The first 3D printing event in the Netherlands

3d printing event

Not so long ago became interested in 3D printing. And then I stumbled upon a one-day seminar in the Netherlands and quite inexpensively. I bought an entrance ticket, took an honestly earned weekend in the middle of the week and went to hell on Eduhoven at the appointed time (1.5 hours by car almost on the border with Germany).

The seminar was held in some huge building, where a bunch of posters about various other design events also hung. Judging by the situation inside, it used to be some kind of factory building, where iron doors in the toilets and classic blue paint on the walls were preserved. Later this conjecture was confirmed by the fact that lunch and drinks were served on wooden ... workbenches with a wooden vise. I immediately remembered the lessons of labor at school, how we pounded parcel boxes, planed mops, turned ... It has long been ... Yes! What am I talking about? A! Seminar ...

In general, I arrived, despite morning traffic jams, ahead of time and I had time to drink coffee and see the exposition unfold. The Ultimaker line was especially widely represented there . As it turned out, this is a local development. Erik de bruijnthe founder of the company, brought to mind (a decent condition) with invited specialists, the idea of an inexpensive 3D printer after he found the quality of RepRap unsatisfactory. Now the company produces and sells assembly kits, and now everyone, for a very reasonable price , can join the world of 3d printing things.

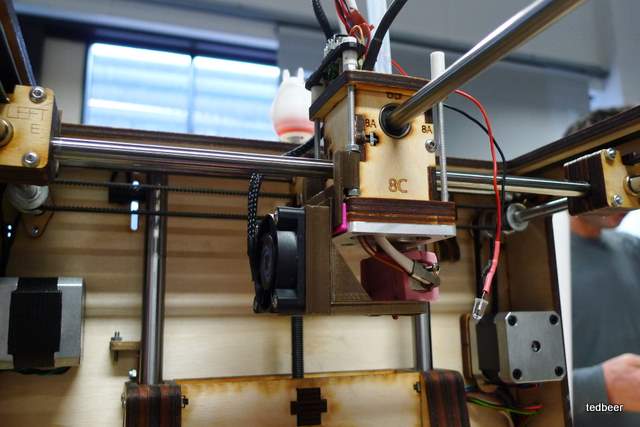

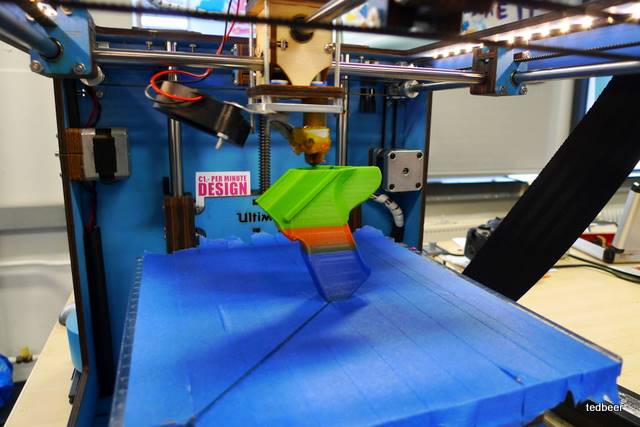

At the exhibition, printers worked hard and I had the opportunity to compare the print quality of Prus-Mendel (the current version of RepRap) and the Ultimate Maker. The ultimaker, in my opinion, clearly went ahead, and the result is repeated from printer to printer, i.e. we can talk about proven technology. Although of course this is only the beginning of the road, but the start is good.

Printed by the ultimaker:

Another example of the work of the ultimaker:

Printed by Prusa:

Eric was the first to talk about his path, the creation of the ultimaker and the company, the history of the RepRap community, which makes the technology accessible to the masses. I talked about the ultmaker above.

Among other slides in Eric's speech, I was struck by a slide with a tree of descendant repraps. The original can be viewed atcompany website .

Next came Bas van Abel , who spoke more about the social aspect of technology development in general, and not just 3D printing. I liked his story about materials for the manufacture of cell phone batteries. We have no idea how this is done, so we do not feel any responsibility for using the technology. Watch the movieon the organization’s website. It briefly describes cobalt mining in the Congo. Workers at a depth of 60 meters spend several days mining ore, a cat. then washed outside in monstrous conditions. Child labor is widely used. Then the ore is exported to the manufacturer for processing and further processing to get into the cell phone battery. And then Apple will make the battery non-removable to throw the phone away in a year or two as soon as the battery degrades. And then, this high-tech garbage falls into India, where sacred cows and children graze in rubbish rubble, again, they are engaged in the extraction of valuable components for recycling, and other waste remains in the rubble. In general, a little distracted from 3D printers.

Then, suddenly, Joris Peels appeared on the scene .. And I painfully recalled where did I closely intersect with him. And it seemed to me that I already saw part of this presentation as if in a dream. Well, I couldn’t remember him so well from my night vigils. Maybe somewhere else I saw? And only during the break, when he greeted me violently and called by name, I remembered that I worked with him at Backbase. Of course! True, I'm in RnD, and he is somewhere in marketing sales. And now it turned out that he founded the company and is developing a 3D printer for children ! Briefly highlighted the basic printing technology. He complained about the lack of simple and intuitive tools for editing 3 models that would be available to children.

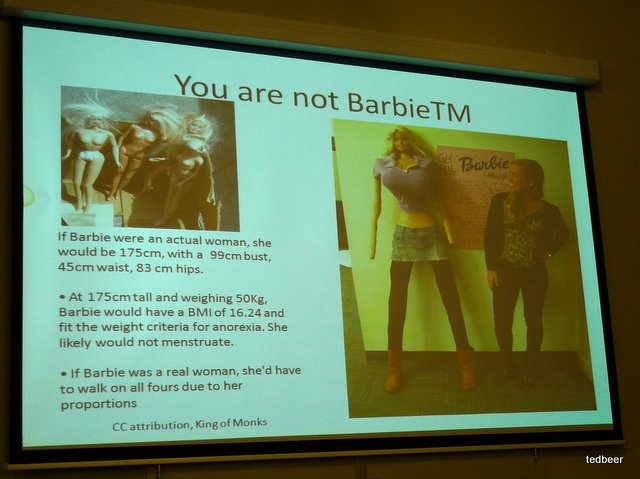

One slide from Joris presentation:

Although it was not originally intended for publication without a speaker, little will be clear there, but in places there are ridiculous slides like the one given above and current technologies are briefly listed. So if you are interested, then look through - the presentation of Joris .

He asked him when he was planning to launch his brainchild on the market. In general, not soon, in a year and a half. Let's hope for the best.

Then there was lunch and you could walk around the exhibition, touch, talk with representatives. Ultimate makers intensively printed a variety of garbage from thingiverse.com (a famous site where people share their 3D models).

The Dutch-style mobile device is a bicycle. Unfortunately, I did not ask which one was inside. There was also a person who converted his printer to batteries.

And here is a giant two-meter machine that can print and a chair. But it seems that with print accuracy everything is generally bad there. Many parts are made of material such as fiberboard (or as it is called thick cardboard).

Although the ultimaker is also not made of space materials, it is laser cut from birch plywood: the

2nd session did not seem to me very interesting. But in the 3rd, 3D printing professionals performed.

Antonius Köster- Director of a German company that has been engaged in various scanning and 3D printing for many years in many areas. He described the numerous areas where 3D printing is in demand, his projects on which the company worked. On the slide, a figurine worth one and a half million non-rubles. To transport the exposure, the figure was scanned and an individual form was made for it:

For example, in surgery, an X-ray 3D image is taken, according to which a skull model is printed. This model examines where the nerve channels pass and surgery is planned. When applying metal brackets to hold together the broken parts of the skull, these brackets bend in place on the skull model. Before mastering 3D scanning and printing, the brackets bent in place during the operation by the surgeon. This means that the operation lasts much longer, and the cost of a surgical operating room is 300 euros per minute. Printing 3D models and materials are cheaper. So on the face (on the face :)) patient savings.

Reene groothedde- Director of RMCenter, spoke a little about European programs for exploring the possibilities of using 3D printing in various industries such as aviation, automotive, etc. For example, there was the idea of 24-hour availability of spare parts for repairs, say, of an airplane. To do this, the part just needs to be printed in place. This is where certification issues arise. Due to the difference in materials and manufacturing techniques of parts, it is necessary to change the design of the part. In addition, operational characteristics are changing, which means that parts must be certified differently. In the aviation industry, parts are replaced according to regulations. Those. the part has a useful life, and it is changed when the time has passed, and not when it has broken. The printed part will have different regulations. In general, there are enough difficulties along this path. Looks like a print experiment is greatwas part of these European programs. Along the way, he also highlighted licensing issues. Take, say, a washing machine. The right to manufacture parts for it may turn out to require a license, as These details can be patented. Those. you can’t just take and print the part to replace the broken one for the customer or even yourself. In general, big business, as always, is a city of fences and obstacles, where it would seem that it does not smell.

Darrin Dickinson - Representative of a company producing Z printers, spoke about the company, technology and the growing demand. Their printers print with powder and a binder. The binder is dyed in 3 or 4 colors (CMYK) as in inkjet printers, so you can print multi-color models. If we add to this that the print accuracy reaches 600dpi, it is not surprising that the printed models look really super-duper. You even want to feel the shoe until you pick it up. You can beat it with such a heavy boot inadvertently: lol: Well, the printed models are not very functional, because quite fragile.

During the conversation, after his speech, I asked about similar work by competitors or amateurs. But he assured me that all kinds of powder printing options and related technologies were patented wherever possible, so no bastard would break through. Such a statement certainly does not add optimism in the development of technology in this direction. We can say that this is another evil corporation that is rowing for itself.

Presentations ended and the informal part began with beer, wine and other drinks and snacks. Talked with a representative of a company selling professional printers Dimensionworking on the same principle as amateur ones. Only unlike them can he print with two plastics at once. One is used to print supporting structures, which in many cases cannot be avoided.

The device from the Dimension series looks solid:

Items printed by this printer. Among them lies a yellowish case printed for some device. Both halves so accurately enter into each other that you do not need to screw together!

An adjustable wrench printed in one pass does not require assembly:

Black plastic is an additional material, which is then dissolved with a special solvent and washed. As a result, in the key all that is needed is spinning and moving.

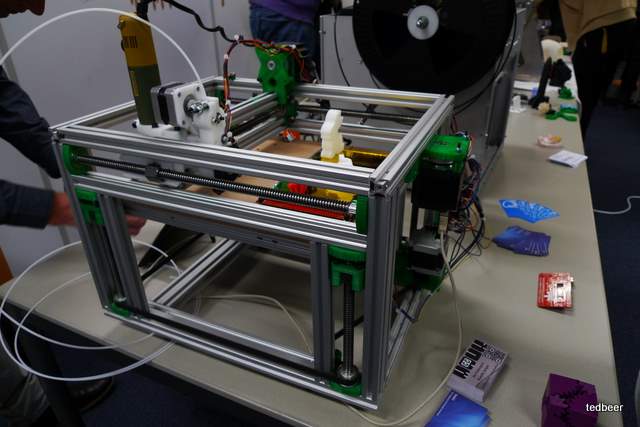

Another amateur device. Please note that he has both a print head and a cutter (yellow-green crap sticks out on the left). Those. It can work both as a printer and as a CNC. The owner did not respond very well about the device. He says that he "redesigned" (overconstructed). It turned out to be too slow due to the use of screw positioning in all axes, although accurate. Plus, the cutter is rather weak, positioning motors, too, so this margin of safety is not required, but you had to sacrifice speed.

The new ultimaker model is one and a half times higher than the original and allows you to print tall models, like the yellow one in the photo. The model is not yet in series.

New technologies can serve not only good:

It’s probably time to stop already. The topic is inexhaustible. They promised to continue next year. So I will keep my finger on the pulse.