Printing History: Dot Matrix, Inkjet, Laser, and LED Technologies (Part 2)

Last time, we looked at the history of printing from ancient times until the invention of the first printer. It was full of secrets and very ambiguous, that you, dear habro-people, kindly noted in your comments. Today we are talking about the history of the personal press, the development of which began in the middle of the twentieth century.

Part 1. The history of printing: the evolution of ideas and technologies

Part 2. The history of printing: matrix, ink-jet, laser and LED technologies

The first real printers

The development of the first printers in the 40-50s was associated with the evolution of the typewriter. In the USSR and the USA, numerous attempts have been made to automate the process of typing characters that print certain characters on paper through an ink-soaked ribbon. So, in our country such developments were called ADCUs (automated digital printing devices), and in America they were simply called Printer - which means “printing”. Later, drum and flap printers appeared that used the ideas of Charles Babbage, which we talked about in a previous article, and could apply different characters through the same ink ribbon.

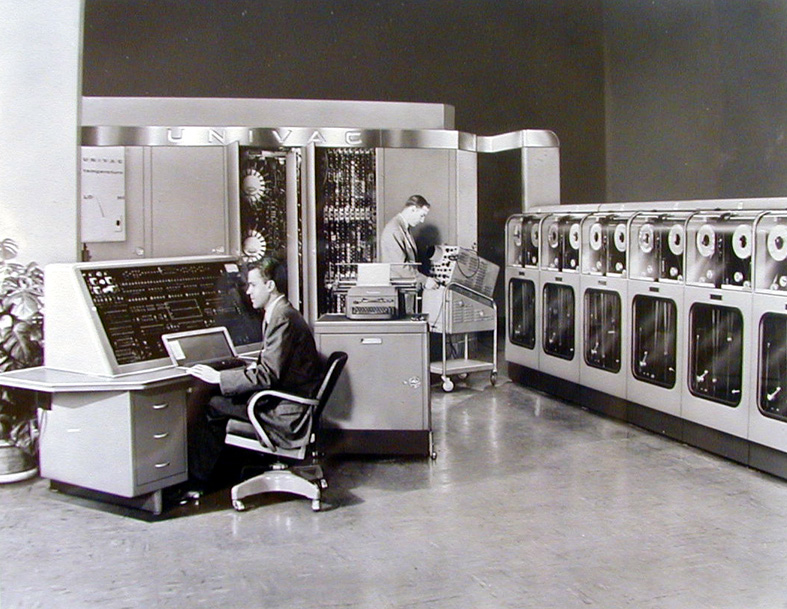

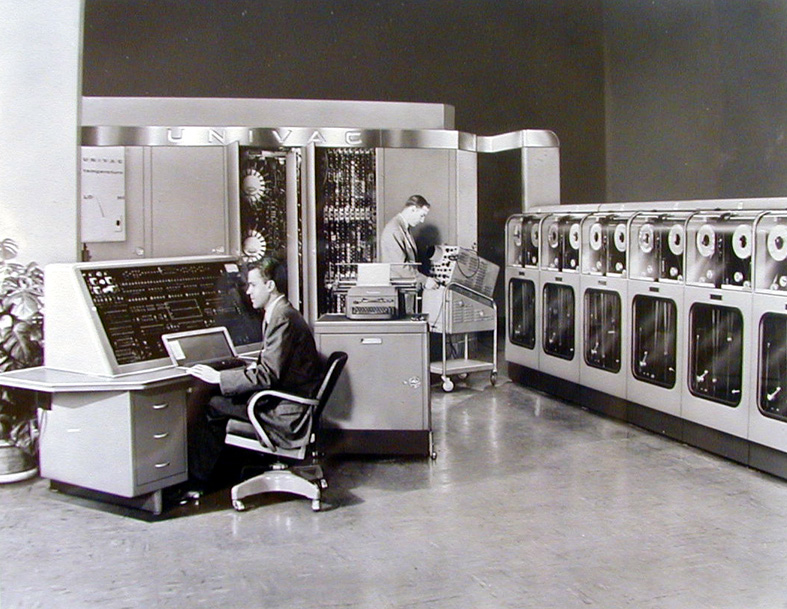

The print of that time cannot be compared to the quality and speed with the modern one. One of the first such "machines" was created for the Univac computer in 1953 in the bowels of Remington-Rand Corporation, it was the first high-speed printer in the world. However, it was high-speed, of course, in the understanding of that time - a printing device could print 600 lines of 120 characters each in a minute.

Dot matrix printers

For the first time, the idea of matrix printing was realized in 1964 by Seiko Epson Corporation. The company's engineers designed a mechanism unique at that time, which constantly imprinted the exact time - it worked like a clock. Unlike petal and drum printers, the image was formed from dots applied to the paper with needles through black or color tape. The evolution of this development has led to the emergence of true dot matrix printers.

The main structural elements of the matrix printer are a print head (carriage), which moves along the line and inflicts characters by striking needles through a ribbon soaked with ink. From here the name "matrix printer" appeared. Indeed, all possible symbols consisted of the resolution of the matrix formed by the arrangement of needles, of which at first there were very few - for example, 9, 24, 35, and so on. The shock movement of the needle was triggered by an electromagnet located in the drum. In more detail, we examined the mechanism in an article directly devoted to matrix technology .

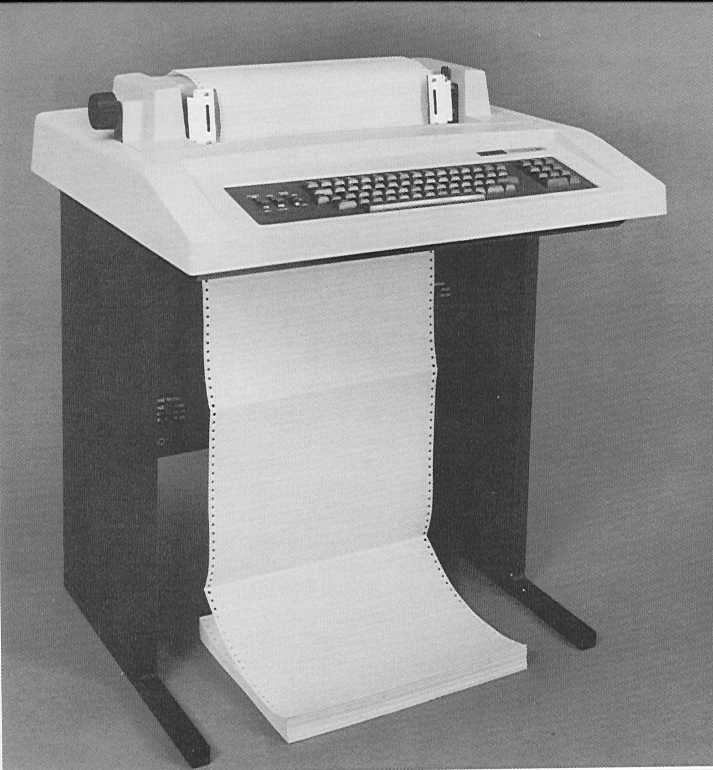

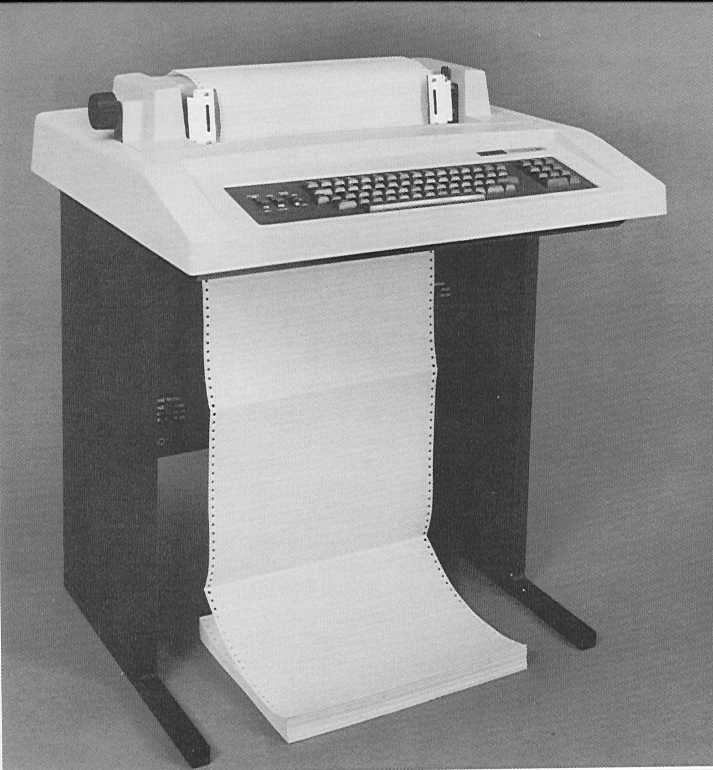

One of the first serial dot matrix printers was the LA30 from DEC (Digital Equipment Corporation). This device was able to print only capital letters of 5 by 7 dots at a speed of 30 characters per second on special-sized paper. The print head of this printer was controlled by a stepper motor, and the paper was pulled by a ratchet drive - not very reliable and noisy. Curiously, the LA30 had both a serial and parallel interface.

However, it was the DEC LA36 printer that actually became the symbol of the printing technology, having won public recognition at the time. The developers fixed the main errors and shortcomings, as well as increased the length of the string to 132 characters in various cases. As a result, standard perforated paper was suitable for printing. The carriage was driven by a more powerful servo drive with an electric motor, an optical position sensor and a tachometer. All this made the printer more convenient and reliable.

Another interesting technical feature of the LA36 is that without taking more than 30 characters per second from the computer, it printed twice as fast. The fact is that when the carriage was returned, the next packet of characters fell into the buffer. Therefore, when printing a new line, the printer made up for lost time at a speed of 60 characters per second. LA36 set the "fashion" for multi-tone print sounds - in quick and normal mode. After all, his head moved in one direction with one speed, and in the other - with twice as much, creating a peculiar office noise background.

But the most popular and purchased model until the 90s was the Epson MX-80, combining relative availability and good performance parameters for that time. Matrix printing technology has dominated the market for a long time, but in recent years, thanks to the development of such areas as inkjet and laser printing, as well as their varieties, they have given way to their main niche and have fallen into the shadow of specialized solutions.

Inkjet printing

If you start from the very beginning, you can consider the moment of the birth of inkjet printing in 1833, when Felix Savart discovered and stated the uniformity of the formation of droplets of liquid discharged through a narrow hole. A mathematical description of this phenomenon was carried out in 1878 by Lord Reilly (who subsequently received the Nobel Prize). But only in 1951, Siemens patented a working device capable of dividing the jet into drops of the same type. This invention led to the creation of a mingograph, one of the first commercial recorders used to record voltage values.

Speaking about inkjet printing, one should not forget about such an approach as drop-on-demand. Today, not many people remember this, but the first inkjet printers had a serious problem with dropping drops that should not have got on paper. The essence of the drop-on-demand method is that the device releases ink droplets only when necessary.

The first developments in this area were used in the Siemens PT-80 character sequential printing device in 1977, as well as in the Silonics printer, which appeared a year later. These printers used the prototype of piezoelectric printing when ink droplets came out under the action of a pressure wave created by the mechanical movement of the piezoceramic element.

In 1979, Canon invented the drop-on-demand printing method, according to which droplets were discharged outward on the surface of a small heater located near the nozzle and controlled by condensation of misty pigment clusters. Canon called this technology bubble printing.

In 1980, Hewlett-Packard independently developed a similar technology called thermal inkjet printing, and already in 1984 the ThinkJet solution appeared on the market - the first commercially successful and relatively inexpensive inkjet printer providing good print quality and resolution.

Inkjet technologies are developing today, providing multi-color printing, printing in large formats, they allow the use of both soluble and pigment dyes (when minimal particles of ink penetrate through nozzles and settle on paper). We can say that modern inkjet printers are in a state of progress and are actively fighting for their place in the sun. Improving the printing speed and resistance of dyes to the effects of time, moisture and friction, as well as reducing the cost of the print made them a serious competitor for laser and LED printers.

Laser printers

Palm in the manufacture of laser printers belongs to the company XEROX. It was her employees in 1969 who realized that the technology of copiers can be applied to printers. Thus, the photodrum is negatively charged, and the laser beam removes a certain part of the charge, passing through the photodrum, exactly where the pixels should be printed. The laser printer toner can be made of various materials: metal shavings, resins, coal dust, etc. In any case, it is also negatively charged and therefore sticks exactly in the place where the laser passes, which will give the drum a positive potential. The drum transfers the electronic image onto paper, to which toner particles are attracted. In the end, the paper gets into the oven, and the toner melts under the action of the heating shaft, fixing on the paper.previous articles .

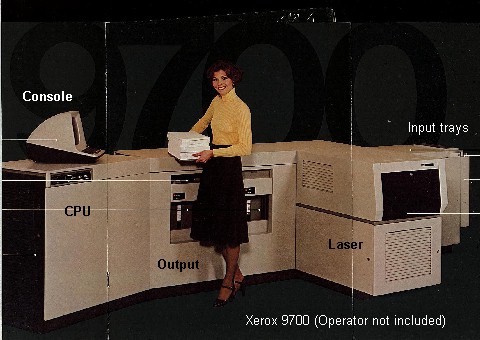

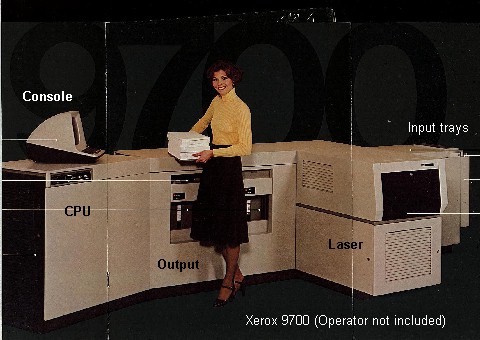

Back in 1971, the first prototype of a laser printer appeared, but only in 1977, XEROX launched the Xerox 9700 Electronic Printing System. In 1981, Xerox continued its development and released the STAR 8010 computer. Together with it, graphic and text editors, as well as a program for combining texts and graphics and, of course, a laser printer are sold. The cost of such equipment at that time was $ 17,000.

The next important stage in the history of laser printers is in 1984. Then Hewlett-Packard company began to produce a series of affordable LaserJet printers, which provided excellent at that time resolution of 300 dpi. In 1992, HP launched its LaserJet 4 printer, costing a little less than $ 1,000 and a resolution of 600 dpi. We can say that this moment became a turning point and laser printers began to gain popularity and conquer the office printing market.

LED printers

LED printers are considered to be more technologically advanced than laser printers. Instead of a laser, they use a long ruler with LEDs that selectively flash to create an electronic pattern on the drum. Thus, this technology is more economical and allows to achieve higher printing speed, all other things being equal (design of the printing mechanism, interface speed, CPU used, etc.). The first LED printer was released by OKI only in 1987, and 10 years later, in 1998, the company also developed the first color LED printer.

In our country, LED printers appeared in 1996 with the opening of the OKI regional office. In 1999, LED printers in Russia began to supply Panasonic and Kyocera.

The history of LED printers in Russia is closely connected with the budget and home model OkiPage 4W, which was positioned in our country as the base model for the office. OkiPage 4W is much cheaper than its laser counterparts, and its sales in the business segment start very vigorously. However, designed for home print volumes (2,500 pages per month), they quickly fail, both due to excess load and low-quality refueling materials. It is believed that precisely because of this situation, LED printing is still not so popular in Russia.

However, at present, LED printers continue their active development, offering a worthy alternative to the classic laser models. The manufacturers' assortment includes both standard color and black-and-white and wide-format LED printers.

Sublimation printing

At the request of workers, we will say a few words about technologies such as thermal sublimation printing and Micro Dry. They appeared relatively later than laser and inkjet printing, and perhaps that is why they have not yet taken a significant place in the market.

The pioneer of sublimation technology is the Frenchman Noel de Plasse. In 1957, Noel de Plasse discovered that some dyes are able to sublimate, that is, pass from a solid state to a gaseous state, bypassing a liquid one. However, in the 60s his discovery did not affect the press, although after 20 years with the spread of personal computers and the development of technology, his ideas became relevant again. In 1985, they began to put thermal dye sublimation printing into practice, actively using Kodak photo printers for direct printing from cameras, as well as Mitsubishi Electric. However, the scope of this technology is very limited, since printing requires special thermal paper, and the transfer speed of the pattern is quite low, because the dye of each color is applied to the paper in turn.

In 1996, Micro Dry printing technology was developed, which is mainly used in Citizen printers. Its essence is to apply a solid dye directly to the carrier. This provides the ability to print with the same quality on any paper, including dyes of the "metallic" class. Printers can print with a resolution of up to 600x600 in color, but the cost of the print is still quite high.

Conclusion

Here we briefly talked about the history of print development, but do not forget that today new technologies continue to be developed. For example, recently we talked about an interesting UV LEDsolid ink printer. Innovations allow the development of large-format printers that print on canvas, polyethylene or other materials. And also for more than 10 years, there are 3D printers that allow you to print various objects from polymers or, for example, chocolate. They undoubtedly deserve a separate discussion.

Part 1. The history of printing: the evolution of ideas and technologies

Part 2. The history of printing: matrix, ink-jet, laser and LED technologies

The first real printers

The development of the first printers in the 40-50s was associated with the evolution of the typewriter. In the USSR and the USA, numerous attempts have been made to automate the process of typing characters that print certain characters on paper through an ink-soaked ribbon. So, in our country such developments were called ADCUs (automated digital printing devices), and in America they were simply called Printer - which means “printing”. Later, drum and flap printers appeared that used the ideas of Charles Babbage, which we talked about in a previous article, and could apply different characters through the same ink ribbon.

The print of that time cannot be compared to the quality and speed with the modern one. One of the first such "machines" was created for the Univac computer in 1953 in the bowels of Remington-Rand Corporation, it was the first high-speed printer in the world. However, it was high-speed, of course, in the understanding of that time - a printing device could print 600 lines of 120 characters each in a minute.

Dot matrix printers

For the first time, the idea of matrix printing was realized in 1964 by Seiko Epson Corporation. The company's engineers designed a mechanism unique at that time, which constantly imprinted the exact time - it worked like a clock. Unlike petal and drum printers, the image was formed from dots applied to the paper with needles through black or color tape. The evolution of this development has led to the emergence of true dot matrix printers.

The main structural elements of the matrix printer are a print head (carriage), which moves along the line and inflicts characters by striking needles through a ribbon soaked with ink. From here the name "matrix printer" appeared. Indeed, all possible symbols consisted of the resolution of the matrix formed by the arrangement of needles, of which at first there were very few - for example, 9, 24, 35, and so on. The shock movement of the needle was triggered by an electromagnet located in the drum. In more detail, we examined the mechanism in an article directly devoted to matrix technology .

One of the first serial dot matrix printers was the LA30 from DEC (Digital Equipment Corporation). This device was able to print only capital letters of 5 by 7 dots at a speed of 30 characters per second on special-sized paper. The print head of this printer was controlled by a stepper motor, and the paper was pulled by a ratchet drive - not very reliable and noisy. Curiously, the LA30 had both a serial and parallel interface.

However, it was the DEC LA36 printer that actually became the symbol of the printing technology, having won public recognition at the time. The developers fixed the main errors and shortcomings, as well as increased the length of the string to 132 characters in various cases. As a result, standard perforated paper was suitable for printing. The carriage was driven by a more powerful servo drive with an electric motor, an optical position sensor and a tachometer. All this made the printer more convenient and reliable.

Another interesting technical feature of the LA36 is that without taking more than 30 characters per second from the computer, it printed twice as fast. The fact is that when the carriage was returned, the next packet of characters fell into the buffer. Therefore, when printing a new line, the printer made up for lost time at a speed of 60 characters per second. LA36 set the "fashion" for multi-tone print sounds - in quick and normal mode. After all, his head moved in one direction with one speed, and in the other - with twice as much, creating a peculiar office noise background.

But the most popular and purchased model until the 90s was the Epson MX-80, combining relative availability and good performance parameters for that time. Matrix printing technology has dominated the market for a long time, but in recent years, thanks to the development of such areas as inkjet and laser printing, as well as their varieties, they have given way to their main niche and have fallen into the shadow of specialized solutions.

Inkjet printing

If you start from the very beginning, you can consider the moment of the birth of inkjet printing in 1833, when Felix Savart discovered and stated the uniformity of the formation of droplets of liquid discharged through a narrow hole. A mathematical description of this phenomenon was carried out in 1878 by Lord Reilly (who subsequently received the Nobel Prize). But only in 1951, Siemens patented a working device capable of dividing the jet into drops of the same type. This invention led to the creation of a mingograph, one of the first commercial recorders used to record voltage values.

Speaking about inkjet printing, one should not forget about such an approach as drop-on-demand. Today, not many people remember this, but the first inkjet printers had a serious problem with dropping drops that should not have got on paper. The essence of the drop-on-demand method is that the device releases ink droplets only when necessary.

The first developments in this area were used in the Siemens PT-80 character sequential printing device in 1977, as well as in the Silonics printer, which appeared a year later. These printers used the prototype of piezoelectric printing when ink droplets came out under the action of a pressure wave created by the mechanical movement of the piezoceramic element.

In 1979, Canon invented the drop-on-demand printing method, according to which droplets were discharged outward on the surface of a small heater located near the nozzle and controlled by condensation of misty pigment clusters. Canon called this technology bubble printing.

In 1980, Hewlett-Packard independently developed a similar technology called thermal inkjet printing, and already in 1984 the ThinkJet solution appeared on the market - the first commercially successful and relatively inexpensive inkjet printer providing good print quality and resolution.

Inkjet technologies are developing today, providing multi-color printing, printing in large formats, they allow the use of both soluble and pigment dyes (when minimal particles of ink penetrate through nozzles and settle on paper). We can say that modern inkjet printers are in a state of progress and are actively fighting for their place in the sun. Improving the printing speed and resistance of dyes to the effects of time, moisture and friction, as well as reducing the cost of the print made them a serious competitor for laser and LED printers.

Laser printers

Palm in the manufacture of laser printers belongs to the company XEROX. It was her employees in 1969 who realized that the technology of copiers can be applied to printers. Thus, the photodrum is negatively charged, and the laser beam removes a certain part of the charge, passing through the photodrum, exactly where the pixels should be printed. The laser printer toner can be made of various materials: metal shavings, resins, coal dust, etc. In any case, it is also negatively charged and therefore sticks exactly in the place where the laser passes, which will give the drum a positive potential. The drum transfers the electronic image onto paper, to which toner particles are attracted. In the end, the paper gets into the oven, and the toner melts under the action of the heating shaft, fixing on the paper.previous articles .

Back in 1971, the first prototype of a laser printer appeared, but only in 1977, XEROX launched the Xerox 9700 Electronic Printing System. In 1981, Xerox continued its development and released the STAR 8010 computer. Together with it, graphic and text editors, as well as a program for combining texts and graphics and, of course, a laser printer are sold. The cost of such equipment at that time was $ 17,000.

The next important stage in the history of laser printers is in 1984. Then Hewlett-Packard company began to produce a series of affordable LaserJet printers, which provided excellent at that time resolution of 300 dpi. In 1992, HP launched its LaserJet 4 printer, costing a little less than $ 1,000 and a resolution of 600 dpi. We can say that this moment became a turning point and laser printers began to gain popularity and conquer the office printing market.

LED printers

LED printers are considered to be more technologically advanced than laser printers. Instead of a laser, they use a long ruler with LEDs that selectively flash to create an electronic pattern on the drum. Thus, this technology is more economical and allows to achieve higher printing speed, all other things being equal (design of the printing mechanism, interface speed, CPU used, etc.). The first LED printer was released by OKI only in 1987, and 10 years later, in 1998, the company also developed the first color LED printer.

In our country, LED printers appeared in 1996 with the opening of the OKI regional office. In 1999, LED printers in Russia began to supply Panasonic and Kyocera.

The history of LED printers in Russia is closely connected with the budget and home model OkiPage 4W, which was positioned in our country as the base model for the office. OkiPage 4W is much cheaper than its laser counterparts, and its sales in the business segment start very vigorously. However, designed for home print volumes (2,500 pages per month), they quickly fail, both due to excess load and low-quality refueling materials. It is believed that precisely because of this situation, LED printing is still not so popular in Russia.

However, at present, LED printers continue their active development, offering a worthy alternative to the classic laser models. The manufacturers' assortment includes both standard color and black-and-white and wide-format LED printers.

Sublimation printing

At the request of workers, we will say a few words about technologies such as thermal sublimation printing and Micro Dry. They appeared relatively later than laser and inkjet printing, and perhaps that is why they have not yet taken a significant place in the market.

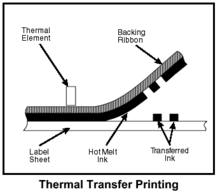

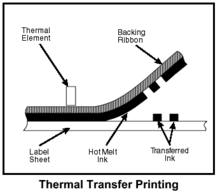

The pioneer of sublimation technology is the Frenchman Noel de Plasse. In 1957, Noel de Plasse discovered that some dyes are able to sublimate, that is, pass from a solid state to a gaseous state, bypassing a liquid one. However, in the 60s his discovery did not affect the press, although after 20 years with the spread of personal computers and the development of technology, his ideas became relevant again. In 1985, they began to put thermal dye sublimation printing into practice, actively using Kodak photo printers for direct printing from cameras, as well as Mitsubishi Electric. However, the scope of this technology is very limited, since printing requires special thermal paper, and the transfer speed of the pattern is quite low, because the dye of each color is applied to the paper in turn.

In 1996, Micro Dry printing technology was developed, which is mainly used in Citizen printers. Its essence is to apply a solid dye directly to the carrier. This provides the ability to print with the same quality on any paper, including dyes of the "metallic" class. Printers can print with a resolution of up to 600x600 in color, but the cost of the print is still quite high.

Conclusion

Here we briefly talked about the history of print development, but do not forget that today new technologies continue to be developed. For example, recently we talked about an interesting UV LEDsolid ink printer. Innovations allow the development of large-format printers that print on canvas, polyethylene or other materials. And also for more than 10 years, there are 3D printers that allow you to print various objects from polymers or, for example, chocolate. They undoubtedly deserve a separate discussion.