If Seagate gets dusty ...

After reading the article “Backblaze statistics: which HDD is the best”, it became clear that Seagate Barracuda (ST3000DM001) is the leader in the number of failures. Two disks of this particular model on a file server failed in less than a year and a half almost simultaneously.

Why did this happen?

A specialist in the repair of equipment at our enterprise got to the bottom of the truth and asked to tell about it in order to give recommendations to the manufacturer to exclude such cases and advice to owners of disks of this brand. To whom advice will no longer help, they can use the HDD to make a three-terabyte gramophone.

"Hero of the day.

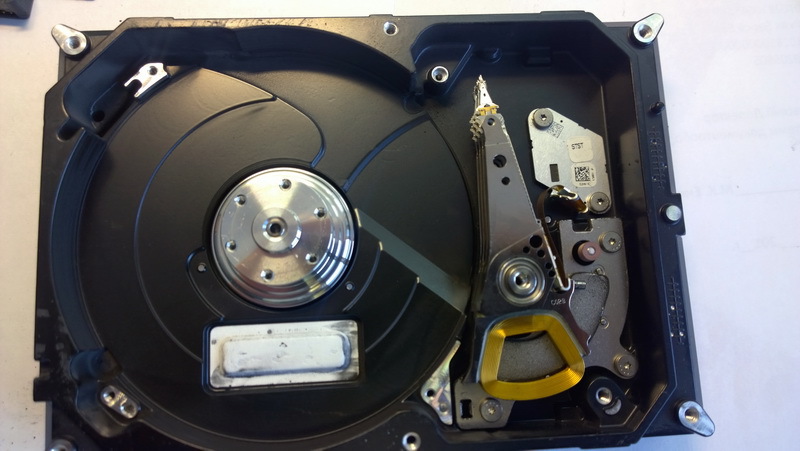

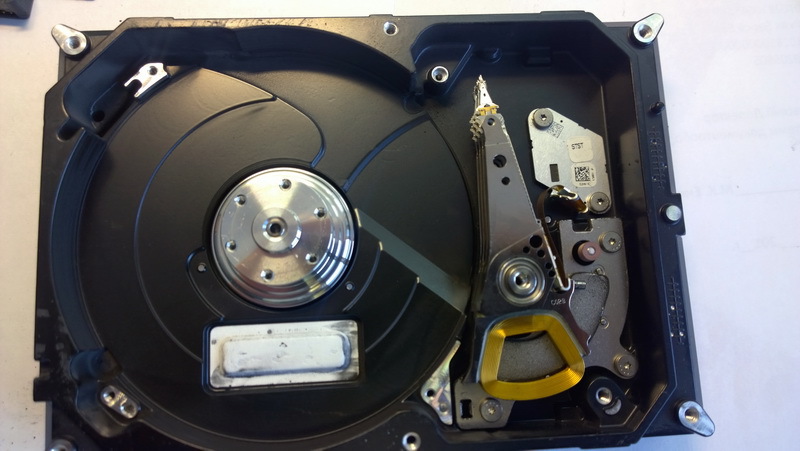

Disks rained, and as it turned out - in the literal sense of the word. This is what remains on the table after disassembling it.

Accessories:

All photos can be viewed in the Seagate Barracuda ST3000DM001 album . From the many shots you can easily understand the design of the hard drive. The article uses only a small number of photographs.

Desert Storm. This is what “mirror” disks look like - the result of exposure to dust and detached ferromagnetic particles.

An internal filter that must catch particles flying by accident.

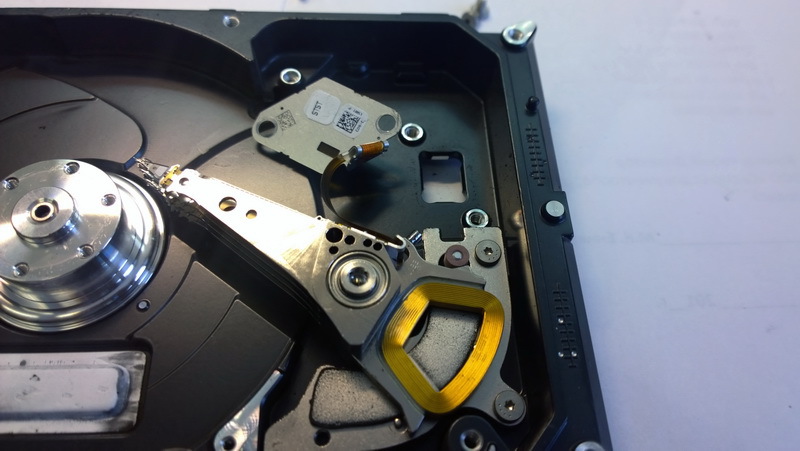

The reason for the failure of the hard drive was dust. During operation, a small amount of dust penetrates into the clean zone, causing initial damage, and then everything happens like an avalanche. The difficulty was locating the dust, but logic and mindfulness do wonders.

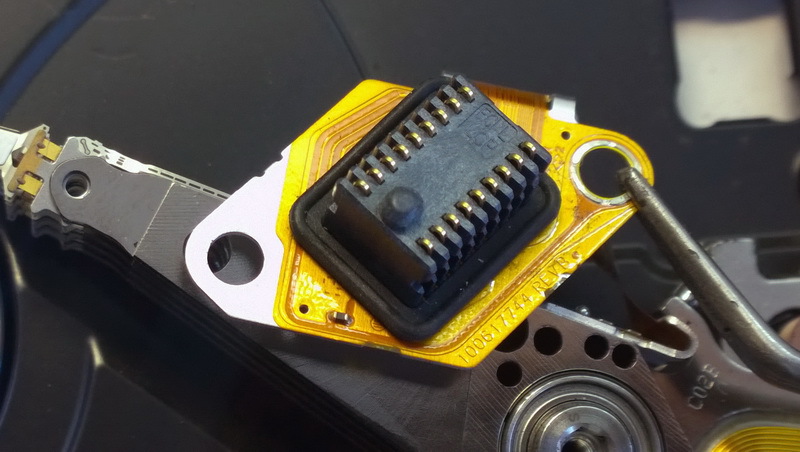

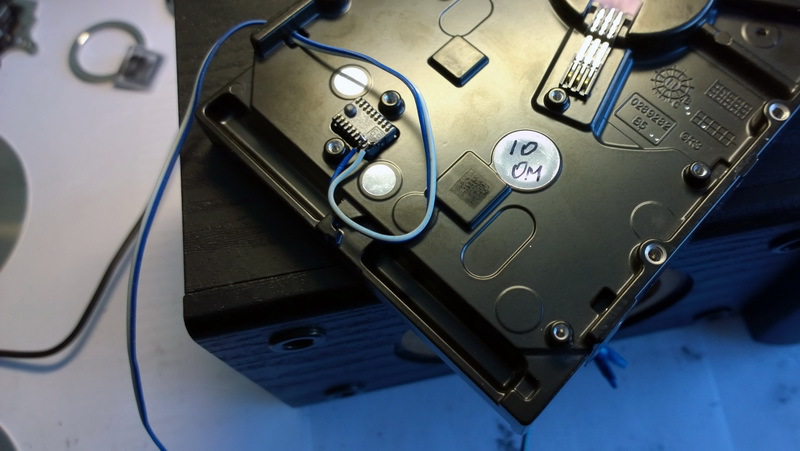

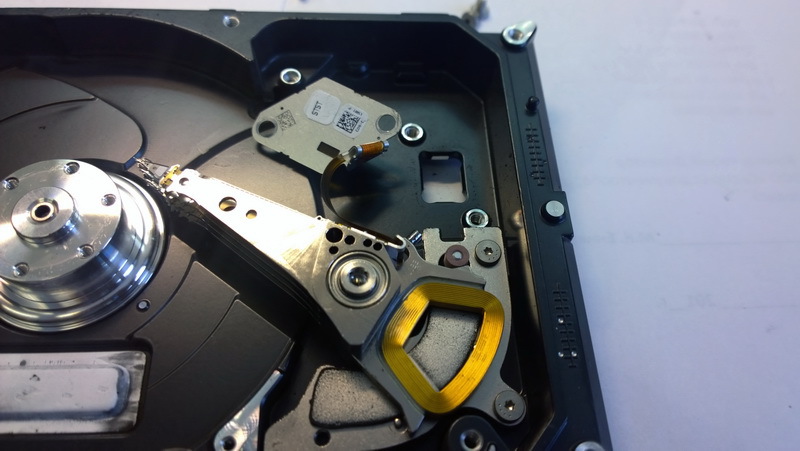

A metal pad in the upper right corner is used to attach a flexible cable and connector to the electronics board.

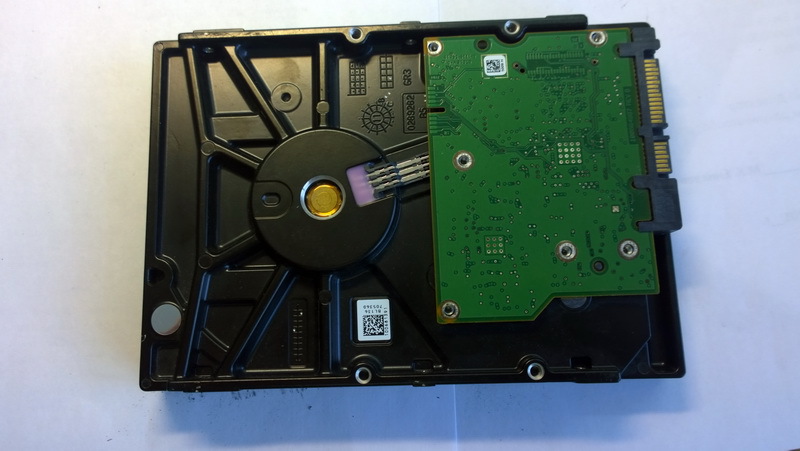

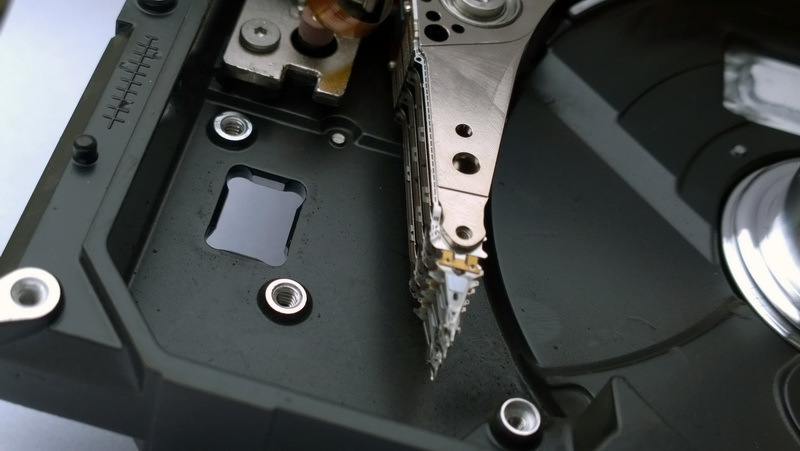

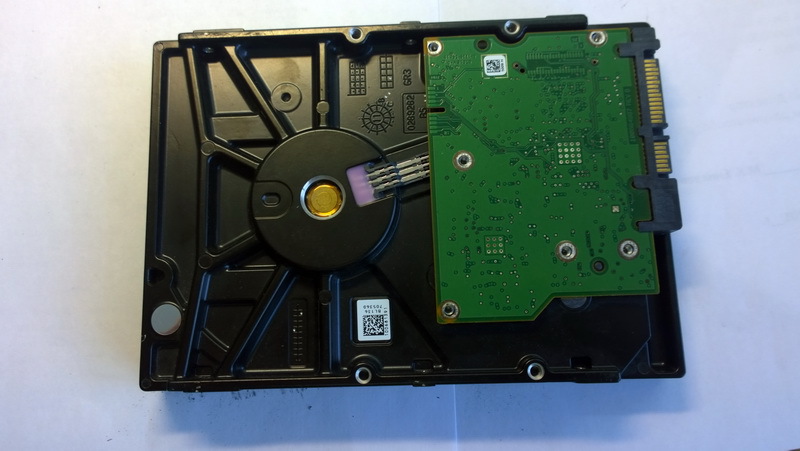

Electronics board. Two adjacent holes in the lower right part of the board are for screws that press the contact pads on the board to the connector.

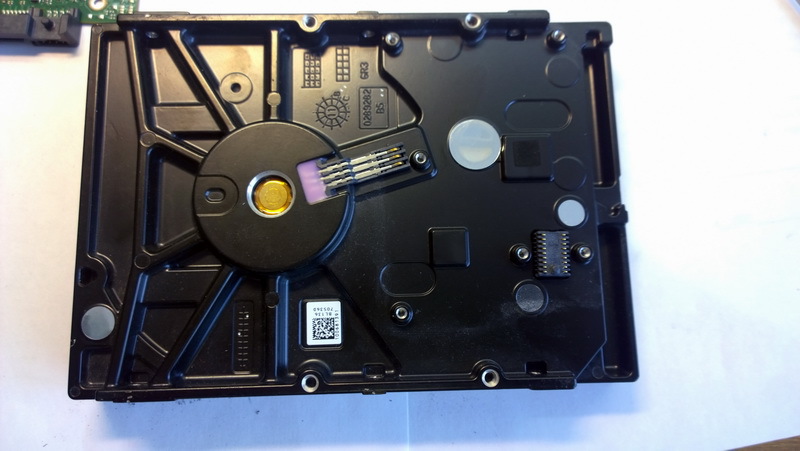

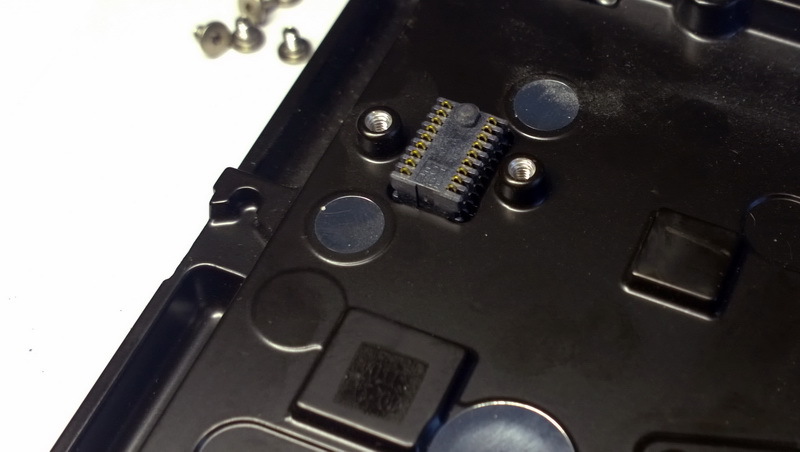

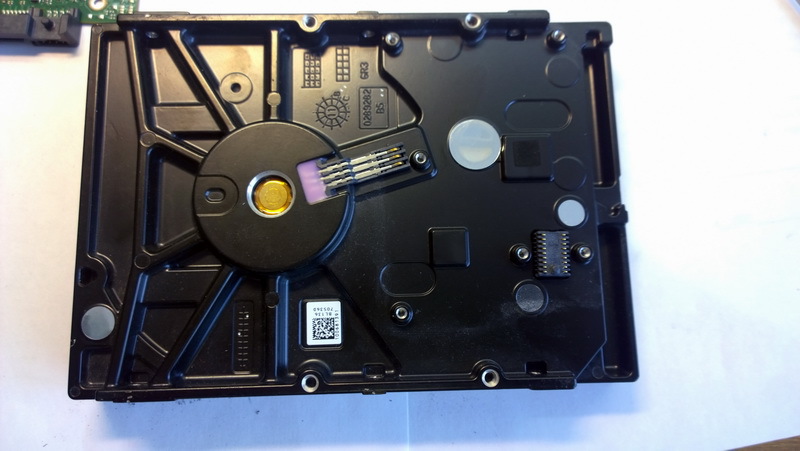

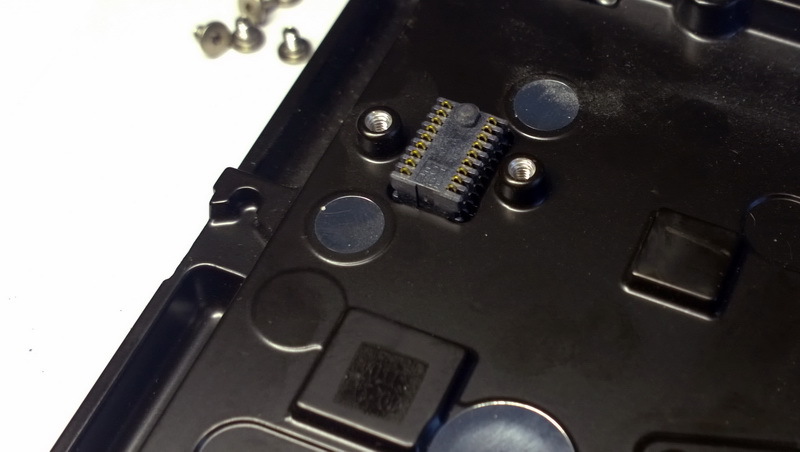

Electronics board dismantled. The connector is in the lower right corner.

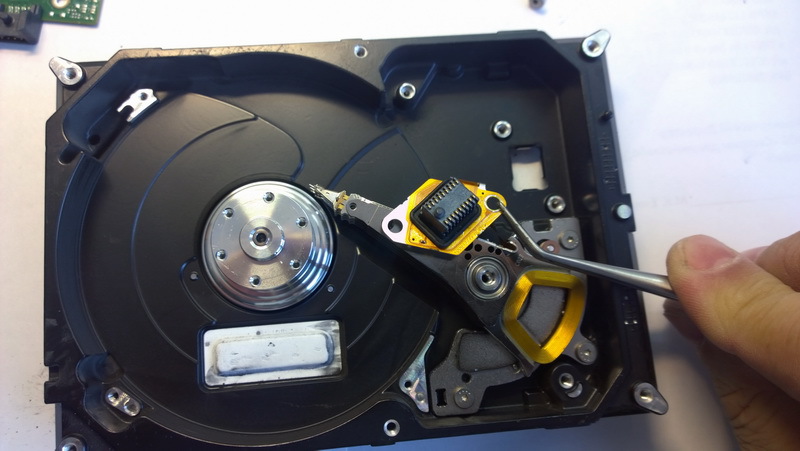

The removed connector.

On the right side, the thickness of the pad is increased by a flexible circuit board and a conductive ring with a thick layer of solder. When attaching a platform with a loop, skew occurs due to different thicknesses.

As a result, the rubber seal on the site does not come in contact with the body around the entire perimeter. The place of non-contact is clearly visible under the microscope. It is through this place that dust enters the disk.

The manufacturer needs to modify this node. This may be an increase in the height of the sealant or a change in material, leveling the heights of the site in the area of attachment, or other techniques.

Judging by the reviews and the article mentioned above, we are not the only owners of the failed model. Maybe manufacturers of hard drives have a HDD recall program - like car manufacturers?

What about those who have already purchased this model?

Before starting operation, it is necessary to seal on the side of the electronics board by filling the hole around the connector with sealant. It is necessary to fill carefully and at a low height so as not to violate the flexibility of the movable contacts. The warranty in this case is likely to suffer, but the life of the disc will last.

What about the one whose hard drive began to crumble?

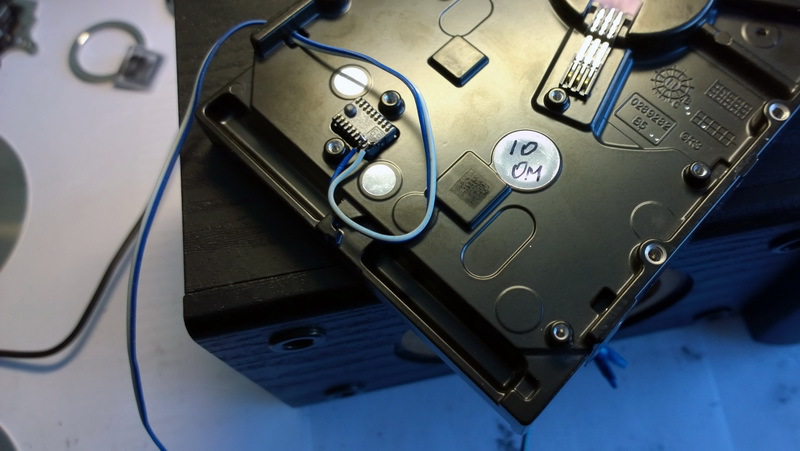

It all depends on the degree of wear. If it has just begun, then you can try to make a seal. If sealing does not help, then you can make a three-terabyte gramophone. The idea of using a disk in this capacity is not new, but an implementation with a speaker and such a large volume has not yet met. If someone does not understand, then a 10-ohm coil located above the magnet (two extreme contacts on the connector) is connected as a speaker to the sound column, and then it's physics.

Especially “lucky” to users who have failed two hard drives - they can make a stereo system. And those who are able to manufacture a quad-system can only sympathize, since the cost of these four “speakers” is a significant amount.

PSI looked at the discussion of the article in various places on the Internet ...

1. About dust. The article does not state that all the dust inside the disk is external dust. Mostly this is ferromagnetic dust from covering pancakes of a hard disk - almost all the dust that has crumbled was collected from the table using a magnet.

External dust penetrating through the leak of the seal serves only as the initiator of the initial destruction.

2. The reasons for the failure of the HDD. In our case, there were only two drives, so it is incorrect to conclude that the detected leaks are the cause of the failure of all drives in this series. Seagate engineers can give statistics on the causes of failures, but they are silent as partisans.

A large number of discs are available in Backblaze and they markThat this series is special in the number of failures, they promised to write a separate article about it, we are waiting.

Those who do not believe Backblaze can read reviews on the ST3000DM001 search - an anomaly has occurred.

3. Fill the connector with sealant. If according to the statistics of the causes of failures, the leakage of the sealant has a significant share, then it makes sense to fill the perimeter. The sealant must be neutral. mixan used paste KPT-8. Skyggedans , if I am not mistaken, made it easier - I cut a ring about 5 mm high from a rubber tube with a diameter of 12 mm and put it on the connector. After installing the board, the ring appeared to be sandwiched between the board and the case - an additional barrier for dust particles turned out. In this case, the guarantee will not be violated.

4. It is advisable to have some kind of answer about the reasons for the mass unreliability of this series from the manufacturer, but there is complete silence. In the event of a fall in rockets, aircraft, etc., it is customary to report the causes of the accident. In our case, there is a massive failure of this series and no reaction, which is extremely strange. This causes damage to the manufacturer, since the stain falls on the entire brand, although only one series can be faulty.

While there are no official recommendations for the further operation of this series - to hand over, change, fill, compact?

5. The gramophone. I repeat that this principle of reproducing sound from a hard disk is not new, but many people do not understand how sound is produced if the disk does not spin? Added an explanation in the description of the video on YouTube. In general, the sound will be even louder if you move the magnetic head away from the disk, but with the disks everything looks more organic. If you make a beautiful horn, bring the disc into rotation at a low speed and apply additional pulses to the rotary coil, then you can arrange the movement of the magnetic head along the rotating disc, which will add beauty during playback. A good toy from the BU HDD.

Why did this happen?

A specialist in the repair of equipment at our enterprise got to the bottom of the truth and asked to tell about it in order to give recommendations to the manufacturer to exclude such cases and advice to owners of disks of this brand. To whom advice will no longer help, they can use the HDD to make a three-terabyte gramophone.

"Hero of the day.

Disks rained, and as it turned out - in the literal sense of the word. This is what remains on the table after disassembling it.

Accessories:

All photos can be viewed in the Seagate Barracuda ST3000DM001 album . From the many shots you can easily understand the design of the hard drive. The article uses only a small number of photographs.

Desert Storm. This is what “mirror” disks look like - the result of exposure to dust and detached ferromagnetic particles.

An internal filter that must catch particles flying by accident.

The reason for the failure of the hard drive was dust. During operation, a small amount of dust penetrates into the clean zone, causing initial damage, and then everything happens like an avalanche. The difficulty was locating the dust, but logic and mindfulness do wonders.

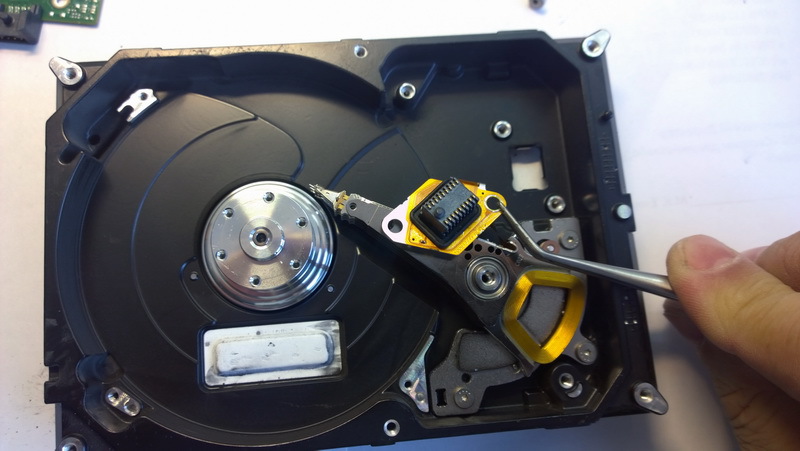

A metal pad in the upper right corner is used to attach a flexible cable and connector to the electronics board.

Electronics board. Two adjacent holes in the lower right part of the board are for screws that press the contact pads on the board to the connector.

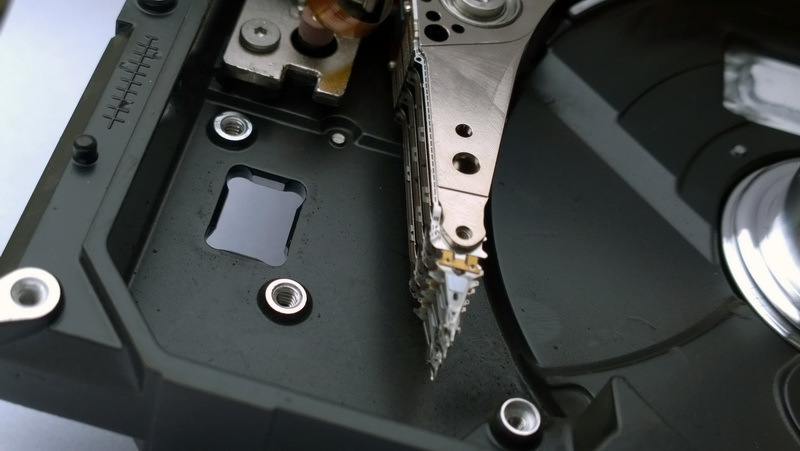

Electronics board dismantled. The connector is in the lower right corner.

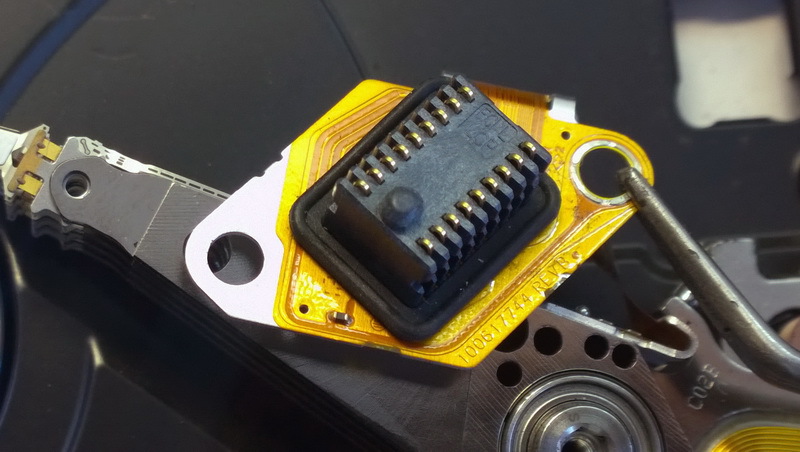

The removed connector.

On the right side, the thickness of the pad is increased by a flexible circuit board and a conductive ring with a thick layer of solder. When attaching a platform with a loop, skew occurs due to different thicknesses.

As a result, the rubber seal on the site does not come in contact with the body around the entire perimeter. The place of non-contact is clearly visible under the microscope. It is through this place that dust enters the disk.

The manufacturer needs to modify this node. This may be an increase in the height of the sealant or a change in material, leveling the heights of the site in the area of attachment, or other techniques.

Judging by the reviews and the article mentioned above, we are not the only owners of the failed model. Maybe manufacturers of hard drives have a HDD recall program - like car manufacturers?

What about those who have already purchased this model?

Before starting operation, it is necessary to seal on the side of the electronics board by filling the hole around the connector with sealant. It is necessary to fill carefully and at a low height so as not to violate the flexibility of the movable contacts. The warranty in this case is likely to suffer, but the life of the disc will last.

What about the one whose hard drive began to crumble?

It all depends on the degree of wear. If it has just begun, then you can try to make a seal. If sealing does not help, then you can make a three-terabyte gramophone. The idea of using a disk in this capacity is not new, but an implementation with a speaker and such a large volume has not yet met. If someone does not understand, then a 10-ohm coil located above the magnet (two extreme contacts on the connector) is connected as a speaker to the sound column, and then it's physics.

Especially “lucky” to users who have failed two hard drives - they can make a stereo system. And those who are able to manufacture a quad-system can only sympathize, since the cost of these four “speakers” is a significant amount.

PSI looked at the discussion of the article in various places on the Internet ...

1. About dust. The article does not state that all the dust inside the disk is external dust. Mostly this is ferromagnetic dust from covering pancakes of a hard disk - almost all the dust that has crumbled was collected from the table using a magnet.

External dust penetrating through the leak of the seal serves only as the initiator of the initial destruction.

2. The reasons for the failure of the HDD. In our case, there were only two drives, so it is incorrect to conclude that the detected leaks are the cause of the failure of all drives in this series. Seagate engineers can give statistics on the causes of failures, but they are silent as partisans.

A large number of discs are available in Backblaze and they markThat this series is special in the number of failures, they promised to write a separate article about it, we are waiting.

The Seagate Barracuda 7200.14 3 TB drives are another story. We'll cover how we handled their failure rates in a future blog post.

Those who do not believe Backblaze can read reviews on the ST3000DM001 search - an anomaly has occurred.

3. Fill the connector with sealant. If according to the statistics of the causes of failures, the leakage of the sealant has a significant share, then it makes sense to fill the perimeter. The sealant must be neutral. mixan used paste KPT-8. Skyggedans , if I am not mistaken, made it easier - I cut a ring about 5 mm high from a rubber tube with a diameter of 12 mm and put it on the connector. After installing the board, the ring appeared to be sandwiched between the board and the case - an additional barrier for dust particles turned out. In this case, the guarantee will not be violated.

4. It is advisable to have some kind of answer about the reasons for the mass unreliability of this series from the manufacturer, but there is complete silence. In the event of a fall in rockets, aircraft, etc., it is customary to report the causes of the accident. In our case, there is a massive failure of this series and no reaction, which is extremely strange. This causes damage to the manufacturer, since the stain falls on the entire brand, although only one series can be faulty.

While there are no official recommendations for the further operation of this series - to hand over, change, fill, compact?

5. The gramophone. I repeat that this principle of reproducing sound from a hard disk is not new, but many people do not understand how sound is produced if the disk does not spin? Added an explanation in the description of the video on YouTube. In general, the sound will be even louder if you move the magnetic head away from the disk, but with the disks everything looks more organic. If you make a beautiful horn, bring the disc into rotation at a low speed and apply additional pulses to the rotary coil, then you can arrange the movement of the magnetic head along the rotating disc, which will add beauty during playback. A good toy from the BU HDD.