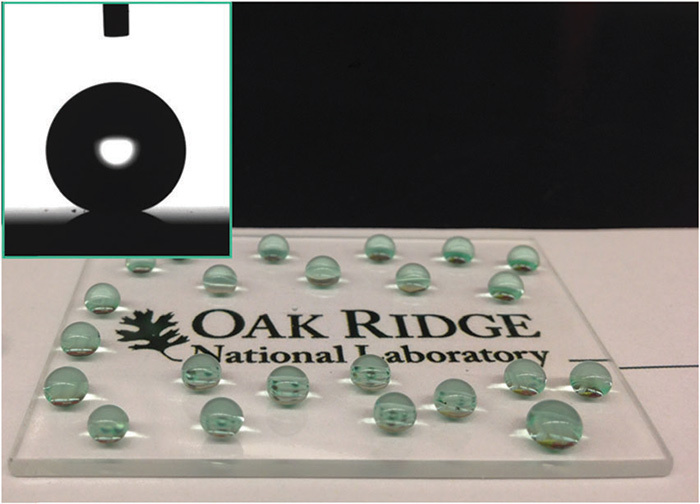

Water-repellent (super-hydrophobic) glass invented

Drops of water on the surface of the new material

Eye moth and lotus leaf became the prototypes for the invention of American chemists - anti-glare, water-repellent (i.e. super-hydrophobic) glass coating. Such glass never fogs up and remains crystal clear even in fog. And the ingressing and departing moisture takes with it all the trash and dust particles.

The discovery has the potential for a huge number of applications: windows, solar panels, sensors, weapons systems, glasses, lenses and many other products.

Chemists from the Oak Ridge National Laboratory invented the material, and the scientific article Monolithic Graded-Refractive-Index Glass-based Antireflective Coatings: Broadband / Omnidirectional Light Harvesting and Self-Cleaning Characteristics in Journal of Materials Chemistry C, 2015 contains details . ( copy ).

The material is a mechanically stable nanostructured layer of a porous glass film. In fact, it combines the water-repellent properties of the lotus leaf and the anti-glare properties of the moth's eye. In both cases, the properties are explained by tiny surface irregularities of the nanoscale.

To repel water, the wetting angle (contact angle) must exceed 150 °. In the new coating, the wetting angle is from 155 ° to 165 °, so that water droplets literally bounce off it, taking dirt and dust with it.

Schematic representation of a new coating and its applications.

The scientific work describes the process of manufacturing a coating film from a base material. As a base material, a special type of glass coating is also used, which has high strength. This is the difference from other similar materials, the authors of the scientific work say . Strength is maintained after heat treatment. The new coating is very abrasion resistant and withstands temperatures up to 500 ° C.

Actually, the entire manufacturing process consists of three stages: depositing a thin layer of glass material on a glass substrate, heat treatment and selective removal of the material by etching. The result is a porous three-dimensional structure resembling a microscopic coral.

A similar coating can be made at existing production facilities using standard methods, without too much difficulty and quite cheaply, the authors of the work say.

By the way, anti-reflective coating strongly suppresses Fresnel reflections, immediately increasing the efficiency of solar panels by 3-6%. Automatic dust cleaning will also add to their efficiency.