Thinking out loud. Four is better than one ... Or the concept of a transport quadrocopter

The article highlights the fundamental shortcomings of such an aircraft as a helicopter, and their solution is proposed. The possible application of this concept in robotic systems and complexes is considered. The described approach does not claim to be unambiguous and accurate, and the article aims to share a technical idea with GT readers.

Aircraft (LA) is a machine or device for flying in the atmosphere or outer space. At the moment, the classification of aircraft has a huge variety of types and types of aircraft, among this many can be identified one of the most widely used types of aircraft - helicopter.

Let us single out the principal shortcomings of the helicopter as a class:

Figure 1 - Mi-26 helicopter in three projections

The width of the cargo compartment of the helicopter is 320 cm, for comparison, the width of the armored personnel carrier BTR-70 is 280 cm, respectively, there is a 20 cm space between each side of the conveyor and the wall of the cargo compartment of the helicopter, which is a negative factor when loading equipment of such dimensions (Fig. 2, right). Figure 2 (left) illustrates the complexity of the loading process using a forklift.

The presence of this factor introduces inconvenience when using helicopters in civilian cargo transportation and is critical when using such aircraft in emergencies and military operations.

Figure 2 - The process of loading with a forklift (left), loading of the BTR-70 (right)

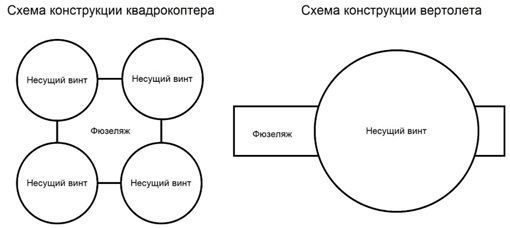

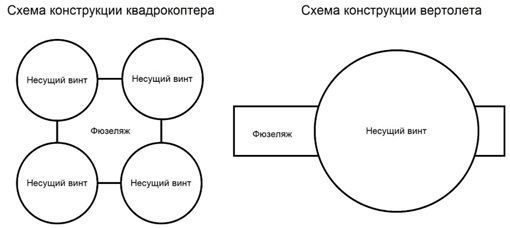

The quadcopter is an aircraft with four rotors that rotate diagonally in opposite directions. Such a layout of rotors allows you to realize an aircraft with a fuselage wider than in helicopters (Fig. 3), and the presence of four rotors will provide four swept zones, which will allow landing and take-off with side roll.

Figure 3 - Block diagram of the designs of the quadrocopter and helicopter

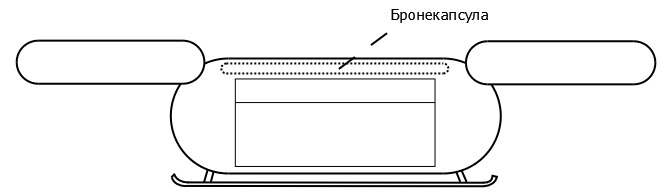

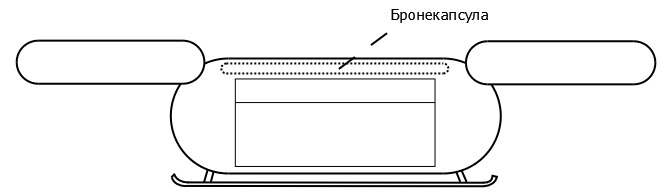

When using this scheme, such components as the fuel system, control system, radar system, electrics are located in the upper part of the fuselage in a special armored capsule (Fig. 4). This arrangement of nodes allows you to place hatches of cargo compartments and cargo ramps in any of the 5 sides of the fuselage (Fig. 5): from the four sides and from the bottom (vertical loading hatch).

Figure 4 - Location of the armored capsule

Figure 5 - Placement of cargo hatches

The considered approach has the following disadvantages:

Possible solutions:

Figure 7 - Placement of rotors

APPLICATION OF CONCEPT IN ROBOTIC

Unmanned aerial vehicle (UAV) - an aircraft without a crew on board, implemented using robotics. The implementation of the cargo quadrocopter, as an UAV, is advisable:

Centralized management with a human operator (one-to-one communication). Management system structure:

Centralized management with a control room (one-to-many communication). Management system structure:

Decentralized management (many-to-many relationship). Management system structure:

FORMULATION OF THE PROBLEM

Aircraft (LA) is a machine or device for flying in the atmosphere or outer space. At the moment, the classification of aircraft has a huge variety of types and types of aircraft, among this many can be identified one of the most widely used types of aircraft - helicopter.

Let us single out the principal shortcomings of the helicopter as a class:

- the difficulty of loading goods and equipment of large dimensions due to the narrow cargo compartment,

- landing is possible only in the absence of side roll due to the narrow fuselage and one area swept by the rotor.

Figure 1 - Mi-26 helicopter in three projections

The width of the cargo compartment of the helicopter is 320 cm, for comparison, the width of the armored personnel carrier BTR-70 is 280 cm, respectively, there is a 20 cm space between each side of the conveyor and the wall of the cargo compartment of the helicopter, which is a negative factor when loading equipment of such dimensions (Fig. 2, right). Figure 2 (left) illustrates the complexity of the loading process using a forklift.

The presence of this factor introduces inconvenience when using helicopters in civilian cargo transportation and is critical when using such aircraft in emergencies and military operations.

Figure 2 - The process of loading with a forklift (left), loading of the BTR-70 (right)

THE SOLUTION OF THE PROBLEM

The quadcopter is an aircraft with four rotors that rotate diagonally in opposite directions. Such a layout of rotors allows you to realize an aircraft with a fuselage wider than in helicopters (Fig. 3), and the presence of four rotors will provide four swept zones, which will allow landing and take-off with side roll.

Figure 3 - Block diagram of the designs of the quadrocopter and helicopter

When using this scheme, such components as the fuel system, control system, radar system, electrics are located in the upper part of the fuselage in a special armored capsule (Fig. 4). This arrangement of nodes allows you to place hatches of cargo compartments and cargo ramps in any of the 5 sides of the fuselage (Fig. 5): from the four sides and from the bottom (vertical loading hatch).

Figure 4 - Location of the armored capsule

Figure 5 - Placement of cargo hatches

DISADVANTAGES OF THE DECISION

The considered approach has the following disadvantages:

- rotor engine vulnerability,

- small fuel tank volume due to placement at the top of the fuselage.

Possible solutions:

- placement of rotors in special nacelles and armored plates covering the engines (Fig. 7)

- placement of fuel tanks on the outside of the aircraft fuselage.

Figure 7 - Placement of rotors

APPLICATION OF CONCEPT IN ROBOTIC

SYSTEMS AND COMPLEXES

Unmanned aerial vehicle (UAV) - an aircraft without a crew on board, implemented using robotics. The implementation of the cargo quadrocopter, as an UAV, is advisable:

- in robotic complexes, for example, as part of a robotic transport and logistics system (fully automatic process of storage and transportation of goods);

- as an independent system, for use in conditions of increased danger to the life of the pilot (emergency, military operations);

- as an independent system for solving tasks requiring a large number of aircraft and a high degree of efficiency (military operations, cargo transportation, emergency medical care).

Centralized management with a human operator (one-to-one communication). Management system structure:

- human operator

- remote terminal

- Aircraft with an onboard intelligent information processing system.

Centralized management with a control room (one-to-many communication). Management system structure:

- human operator

- remote terminal

- one or a group of aircraft with an onboard intelligent control system.

Decentralized management (many-to-many relationship). Management system structure:

- request sources (person, technical system),

- LA group with onboard intelligent control system.