Inside view: 13 LED lamps and a bottle of rum. Part 3

Hello again, my little lovers of the guts!

We finally got to the final part of the story about LED lamps, in which we look at 4 lamps in the E27 base, and also summarize the final results of this protracted story.

The past two parts are here and here .

We will not drag out our story about lamps and immediately turn to the main thing - the insides of patients, LED lamps from ASD , Gauss and Supra .

LED bulbs in the base E27: spacious housing = guarantee of a successful bulb

As we remember from the first part , all the LED lamps in the E27 base showed decent characteristics in terms of ripple, not exceeding 1%. Naturally, such a driver requires a sufficiently spacious enclosure to accommodate, if only because it has more components than a capacitor ballast. However, by the example of a light bulb from Gauss, we could make sure that even in the GU5.3 package it is possible to compactly accommodate a ripple-free driver made using transformerless technology.

Well, let’s see what’s inside the first experimental rabbit from today's list - ASD lamp .

The lid can be removed quite easily, with almost bare hands, which, apparently, is a manufacturing flaw / defect, since there is glue on the back. At the same time, the LED assembly is attached directly to the metal housing of the lamp, but the heat sink is organized only along the outer ring, which, as the reader probably already understands, is nicht gut. For example, in the same E14 and GU5.3 lamps, the assembly contacts the heat sink housing over the entire area.

It is easy to notice that the provided volume is used at ease, without much effort to minimize the size of the driver. The electrical circuit is shown in the image below. It is made according to the already classic for lamps with a large housing transformerless lower topology. The arrangement of 28 LEDs is consistent, with SMD resistors (?) Added in some places. If someone knows why this is done, please write in the comments.

Separate LEDs are packed in elongated housings and soldered between copper contacts, ASD uses similar SMD components in GU5.3 lamps. In the figure below, the boundary between two such contacts is clearly visible (dark gray area). The size of the light emitting element is 253 by 83 microns.

Next in line will be two lamps from Gauss with a power of 6.5 and 12 watts, respectively. Despite the similarity by many criteria, these LED lamps have some differences, for example, a driver, and most interestingly, there are different LEDs inside.

The scattering bulb is very well attached to the lamp body - you have to sweat a lot to break it (yes, just break it!) From there, because the glues and sealants in the Gauss company do not spare for bulbs. Thus, it is completely safe to use these lamps in rooms with high humidity.

However, Gauss bulbs have the same problem as ASD, the metal heat dissipator in the lamp housing is connected to an aluminum substrate, on which the LEDs are mounted only in a relatively small ring around. Of course, from the point of view of thermal physicists such a solution. perhaps it makes sense, but still ...

About maintainability

Gauss has approached this aspect in an interesting way. Of course, I will not argue that the lamps of this manufacturer are fully repairable, and the rest are not. However, the engineers of this company, obviously, worked out both the moment of assembly and disassembly of the lamp. The LED assembly on the aluminum plate is not tightly soldered to the driver, as we can see everywhere, but is connected using a simple connector. If you so desire, you can gut the light bulb, get the driver and LED assembly, replace the necessary components (capacitors, for example) and assemble the driver with diodes back, or at least use a good, “unblinking” driver for your purposes!

The driver itself is made by transformerless technology. LED blocks (total of 12 pieces, each in a separate SMD package) are connected in series.

The sapphire substrate of light-emitting chips is structured, as in the case of ASD - is it possible that they produce only one substrate? LEDs have a radiating surface as much as 283 by 140 square micrometers, which is one of the largest indicators among the presented lamps.

We turn now to the 12 W bulb. In principle, it differs little from a 6.5 W lamp: a similar driver, albeit with its own characteristics, the same plastic bulb with a metal ring-diffuser inside, similar LED modules, albeit in a larger quantity; however, only this lamp has a special compound for the driver.

About driver fill

The esteemed LampTester already disassembled the lamp from Gauss . However, I allow myself to disagree with the author in terms of organizing the heat removal of this lamp. The electrical circuit and the heat sink were made correctly: the inductor and one of the capacitors are placed closer to the hot zone of the lamp, which is surrounded by a metal rim for heat dissipation, while the more sensitive elements are located in the “cold part”. In addition, pouring should increase heat transfer with the metal shell, because, as you know, air is a good heat insulator (we recall the old window frames). We already saw a similar fill when parsing the light bulbs from Optogan and SvetaLED .

There were some problems with the driver circuitry, so the block where the coil should be is left under a question mark. On the one hand, the control chip used implies a transformerless driver, but on the other hand, the choke used has 3 pins per board, which, it would seem, tells us about the driver based on the flyback converter, but the resistance between the contacts / legs of the coil is only 1.7, 5.8 and 6.2 Ohm, which should not fit into the galvanic isolation circuit in this driver.

In a 12 W light bulb, as many as 32 cases with LEDs are installed. True, the LEDs themselves have a slightly different size of 275 by 148 μm versus 283 by 140 μm for 6.5 W bulbs and an excellent arrangement of contact tracks. At first glance, the LEDs are almost identical, but still I wonder what it can be connected with: different batches of LEDs or are they really different for different power lamps? Let me remind you that under the knife there were lamps of the same color temperature - 2700K.

LED modules from the same company may still be different - this is a twist!

And the last in this class, a Supra light bulb. The lamp opens hard, that is, everything is in perfect order with tightness: enough sealant is poured. The neutral line contact is not soldered to the base itself, but only pressed against it, as we said in the previous part, this fixation method is not the most reliable - it is quite difficult to remove the base, but you can!

But what really surprised me is the LED assembly, mounted on a very flexible textolite instead of an aluminum substrate, which in turn is connected with thermal grease with a heat sink body. As a result, another positive aspect was the presence of a full heat dissipator, and not a ring, like the three lamps considered above.

The driver of the lamp presented is made on the basis of technology ... Yes, a similar story, as with the Gauss 12 W bulb. With a simple dialing, it is difficult to understand what a throttle is with three contacts on the board. Therefore, in the final table, even though these two drivers will appear under the "flyback converter", they are most likely executed according to the transformer-less topology. Although conscious readers sometimes send useful links , from which it follows that the chip used implies a transformerless driver.

Now let's draw some analogies. The LEDs are connected in series-parallel, as with the ASD lamp (bell number times).

The name of the control chip is BP2822 from BPSemi

If we look at the light emitting elements themselves, it turns out that in terms of size (251 by 83 versus 253 by 83 microns), the location of the pads and the microstructure, they are completely identical to the LEDs in the ASD lamp (bell number two). Yes, they are packed in a two-piece case, but often the diode manufacturer itself “packs” them in different cases: one, two, three, four, and so on. So it is quite possible to put forward the assumption that the ASD and Supra bulbs are filled with LED modules of the same manufacturer. With the equivalent filling (driver + LEDs), similar lighting performance, it is not surprising that in retail the cost of lamps is almost the same - about 250-270 rubles (August-September 2015).

Deja vu? So yes, complete identity with ASD lamp

Final conclusions

Well, after such a long and somewhere not always successful, but somewhere exceptionally intriguing testing of LED lamps, as well as traveling around their inner world, it remains to summarize the final results.

- About the appearance. As we can see, even those LED lamps that seem to be sealed are actually not. Therefore, my dear reader and buyer, before buying them for rooms with high humidity, be sure to check the mount of the diffuser!

- About the drivers. The drivers of all the lamps were divided into two large camps: a capacitor ballast (strong ripple coefficient up to 10-15%) and a transformerless driver (K p <1%). Usually, an advanced driver is installed in lamps with an E27 base, while almost all the lamps in the E14 and GU5.3 base are equipped with a capacitor ballast, which gives a strong ripple coefficient. A pleasant exception was the Gauss GU5.3 lamp, which has a compactly packed transformerless driver on board. However, the pulsations of these lamps have a very high frequency - several hundred Hz.

- About thermal contact and thermal tap. Many manufacturers commit a poor-quality installation of the LED assembly in the lamp, as a result of which the thermal contact between the aluminum or textolite substrate and the heat diffuser / radiator is broken, which, anyway, leads to premature failure of the most sensitive component - light-emitting diodes. Most of the claims arose with Pulsar. Plus, some manage to glue assemblies on some analogue of gel-like adhesive tape (for example, as Wolta does).

- About the substrate for LED assemblies. Some manufacturers place LED modules on a textolite rather than an aluminum substrate - a very interesting solution that reduces the weight and dimensions of the lamp, but needs additional testing and verification, although I personally like it very much!

- About LEDs and technology for their manufacture. According to the type of structuring of the used sapphire substrate, the lamps were divided into three types. We will arbitrarily call them: “shield”, “asterisk” and “rings”:

Modern technologies for texturing sapphire substrates for LEDs in comparison.

Some lamps in terms of appearance of used LEDs are similar to the degree of mixing, which raises serious questions for manufacturers. So, for example, with some degree of certainty, it can be argued that the LEDs in the lamps of ASD and Supra were produced almost at the same factory. - About the versatility of production. As the practice of opening lamps showed, sometimes the versatility of the production of LED lamps is not a determining factor. So, for example, it seems that the same lamps from the Gauss company, differing only in power, have both different drivers and different LEDs that are little similar to each other.

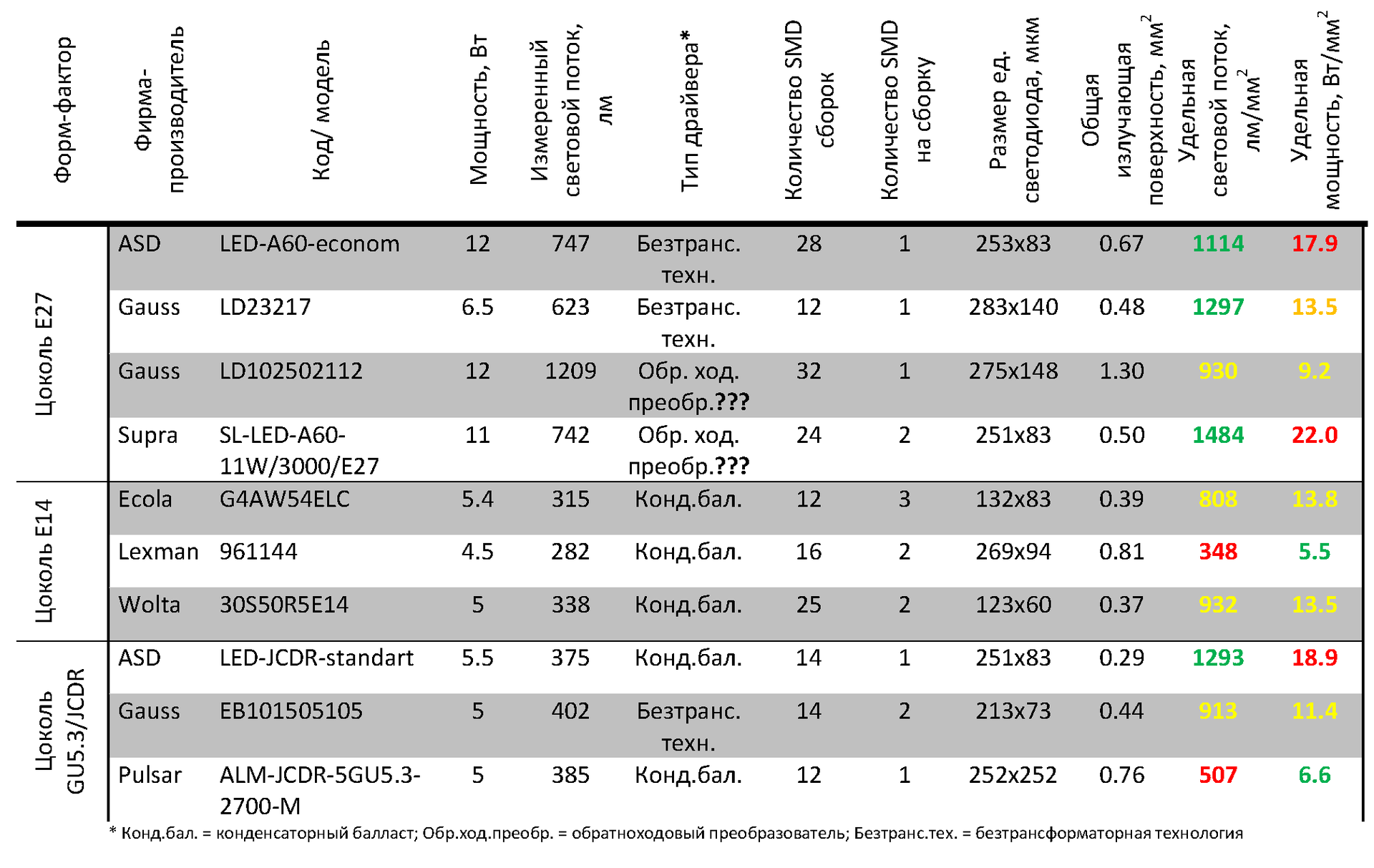

- About luminous flux, power and a little about heat transfer. If we collect all the geometric characteristics and the specific lamp characteristics associated with them in one table (neglecting losses in the driver), we will see that the specific light flux and power dissipation are inversely related. Lamps of some manufacturers, for example, Supra, give out amazing 1,500 lm / mm 2 , but 22 W of dissipated energy for the same mm 2 has to be paid for . This is where the time comes to compromise and pay for the “analogue” of a 100W light bulb. Unfortunately, this is an impossible task without the redistribution of thermal energy released by the LEDs, and, accordingly, special radiator-diffusers.

NB: The author of the article is not a professional electrical engineer, so if you notice an error or oversight in circuits, text, or elsewhere, please write to the PM.

PS: There are at least two confirmed manufacturers of control chips Monolithic Power and BPSemi . Also some reference design from Dialog Semiconductor (jointly iWatt)

PPS: All circuits are drawn in the free (open-source) QUCS software package , which toster helped to find .

UPD: The comment from D3 brought interesting information about interference and protection methods - here .

A full list of published articles “Inside View” on Habré and GT:

Opening the Nvidia 8600M GT chip , a more detailed article is given here: Modern chips - inside view Inside

view: CD and HDD

Inside view: LED bulbs

Inside view: LED industry in Russia

Inside view : Flash memory and RAM

Inside view: the world around us

Inside view: LCD and E-Ink displays

Inside view: digital camera arrays

Inside view: Plastic Logic

Inside view: RFID and other marks

Inside view: graduate school in EPFL. Part 1

Inside Look: Graduate School at EPFL. Part 2

Inside view: the world around us - 2

Inside view: the world around us - 3

Inside view: the world around us - 4

Inside view: 13 LED lamps and a bottle of rum. Part 1

Inside view: 13 LED lamps and a bottle of rum. Part 2

Inside view: 13 LED lamps and a bottle of rum. Part 3

Inside Look: IKEA LED Strikes Back

Inside Look: Are Filament Lamps So Good?

and 3DNews:

Microview: comparing displays of modern smartphones

. Secondly , in addition to the HabraHabr blog , articles and videos can be read and viewed on Nanometer.ru , YouTube , and Dirty .

Sometimes it is possible to read briefly, and sometimes not so much about the news of science and technology on my Telegram channel - we are welcome;)