SAP F&R: The process of creating orders. Part 2

Hello, Habr! In the last article, we settled on the “Needs Calculation” block. Brief reminder: SAP F&R - demand forecasting and inventory management system at the target location-supplier location level. The system is part of the SAP SCM (supply chain management) solution and is implemented in two variations:

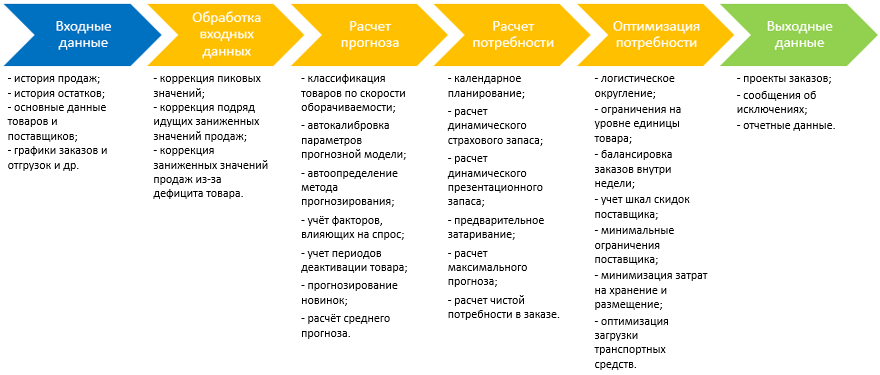

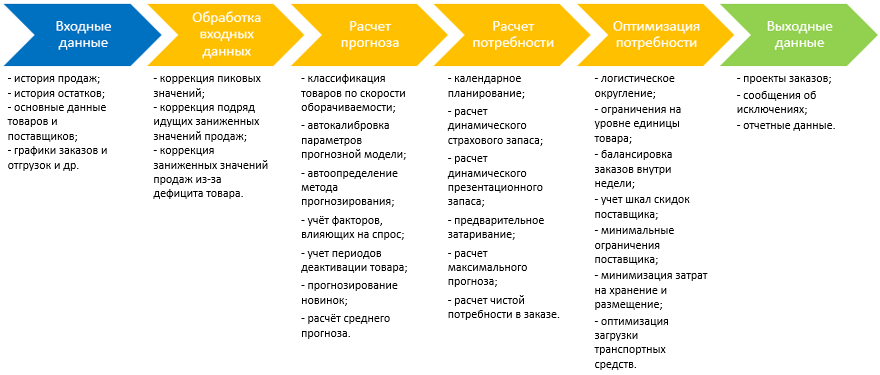

All SAP F&R functionality is divided into 4 main blocks:

SAP F&R is supplied with sales data broken down by product-location, stock history, basic data of goods and suppliers, pre-defined delivery schedules and some configuration parameters that allow the system to function effectively in accordance with the retailer’s business.

As a result of the work of the forecast calculation module, an average forecast is formed - such a value of the volume of goods at the location that with a probability of 50% will satisfy customer demand in the store, or, in other words, will ensure the level of customer service = 50%.

In order to avoid lost sales, the target level of customer service, as a rule, is planned at least 95%. This means that in 95 cases out of 100, the customer will buy what he planned in the store. Providing a high level of service in SAP F&R is carried out by means of an insurance premium to the average forecast, which depends not only on the target level of service, but also on the variability of the past sales values of the goods. Thus, the maximum sales forecast is generated in the system, the volume of which will be enough to minimize the stock in the warehouse or store (and, therefore, the withdrawal of capital frozen in stocks) and comply with the target level of customer service.

The system “thinks” in periods of demand and stock. The stock period is the time from the date of order to the date of availability of this order. The demand period is the time from the availability date of the first order to the availability date of the second order. The system only calculates demand for the first demand period in order to minimize inventory at a location. If optimization is used, the system “climbs” in the following periods of demand at a given optimization horizon. In this case, in the next demand period, the order will be reduced by the amount borrowed by the system from this order to optimize the previous one.

The need for the system is calculated according to the formula:

Demand = Projected quantity of goods + presentation (minimum) stock (or stock on the shelf) + dynamic safety stock.

SAP F&R automatically calculates the changing safety stock. In the terminology of the system, such a safety stock is called dynamic. The amount of insurance stock depends on two values:

• Variations in the time series of sales history.

The greater the variability, the greater the volume of safety stock.

As a result of calculating the safety stock, we see the following graph:

The blue line is the average forecast. The green line is the maximum forecast for product sales. The maximum forecast consists of the average forecast and dynamically calculated insurance stock. The figure shows the volume of safety stock at various levels of service: from 75 to 99. The maximum forecast is the volume of goods that will satisfy demand with a given probability (= level of service). To analyze the accuracy of the forecast “forecast-fact”, the values of the maximum forecast are used.

The order quantity in F&R is calculated according to the formula:

Order = demand volume - (current stock + goods in transit) + logistic rounding volume.

In this way, the order quantity of the goods is calculated. Also, the function of preliminary distribution of goods is included in the order calculation block.

Pre-distribution is a feature that provides a forecast transfer to previous weeks. This can be useful to reduce the load on the acceptance department and logistics, for example, by the new year, when order volumes are sure to grow, and you need to make great efforts to ensure the availability of goods without shortages. To do this, some part of the forecast for 52 or 51 weeks is carried over to previous weeks.

The following article is about order optimization in the SAP F&R system.

Read me:

» SAP F&R: The process of creating orders. Part 1

» Overview: SAP F&R today and tomorrow - the future of sales forecasting

» The art of forecasting in the SAP F&R system for inventory management

- SAP F&R SCM - implementation with seamless integration with SAP systems;

- SAP F&R OI - implementation with integration with non-SAP systems.

All SAP F&R functionality is divided into 4 main blocks:

- Input Processing

- Prediction calculation

- Requirement calculation

- Need optimization

SAP F&R is supplied with sales data broken down by product-location, stock history, basic data of goods and suppliers, pre-defined delivery schedules and some configuration parameters that allow the system to function effectively in accordance with the retailer’s business.

As a result of the work of the forecast calculation module, an average forecast is formed - such a value of the volume of goods at the location that with a probability of 50% will satisfy customer demand in the store, or, in other words, will ensure the level of customer service = 50%.

In order to avoid lost sales, the target level of customer service, as a rule, is planned at least 95%. This means that in 95 cases out of 100, the customer will buy what he planned in the store. Providing a high level of service in SAP F&R is carried out by means of an insurance premium to the average forecast, which depends not only on the target level of service, but also on the variability of the past sales values of the goods. Thus, the maximum sales forecast is generated in the system, the volume of which will be enough to minimize the stock in the warehouse or store (and, therefore, the withdrawal of capital frozen in stocks) and comply with the target level of customer service.

Requirement calculation

The system “thinks” in periods of demand and stock. The stock period is the time from the date of order to the date of availability of this order. The demand period is the time from the availability date of the first order to the availability date of the second order. The system only calculates demand for the first demand period in order to minimize inventory at a location. If optimization is used, the system “climbs” in the following periods of demand at a given optimization horizon. In this case, in the next demand period, the order will be reduced by the amount borrowed by the system from this order to optimize the previous one.

The need for the system is calculated according to the formula:

Demand = Projected quantity of goods + presentation (minimum) stock (or stock on the shelf) + dynamic safety stock.

Dynamic safety stock

SAP F&R automatically calculates the changing safety stock. In the terminology of the system, such a safety stock is called dynamic. The amount of insurance stock depends on two values:

- The target level of customer service.

The level of customer service is set into the system manually by product group (any) or by sales class by turnover rate .

• Variations in the time series of sales history.

The greater the variability, the greater the volume of safety stock.

Maximum forecast

As a result of calculating the safety stock, we see the following graph:

The blue line is the average forecast. The green line is the maximum forecast for product sales. The maximum forecast consists of the average forecast and dynamically calculated insurance stock. The figure shows the volume of safety stock at various levels of service: from 75 to 99. The maximum forecast is the volume of goods that will satisfy demand with a given probability (= level of service). To analyze the accuracy of the forecast “forecast-fact”, the values of the maximum forecast are used.

Order Volume Calculation

The order quantity in F&R is calculated according to the formula:

Order = demand volume - (current stock + goods in transit) + logistic rounding volume.

In this way, the order quantity of the goods is calculated. Also, the function of preliminary distribution of goods is included in the order calculation block.

Preliminary distribution

Pre-distribution is a feature that provides a forecast transfer to previous weeks. This can be useful to reduce the load on the acceptance department and logistics, for example, by the new year, when order volumes are sure to grow, and you need to make great efforts to ensure the availability of goods without shortages. To do this, some part of the forecast for 52 or 51 weeks is carried over to previous weeks.

The following article is about order optimization in the SAP F&R system.

Read me:

» SAP F&R: The process of creating orders. Part 1

» Overview: SAP F&R today and tomorrow - the future of sales forecasting

» The art of forecasting in the SAP F&R system for inventory management