We study new worlds with the help of an open-source ATV project from NASA

- Transfer

NASA's Jet Propulsion Laboratory has adapted the design of a Martian all-terrain vehicle so that you can create something similar in your garage.

I have a special attitude to Mars rovers from the NASA Jet Propulsion Laboratory (JPL). I really enjoyed studying the photos of Sojourner nodding into the rocks, and I still wonder if he managed to go around the Mars Pathfinder boarding module after the connection with him was lost . My heart broke after being silenced by " Spirit " and " Opportunity"continues to inspire me, having worked so long after the planned end of the mission, even when a dust storm threatens to starve him. I remember particularly well how insane the idea seemed to throw the Curiosity to the surface from a robotic sky crane, and how I was amazed watching for the smooth progress of the operation from the press room in the laboratory.

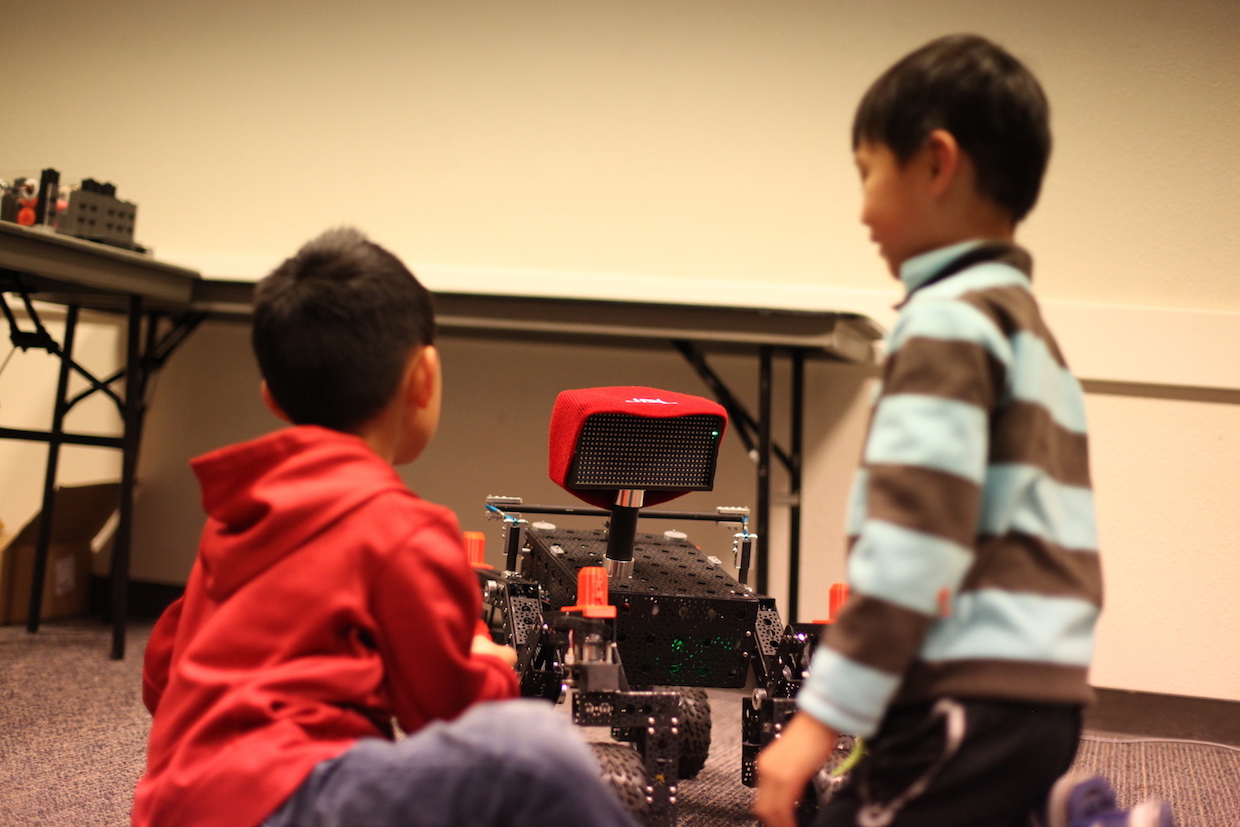

I’m not the only one who thinks that all-terrain vehicles from JPL are incredibly good, and many other all-terrain vehicle enthusiasts pestered the laboratory with requests to create a small and cute all-terrain vehicle that could be built at home. JPL worked on this for a long time, and just announced the creation of the final product in the framework of the project " open source all-terrain vehicle " and its slogan "space robots for everyone!"

JPL open source vehicle (FOC)

An open source all-terrain vehicle at JPL was developed by a very small team — two student interns and the head of the project. They were assisted by experienced robotics engineers in the lab. The goal was to make something affordable and inexpensive, since the previous educational project of the laboratory, called ROV-E, was not only extremely popular, but also extremely expensive - it cost more than $ 30,000. The aim of the FOC project was to reduce the cost by at least an order of magnitude, preserve the usefulness of the device, make it attractive and easy to create - all this in just 10 weeks.

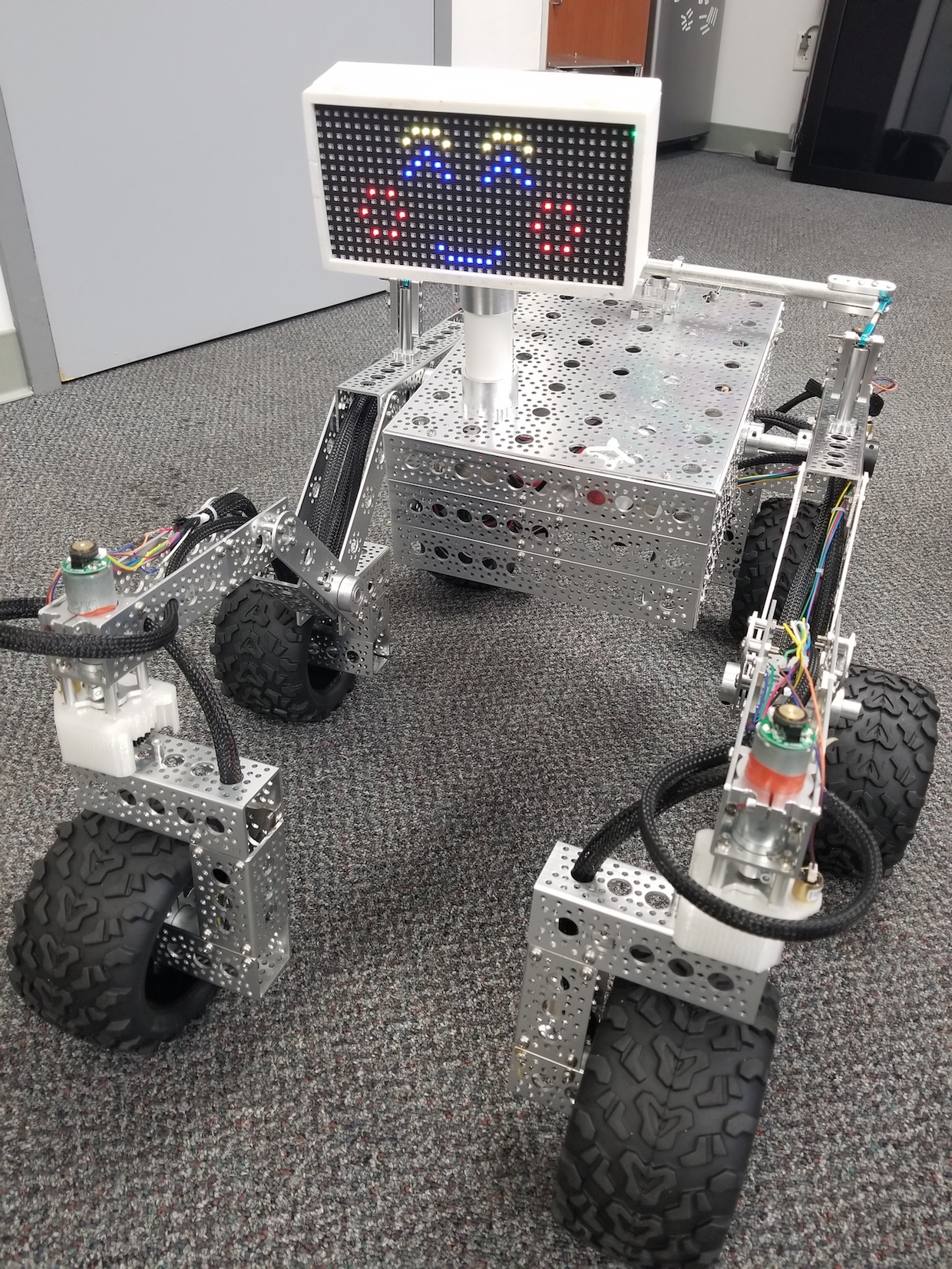

They succeeded - they developed a scheme according to which a robot can be assembled from available and ready-made, sold in parts stores, for only $ 2500. The FOC drive system is designed in the image of the “Curiosity”, when six independent wheels can be rotated mounted on a swinging suspension capable of overcoming obstacles. The laser drill in front was replaced by a programmable screen - a pity, but these are safety requirements. And although the robot does not have built-in autonomy, the laboratory agitates enthusiasts to work together to create additional functions of the robot, both in terms of hardware and software.

JPL estimates that about 200 man-hours should be spent on building a robot, and although power tools are always useful, at a minimum you will only need a drill, a dremel, a soldering iron, several other simple tools, a basic familiarity with Linux and Python, and, possibly, safety friend - if you've never done something like this before. The documentation posted on GitHub seems to be quite comprehensive, and even a forum is organized where the guys from JPL answer the questions. We managed to interview one of them - it was Mick Cox, the head of the Internet of Things team at JPL, who also led the creation of the FOC.

IEEE Spectrum : What led you to the development of the wok? Where did the project come from, what are the people involved in JPL doing?

Mick Cox: The wok is partly based on the JPL educational project, known as ROV-E (an educational vehicle with remote control), which was distributed to museums, schools and various events in order to raise people's interest in robotics and the study of space. People constantly asked us if we could distribute schemes for self-assembly of the robot, but the ROV-E was complicated and expensive. We wanted to release a new all-terrain vehicle, which the high school team will be able to collect no more than $ 2500. This project is an open source all-terrain vehicle.

We hope that, having published the plans of the all-terrain vehicle, we will be able to inspire a new generation of engineers, robotics and scientists by building our own Martian all-terrain vehicle! I managed this project, but in general I work at JPL as a data processing specialist and lead the Internet of Things project. For two weeks, two students and I developed, built and documented an all-terrain vehicle. One of them (Eric Dzhankins) was taken to the laboratory staff, and now he is helping in our group of robotics prototypes. The other (Olivia Lofaro) is still studying, and is now working as an intern on Google X.

Describe how the design of the all-terrain vehicle was going. What were the priorities, how much did the final version differ from the concept?

There were very few strict requirements:

- Swinging suspension, similar to those used on Martian all-terrain vehicles.

- 6-wheel drive and corner steering [corner steering], similar to that used on Martian all-terrain vehicles.

- Fully assembled from finished parts sold in stores, or such that can be printed on a 3D printer.

- Cost less than $ 2500.

- Attractive appearance.

The very first version of the scheme was based on plastic pipes and printed joints on a 3D printer. We crossed it out after engineers expressed doubts about the reliability of the robot created from such materials. The second scheme went to aluminum profiles with mounting holes, but the geometry of the legs was not enough to climb obstacles. The third, final scheme, lowered the body and optimized the geometry of the legs, which allows the all-terrain vehicle to conquer more aggressive obstacles. All three iterations were completed in about 6 weeks.

Regarding other projects of school-oriented robots, this one looks pretty daunting. How to introduce it to students without any experience in robotics, to convince them that they can cope with it?

Our project has always been intended for high school students and above, and we remembered this, creating very detailed instructions. There each step of the assembly is described in detail, and not only how to assemble the robot, but also why this engineering decision was made. Each of the skills required for its assembly (soldering, basic assembly skills, finding errors in electronics) is listed, and we have compiled links to training materials on the Internet that we think will be useful for acquiring these skills. In addition, we tested our documentation by assembling a robot together with several teams of schoolchildren who had no previous experience in robotics. All teams coped with the assembly. This all-terrain vehicle should teach many of the critical aspects of robotics: engineering, computer-aided design, manufacturing, electrical engineering, software development. The combination may sound scary, but many of the already existing projects in the field of robotics will not give such experience in all these areas at once.

What do you think people will do with all-terrain vehicles after construction? What interesting upgrades can you think of for him?

We hope that people will empower the robot and pass it on to the community! We would look with interest at the improvements that reduce the cost of the robot, but retain the same suspension and the same drive capabilities. In addition, we hope to increase the possibilities through the installation of cameras, accelerometers, sensors and scientific instruments, robotic hands, solar panels, new methods of control, and everything else that you can think of!

What would you recommend to schoolchildren who, after assembling such a robot, would want to work, say, in JPL?

The best thing you can do is keep doing it, practice, create good things! We really like to see how more and more teams are interested in robotics around the world, and it's great that the threshold for entering this area has decreased so much. JPL has many study programs, especially in the summer. We are constantly in search of a new generation of researchers and builders.