How can a pipeline make website production better?

Talk about successful production. If you produce a good and sought-after product in the market at a competitive price, then your business will grow 100%. Further on how you grow, subsequent success or failure will depend. If you grow quantitatively, just satisfying demand, then most likely you will have problems or closure. If you increase efficiency, then you have a chance and this chance is very good.

In order to increase production efficiency, a conveyor was invented in the middle of the 19th century. The speed of the conveyor directly affects the speed of production. Speed depends on the correct selection of operations in the areas and their automation. By adjusting the speed of the conveyor, you can get a sought-after product at a competitive price and the required quality.

But here is the question. Is it possible to put creative work (custom services) on the conveyor? We will answer this question on the example of website development. “Unlike mass production, each site is an individual product that solves individual tasks.” - Many say. Yes, they are right, but what does that change? Let's figure it out. Welcome to the WebCanape pipeline.

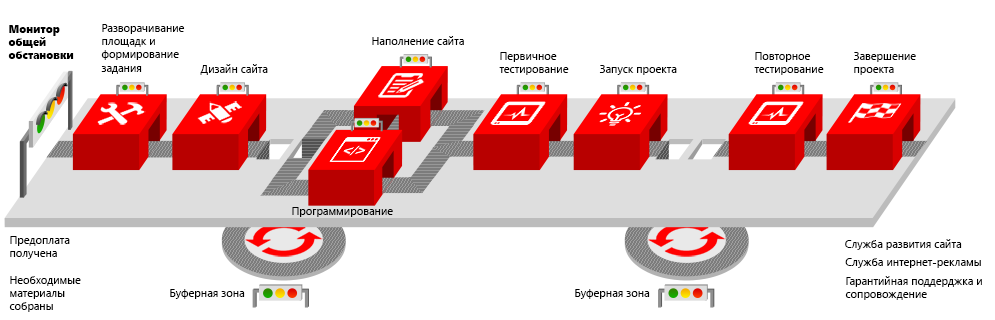

WebCanape Virtual Pipeline

From the start point to the end, the conveyor passes in 7 days. In one day, one of seven typical groups of operations is performed: the formation of a project assignment, production (we parallelize it into three lines — site design, site content, programming), approval, testing, project launch, retesting, and project delivery. Note that part of operations is a creative process.

In order for the conveyor to move without stops and delays, the executive manager, who oversees the project at all stages, collects all the necessary materials at the first stage. The main list, without which the project cannot be put into operation, includes: text and graphic materials, corporate identity elements, photo materials, data for filling out product catalogs, access to the domain and hosting. Having collected all the materials, you can start the conveyor and guarantee its non-stop operation, which in turn guarantees the creation of the site on time.

At each stage, production resources are selected in such a way that the conveyor can serve twice as many orders as it arrives at the entrance. This allows you to smooth out the unevenness of demand and work with projects from buffer lines.

A project falls into the buffer line if it cannot move on due to delayed coordination with the client of the design or content. After approval, the project returns to the main line and continues to move forward. At the same time, the calendar terms of the project are delayed, but the contractual terms (we consider them in normal days) are extended for the delay time in the buffer zone. Remember these two parameters, we will need them later.

Naturally, the presence of projects in the buffer zone is liabilities in production. The more of them, the greater the degree of uncertainty in the system. This directly affects the decrease in overall production efficiency and the speed of money turnover in the system. The number of such projects and their downtime must be minimized. This is the main task of executive managers after the project is launched.

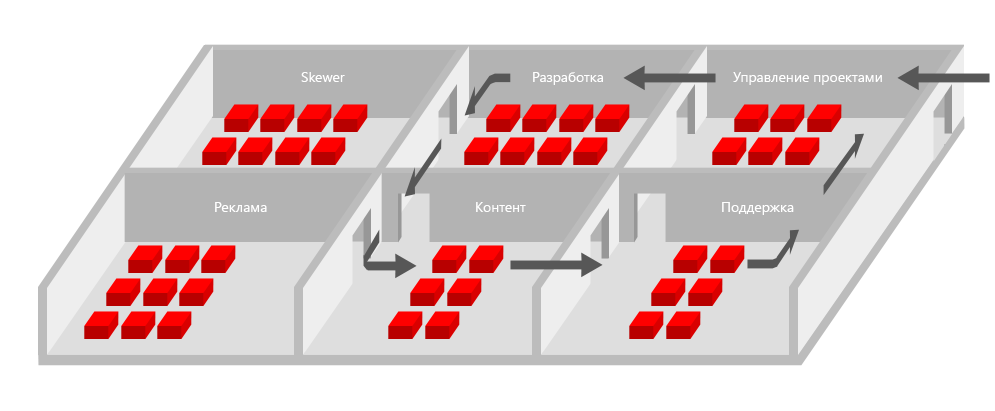

Where does the conveyor live and what does it look like

Despite the fact that the conveyor is virtual, the workplaces (production units) in the office, as in a real enterprise, are built into the correct production chain. Although the order passes from node to node via virtual channels, the physical distance between the nodes and their relative position is very important. This allows you to better represent and control the production process, optimize communications and working hours.

The executive manager controls the movement of the project on the conveyor using CanapeCRM. This system collects all statistics on the stages of the project movement, notifications are generated for clients, etc.

As soon as the project arrives on the conveyor, the executive manager, in accordance with the regulations, deploys and configures the basic assembly, arranges tasks on production sites. Redmine is used for this.

For operational planning of loading sites, information boards are used, which show how many projects are on the line at the moment, in what status and what are the deadlines for release. The display uses the principle of a traffic light that is clear to everyone. Green - the project fits into deadlines, yellow - the deadlines are close to deadline, red - the project is late. The color of the project indicates what priority they need to deal with.

At each production site there is a team leader. He is engaged in planning, is responsible for the quality of operations in accordance with the standards and regulations, provides training and growth for beginners. In general, he oversees the smooth operation of his section of the conveyor.

Upon completion of production, statistics are collected and the project is evaluated according to 4 main parameters: terms in calendar days, terms in standard days, compliance with standards in standard hours, and customer feedback. This allows you to objectively determine the success of the project.

Parameters such as the effectiveness of a site as a marketing tool are evaluated by the product management department even at the stage of creating a standard solution on the basis of which sites are assembled on the conveyor.

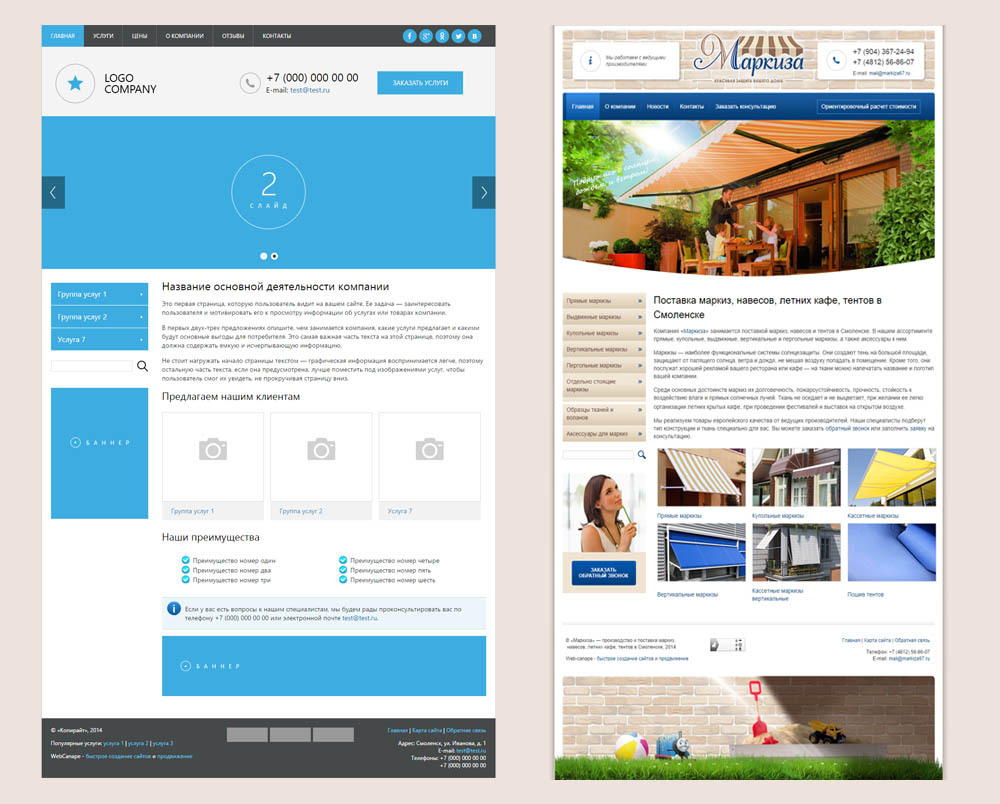

The image below shows what the site looks like before the designer and content manager get to work and after they work.

How this happens and more, read on. On our site you can see examples of work on this technology.

How do sites get better? Conveyor stages

Setting to work. Before the project goes to work, the manager forms a development task. The task in our case is a working prototype of the site. According to the principle of "canapes", the manager forms a modular composition of the project. Each of the modules has a number of visual and functional states, choosing which correctly, we get a high-quality workpiece for a future site. The task of the manager at this stage is to choose the most optimal proven solutions that are suitable for specific client tasks. Further, designers, copywriters and programmers will work with these modules.

Design and layout.The graphic grid of standard solutions is thought out and tested two weeks before it gets into the release of the base assembly and already further on the conveyor. The main work of the designer on the assembly line is to work out the promotional component of the site in order to interest the visitor in a few seconds and show that he got to where he wanted. After that, the interface elements (or modules) of the site are worked out in order to correctly place accents and support the main graphic image.

All graphic elements of the site are pre-grouped into smart objects (menu, header, authorization, etc.), with which the designer then works. This is done for convenience and order. Here two monitors are very useful for the designer. In one, the designer works with a smart object, and in the second he sees the whole site. Cutting design is automated using slices available in Photoshop. If everything is done correctly, then a lot of time is saved on this and the result is standard good.

Filling. First, texts are prepared. In this phase, at least 97% uniqueness must be achieved. This is necessary for further successful search engine promotion. For verification, the ETXT program is used.

When placing texts on the site, two types of templates are used: design and service. One example of a text layout template is the “selling section”. There are several options for such patterns. This allows content managers, without involving a designer and layout designer, to quickly make high-quality site content. Utility templates are needed more for search engines. These are fragments of the site, covered with special micro-markup, which only search engines see. With its help, search engines understand where on the site the phone, address, products, reviews, etc., which in turn affects the results of the site in search engines.

Functional development.If it is necessary to develop unique functionality that is not part of the basic assembly, the project goes to the programming area. At the touch of a button, the programmer creates a copy of the base site for its completion. All changes to the program code are recorded through the version control system. This allows later (at the stage of technical support) to see the history of the project improvements. When the improvements are ready, a copy of the site merges with the main one and the project is submitted for testing.

Testing.Testing takes place in two iterations. At the first step, automatic tests are run that check the correct operation of the site (the correct settings for search engine optimization, the work of forms ...). At the second step, the tester looks at the general status of the project for compliance with quality criteria (appearance, content, notification texts, non-standard functionality, etc.). The same two iterations are performed after the project is posted on the hosting and the domain is bound.

The completion of the project.At this stage, many organizational tasks are being addressed. It turns out the second part of the payment :) All statistics are collected from production sites (development time in standard days, actual days, hours) to compare the collected indicators with the planned ones (this will be needed to adjust the premiums of managerial staff). Customer feedback requested. The project is published in the portfolio, transferred to warranty support and to the promotion and advertising department.

We have listed the main stages of the project movement. Only at the stage of delivery of the project more than 30 points that must be completed by the manager. In order not to forget all this, we use a corporate code of rules and regulations. This is such a thick managers handbook.

Instead of a conclusion

What is important for the client? Price. Dates. Quality. What guarantees the conveyor?

- Automation significantly reduces production costs - price

- The conveyor belt will definitely arrive at the appointed date - dates

- All stages will be completed, all regulations will be fulfilled - quality

Of course, not everything is perfect in this world. And there are crashes on conveyors. But if you strive for excellence, you can achieve good results. If you have questions, we are ready to answer them.

Vasily Churanov and WebCanape team