We make a desktop device for the manufacture of printed circuit boards in one click

Once again, washing the sink from the red spots of ferric chloride, after etching the board, I thought it was time to automate this process. So I began to make a device for the manufacture of circuit boards, which now can be used to create simple electronics.

Below I will talk about how this device was made.

The basic process for manufacturing a printed circuit board using the subtractive method is that unnecessary foil sections are removed on the foil material.

Today, most electronics engineers use technologies such as laser-ironing for home-made circuit boards. This method involves removing unnecessary parts of the foil using a chemical solution that corrodes the foil in unnecessary places. The first experiments with LUT several years ago showed me that this technology is full of little things, sometimes completely hindering the achievement of an acceptable result. Here and the preparation of the surface of the board, and the choice of paper or other material for printing, and the temperature in conjunction with the heating time, as well as the features of washing the remains of the glossy layer. You also have to work with chemistry, and this is not always convenient and useful at home.

I wanted to put on the table some device into which you can send the source of the board to the printer, press a button and after some time get the finished board.

You can find out a little google that people, starting in the 70s of the last century, began to develop desktop devices for the manufacture of printed circuit boards. The first step was the appearance of milling machines for printed circuit boards, which cut tracks on a foil textolite with a special cutter. The essence of the technology lies in the fact that at high speeds the milling cutter mounted on a rigid and precise coordinate table with CNC cuts the foil layer in the right places.

The desire to immediately buy a specialized machine passed after studying prices from the supplier. I, like most hobbyists, am not ready to pay such money for the device. Therefore, it was decided to make the machine independently.

It is clear that the device should consist of a coordinate table that moves the cutting tool to the desired point and the cutting device itself.

On the Internet there are enough examples of how to make a coordinate table for every taste. For example, the same RepRap cope with this task (with adjustments for accuracy).

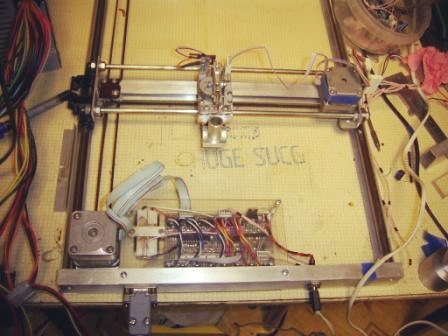

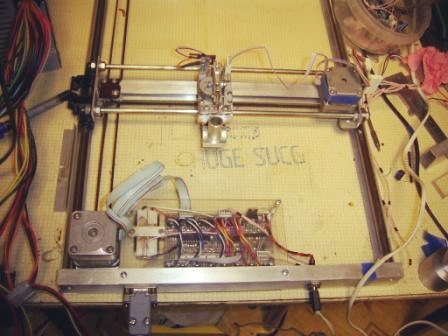

From one of my previous hobby projects for creating a plotter, I still have a home-made coordinate table. Therefore, the main task was to create a cutting tool.

Equipping a plotter with a miniature engraver like Dremel could be a logical step. But the problem is that a plotter, which can be cheaply assembled at home, is difficult to make with the necessary rigidity, parallelism of its plane to the plane of the PCB (even the PCB itself can be curved). As a result, it would not have been possible to cut boards of less good quality on it. In addition, the fact that the milling cutter becomes dull with time and loses its cutting properties did not favor the use of milling. It would be great if copper could be removed from the surface of the PCB using a non-contact method.

Already there are laser machines from the German manufacturer LPKF, in which the foil is simply vaporized by a powerful infrared semiconductor laser. Machines are characterized by accuracy and processing speed, but their price is even higher than that of milling machines, and collecting such a thing from materials accessible to everyone and somehow cheapening it does not seem to be a simple task.

From the foregoing, I formed some requirements for the desired device:

So I began to think about a possible alternative to the laser in the field of non-contact removal of copper from the PCB. And I came across a method of electrospark processing , which has long been used in metalworking for the manufacture of precision metal parts.

With this method, the metal is removed by electric discharges that evaporate and spray it from the surface of the workpiece. Thus, craters are formed, the size of which depends on the energy of the discharge, its duration and, of course, the type of workpiece material. In the simplest form, electrical erosion began to be used in the 40s of the XX century for punching holes in metal parts. Unlike traditional machining, holes could be obtained in almost any shape. Currently, this method is actively used in metalworking and has spawned a series of types of machine tools.

An obligatory part of such machines is a current pulse generator, a system for feeding and moving an electrode - it is an electrode (usually a copper, brass or graphite) that is the working tool of such a machine. The simplest current pulse generator is a simple capacitor of the desired rating, connected to a constant voltage source through a current-limiting resistor. In this case, the capacitance and voltage determine the discharge energy, which in turn determines the size of the craters, and hence the purity of the treatment. True, there is one significant nuance - the voltage on the capacitor in the operating mode is determined by the breakdown voltage. The latter almost linearly depends on the gap between the electrode and the workpiece.

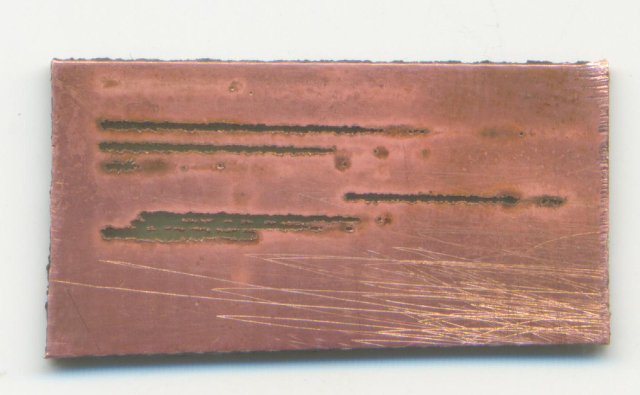

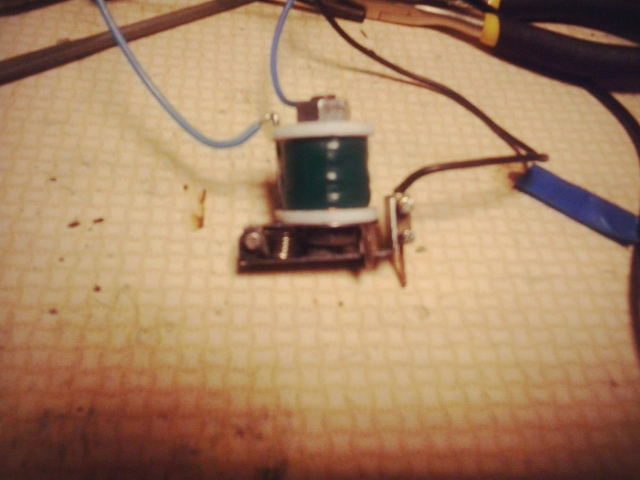

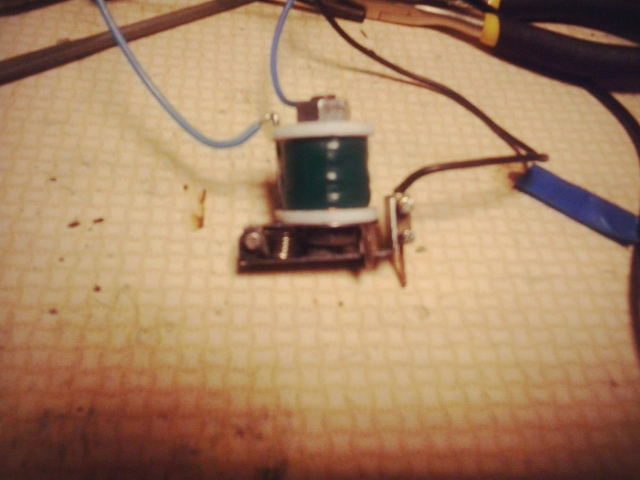

During the evening, a prototype of an erosion tool was made, which is a solenoid, to the anchor of which a copper wire is attached. The solenoid provided vibration to the wire and interrupted contact. The LATR was used as a power source: a rectified current charged the capacitor, and an alternating current fed the solenoid. This design was also fixed in the pen holder of the plotter. In general, the result met expectations, and the head left continuous stripes with torn edges on the foil.

The method clearly had the right to life, but it was necessary to solve one problem - to compensate for the consumption of wire, which is consumed during operation. To do this, it was necessary to create a feed mechanism and a control unit for it.

After that, I started spending all my free time in one of the hackspaces of our city, where there are metalworking machines. Continued attempts to make an acceptable cutting device. The erosion head consisted of a pair of stem-bush, providing vertical vibration, return spring and lingering mechanism. To control the solenoid, it was necessary to fabricate a simple circuit consisting of a pulse generator of a given length on the NE555, a MOSFET transistor and an inductive current sensor. Initially, it was supposed to use the self-oscillation mode, that is, apply a pulse to the key immediately after the current pulse. In this case, the oscillation frequency depends on the size of the gap and the drive is controlled according to the measurement of the period of self-oscillations. However, a stable self-oscillating mode was possible in the range of amplitudes of oscillation of the head, which was less than half the maximum. Therefore, I decided to use a fixed frequency of oscillations generated by the hardware PWM. In this case, the state of the gap between the wire and the board can be judged by the time between the end of the opening pulse and the first current pulse. For greater stability during operation and improving the frequency characteristics, the solenoid was fixed above the wire pulling mechanism, and the anchor was placed on a duralumin bracket. After these improvements, it was possible to achieve stable operation at frequencies up to 35 Hz. For greater stability during operation and improving the frequency characteristics, the solenoid was fixed above the wire pulling mechanism, and the anchor was placed on a duralumin bracket. After these improvements, it was possible to achieve stable operation at frequencies up to 35 Hz. For greater stability during operation and improving the frequency characteristics, the solenoid was fixed above the wire pulling mechanism, and the anchor was placed on a duralumin bracket. After these improvements, it was possible to achieve stable operation at frequencies up to 35 Hz.

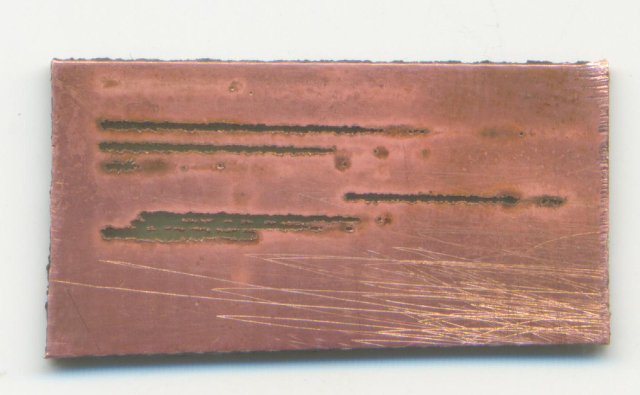

Having fixed the cutting head on the plotter, I began experiments on cutting insulating tracks on printed circuit boards. The first result was achieved and the head more or less steadily provides continuous cutting. Here is a video demonstrating what happened:

The fundamental possibility of manufacturing circuit boards with the help of electric spark processing is confirmed. In the near future, to increase accuracy, increase processing speed and cleanliness of the cut, as well as put some of the best practices in the public domain. I also plan to adapt the module for use with RepRap. I will be glad to ideas and comments in the comments.

Below I will talk about how this device was made.

The basic process for manufacturing a printed circuit board using the subtractive method is that unnecessary foil sections are removed on the foil material.

Today, most electronics engineers use technologies such as laser-ironing for home-made circuit boards. This method involves removing unnecessary parts of the foil using a chemical solution that corrodes the foil in unnecessary places. The first experiments with LUT several years ago showed me that this technology is full of little things, sometimes completely hindering the achievement of an acceptable result. Here and the preparation of the surface of the board, and the choice of paper or other material for printing, and the temperature in conjunction with the heating time, as well as the features of washing the remains of the glossy layer. You also have to work with chemistry, and this is not always convenient and useful at home.

I wanted to put on the table some device into which you can send the source of the board to the printer, press a button and after some time get the finished board.

You can find out a little google that people, starting in the 70s of the last century, began to develop desktop devices for the manufacture of printed circuit boards. The first step was the appearance of milling machines for printed circuit boards, which cut tracks on a foil textolite with a special cutter. The essence of the technology lies in the fact that at high speeds the milling cutter mounted on a rigid and precise coordinate table with CNC cuts the foil layer in the right places.

The desire to immediately buy a specialized machine passed after studying prices from the supplier. I, like most hobbyists, am not ready to pay such money for the device. Therefore, it was decided to make the machine independently.

It is clear that the device should consist of a coordinate table that moves the cutting tool to the desired point and the cutting device itself.

On the Internet there are enough examples of how to make a coordinate table for every taste. For example, the same RepRap cope with this task (with adjustments for accuracy).

From one of my previous hobby projects for creating a plotter, I still have a home-made coordinate table. Therefore, the main task was to create a cutting tool.

Equipping a plotter with a miniature engraver like Dremel could be a logical step. But the problem is that a plotter, which can be cheaply assembled at home, is difficult to make with the necessary rigidity, parallelism of its plane to the plane of the PCB (even the PCB itself can be curved). As a result, it would not have been possible to cut boards of less good quality on it. In addition, the fact that the milling cutter becomes dull with time and loses its cutting properties did not favor the use of milling. It would be great if copper could be removed from the surface of the PCB using a non-contact method.

Already there are laser machines from the German manufacturer LPKF, in which the foil is simply vaporized by a powerful infrared semiconductor laser. Machines are characterized by accuracy and processing speed, but their price is even higher than that of milling machines, and collecting such a thing from materials accessible to everyone and somehow cheapening it does not seem to be a simple task.

From the foregoing, I formed some requirements for the desired device:

- The price is comparable to the cost of an average home 3D printer

- Contactless copper removal

- The ability to assemble the device from the available components yourself at home

So I began to think about a possible alternative to the laser in the field of non-contact removal of copper from the PCB. And I came across a method of electrospark processing , which has long been used in metalworking for the manufacture of precision metal parts.

With this method, the metal is removed by electric discharges that evaporate and spray it from the surface of the workpiece. Thus, craters are formed, the size of which depends on the energy of the discharge, its duration and, of course, the type of workpiece material. In the simplest form, electrical erosion began to be used in the 40s of the XX century for punching holes in metal parts. Unlike traditional machining, holes could be obtained in almost any shape. Currently, this method is actively used in metalworking and has spawned a series of types of machine tools.

An obligatory part of such machines is a current pulse generator, a system for feeding and moving an electrode - it is an electrode (usually a copper, brass or graphite) that is the working tool of such a machine. The simplest current pulse generator is a simple capacitor of the desired rating, connected to a constant voltage source through a current-limiting resistor. In this case, the capacitance and voltage determine the discharge energy, which in turn determines the size of the craters, and hence the purity of the treatment. True, there is one significant nuance - the voltage on the capacitor in the operating mode is determined by the breakdown voltage. The latter almost linearly depends on the gap between the electrode and the workpiece.

During the evening, a prototype of an erosion tool was made, which is a solenoid, to the anchor of which a copper wire is attached. The solenoid provided vibration to the wire and interrupted contact. The LATR was used as a power source: a rectified current charged the capacitor, and an alternating current fed the solenoid. This design was also fixed in the pen holder of the plotter. In general, the result met expectations, and the head left continuous stripes with torn edges on the foil.

The method clearly had the right to life, but it was necessary to solve one problem - to compensate for the consumption of wire, which is consumed during operation. To do this, it was necessary to create a feed mechanism and a control unit for it.

After that, I started spending all my free time in one of the hackspaces of our city, where there are metalworking machines. Continued attempts to make an acceptable cutting device. The erosion head consisted of a pair of stem-bush, providing vertical vibration, return spring and lingering mechanism. To control the solenoid, it was necessary to fabricate a simple circuit consisting of a pulse generator of a given length on the NE555, a MOSFET transistor and an inductive current sensor. Initially, it was supposed to use the self-oscillation mode, that is, apply a pulse to the key immediately after the current pulse. In this case, the oscillation frequency depends on the size of the gap and the drive is controlled according to the measurement of the period of self-oscillations. However, a stable self-oscillating mode was possible in the range of amplitudes of oscillation of the head, which was less than half the maximum. Therefore, I decided to use a fixed frequency of oscillations generated by the hardware PWM. In this case, the state of the gap between the wire and the board can be judged by the time between the end of the opening pulse and the first current pulse. For greater stability during operation and improving the frequency characteristics, the solenoid was fixed above the wire pulling mechanism, and the anchor was placed on a duralumin bracket. After these improvements, it was possible to achieve stable operation at frequencies up to 35 Hz. For greater stability during operation and improving the frequency characteristics, the solenoid was fixed above the wire pulling mechanism, and the anchor was placed on a duralumin bracket. After these improvements, it was possible to achieve stable operation at frequencies up to 35 Hz. For greater stability during operation and improving the frequency characteristics, the solenoid was fixed above the wire pulling mechanism, and the anchor was placed on a duralumin bracket. After these improvements, it was possible to achieve stable operation at frequencies up to 35 Hz.

Having fixed the cutting head on the plotter, I began experiments on cutting insulating tracks on printed circuit boards. The first result was achieved and the head more or less steadily provides continuous cutting. Here is a video demonstrating what happened:

The fundamental possibility of manufacturing circuit boards with the help of electric spark processing is confirmed. In the near future, to increase accuracy, increase processing speed and cleanliness of the cut, as well as put some of the best practices in the public domain. I also plan to adapt the module for use with RepRap. I will be glad to ideas and comments in the comments.