We make a source of non-actinic light on LEDs

We have already talked about the manufacture of printed circuit boards using photoresist many times, including on the Habr . For many years (seriously) I suffered from this, but I did not succeed in absolutely nothing. Having spent half of the POSITIV can donated many years ago, I received only one, half turned out, payment. In 50% of cases, the resist was washed off completely; in 50%, it was not washed off anywhere. Considering that in the future I will have to work with photoresist in more difficult conditions (for my “home” microcircuits), I decided to eliminate all possible sources of problems.

We have already talked about the manufacture of printed circuit boards using photoresist many times, including on the Habr . For many years (seriously) I suffered from this, but I did not succeed in absolutely nothing. Having spent half of the POSITIV can donated many years ago, I received only one, half turned out, payment. In 50% of cases, the resist was washed off completely; in 50%, it was not washed off anywhere. Considering that in the future I will have to work with photoresist in more difficult conditions (for my “home” microcircuits), I decided to eliminate all possible sources of problems.One of these problems that can ruin all the work with the photoresist is the background illumination of the photoresist with indoor / day lighting. It can be solved using non-actinic lighting, as lighting that does not cause flare. For black and white photography for example - it was a red light lamp. In this article I will talk about how I solved this problem.

A novolac-based photoresist (most resistors for radio electronics are just that) is sensitive to blue light, 450nm and shorter. And although blue light bulbs emit little, in my casethis can be a problem. In order to work comfortably - the light should be bright, and if possible not dull red - you can gouge out your eyes in it. I tried to solve this problem using a bunch of LEDs, which I had just overloaded from another project.

What do we need

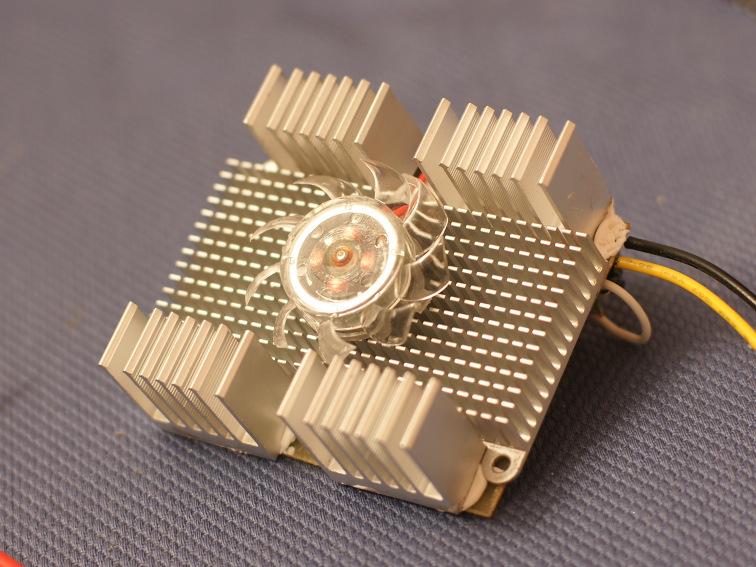

To make the light as close to white as possible, I took 3x 3W green LEDs, 6x orange and 3x red. They cover almost the entire spectrum except the blue part. Because each LED emits ~ 1.5W of heat - they all need to be put on thermal grease, and the printed circuit board should be cooled with active cooling radiators (this is the problem that makes bright LED lamps impossible). If the temperature of the LED crystal is above 100 degrees, it quickly degrades (1000 hours or less, while in normal mode - 50 thousand hours). Radiators are glued with hot glue.

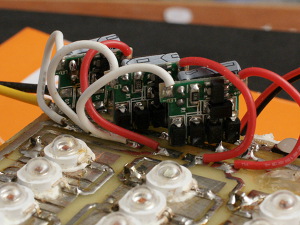

My fatal error is visible on the board - the metal “bottom” of the LEDs can be connected to one of the terminals of the LED (+ in some of my diodes), respectively, if the diode accidentally touches the board directly, without thermal paste, then one diode may be connected to the driver instead of the whole rulers. That’s how I killed one diode - the driver for one diode produced a current much higher than the nominal value, and the diode died almost instantly. I had to scratch these common “polygons” in order to exclude such situations in the future. Drivers for diodes - at 0.65A from DX (on the far driver - I see how, instead of diodes that allow them to be connected in any polarity, I soldered jumpers so as not to lose the extra 0.5W on the diodes).

My fatal error is visible on the board - the metal “bottom” of the LEDs can be connected to one of the terminals of the LED (+ in some of my diodes), respectively, if the diode accidentally touches the board directly, without thermal paste, then one diode may be connected to the driver instead of the whole rulers. That’s how I killed one diode - the driver for one diode produced a current much higher than the nominal value, and the diode died almost instantly. I had to scratch these common “polygons” in order to exclude such situations in the future. Drivers for diodes - at 0.65A from DX (on the far driver - I see how, instead of diodes that allow them to be connected in any polarity, I soldered jumpers so as not to lose the extra 0.5W on the diodes).All this is connected to a 12V power supply, 4 diodes in series require about 10V. In principle, in this case one could use a simpler linear regulator instead of a pulse one, the efficiency would be approximately the same.

Turn on

results

It turned out that if there is a green part of the spectrum in the light source - the light immediately looks almost natural, the eyes do not strain and you can work comfortably. In terms of brightness, 0.65 * 2.5 * 12 = 20W of LED lighting is more than enough, and an order of magnitude better than a standard red lamp for developing photo paper. With photoresist, it finally worked out perfectly. Well, as a free bonus - funny multi-colored shadows throughout the room due to multi-colored point light sources.

It turned out that if there is a green part of the spectrum in the light source - the light immediately looks almost natural, the eyes do not strain and you can work comfortably. In terms of brightness, 0.65 * 2.5 * 12 = 20W of LED lighting is more than enough, and an order of magnitude better than a standard red lamp for developing photo paper. With photoresist, it finally worked out perfectly. Well, as a free bonus - funny multi-colored shadows throughout the room due to multi-colored point light sources. In the photo on the right is a hard-set “daylight” white balance. The eye automatically corrects the color, and the yellow tint does not rush into the eyes.