Construction of communication line Kamchatka - Sakhalin - Magadan. Cable Innovator Tour - Ship Layer

Probably, many people know that the company Rostelecom has been conducting a global construction of a communications highway in the Far East for the second year. Since 2014, the construction of an underwater fiber-optic communication line (POLS) Kamchatka - Sakhalin - Magadan. Last year, in the month of June, this project moved to the most difficult part of this project - to lay the submarine cable. This work is carried out by the ship-cable laying company Global Marine Enable Innovator .

Last year, this boat already came to us in the port , but, unfortunately, it did not take excursions. And this year, apparently under the impression of the successes of last year, Rostelecom invited several media representatives on board to show this miracle of technology, which is the most difficult work in this project.

Initially it was planned that during the summer of 2015 all the works on the project would be carried out and both branches of the AOLS would be laid in Magadan and Kamchatka.

But the Sea of Okhotsk turned out to be inhospitable and did not accept the entire cable. Weather conditions and bottom relief did not allow both branches to be laid in one season. And now, at the end of May, Сable Innovator arrived in our city to take on board part of the team and specialists from the customer companies Rostelecom and Huawei.

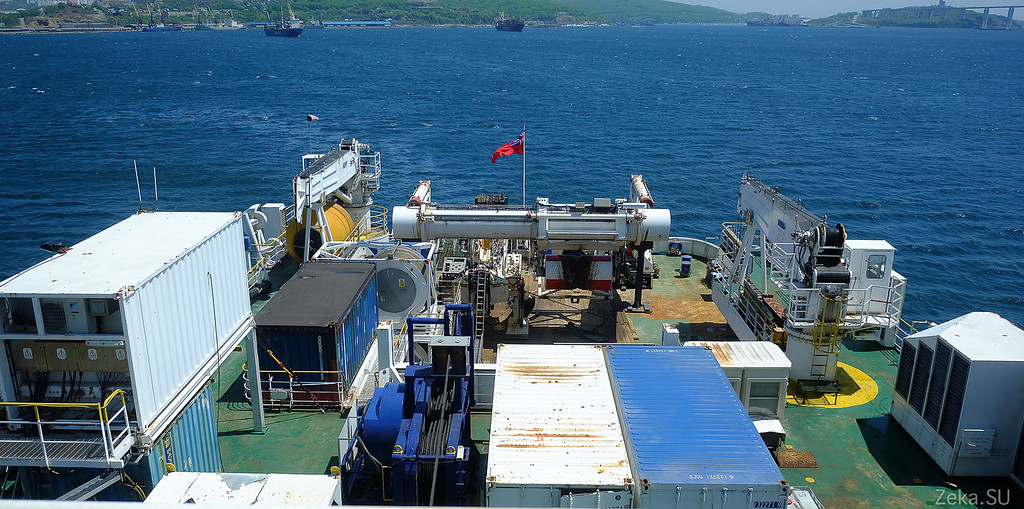

So, Сable Innovator - the world's largest cable laying machine for optics, was built in 1995 at the Kvaerner Masa shipyard in Finland. It is a diesel-electric (diesel engines, but the drive for electric screws). Equipped with a bunch of stabilization systems and thrusters in order to position the ship in any conditions with an accuracy of one meter (as the participants of the works complained to me, because of the additional propulsion units installed on the ship on the sides, they are forbidden to fish from the side so that the line is not tightened in the mechanisms; oh, sadness, sadness, grief).

In the photo you can see that it is equipped with two cuttings, fore and aft. In the stern cabin there are staff members who are responsible for the laying process itself; in the bow, everything is the same as in all other ships: the captain, the navigator.

There are 3 holds for the cable tank, their capacity is enough to lay the cable on the floor of the globe.

Scheme of the device of a similar ship:

For laying under water, 2 devices are used - Plow and Robot. The plow is lowered from the stern and dragged behind the ship. He plows the trench at the bottom of the sea and lays a cable into it. Plow is the main tool. But the robot is already used in emergency cases, when there are rocks on the bottom of the sea, when the cable breaks and you need to find its end, and for the repair of submarine cables.

I will divide the tour into 3 parts:

Part 1 - Felling, the captain's bridge;

Part 2 - Cable Deck;

Part 3 - Underwater tools Plow and Robot.

On Habré already wrote similar materials, and then you can not read anything new for yourself.

In order for you to understand a little how to lay the cable in general, I will tell you a little theory.

The works are divided into several stages:

1. Research and design

At this stage, the seabed is investigated, or ready-made materials from previous studies are taken. Depending on the topography of the bottom, the route is built. Naturally, current communications at the bottom are taken into account. But the benefit is that the Sea of Okhotsk is not rich in underwater pipelines and underwater optical highways, well, except that the secret communication cables of the Pacific Fleet to which enemy submarines listen .

2. Cable manufacture and loading

The cable is made immediately with a coil so that you can run it from beginning to end under ideal conditions and load it onto the ship. At the production stage, erbium amplifiers EDFA (Erbium Doped Fiber Amplifier), a fiber-optic amplifier on erbium-doped optical fiber, are immediately incorporated into the cable.

Due to the fact that Russia does not have such civilian ships, the manufacture of the cable and its installation were entrusted to Huawei.

By the way, due to the fact that the work was not completed in one season, the cable was unloaded in Singapore, and Сable Innovator worked on other orders.

3. Gasket

Everything is simple. At the bottom, from the ship, they lower the plow and turn the small one forward. He digs a trench, a cable is buried in it.

The only difference with the picture is that there is a couple of kilometers under the ship.

For safety, one more Neptunia tug boat participated in laying the cable from Magadan to Sakhalin. It was on a safety net and cleared the bottom of the trash from the trawl along the way. Here it is:

This year Neptunia did not go with them.

Here is another informative video:

4. If everything went well and the cable reached from shore to shore, then it was connected to the coast station. And from the station already, in the old manner, with wires pulling the Internet to the consumer.

In Magadan at Rostelkom everything went well. The cable was stretched, tested for six months and now they sell fast Internet to everyone.

According to the latest information, from June 7, 2016, the cable was connected to the coast station in Ust-Bolsheretsk and cable laying to Sakhalin should end on July 22. So, the chance that next year the normal Internet will appear in Kamchatka is very high.

All right, it was all lyrics, and now we will go on a tour of the ship.

The ship stood near the island of Russian, I even thought that you can go to him on a kayak, but, alas, the weather did not allow.

We were brought aboard by a small boat: The

hospitable ladder opened its arms to the guests and crew members:

Then the labyrinths of corridors and stairs began:

Everyone was invited to the mess room and the Captain and Russian assistant told us what we would see:

Naturally, a conversation on all ships safety engineering begins. Where to run in the event of a siren. For these purposes, everyone was recorded and counted on their heads, so that in the event of something not losing anyone:

I don’t understand anything in the captain’s bridges, so if anyone knows better, correct me:

View of the front deck: The

same, but from the other side:

View from the bridge to the bridge over the Eastern Bosphorus:

Walkie-talkie to communicate with the crew, and so I understand Telex:

Actually, we are on a guided tour. Rostelecom and media representatives:

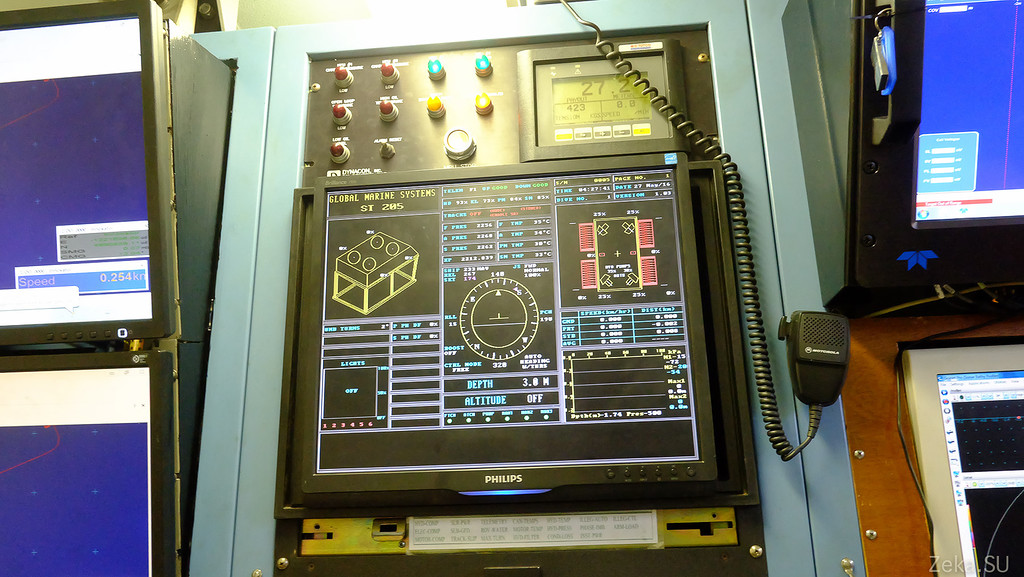

One of the control panels. Those colored buttons turn on the lights:

Compass:

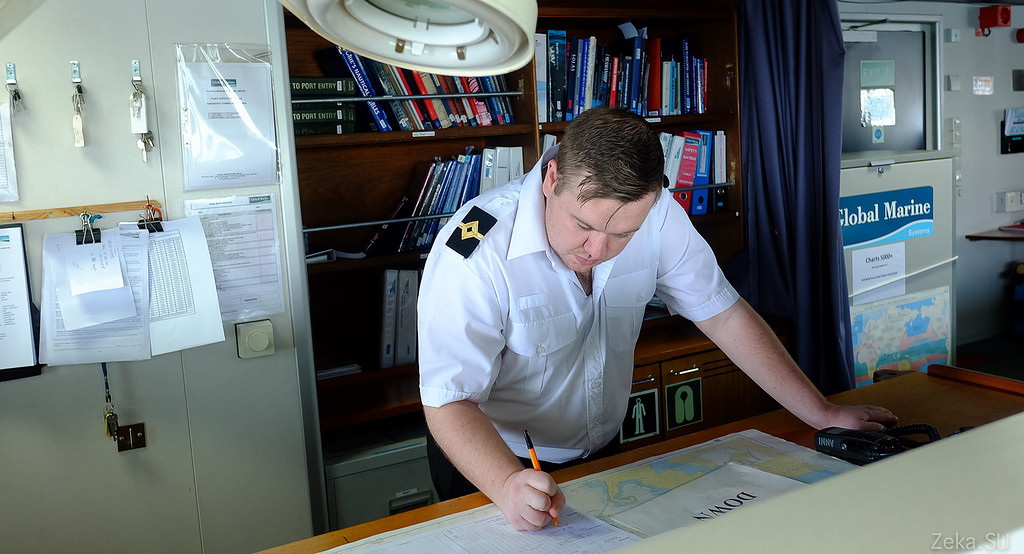

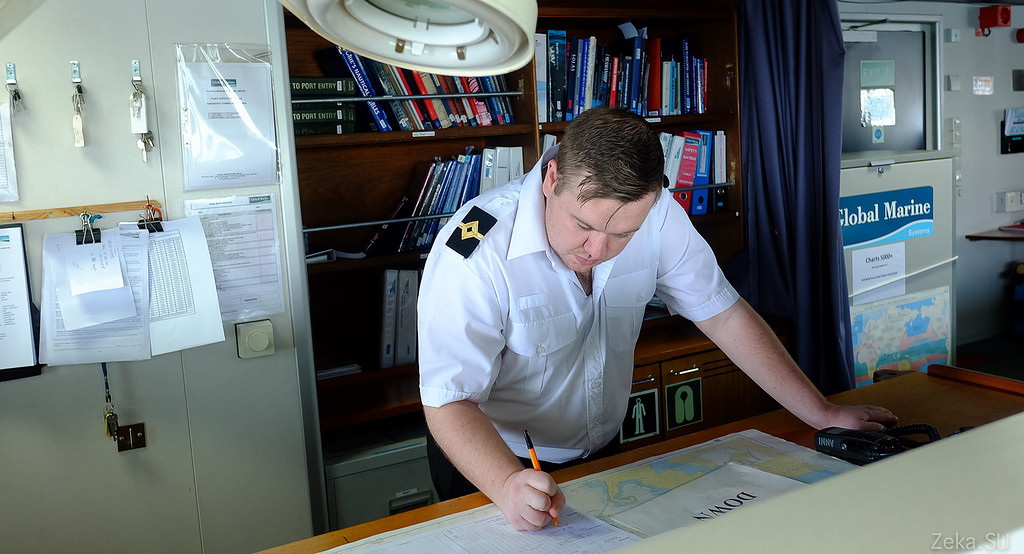

So I understand, this is the navigator's workplace. Behind it you can see a box with maps:

World and Russian navigation, and the master's own place of work. All these “full speed ahead”, “stop machine”:

Captain, assistant and Alexey Sapunov, director of the Far East region of Rostelecom:

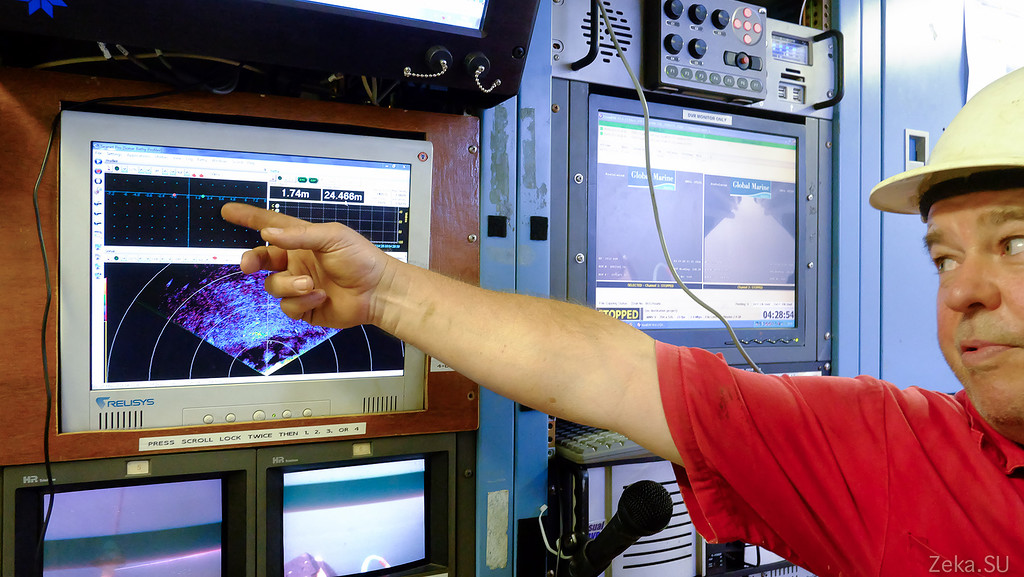

But this is the aft control room. There are more sensitive and delicate ship management tools. With the help of these joysticks and a stabilization system, you can move ships literally one meter to the right and left:

This is also the translation from cameras installed on the underwater vehicle. At the moment, it is floating under water in the Bosphorus East: The

submarine is

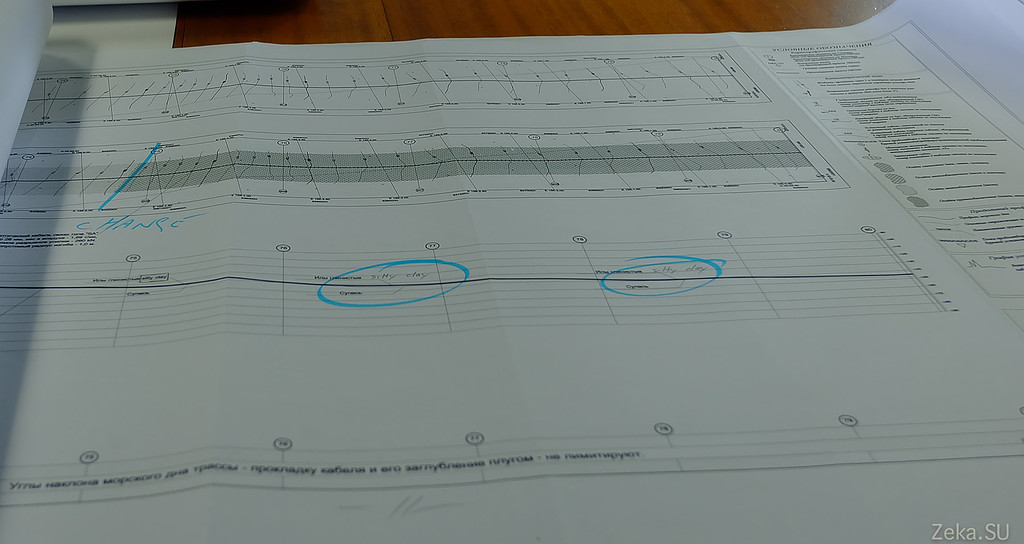

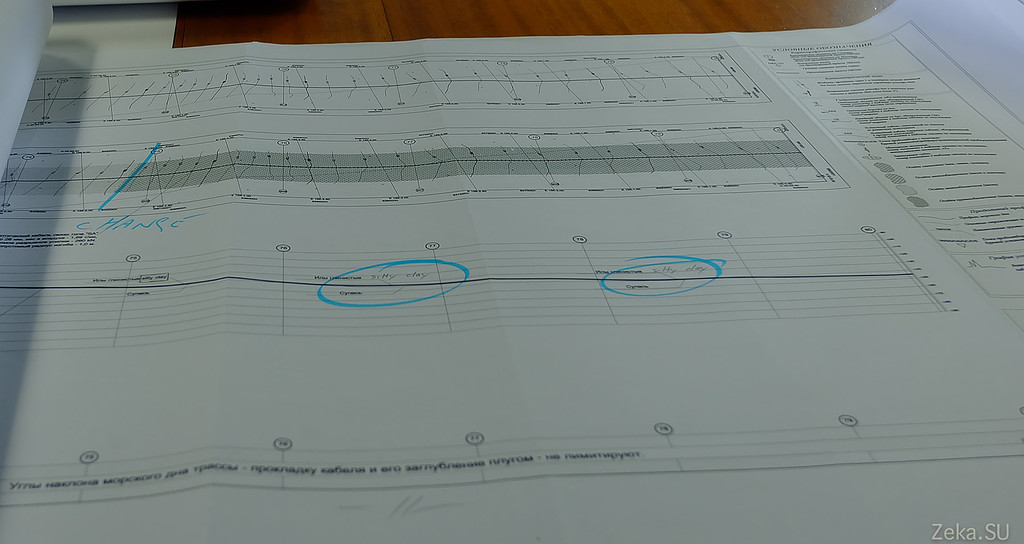

plowing the Sea of Japan at a depth of a couple of meters: on the sly I photographed a secret map of the sea floor of the Sea of Okhotsk with a cable pattern. I hope they will not beat me very much for this:

Safety plan on the ship:

Cozy on the balcony. Sofa, flowers grow, on the other hand, similarly:

Crew Jobs:

View from the bridge to Vladivostok and the internal raid in the Eastern Bosphorus:

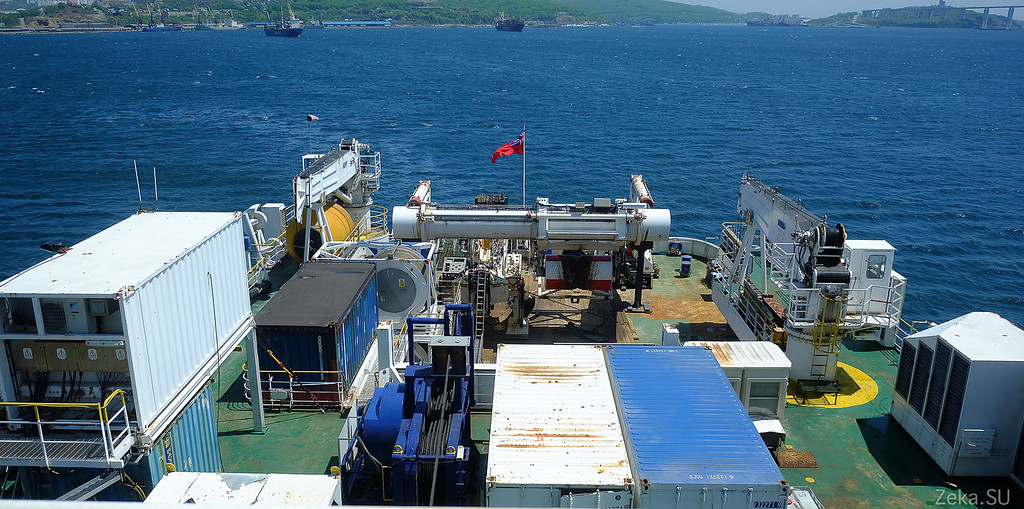

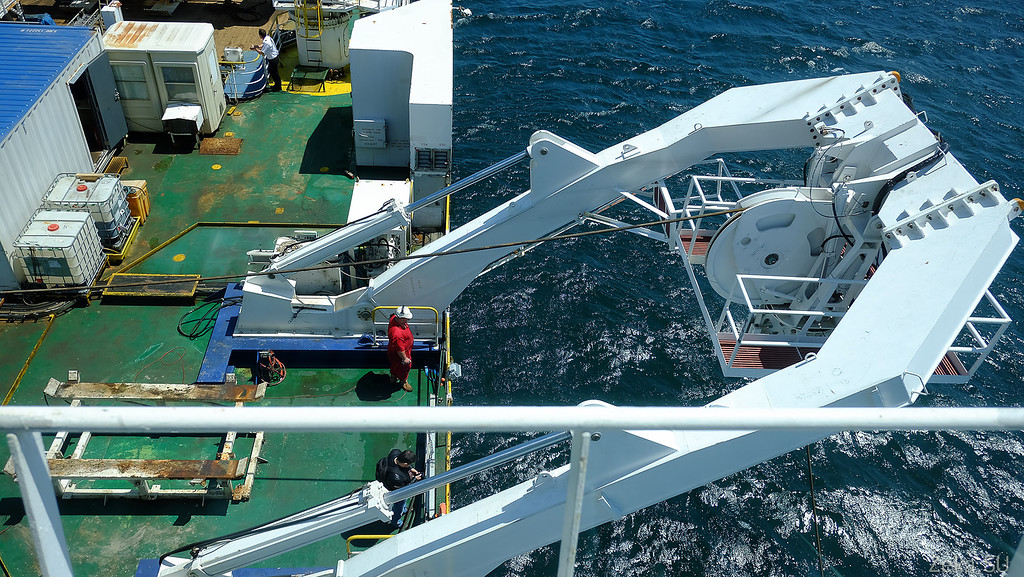

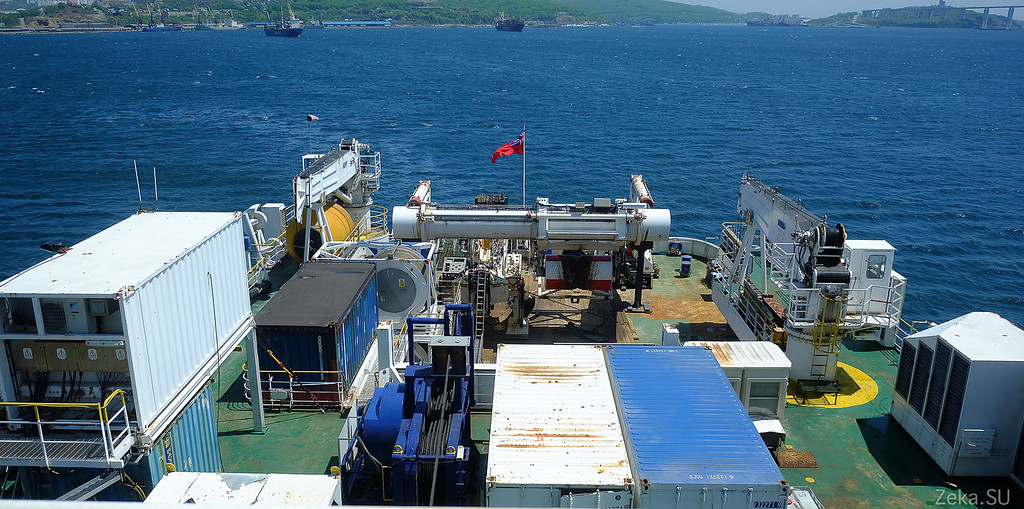

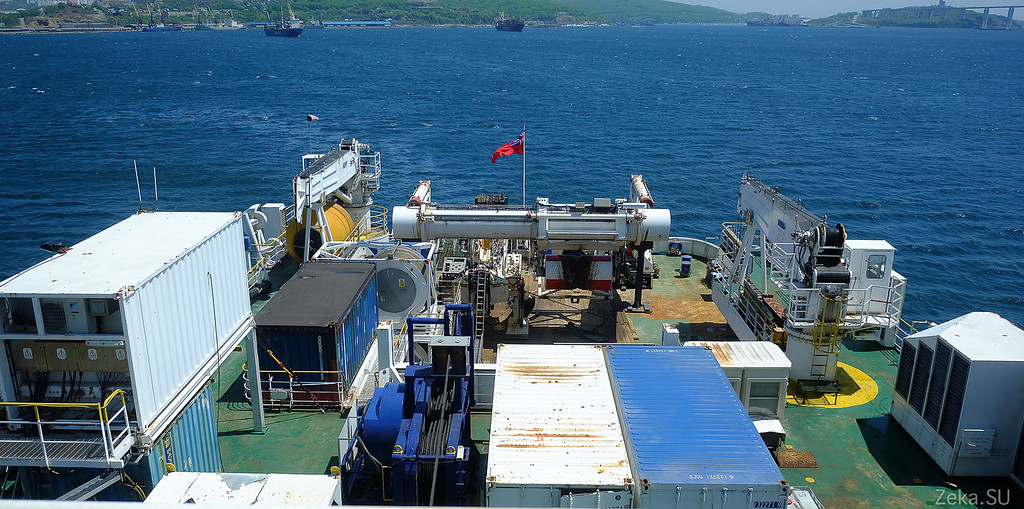

And this is a view of the stern of the vessel. A crane is visible that controls the cable feed and the plow (located below it on the left). In the containers there are additional equipment and ... "offices" of those who manage all this. In one of the containers there is a control room for the underwater robot. This is done so that it is easy to change the functionality of the vessel, depending on customer requirements. No part of the equipment is needed - unloaded the container in the port and all the rules:

In general, thank Captain Christopher Niva for the tour and go on:

On the nose, nothing extra:

On the upper deck, a spare screw and anchors:

Still there frantically smelled Asian food from the ventilation system and stood incomprehensible person:

On the other side was his friend, but without shoes:

We then argued for a long time who these people were and why they were so punished? Our version was to scare away seabirds so that the deck would not be soiled. It turned out that we were only half right. These gentlemen really work as stuffed animals. Only not from the birds, but from their more intelligent two-legged competitors. It turns out that if you stand on the roadstead in the port, incomprehensible people can get on board from a small boat, and stuffed from afar resemble security officers.

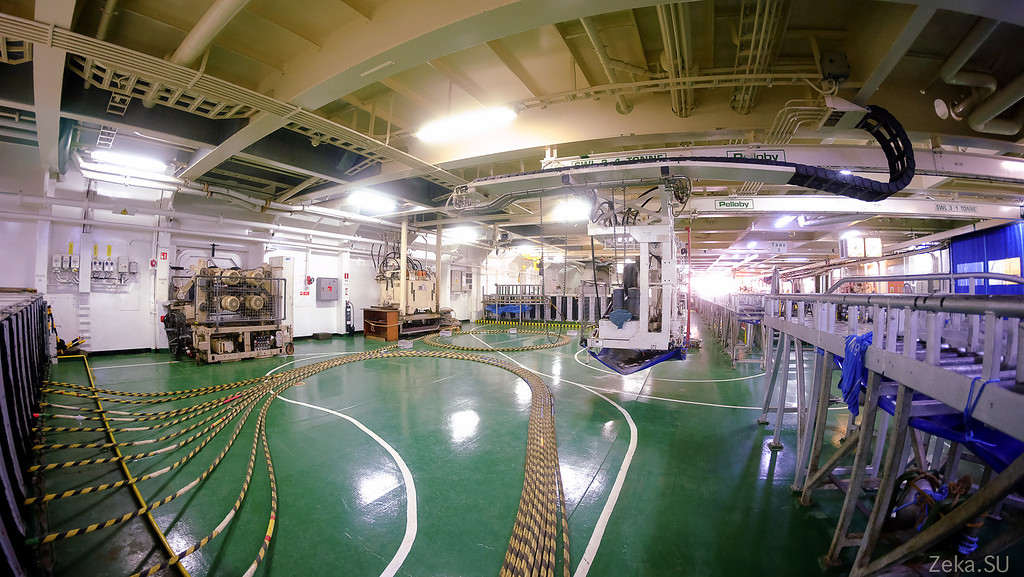

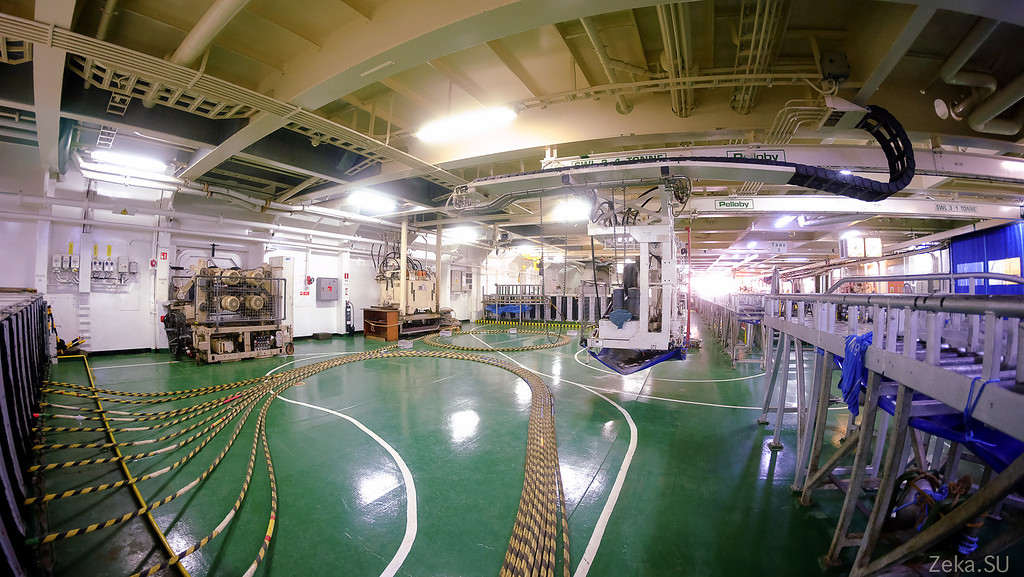

On this deck, they carry out all the work related to cable processing, feeding it to the stern and repairing it. In addition, there are storages on this deck - cable tanks and storages for optical amplifiers.

And now about this all in order.

The deck itself resembles a factory workshop in miniature: conveyors, hoists, warehouses with products:

The captain of the cable deck will no longer entertain us:

First I will tell you about the submarine cable.

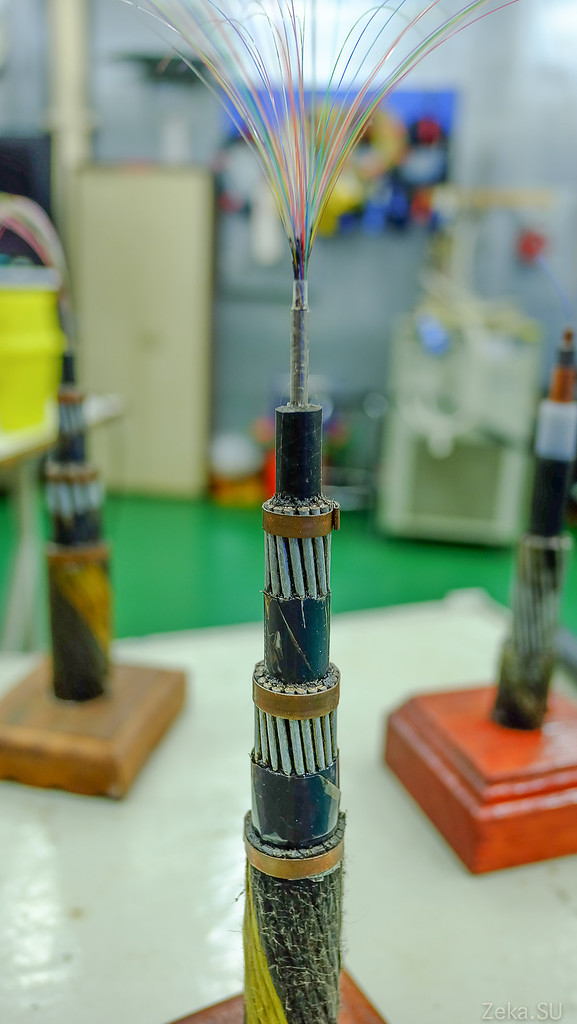

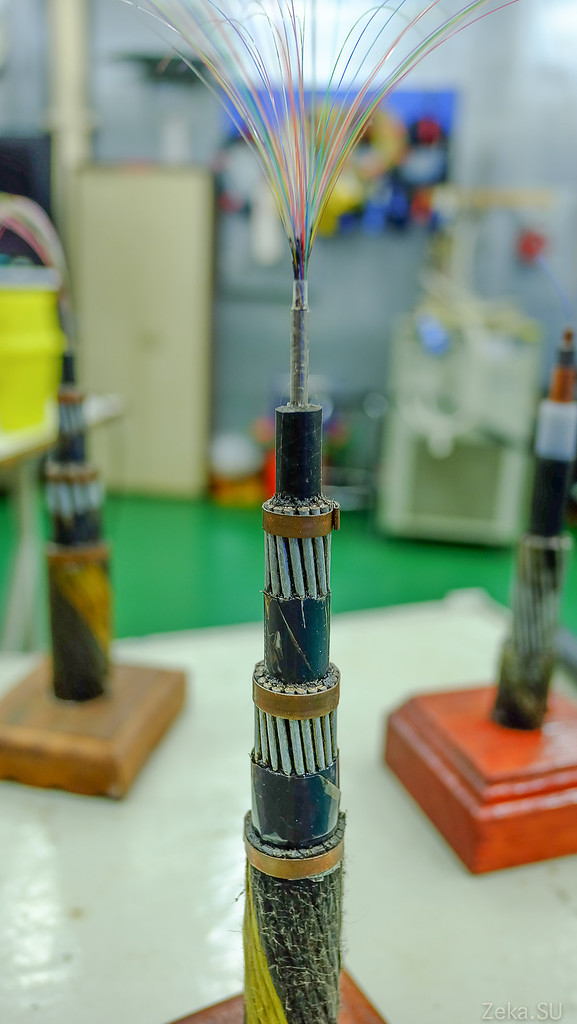

I have in my hands an underwater optical cable in section. It consists of several protective shells made of plastic, carrying steel or aluminum wires and in the very middle are optical fibers:

I think it is clearer:

To be brief and concise, it works like this: optical fibers are inside an aluminum, copper, plastic tube, sometimes filled with grease. The tube is wrapped with an insulating material or filled with polyethylene. All of this is wrapped in steel reinforcing threads that are wrapped with a waterproof sheath, such as polyethylene. Sometimes several layers of supporting cables are used. As in the above photo.

Rostelecom is laying almost the same cable, with the only difference: it has only 4 wires of optical fiber laid. But this should be enough for the coming years, because the sealing equipment allows transmitting up to 8Tbit / s via this cable. What should be enough for these regions with interest for the next thirty years. Naturally, there will be much less traffic, as there are few consumers in these areas and they do not need to feed the maximum flow.

In the welding room there is a whole exhibition of cables with which one had to work:

Judging by the appearance, the leftmost cable is intended for laying in the most dangerous places of the globe. Where not only sharks and crocodiles can gnaw him, but also elephants and hippos stomp on them:

So, we are with you in the welding shop where the cable connection works are being carried out. Immediately pay attention to the door with a sign "Do not enter! Dangerously". There is an X-ray room. But we will come back to this later.

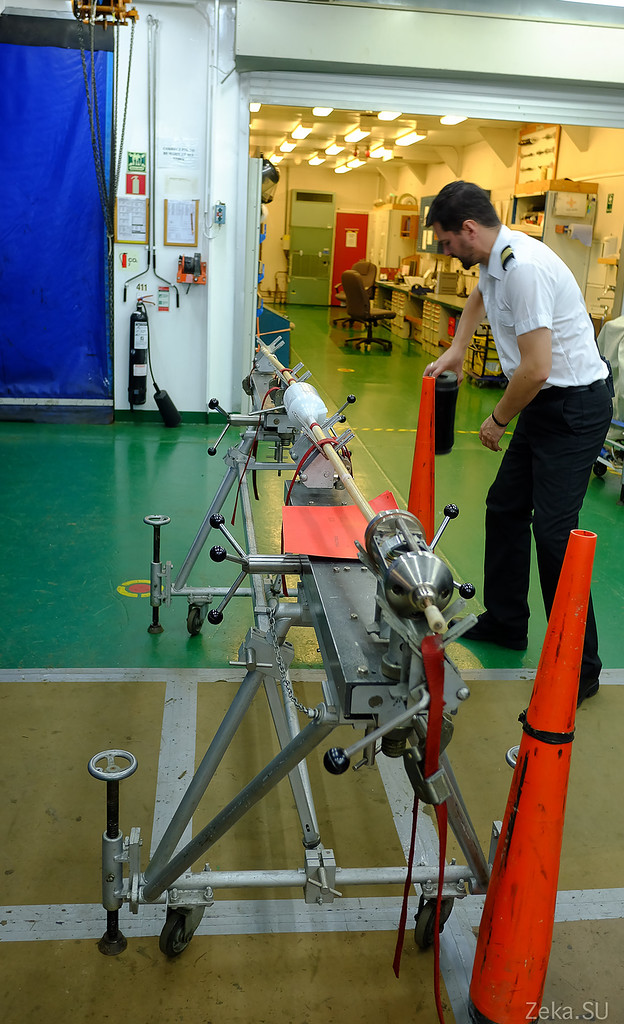

The welding shop is necessary for the repair of the submarine cable in case of an impulse, for connecting the cable from the shore to the submarine cable being mounted, well, or in the case for building it up. In our case, as the site master said: “We in Kamchatka will connect the cable to the shore end quickly, you only need 4 strings to be welded.”

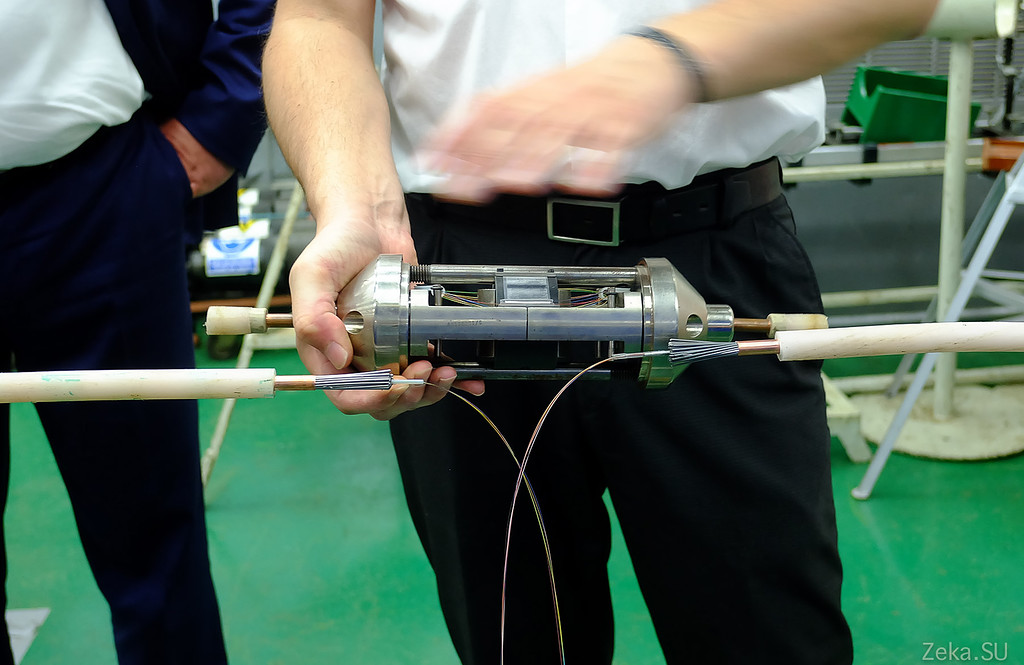

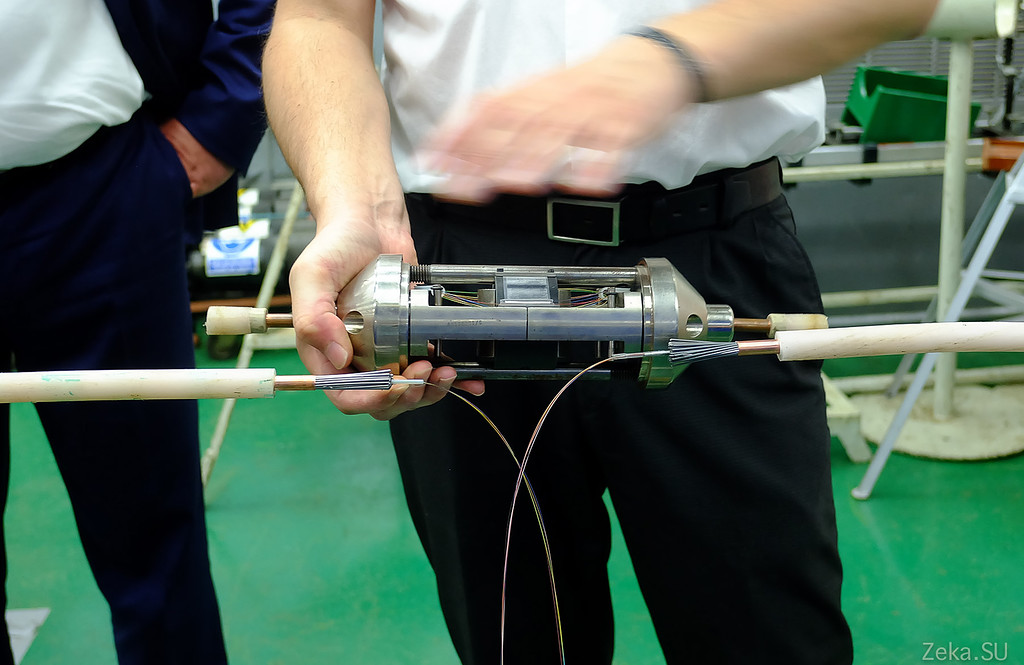

This is a coupler. In it the welded fibers keep within and the ends of a cable are connected. True, we were assured that this sample is old, there are already clutches of the new model, more durable.

In this way we insert the coupling into the cable break and fasten:

Heavy Gizmo:

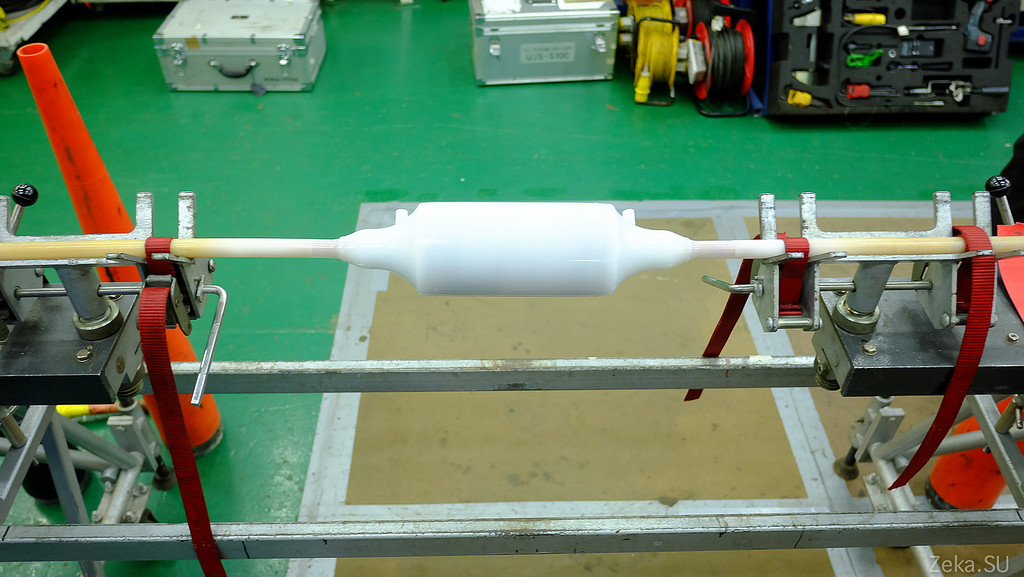

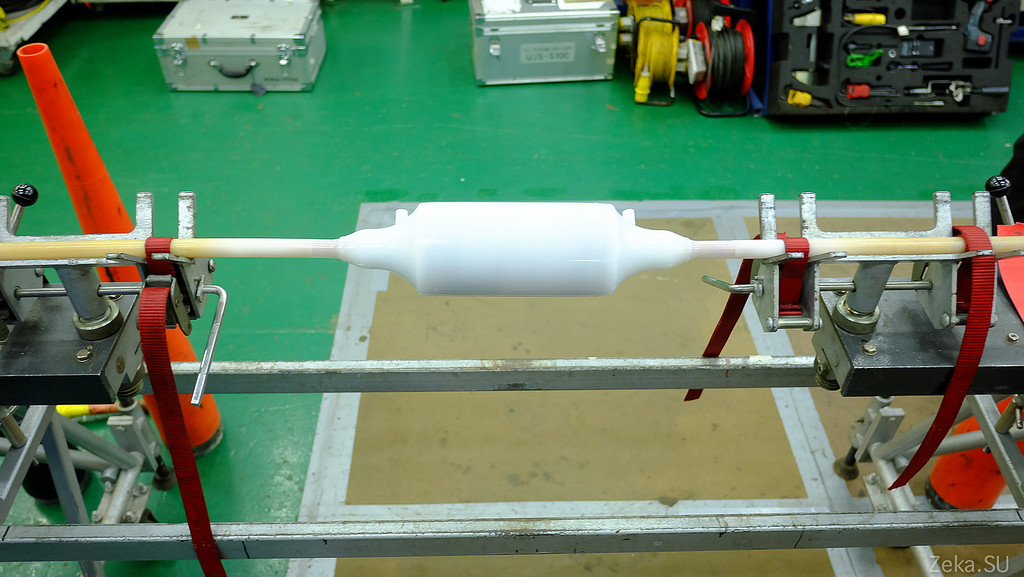

Next Stage. Waterproofing. The clutch is carefully poured with plastic:

So that the clutch does not burst at the junction with the cable, it is terminated with such “rubber” things:

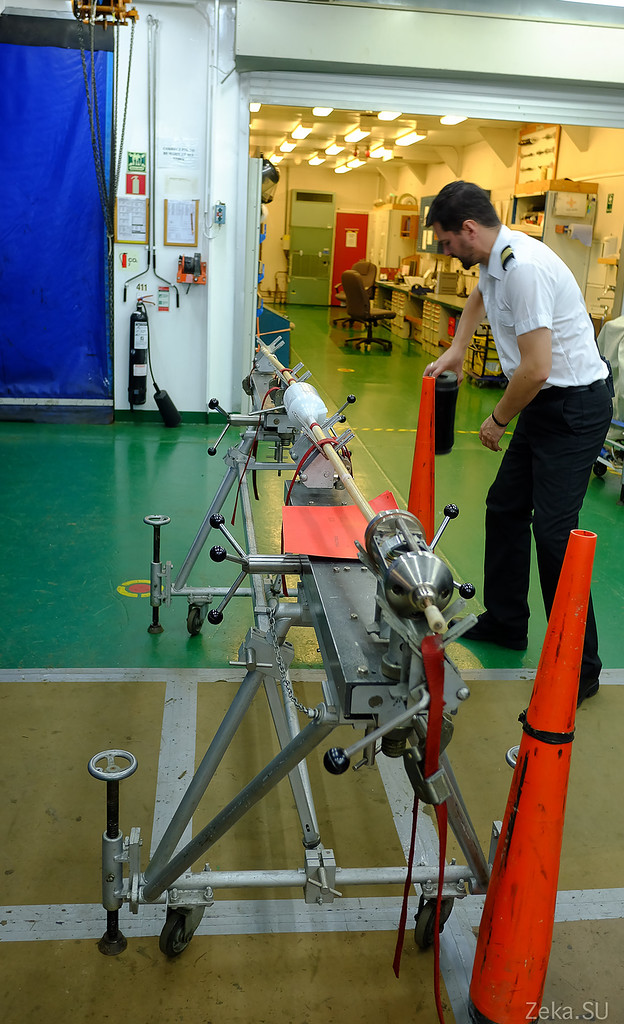

The result is a tight, heavy and durable “gut” that you can safely take with anything. In one such on a shoulder you will not drag. I understand why they need winches and hoists here:

Packing tightness is checked on X-rays. Remember that cabinet, which is dangerous to enter?

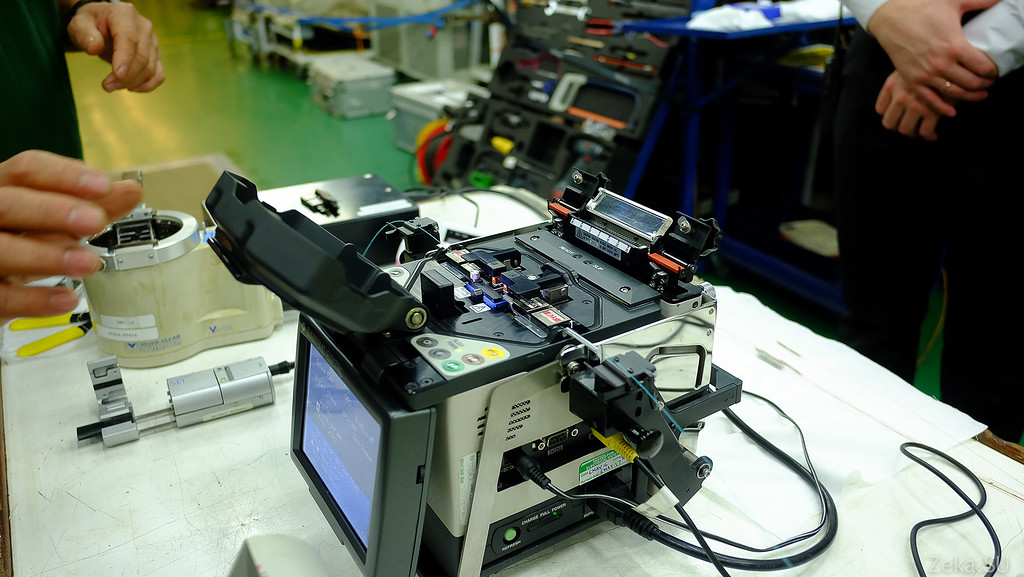

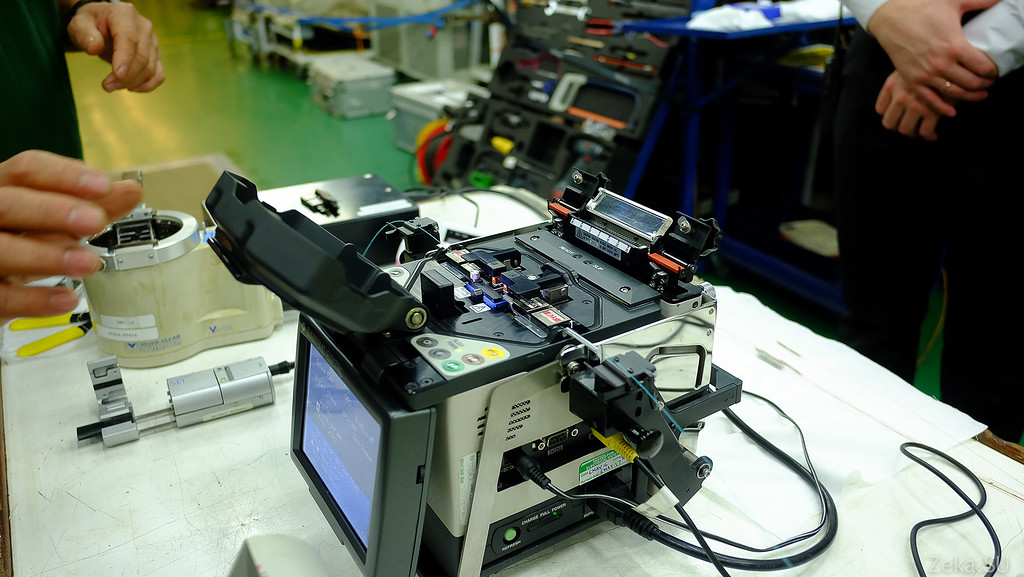

And now about the main thing! The most important thing is to weld the optical fibers well. That's actually the whole set of the young welder.

First, the cable is cleaned and the end of the cable is carefully cut so that it is smooth:

Then the two ends are inserted into the welding machine:

Press the button and watch:

Then repeat it for each core. Just after these operations, all the welded cable threads are placed into the sleeve and a “protective gut” is assembled around it:

At this point we finish the inspection of the workshop and proceed to the cable storages.

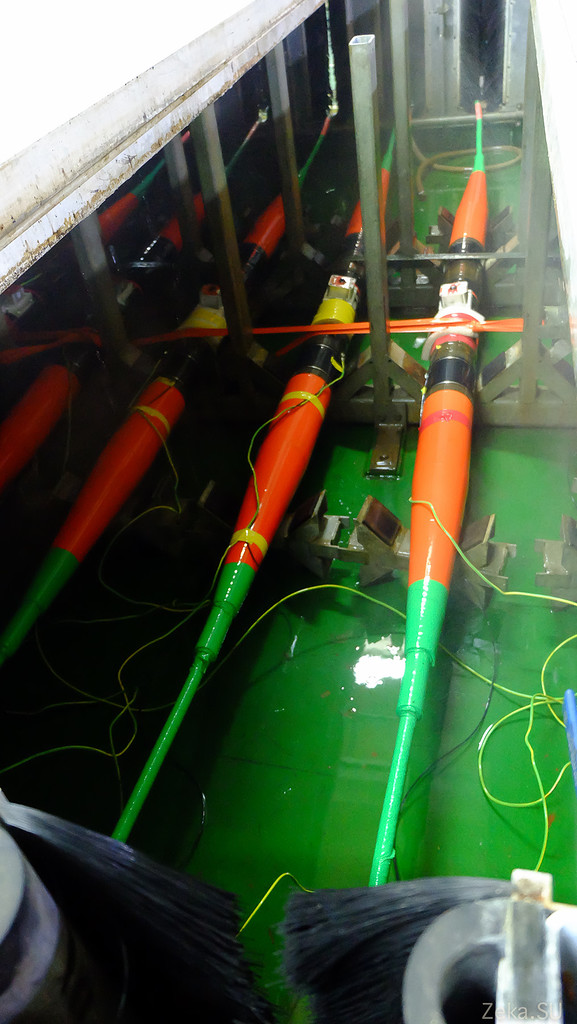

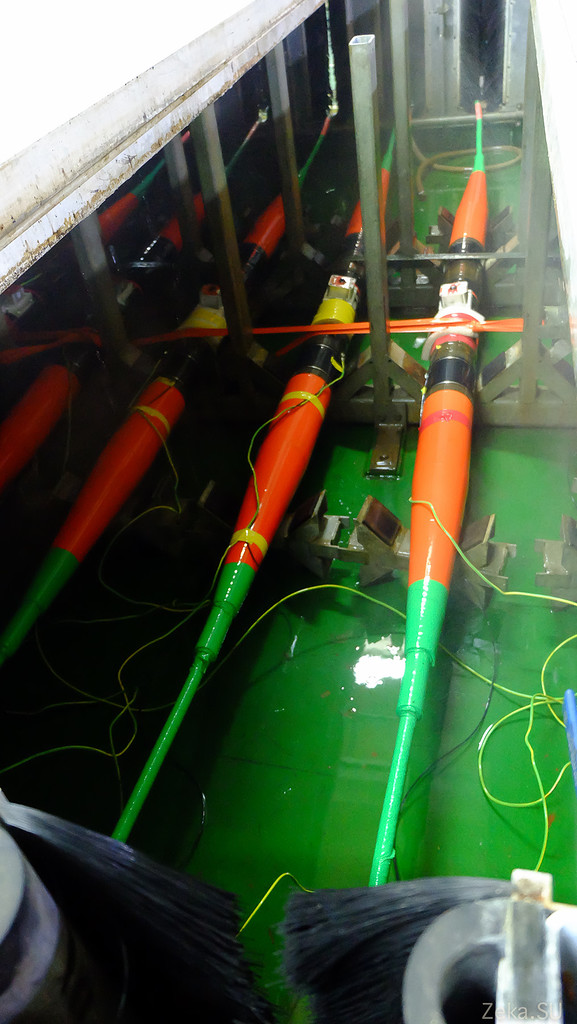

All 900 km of cable are laid in one of three cable tanks:

As you can see, there is only 3.5 meters of cable in the tank in height:

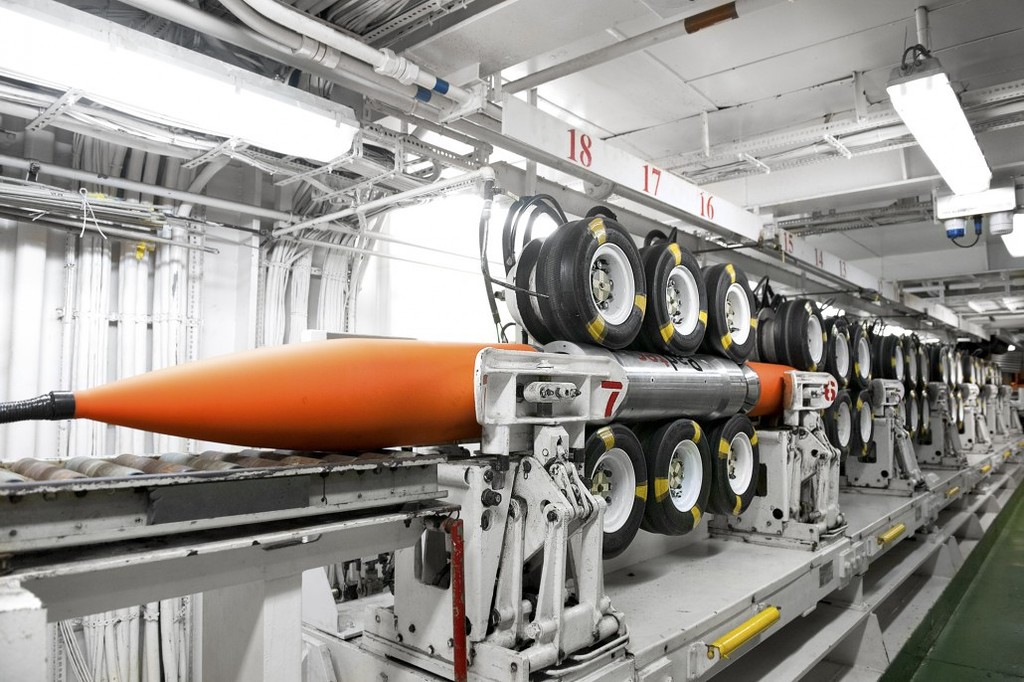

There is an optical amplifier installed on the cable, every 80 km. Here they are in a special storage:

A special microclimate is maintained in the storage. Apparently due to the peculiarities of the equipment:

Amplifiers are most often made on the basis of doping fiber with a rare-earth element — erbium.

How it works?

An additional high power laser beam, but different from the frequency of the laser transmitting information, is introduced into the fiber and causes erbium atoms in the amplifier to go into an excited unstable state. When a photon of laser radiation with a useful information weakened by a long fiber road, is received by this atom, it receives energy from this excited atom and is re-emitted with a new force and flies farther, more precisely it is reemitted in the form of 2 quanta and more useful photons become.

For those who write the above incomprehensible, I explain on the fingers.

Tennis balls are thrown into the pipe, on which information is recorded and they fly through the pipe from point A to point B. The pipe is long, and when experiencing air resistance they slow down and may not reach its end. Nearby, through a parallel pipe, the air is pumped at high speed, and it causes the wheel blades to turn quickly like a water mill, or a paddle steamer, located somewhere in the middle of the pipe. Having flown to this wheel, tennis balls get this wheel on the ass, like a tennis racket and with new forces fly further ... another 80km.

Who cares - read a normal and useful article on this topic , well, or Wikipedia .

Here are some additional equipment for working with cable. Tennis table and bicycles. The crew revealed the secret of bicycles.

A pier was under repair in Singapore, and there it was too far to go around the port area. I had to buy bicycles. But the secret of the tennis table refused to open. Mysterious English agents:

Self-propelled truck for transportation of amplifiers and ready-made coupling couplings:

Conveyor with guides for pulling the cable from the hold to the stern of the vessel:

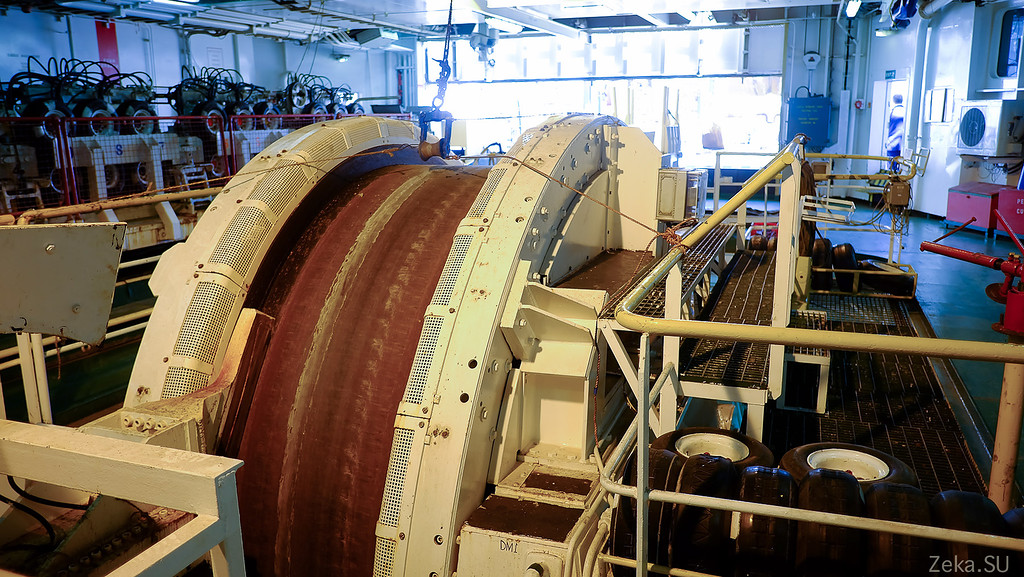

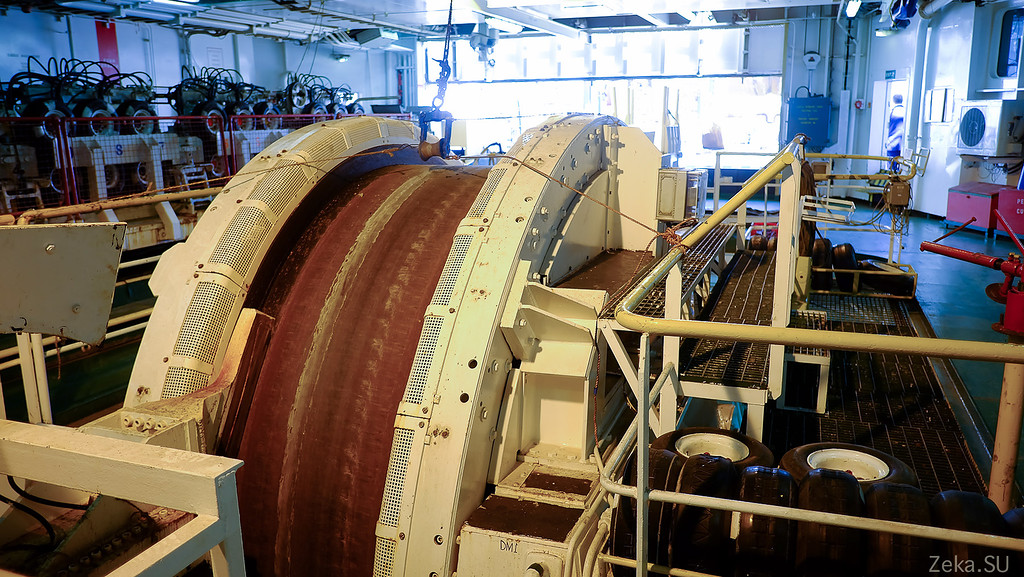

And this is already a winch to pull or feed the cable into the sea, hard to pull the cable from the depth of a couple of kilometers, you can overstrain:

This is how it looks in the work:

Another part of the feeder:

And this, as I understand it, is just the spare couplings, amplifiers in case of an unexpected cable break. You understand that it is better to take everything in advance. There are no stores in the Sea of Okhotsk:

. In general, let's thank this person for an excellent tour and go on. On the stern, where we look deep-water equipment:

All cable laying work is carried out from the stern of the vessel:

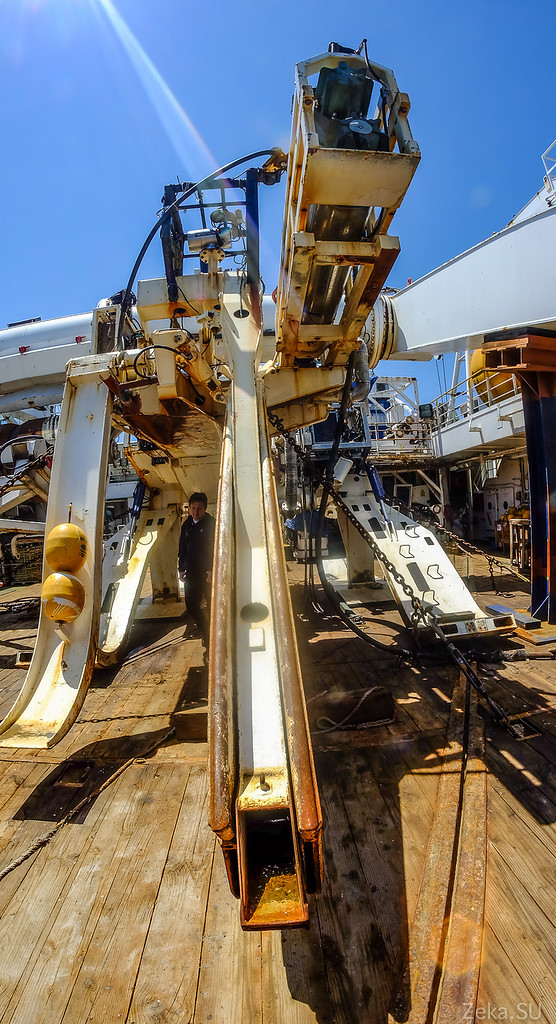

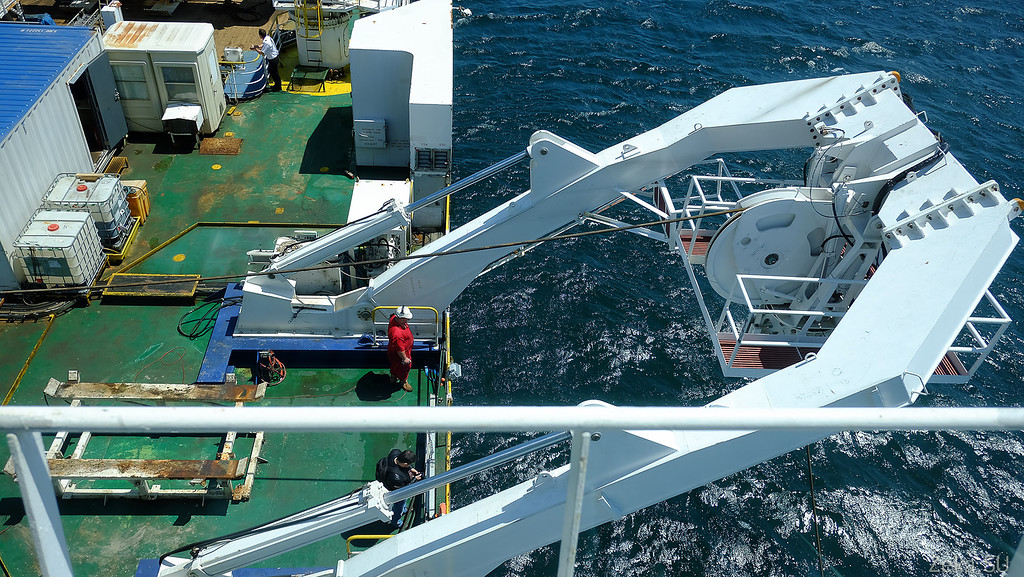

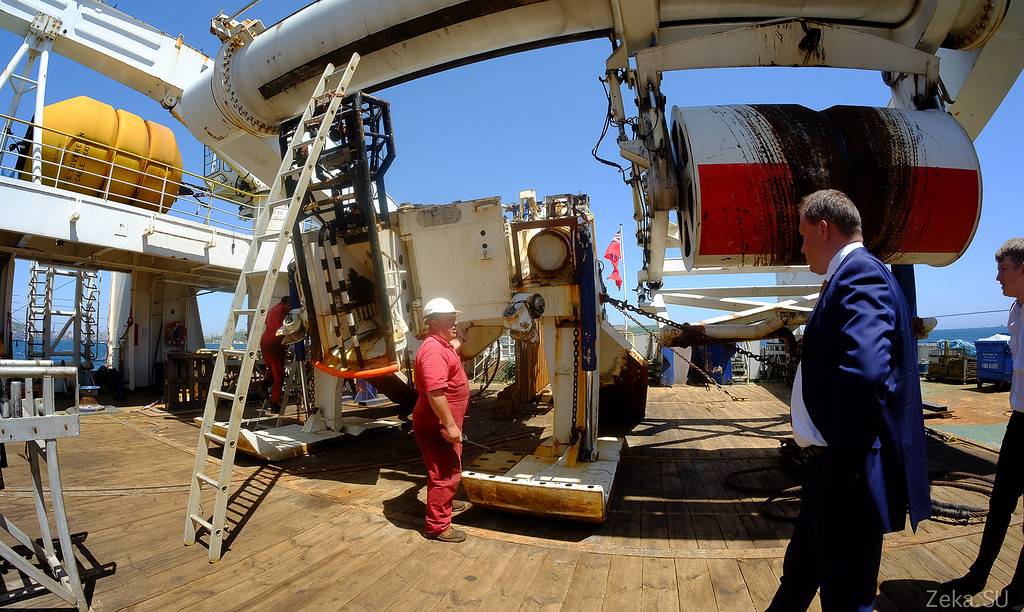

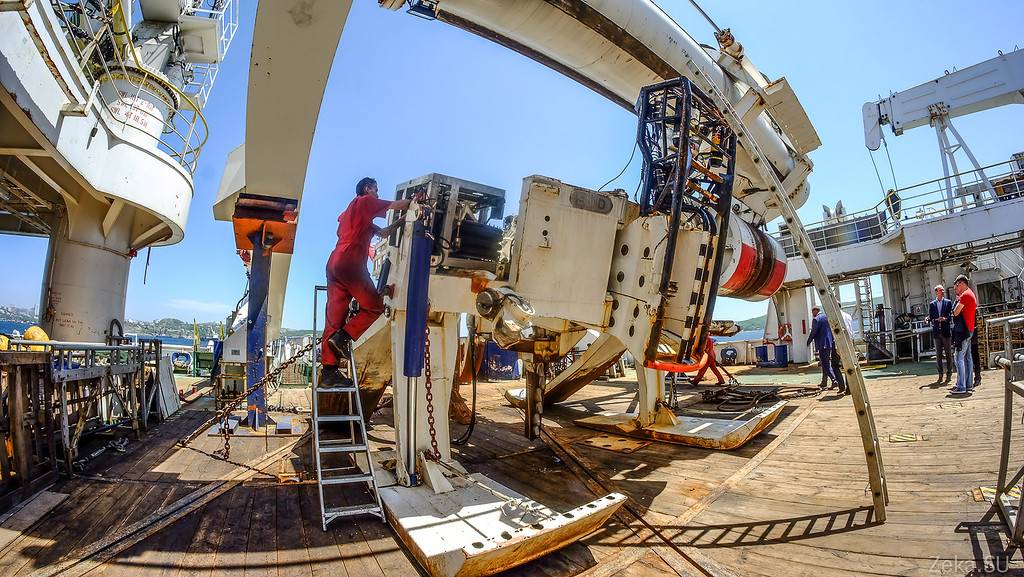

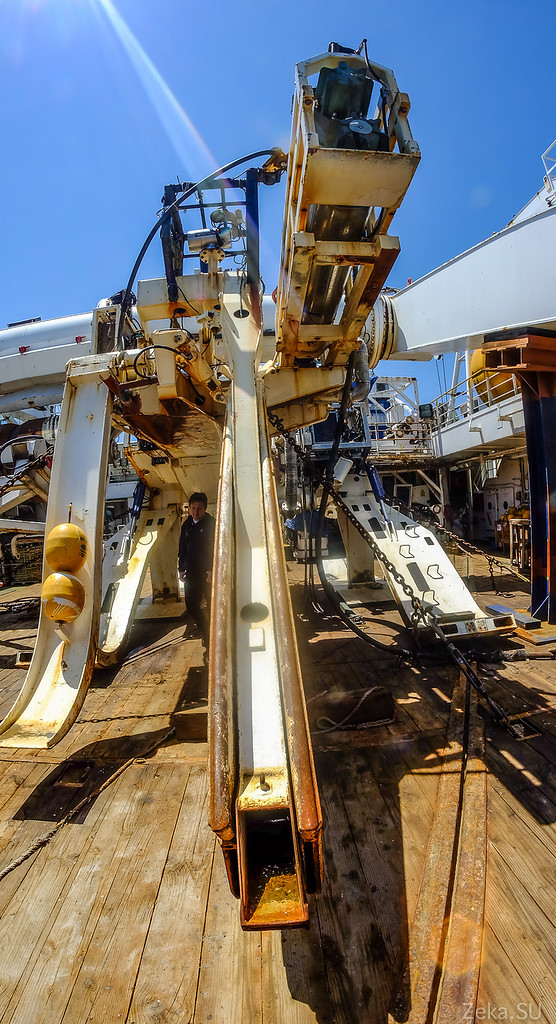

As you can see, two cargo cranes are installed here. A crane for lowering the plow, it leans back like on our military fighter vessels , by the way, is completely new. The team had to replace it recently for repair in Singapore. The second similar crane is located on the left side and is designed to work with an underwater robot.

Crane for the underwater vehicle:

General view of the deck. Workplaces for the operators of management of this equipment and warehouses of consumables are organized in containers:

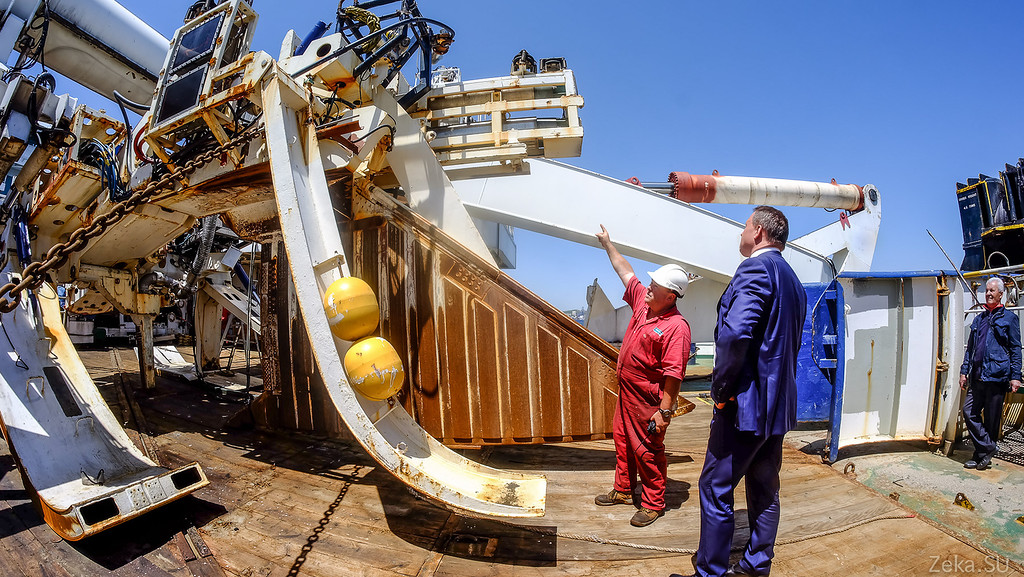

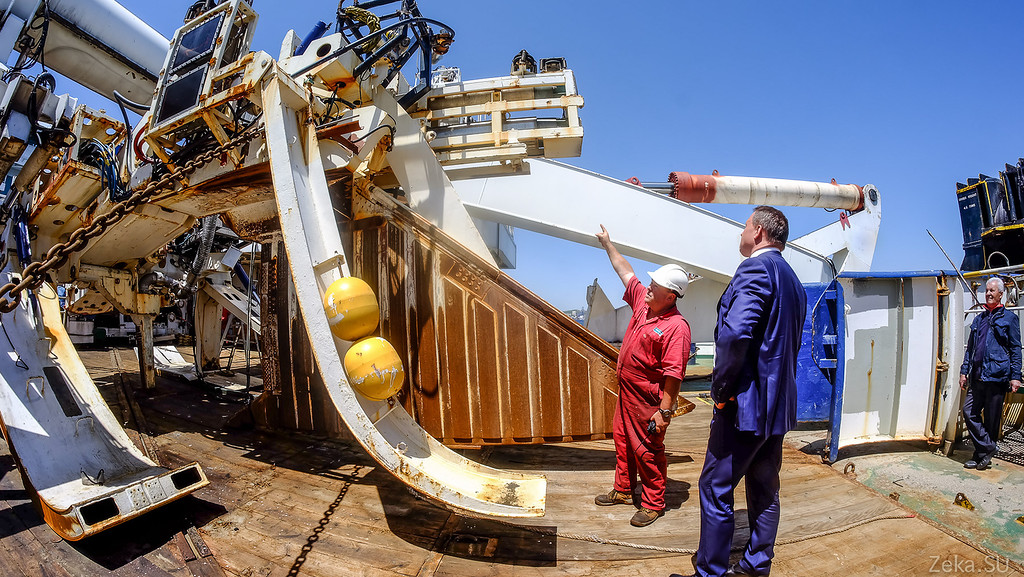

Head of deck economy and Rostelecom representatives:

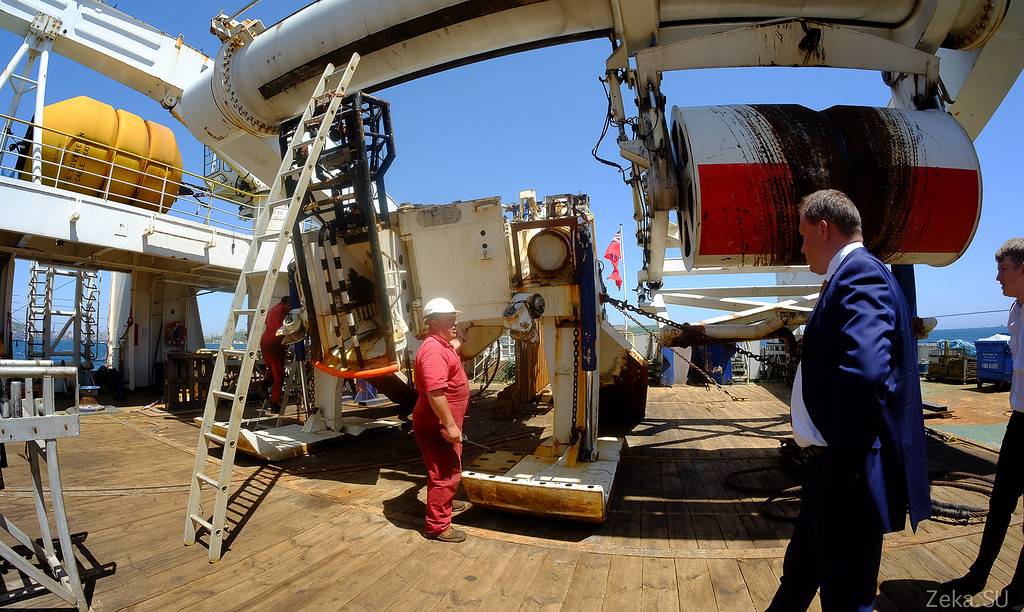

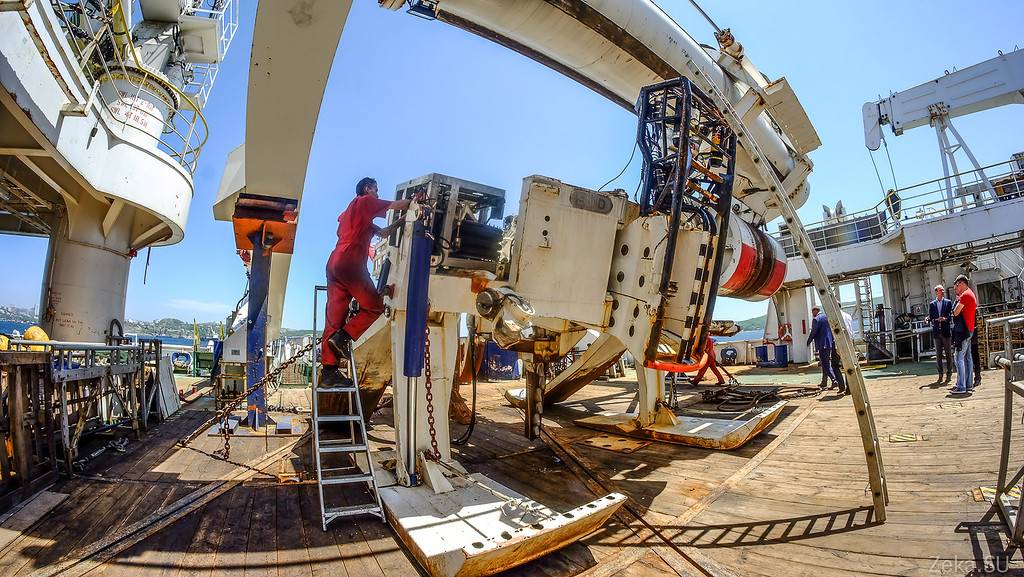

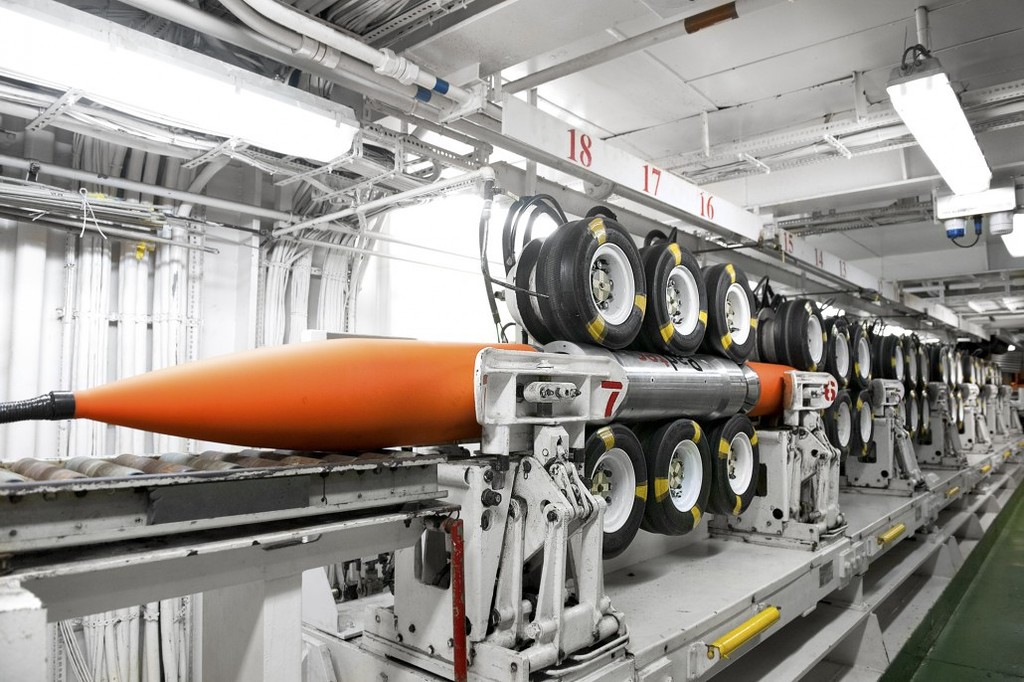

This is a plow. It is lowered into the water, to a depth of 2.5 km and on these skis it drags on a rope along the bottom behind the ship:

There are cameras and several moving parts on it to regulate the depth of plowing:

With this tooth, it plows the bottom to a depth of 1-1.5 meters and the cable is laid in a trench: The

dude told me that in the Sea of Okhotsk, when laying the cable to Magadan it was difficult. That plow sank in huge sediments of silt, then ran across rocks and even broke a couple of times. I had to get, cook, repair. In general, have suffered enough. Add to this still cold weather:

An impressive construction. Compare with human growth:

Actually, through this hole at the bottom and place the cable in the trench:

It looks like a plow, went to the depths of the ocean:

The photo shows the crane, cable conveyor and cable for the plow in the coils:

Now let's go to the robot.

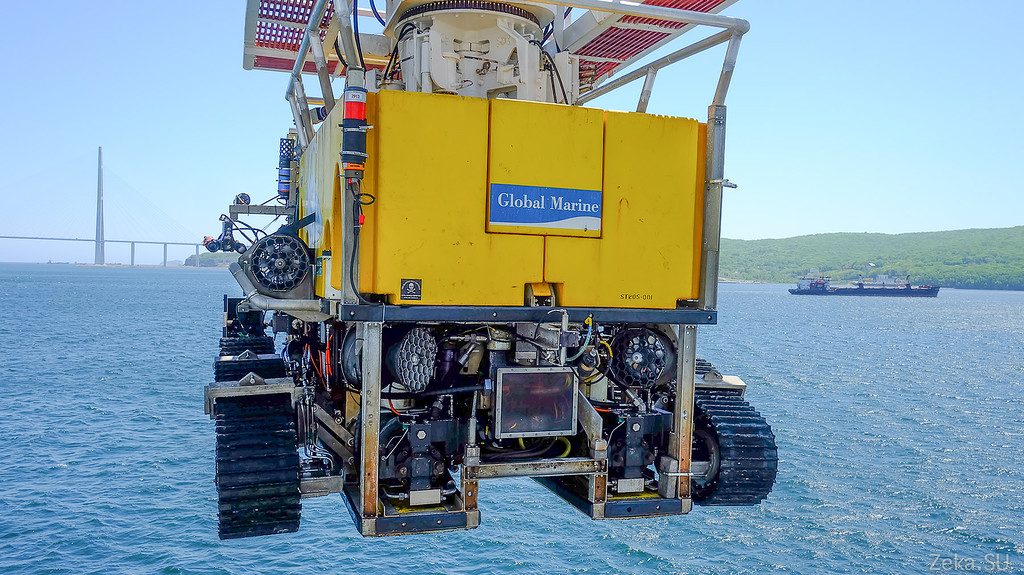

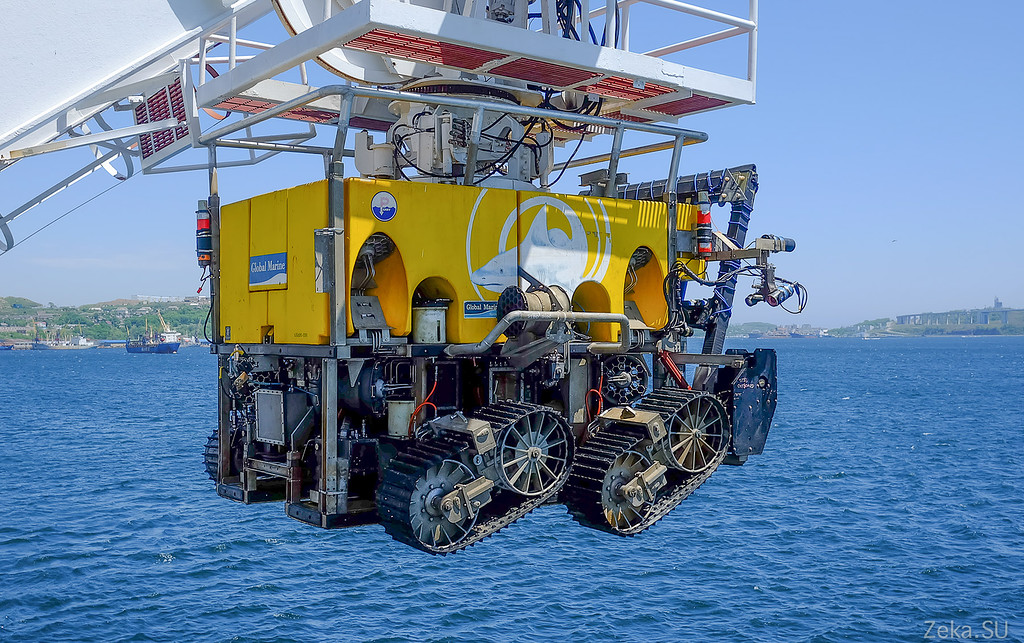

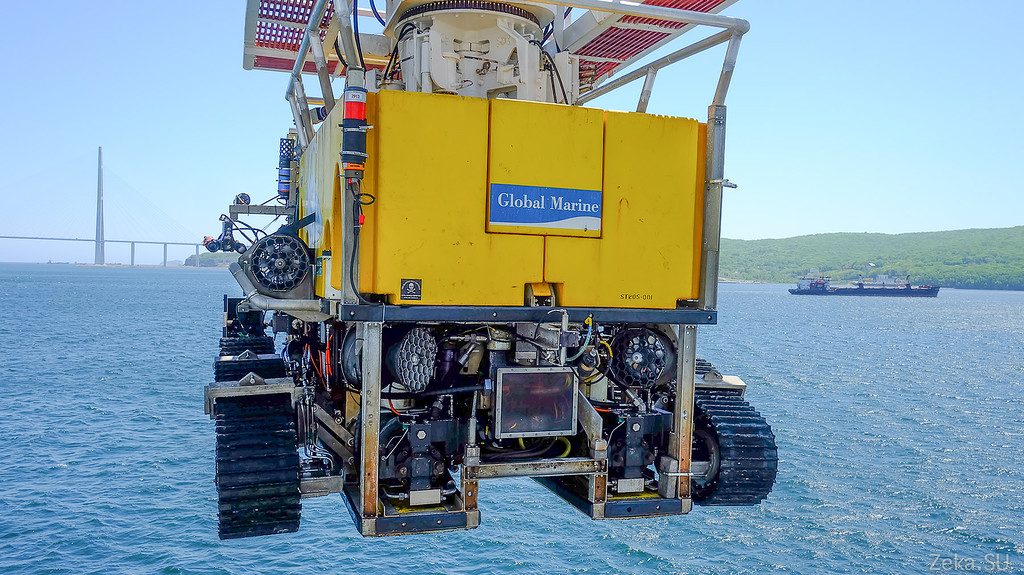

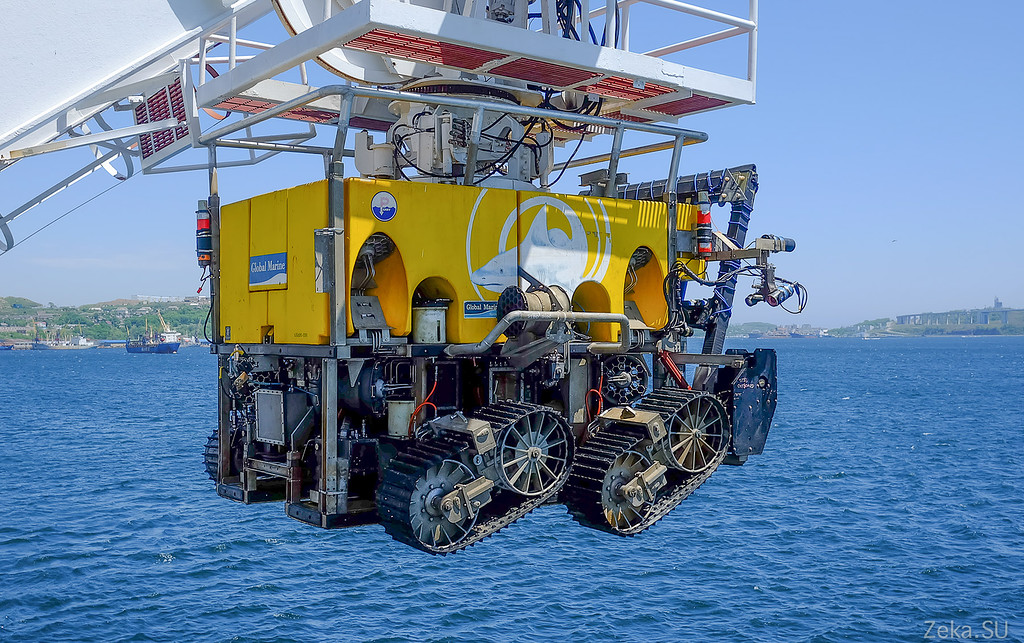

Underwater controlled vehicle. It is used for fine work with the cable. For laying on the stone bottom and searching for cable gusts: The

robot is equipped with cameras, it can swim under water and ride along the bottom. There are hydro monitors on board to erode the soil, or vice versa, to cover the cable with soil:

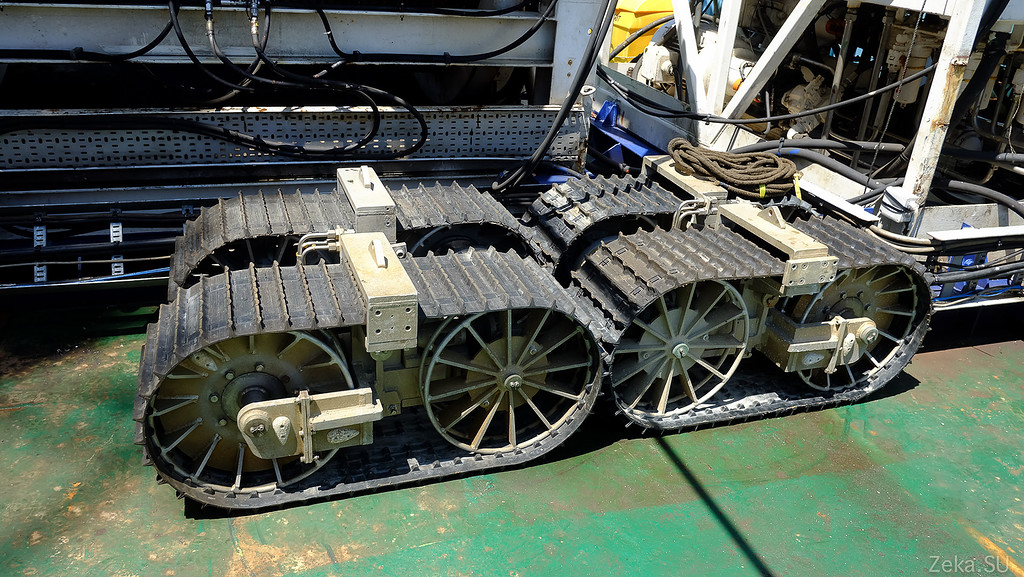

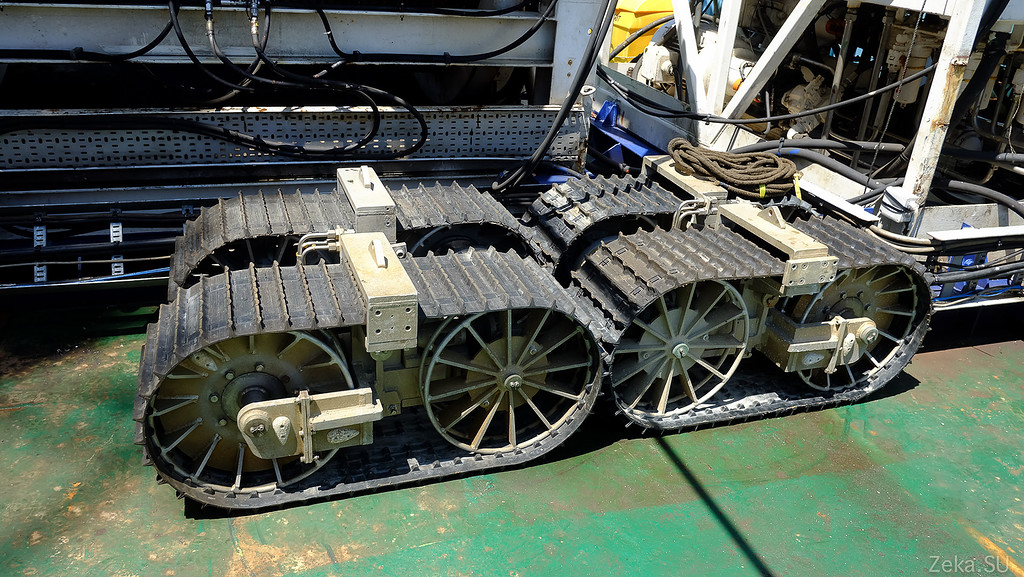

Deck for servicing the robot, spare tracks are lying on the background:

Agree - handsome. In our country, there are definitely no such:

Laying the cable with a robot is several times slower and more expensive. For example, consumables: -

Want to see how he can swim with us?

- Of course we want!

And here we were immediately kicked out of the deck:

And he was sent down to conquer the depths of the Eastern Bosphorus:

Crane:

Find the robot?

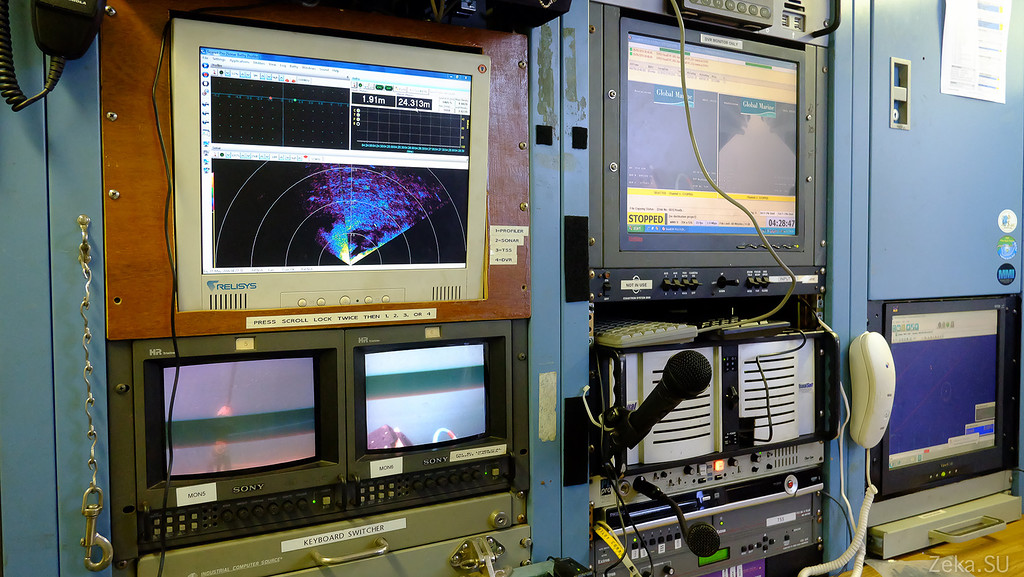

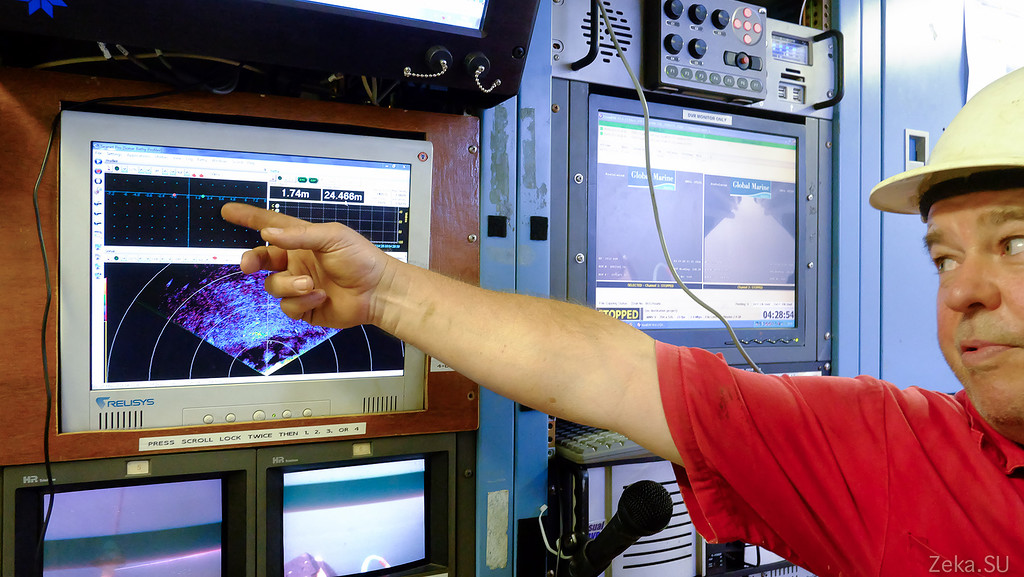

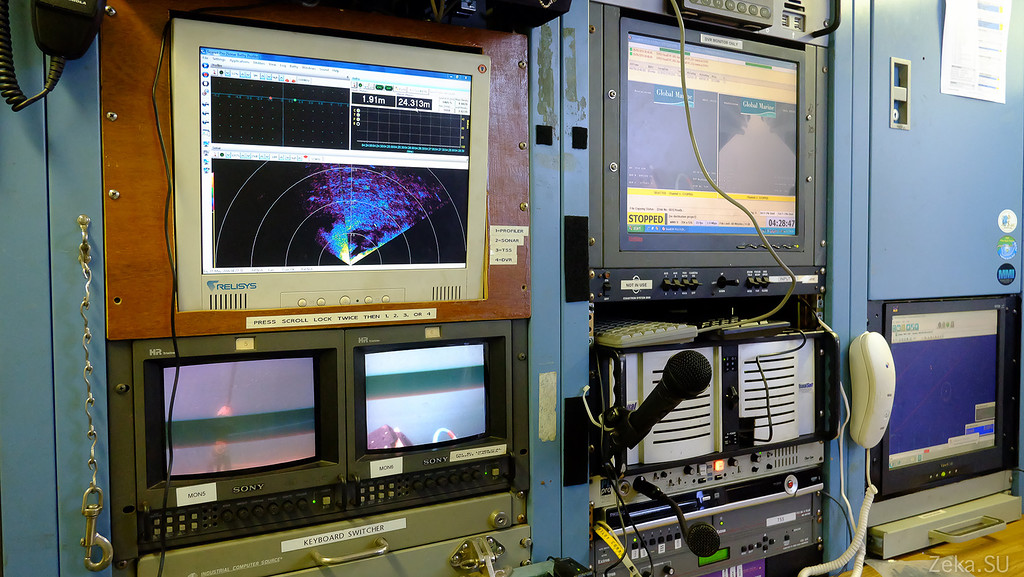

In one of the containers the control room for the underwater unit was built. The robot is controlled by 2 driver-operators:

It has several cameras installed, both navigation and, for example, a camera that controls the state of the suspension so that it does not fall off:

There is also a sonar, and cameras that are just installed at the place where the cable works to watch the work of manipulators and hydraulic monitors:

They did not lower them to the bottom, floats at a depth of 2 meters:

Telemetry:

Control panel:

And here is the second driver. Hiding around the corner:

At this point , we say thanks to this wonderful man for a smart excursion:

In general, on this positive note, I would probably end my excursion aboard the cable layer.

Of course, it’s a pity that in such a big country there are no vessels of this class, but the country itself has no task for laying ocean cables. For forcing rivers and bays rather more simple technical means. Such work probably can do the military, but the military perform only work aimed at ensuring the security of the country. And here is another.

Thanks to the company Rostelecom, which invited me to this beautiful boat.

Last year, this boat already came to us in the port , but, unfortunately, it did not take excursions. And this year, apparently under the impression of the successes of last year, Rostelecom invited several media representatives on board to show this miracle of technology, which is the most difficult work in this project.

Initially it was planned that during the summer of 2015 all the works on the project would be carried out and both branches of the AOLS would be laid in Magadan and Kamchatka.

But the Sea of Okhotsk turned out to be inhospitable and did not accept the entire cable. Weather conditions and bottom relief did not allow both branches to be laid in one season. And now, at the end of May, Сable Innovator arrived in our city to take on board part of the team and specialists from the customer companies Rostelecom and Huawei.

So, Сable Innovator - the world's largest cable laying machine for optics, was built in 1995 at the Kvaerner Masa shipyard in Finland. It is a diesel-electric (diesel engines, but the drive for electric screws). Equipped with a bunch of stabilization systems and thrusters in order to position the ship in any conditions with an accuracy of one meter (as the participants of the works complained to me, because of the additional propulsion units installed on the ship on the sides, they are forbidden to fish from the side so that the line is not tightened in the mechanisms; oh, sadness, sadness, grief).

In the photo you can see that it is equipped with two cuttings, fore and aft. In the stern cabin there are staff members who are responsible for the laying process itself; in the bow, everything is the same as in all other ships: the captain, the navigator.

There are 3 holds for the cable tank, their capacity is enough to lay the cable on the floor of the globe.

Scheme of the device of a similar ship:

For laying under water, 2 devices are used - Plow and Robot. The plow is lowered from the stern and dragged behind the ship. He plows the trench at the bottom of the sea and lays a cable into it. Plow is the main tool. But the robot is already used in emergency cases, when there are rocks on the bottom of the sea, when the cable breaks and you need to find its end, and for the repair of submarine cables.

I will divide the tour into 3 parts:

Part 1 - Felling, the captain's bridge;

Part 2 - Cable Deck;

Part 3 - Underwater tools Plow and Robot.

Submarine cable laying technology

On Habré already wrote similar materials, and then you can not read anything new for yourself.

In order for you to understand a little how to lay the cable in general, I will tell you a little theory.

The works are divided into several stages:

1. Research and design

At this stage, the seabed is investigated, or ready-made materials from previous studies are taken. Depending on the topography of the bottom, the route is built. Naturally, current communications at the bottom are taken into account. But the benefit is that the Sea of Okhotsk is not rich in underwater pipelines and underwater optical highways, well, except that the secret communication cables of the Pacific Fleet to which enemy submarines listen .

2. Cable manufacture and loading

The cable is made immediately with a coil so that you can run it from beginning to end under ideal conditions and load it onto the ship. At the production stage, erbium amplifiers EDFA (Erbium Doped Fiber Amplifier), a fiber-optic amplifier on erbium-doped optical fiber, are immediately incorporated into the cable.

Due to the fact that Russia does not have such civilian ships, the manufacture of the cable and its installation were entrusted to Huawei.

By the way, due to the fact that the work was not completed in one season, the cable was unloaded in Singapore, and Сable Innovator worked on other orders.

3. Gasket

Everything is simple. At the bottom, from the ship, they lower the plow and turn the small one forward. He digs a trench, a cable is buried in it.

The only difference with the picture is that there is a couple of kilometers under the ship.

For safety, one more Neptunia tug boat participated in laying the cable from Magadan to Sakhalin. It was on a safety net and cleared the bottom of the trash from the trawl along the way. Here it is:

This year Neptunia did not go with them.

Here is another informative video:

4. If everything went well and the cable reached from shore to shore, then it was connected to the coast station. And from the station already, in the old manner, with wires pulling the Internet to the consumer.

In Magadan at Rostelkom everything went well. The cable was stretched, tested for six months and now they sell fast Internet to everyone.

According to the latest information, from June 7, 2016, the cable was connected to the coast station in Ust-Bolsheretsk and cable laying to Sakhalin should end on July 22. So, the chance that next year the normal Internet will appear in Kamchatka is very high.

All right, it was all lyrics, and now we will go on a tour of the ship.

The ship stood near the island of Russian, I even thought that you can go to him on a kayak, but, alas, the weather did not allow.

We were brought aboard by a small boat: The

hospitable ladder opened its arms to the guests and crew members:

Then the labyrinths of corridors and stairs began:

Everyone was invited to the mess room and the Captain and Russian assistant told us what we would see:

Naturally, a conversation on all ships safety engineering begins. Where to run in the event of a siren. For these purposes, everyone was recorded and counted on their heads, so that in the event of something not losing anyone:

Captain's bridge

I don’t understand anything in the captain’s bridges, so if anyone knows better, correct me:

View of the front deck: The

same, but from the other side:

View from the bridge to the bridge over the Eastern Bosphorus:

Walkie-talkie to communicate with the crew, and so I understand Telex:

Actually, we are on a guided tour. Rostelecom and media representatives:

One of the control panels. Those colored buttons turn on the lights:

Compass:

So I understand, this is the navigator's workplace. Behind it you can see a box with maps:

World and Russian navigation, and the master's own place of work. All these “full speed ahead”, “stop machine”:

Captain, assistant and Alexey Sapunov, director of the Far East region of Rostelecom:

But this is the aft control room. There are more sensitive and delicate ship management tools. With the help of these joysticks and a stabilization system, you can move ships literally one meter to the right and left:

This is also the translation from cameras installed on the underwater vehicle. At the moment, it is floating under water in the Bosphorus East: The

submarine is

plowing the Sea of Japan at a depth of a couple of meters: on the sly I photographed a secret map of the sea floor of the Sea of Okhotsk with a cable pattern. I hope they will not beat me very much for this:

Safety plan on the ship:

Cozy on the balcony. Sofa, flowers grow, on the other hand, similarly:

Crew Jobs:

View from the bridge to Vladivostok and the internal raid in the Eastern Bosphorus:

And this is a view of the stern of the vessel. A crane is visible that controls the cable feed and the plow (located below it on the left). In the containers there are additional equipment and ... "offices" of those who manage all this. In one of the containers there is a control room for the underwater robot. This is done so that it is easy to change the functionality of the vessel, depending on customer requirements. No part of the equipment is needed - unloaded the container in the port and all the rules:

In general, thank Captain Christopher Niva for the tour and go on:

On the nose, nothing extra:

On the upper deck, a spare screw and anchors:

Still there frantically smelled Asian food from the ventilation system and stood incomprehensible person:

On the other side was his friend, but without shoes:

We then argued for a long time who these people were and why they were so punished? Our version was to scare away seabirds so that the deck would not be soiled. It turned out that we were only half right. These gentlemen really work as stuffed animals. Only not from the birds, but from their more intelligent two-legged competitors. It turns out that if you stand on the roadstead in the port, incomprehensible people can get on board from a small boat, and stuffed from afar resemble security officers.

Cable deck

On this deck, they carry out all the work related to cable processing, feeding it to the stern and repairing it. In addition, there are storages on this deck - cable tanks and storages for optical amplifiers.

And now about this all in order.

The deck itself resembles a factory workshop in miniature: conveyors, hoists, warehouses with products:

The captain of the cable deck will no longer entertain us:

First I will tell you about the submarine cable.

I have in my hands an underwater optical cable in section. It consists of several protective shells made of plastic, carrying steel or aluminum wires and in the very middle are optical fibers:

I think it is clearer:

To be brief and concise, it works like this: optical fibers are inside an aluminum, copper, plastic tube, sometimes filled with grease. The tube is wrapped with an insulating material or filled with polyethylene. All of this is wrapped in steel reinforcing threads that are wrapped with a waterproof sheath, such as polyethylene. Sometimes several layers of supporting cables are used. As in the above photo.

Rostelecom is laying almost the same cable, with the only difference: it has only 4 wires of optical fiber laid. But this should be enough for the coming years, because the sealing equipment allows transmitting up to 8Tbit / s via this cable. What should be enough for these regions with interest for the next thirty years. Naturally, there will be much less traffic, as there are few consumers in these areas and they do not need to feed the maximum flow.

In the welding room there is a whole exhibition of cables with which one had to work:

Judging by the appearance, the leftmost cable is intended for laying in the most dangerous places of the globe. Where not only sharks and crocodiles can gnaw him, but also elephants and hippos stomp on them:

So, we are with you in the welding shop where the cable connection works are being carried out. Immediately pay attention to the door with a sign "Do not enter! Dangerously". There is an X-ray room. But we will come back to this later.

The welding shop is necessary for the repair of the submarine cable in case of an impulse, for connecting the cable from the shore to the submarine cable being mounted, well, or in the case for building it up. In our case, as the site master said: “We in Kamchatka will connect the cable to the shore end quickly, you only need 4 strings to be welded.”

This is a coupler. In it the welded fibers keep within and the ends of a cable are connected. True, we were assured that this sample is old, there are already clutches of the new model, more durable.

In this way we insert the coupling into the cable break and fasten:

Heavy Gizmo:

Next Stage. Waterproofing. The clutch is carefully poured with plastic:

So that the clutch does not burst at the junction with the cable, it is terminated with such “rubber” things:

The result is a tight, heavy and durable “gut” that you can safely take with anything. In one such on a shoulder you will not drag. I understand why they need winches and hoists here:

Packing tightness is checked on X-rays. Remember that cabinet, which is dangerous to enter?

And now about the main thing! The most important thing is to weld the optical fibers well. That's actually the whole set of the young welder.

First, the cable is cleaned and the end of the cable is carefully cut so that it is smooth:

Then the two ends are inserted into the welding machine:

Press the button and watch:

Then repeat it for each core. Just after these operations, all the welded cable threads are placed into the sleeve and a “protective gut” is assembled around it:

At this point we finish the inspection of the workshop and proceed to the cable storages.

All 900 km of cable are laid in one of three cable tanks:

As you can see, there is only 3.5 meters of cable in the tank in height:

There is an optical amplifier installed on the cable, every 80 km. Here they are in a special storage:

A special microclimate is maintained in the storage. Apparently due to the peculiarities of the equipment:

Amplifiers are most often made on the basis of doping fiber with a rare-earth element — erbium.

How it works?

An additional high power laser beam, but different from the frequency of the laser transmitting information, is introduced into the fiber and causes erbium atoms in the amplifier to go into an excited unstable state. When a photon of laser radiation with a useful information weakened by a long fiber road, is received by this atom, it receives energy from this excited atom and is re-emitted with a new force and flies farther, more precisely it is reemitted in the form of 2 quanta and more useful photons become.

For those who write the above incomprehensible, I explain on the fingers.

Tennis balls are thrown into the pipe, on which information is recorded and they fly through the pipe from point A to point B. The pipe is long, and when experiencing air resistance they slow down and may not reach its end. Nearby, through a parallel pipe, the air is pumped at high speed, and it causes the wheel blades to turn quickly like a water mill, or a paddle steamer, located somewhere in the middle of the pipe. Having flown to this wheel, tennis balls get this wheel on the ass, like a tennis racket and with new forces fly further ... another 80km.

Who cares - read a normal and useful article on this topic , well, or Wikipedia .

Here are some additional equipment for working with cable. Tennis table and bicycles. The crew revealed the secret of bicycles.

A pier was under repair in Singapore, and there it was too far to go around the port area. I had to buy bicycles. But the secret of the tennis table refused to open. Mysterious English agents:

Self-propelled truck for transportation of amplifiers and ready-made coupling couplings:

Conveyor with guides for pulling the cable from the hold to the stern of the vessel:

And this is already a winch to pull or feed the cable into the sea, hard to pull the cable from the depth of a couple of kilometers, you can overstrain:

This is how it looks in the work:

Another part of the feeder:

And this, as I understand it, is just the spare couplings, amplifiers in case of an unexpected cable break. You understand that it is better to take everything in advance. There are no stores in the Sea of Okhotsk:

. In general, let's thank this person for an excellent tour and go on. On the stern, where we look deep-water equipment:

Deepwater Equipment

All cable laying work is carried out from the stern of the vessel:

As you can see, two cargo cranes are installed here. A crane for lowering the plow, it leans back like on our military fighter vessels , by the way, is completely new. The team had to replace it recently for repair in Singapore. The second similar crane is located on the left side and is designed to work with an underwater robot.

Crane for the underwater vehicle:

General view of the deck. Workplaces for the operators of management of this equipment and warehouses of consumables are organized in containers:

Head of deck economy and Rostelecom representatives:

This is a plow. It is lowered into the water, to a depth of 2.5 km and on these skis it drags on a rope along the bottom behind the ship:

There are cameras and several moving parts on it to regulate the depth of plowing:

With this tooth, it plows the bottom to a depth of 1-1.5 meters and the cable is laid in a trench: The

dude told me that in the Sea of Okhotsk, when laying the cable to Magadan it was difficult. That plow sank in huge sediments of silt, then ran across rocks and even broke a couple of times. I had to get, cook, repair. In general, have suffered enough. Add to this still cold weather:

An impressive construction. Compare with human growth:

Actually, through this hole at the bottom and place the cable in the trench:

It looks like a plow, went to the depths of the ocean:

The photo shows the crane, cable conveyor and cable for the plow in the coils:

Now let's go to the robot.

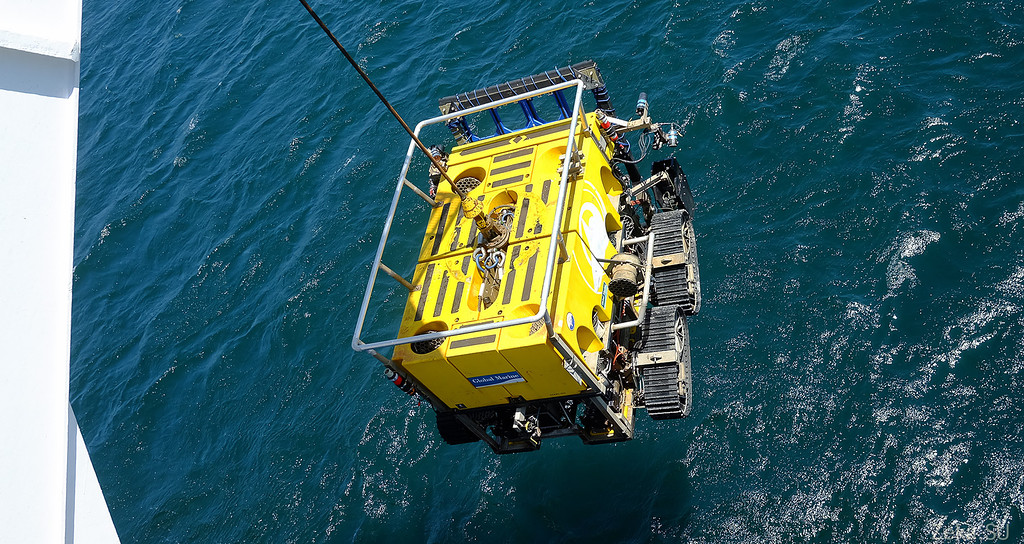

Underwater controlled vehicle. It is used for fine work with the cable. For laying on the stone bottom and searching for cable gusts: The

robot is equipped with cameras, it can swim under water and ride along the bottom. There are hydro monitors on board to erode the soil, or vice versa, to cover the cable with soil:

Deck for servicing the robot, spare tracks are lying on the background:

Agree - handsome. In our country, there are definitely no such:

Laying the cable with a robot is several times slower and more expensive. For example, consumables: -

Want to see how he can swim with us?

- Of course we want!

And here we were immediately kicked out of the deck:

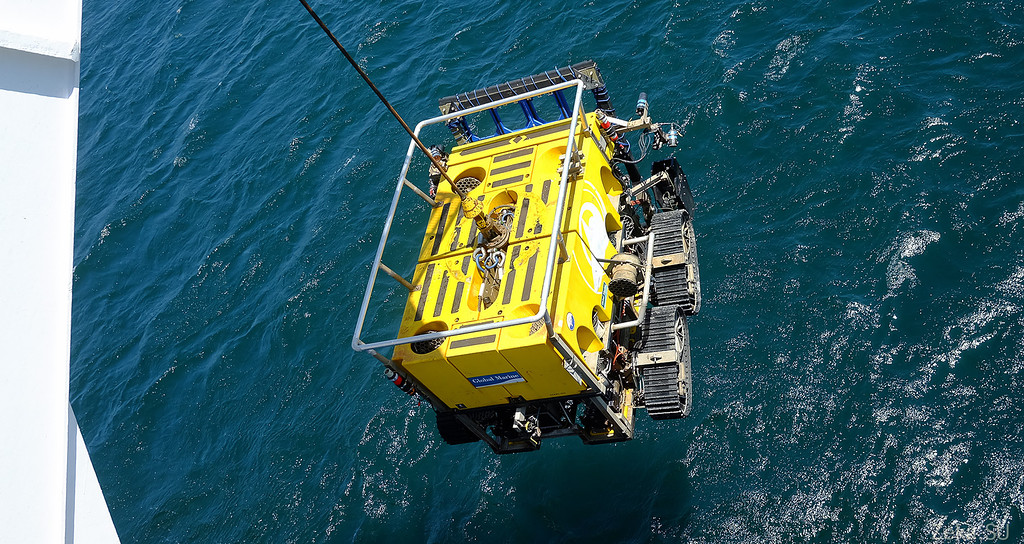

And he was sent down to conquer the depths of the Eastern Bosphorus:

Crane:

Find the robot?

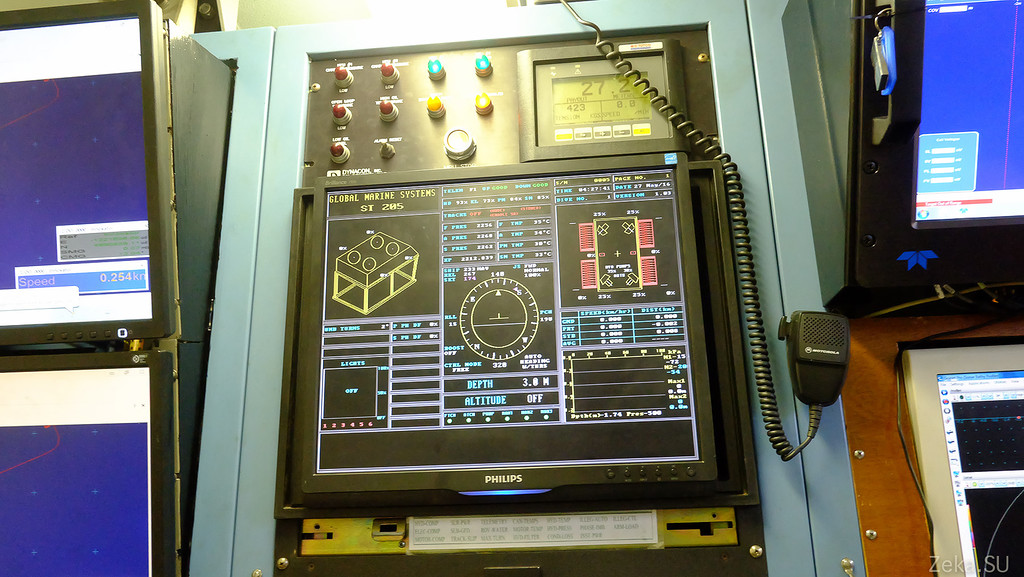

In one of the containers the control room for the underwater unit was built. The robot is controlled by 2 driver-operators:

It has several cameras installed, both navigation and, for example, a camera that controls the state of the suspension so that it does not fall off:

There is also a sonar, and cameras that are just installed at the place where the cable works to watch the work of manipulators and hydraulic monitors:

They did not lower them to the bottom, floats at a depth of 2 meters:

Telemetry:

Control panel:

And here is the second driver. Hiding around the corner:

At this point , we say thanks to this wonderful man for a smart excursion:

In general, on this positive note, I would probably end my excursion aboard the cable layer.

Of course, it’s a pity that in such a big country there are no vessels of this class, but the country itself has no task for laying ocean cables. For forcing rivers and bays rather more simple technical means. Such work probably can do the military, but the military perform only work aimed at ensuring the security of the country. And here is another.

Thanks to the company Rostelecom, which invited me to this beautiful boat.