The printer that printed everything

The other day, an amazing MIMAKI UJF-3042 printer was brought to our office. The fact is that the UJF-3042 is really very different from other printing devices on the market, and we will tell you what exactly.

Technology

We have repeatedly written about LED printing, which has several advantages over laser printing. However, this printer uses not just LED, but UV LED printing. The transition to higher light frequencies allows us to achieve several important effects at once: the lamp life is extended (up to 5 times), energy is saved, productivity is improved due to almost dry printing, and it is possible to print on heat-sensitive materials. By the way, the piezoelectric head used in the printer also provides the application of dye "cold" method.

The next feature is hard UV curable ink (LH-100). They are highly resistant to mechanical and chemical influences. Not only standard CMYKs are available for this printer, but also cartridges with white color and varnish.

White ink is intended for bright printing on transparent or colored surfaces, and varnish allows you to give the prints a glossy effect and additionally protects the product from external influences.

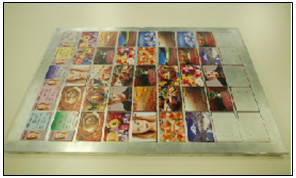

The printer can print on A3 format, and paper is also included in its "arsenal". This means that the user can also create any posters and posters. But finally, the technology of sequential application of dyes allows you to achieve 3D effects that make souvenir products even more attractive.

What do you want to print on?

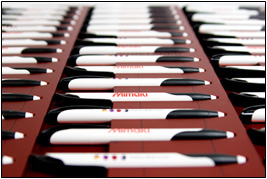

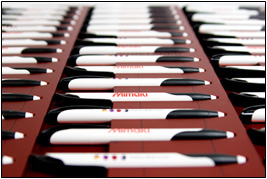

This printer allows you to print on almost anything if the thickness of this “anything” does not exceed 5 cm. That is, any pens, bottle openers, small boxes, and even toothbrushes are fine! We are no longer talking about badges, thick cardboard cards, DVDs, acrylic plates, dibond, forex, glass and films. It is only necessary to securely seal the sealed objects on a substrate or a special clamping device and correctly set the print parameters. By the way, the printer driver also allows you to apply the image to three-dimensional objects, for example, on round pens.

Handle clamping device Handle

clamping device

However, for materials such as metals or glass that need to be pretreated in order to achieve acceptable adhesion, it is necessary to carry out priming, firing or coronation - after which the dye is equally effectively applied to the surface.

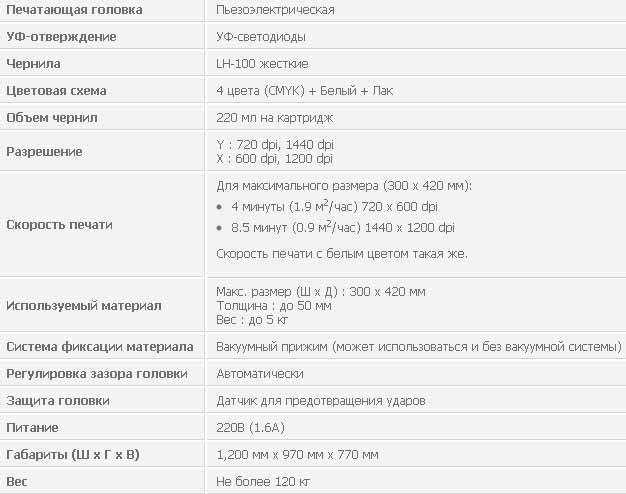

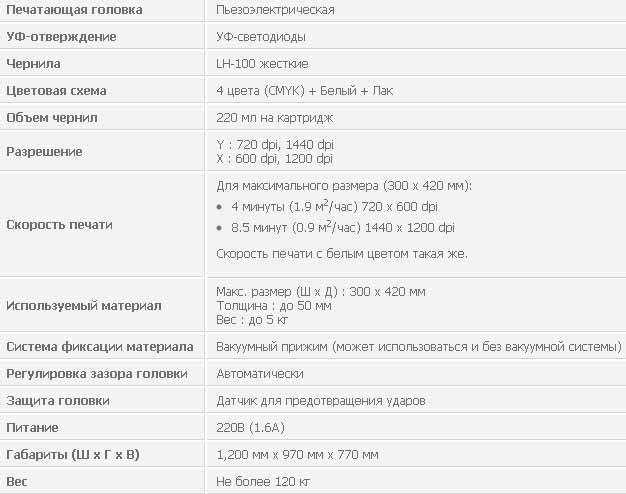

Technical characteristics

Besides the fact that MIMAKI UJF-3042 is just an interesting technical novelty, it also allows you to create souvenir products much faster, significantly reducing its production time and cost, compared to applying films. In addition, unlike films, solid dyes are more resistant to mechanical and chemical influences, longer retaining spectacular prints on virtually any surface.

Technology

We have repeatedly written about LED printing, which has several advantages over laser printing. However, this printer uses not just LED, but UV LED printing. The transition to higher light frequencies allows us to achieve several important effects at once: the lamp life is extended (up to 5 times), energy is saved, productivity is improved due to almost dry printing, and it is possible to print on heat-sensitive materials. By the way, the piezoelectric head used in the printer also provides the application of dye "cold" method.

The next feature is hard UV curable ink (LH-100). They are highly resistant to mechanical and chemical influences. Not only standard CMYKs are available for this printer, but also cartridges with white color and varnish.

White ink is intended for bright printing on transparent or colored surfaces, and varnish allows you to give the prints a glossy effect and additionally protects the product from external influences.

The printer can print on A3 format, and paper is also included in its "arsenal". This means that the user can also create any posters and posters. But finally, the technology of sequential application of dyes allows you to achieve 3D effects that make souvenir products even more attractive.

What do you want to print on?

This printer allows you to print on almost anything if the thickness of this “anything” does not exceed 5 cm. That is, any pens, bottle openers, small boxes, and even toothbrushes are fine! We are no longer talking about badges, thick cardboard cards, DVDs, acrylic plates, dibond, forex, glass and films. It is only necessary to securely seal the sealed objects on a substrate or a special clamping device and correctly set the print parameters. By the way, the printer driver also allows you to apply the image to three-dimensional objects, for example, on round pens.

Handle clamping device Handle

clamping device

However, for materials such as metals or glass that need to be pretreated in order to achieve acceptable adhesion, it is necessary to carry out priming, firing or coronation - after which the dye is equally effectively applied to the surface.

Technical characteristics

Besides the fact that MIMAKI UJF-3042 is just an interesting technical novelty, it also allows you to create souvenir products much faster, significantly reducing its production time and cost, compared to applying films. In addition, unlike films, solid dyes are more resistant to mechanical and chemical influences, longer retaining spectacular prints on virtually any surface.