Product Lifecycle Management System: CAD included

In the comments to our previous article , quite logical claims were expressed, mainly from those who are in the subject. Say, our example of designing a computer case part in the CATIA system is a shaped hammering of nails with a microscope. Indeed, if we transfer the analogy to the IT solutions that are more familiar to Habr users, it’s the same as installing Photoshop only for resizing the image. For example, a simple computer-aided design system can cope with a computer case, but we wanted to start with some simple example.

In the comments to our previous article , quite logical claims were expressed, mainly from those who are in the subject. Say, our example of designing a computer case part in the CATIA system is a shaped hammering of nails with a microscope. Indeed, if we transfer the analogy to the IT solutions that are more familiar to Habr users, it’s the same as installing Photoshop only for resizing the image. For example, a simple computer-aided design system can cope with a computer case, but we wanted to start with some simple example.Now let's move on to the complex and more realistic. One of the customers of Dassault Systemes (a French company) is the French PSA Peugeot Citroen. In the development of cars of this alliance, not only CATIA 3D CAD system is used, but also many other software solutions. Together they form a whole system, which is commonly referred to as PLM (Product Lifecycle Management) - Product Lifecycle Management System. Actually designing a product is only a small part of the entire system.

Great attention is paid to the issue of managing the activities of a large enterprise, which may have thousands of employees, one way or another responsible for a particular project, hundreds of contractors and dozens of problems that arise every minute and need to be addressed. In fact, the PLM system is so multifaceted that it includes many elements of other (also complicated) software systems, the names of which also consist of three letters: CRM, ERP, and so on. Only here is the product put at the forefront, which means that such a solution is for companies creating something that can be touched. For example, cars.

Inside - the beginning of the story about the PLM system from the point of view of the project manager, as well as a simple example of designing a car design in CATIA V6.

The bosses are on the alert!

We start by analyzing the project from a management perspective. What are some typical tasks for a project manager? If in general terms, then this is: to assemble a team of performers, formulate a common task, assign areas of responsibility and monitor implementation, periodically intervening and solving problems. And this - if it is already clear what and how we will produce. And if not?

Suppose a company in the recent past had one successful product (well, for example, Tablet), and now it wants to earn even more money by introducing an updated model on the market (say, Tablet 2). Already at the planning stage, you need to consider many factors. User reviews of the previous product (they want a built-in video camera, three weeks of battery life and a slot for memory cards), economic feasibility (the first model was released less than a year ago, and as a whole it’s not bad to buy), requirements of top management (demoralize competitors, win 100% , no - 110% of the market!), the cost of components (sawing a hole in the housing under the memory card will increase the cost by 10%).

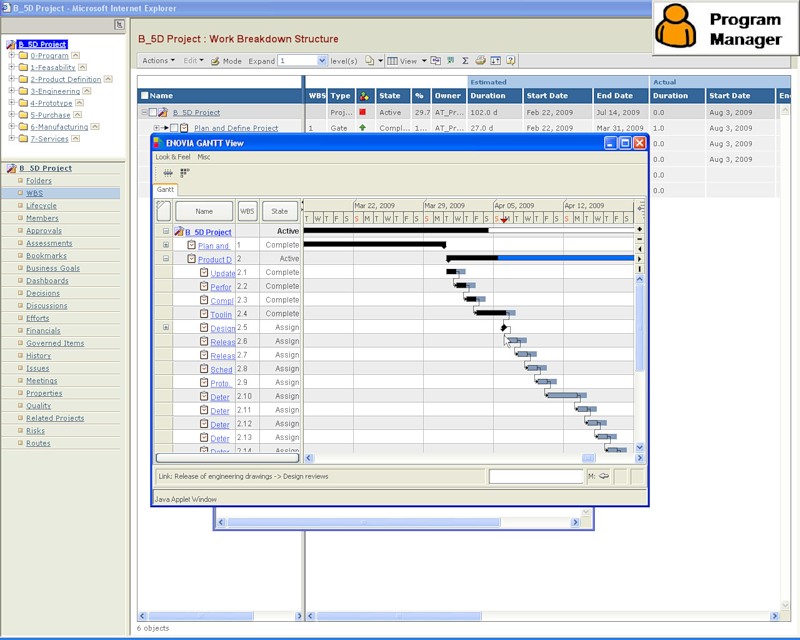

The ENOVIA solution is responsible for the analysis of such information in the Dassault Systemes PLM system. In fact, this is a system of joint development and planning, where each participant has access to “their” data, and the authorities also have the opportunity to see the big picture, and also draw beautiful graphics for overfulfilling plans for even tougher authorities with one click. As applied to the auto industry, such a system may look like this:

Please note that the project is open in the browser. A remote access system is provided: a business trip will not prevent you from observing subordinates. Numerous menus can tell about the stages of the project: tasks, design, creation and testing of a prototype, purchase of components from third parties, production and maintenance. ENOVIA stores the entire history of the car, starting with a fundamental decision on the development and production and ending with the date of discontinuation of production of the latest spare parts for a model that has long been discontinued. You can always trace how effectively work was carried out in certain areas, what to do next, and who is to blame. On the right there is a list of project participants - heads of development areas and simple engineers.

The obvious thing: the project timeline. It is clear that the same can be drawn in "outluk". The difference is that the timing of the development of the smallest details is taken into account: up to the last bulb. ENOVIA stores data on the success of each small task, and as a whole allows to reduce the total amount of inconsistencies that arise in a large organization to reasonable limits.

Back to CATIA

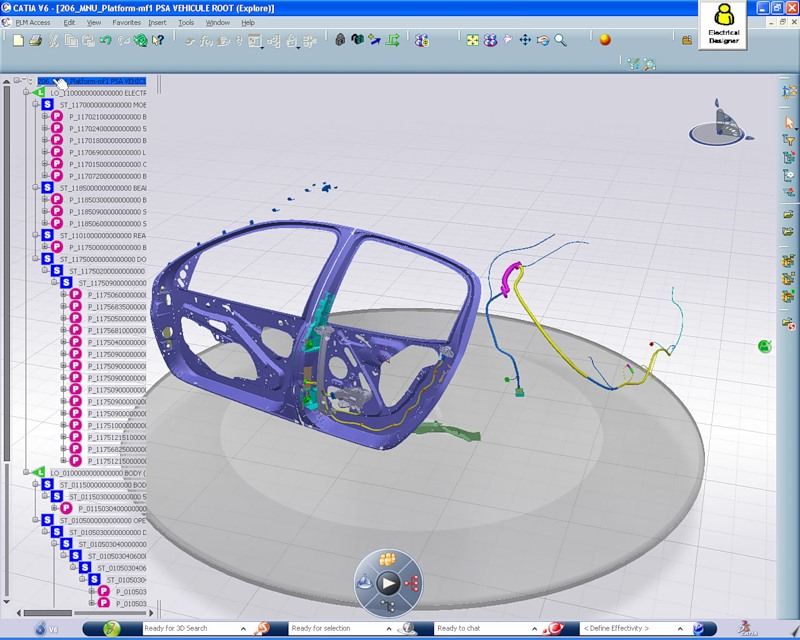

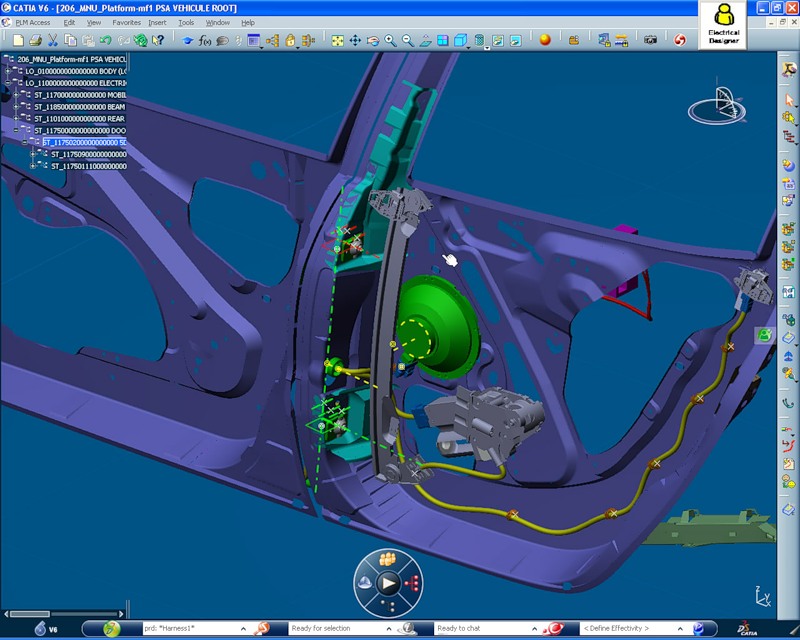

However, let's go down a few levels below, to where the desires of the leadership (to do better, more, more money) are realized by talented engineers and designers. I want to show how the CATIA 3D design system is used to develop real, and very complex products. This time we are dealing with a Peugeot 206, in which we need to refine the built-in audio system. To do this, we open the desired set of parts, in this case, the door where you want to place the speakers.

Compare this with the example from the previous article.: here we are dealing with thousands of elements united in groups: separately body elements, separately electrics, mechanics, etc. Even the opening of such a project, on a powerful multiprocessor workstation, takes a long time, therefore, in the new version of CATIA V6, a special mechanism was invented to help select the very design element that is needed now. Just so as not to waste time.

We increase the necessary detail: here you can also see other elements of the electrics integrated in the door: a mechanism for raising the glass, buttons in the driver's door, limit switches, etc.

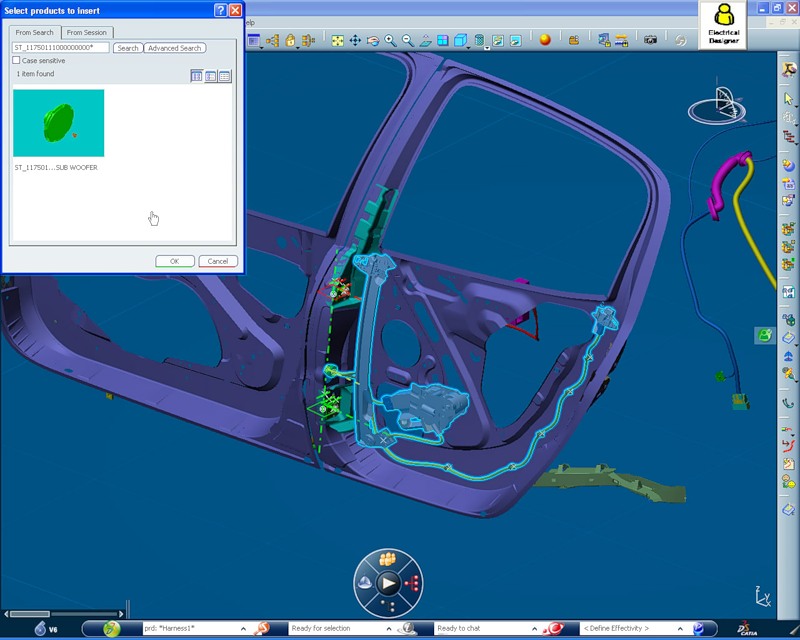

There is no need to design a speaker separately: we simply select it from the list of ready-made elements.

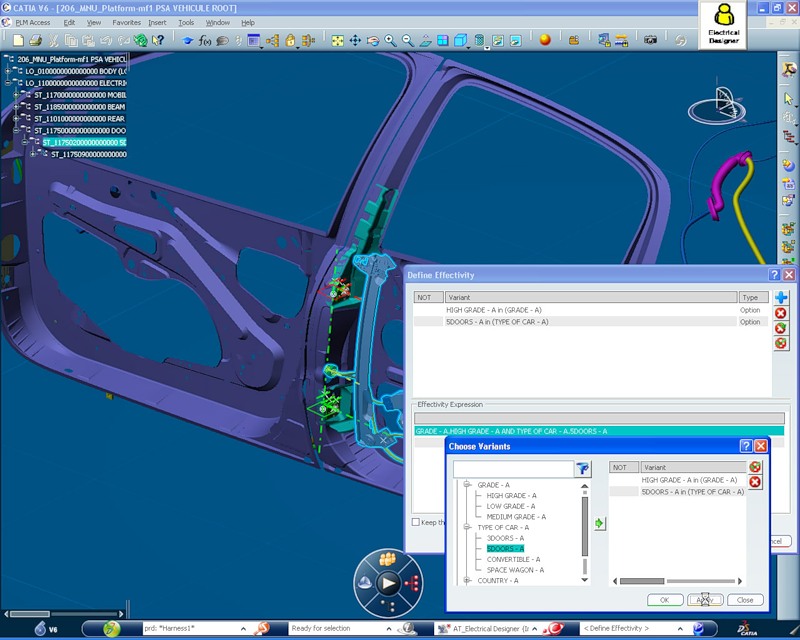

And indicate the modification of the car (five-door), as well as the type of configuration.

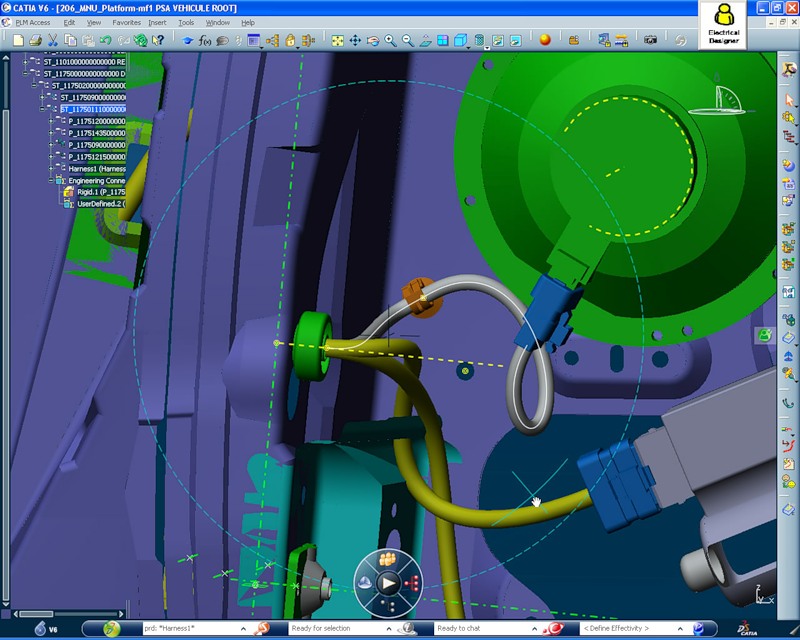

We place the speaker in the door. Naturally, this is not limited to everything: you need to think about connecting a speaker and outputting a cable to the car interior.

An intermediate mount is already provided for the cable inside the housing.

It remains to indicate the main reference points for the tourniquet. The first option is not very successful: the tourniquet is very tight and from vibration may burst, or the mount may fly off.

Therefore, we are moving the intermediate hardware to a new location.

And we get a more reliable design. Here is the full video of this design phase (it is better to open the link and watch in 720p format):

It remains only to update the project, after which our contribution will become available to other participants in the development of the car. That's all for now, but in the next article we will show work on the car suspension from this project, and also give some more examples of project management using Dassault Systemes solutions.