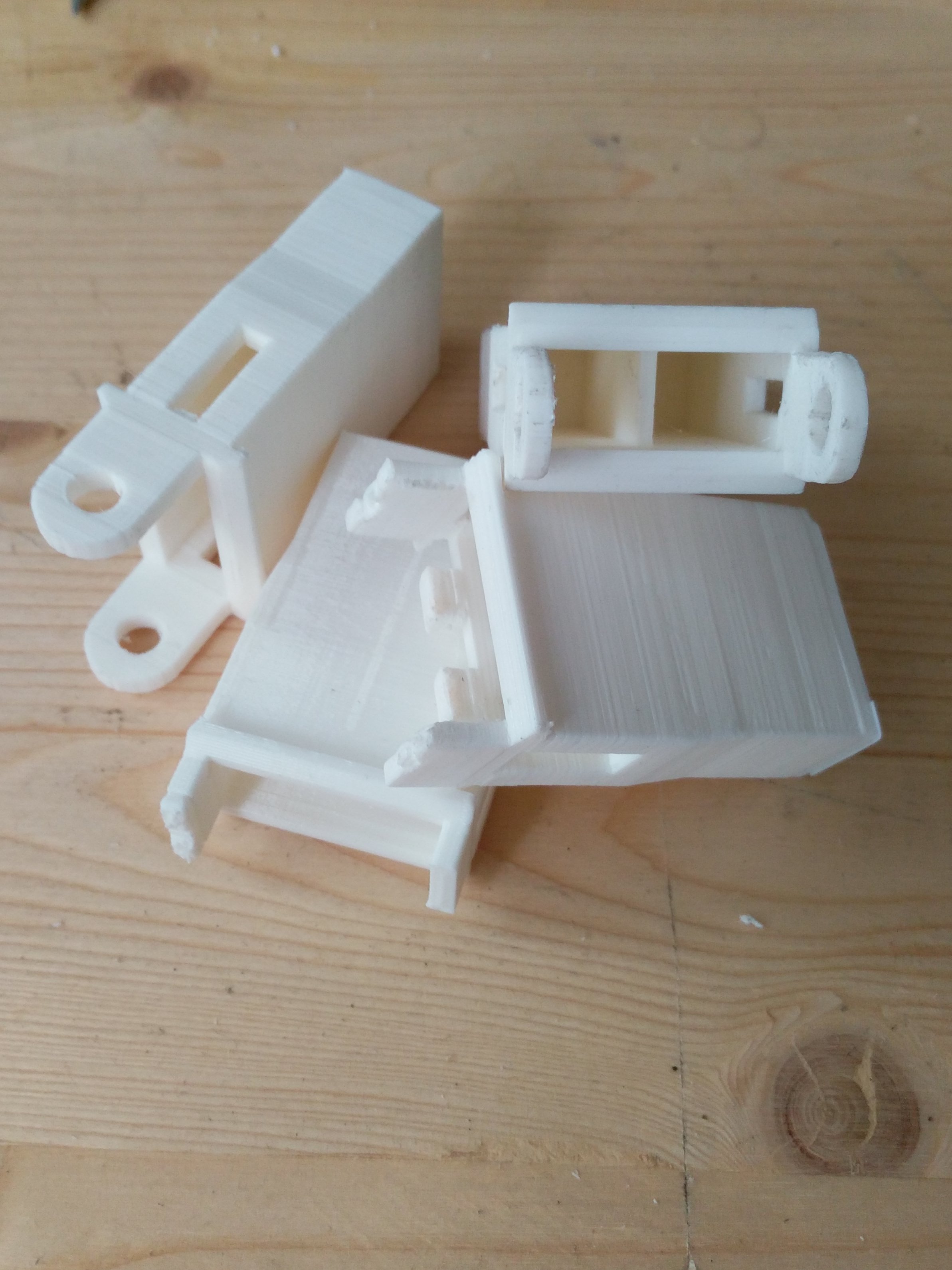

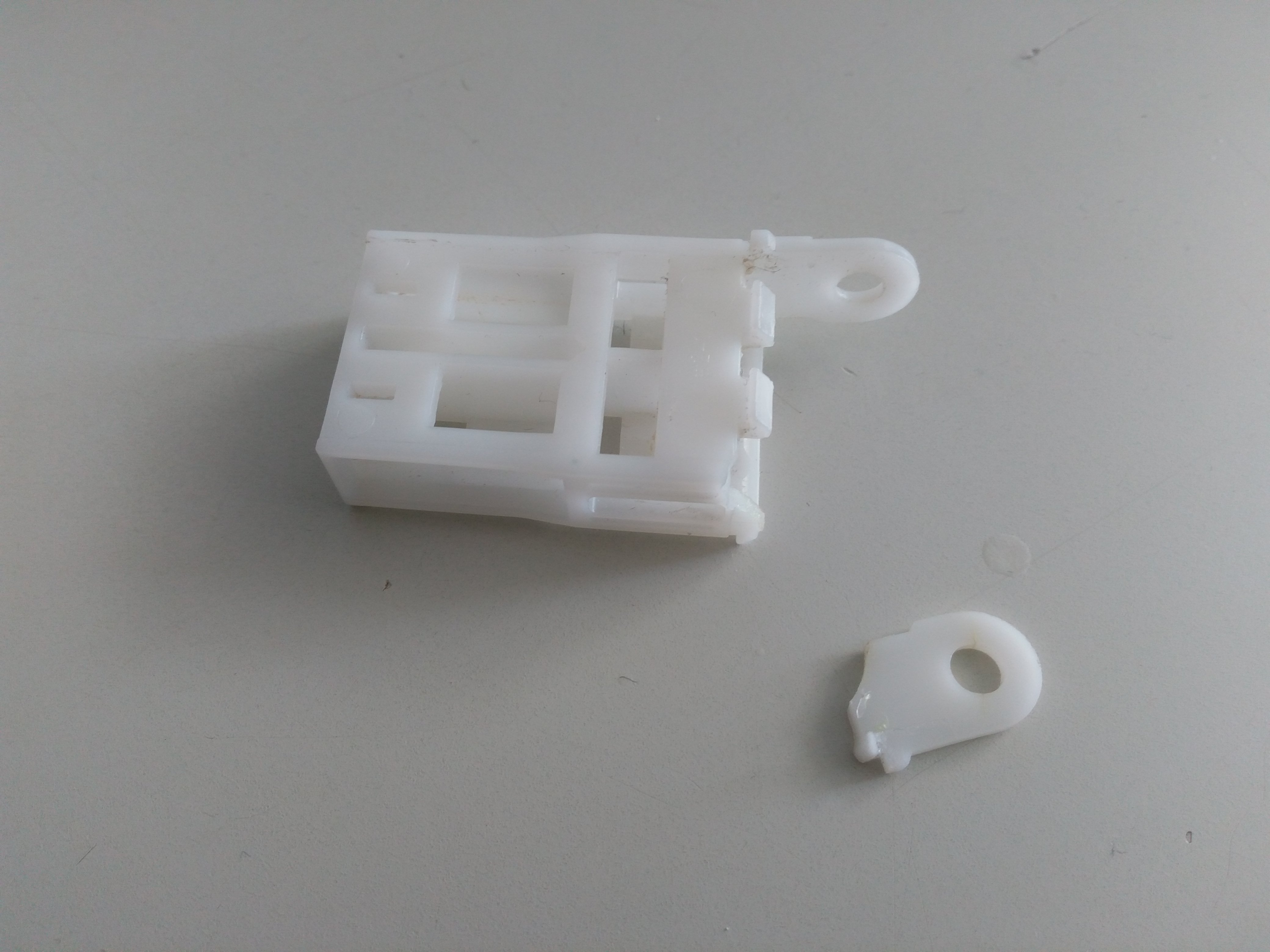

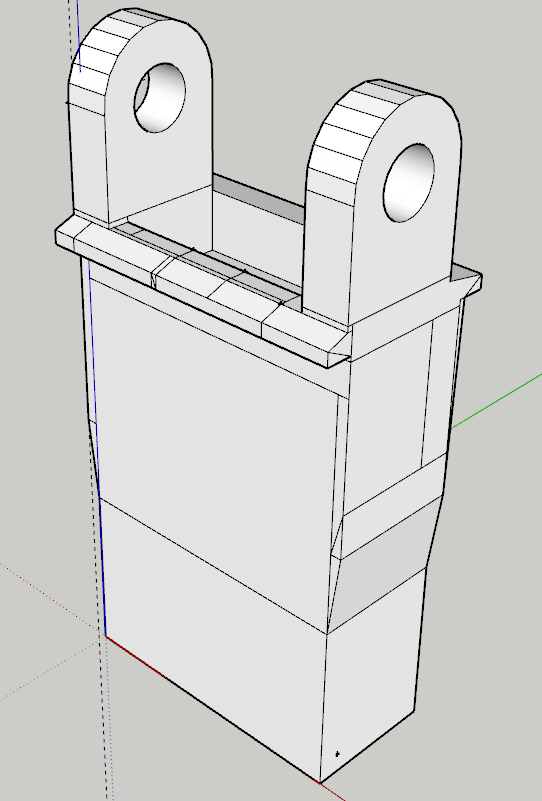

cobbled together, more from a strong, own version.

Prokosil a couple of mm with a hook, but it works even that way. And I am sure it will not break. The hook itself is made in cartridge format, for easy replacement.

Moral 3:

This is Samsung.

Moral 4:

how I see the correct behavior of the corporation in this case:

“Dear users! We found a design defect in our product. We have already fixed the problem, and provide customers with the replacement of a defective part with a more reliable one. ” I have never heard of such a thing, but I want to believe.

With great pleasure I will study the comments of representatives of Samsung, if any, as well as the opinions of all interested and interested.

Three-dimensional printing will save us, all the world. Thanks for attention!

The cause of the breakdown was discovered without difficulty. The small plastic part in the cover was broken. At the same time, due to the design features, the part remained in place, and the failure was almost imperceptible.

Detail can be found and ordered. But it seemed to me that there is a cheaper and faster way. There is a 3D printer standing idle, I'll draw it once, and then I can print at least a hundred in reserve.

When I first met, I studied the problem detail inattentively. The essence of the detail is a loop on which the device lid is held. And what is there, a loop: two holes and a pin. There is nothing to wise and even harmful.

Quickly measuring the original, he marveled. I added strength in some places according to my understanding,

printed:

Share it.

Not without a file - but found:

The copy lasted three days and was again broken.

"Along the same", say sophisticated printers. “And in general, of what is there, the detail was painted and printed, it’s a big deal.” And they will be partly right (survived, three-dimensional design and printing at home is not new).

However, let's continue and look at our item more closely. This is interesting, I promise.

Let's start with the fact that the loop is made of plastic with a thickness of two millimeters. The very thing that embarrassed me in the first place, and that I tried to improve in my copy. On the unfortunate two millimeters hanging lid weighing at least a kilogram. Pin, at the same time, - iron. I do not have the appropriate education, but even to me it is clear: the decision is strange. The margin of safety is clearly insufficient even for a static connection. And even more so for a heavy cover.

The original turned out to be more than one detail. Disassembly, research and subsequent assembly made me experience a whole range of feelings. In order not to be unsubstantiated and not spread out, I submit to your attention the anatomical atlas:

The general idea of an engineering miracle: a smooth course of the lid and reliable fixation in extreme positions.

As you can see, with the reliability of the pad.

And speaking quite simply: the part is doomed to break. With high probability in the first months of intensive use.

Mechanical damage in the service will fall on the client, which means a non-warranty case and part for the money for the order. I don’t even want to think about the time and cost.

The wisdom and obvious shoals of the details made me think: after all, they probably have a whole department of engineers, or even a division. And quality control service. And just control. And statistics on warranty repairs. How did this product get into production? What did the company do when it discovered the problem? And did you even find it?

In this particular case, the breakdown of this detail also means the disruption of the automatic feeding system of the original scanner. The automatic feed mechanism is built into the cover, and its exact position and good pressure are critical. Otherwise the mechanism starts - attention - to tear the originals. As already mentioned, it is difficult to detect a broken ear due to the design features. Everything looks working, only it is shifted to millimeters.

Hell with them even, with all these holes, springs and other wisdoms. But hang the weight of two millimeters thick, and even pull the weight as a lever - anyone who did something at least a couple of times with his hands, without any matan and mat, obviously: it will break. Who are you, corporation engineers? The consumer must know their heroes! Tell me, what are you doing at work? And what is your education? Let's hope it's benign.

And now, of course, the moral of the fable. More precisely, a few. And also the disclosure of intrigue.

Moral 1:

for enthusiasts, 3D printers, repairmen and other users. Carefully inspect the part and think carefully before messing with it. It is possible that the detail was designed by the legendary Drunken Master. His kung fu is stronger and you have to sweat.

Moral 2:

cobbled together, more from a strong, own version.

Prokosil a couple of mm with a hook, but it works even that way. And I am sure it will not break. The hook itself is made in cartridge format, for easy replacement.

Moral 3:

This is Samsung.

Moral 4:

how I see the correct behavior of the corporation in this case:

“Dear users! We found a design defect in our product. We have already fixed the problem, and provide customers with the replacement of a defective part with a more reliable one. ” I have never heard of such a thing, but I want to believe.

With great pleasure I will study the comments of representatives of Samsung, if any, as well as the opinions of all interested and interested.

Three-dimensional printing will save us, all the world. Thanks for attention!

Only registered users can participate in the survey. Sign in , please.