The pitfalls of 3D printing: Does everyone need such a printer

Marketers vied with each other to describe the merits of 3D printers using FDM technology. However, is a happy buyer really becoming the owner of a “magic box” capable of reproducing any plastic part, or is it a DIY tool, like an engraver or a burning device, and will not be useful to everyone?

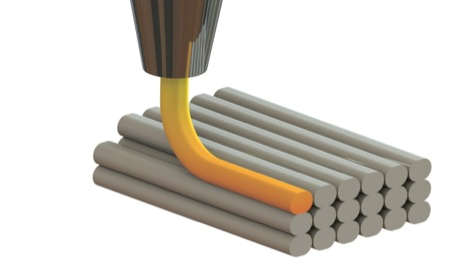

FDM or Fused deposition modeling (as well as FFF or Fused Filament Fabrication) is an additive method of “growing” objects, on the basis of which almost all modern “household” 3D printers are built. The technique implies a layer-by-layer “growing” of an object from molten plastic fed in the form of a rod.

The idea was originally patented, but the patent expired and after that inexpensive 3D printers of various manufacturers — from eminent Americans to nameless Chinese — rushed onto the market for every taste and budget. Someone chooses by brand - however, if you have knowledge of electronics and the desire to solve emerging problems on your own (without technical support from the manufacturer), you can save money by purchasing a kit or even assembling a printer from scratch on one of the hundreds of published models.

FDM technology is really impressive. Today it is no longer just a tool for rapid prototyping for designers and architects. In fact, having a three-dimensional model of the object, we can reproduce it at home, if necessary, change the scale or slightly modify it in the editor. For example, you can download the model of attachment for the phone in the car and scale it for your own device. Or from scratch to draw any household detail - from the lampshade on the lamp to the door handle, not to mention all sorts of trivialities like homemade mounts to the GoPro, elements of children's designers, etc.

Of course, 3D printing cannot replace a conveyor with mass production - the speed of layer-by-layer formation of plastic parts is low, so one “typical” printer can serve, at best, only the requests of its owner. But the task obzkakat existing production technology and not worth it. 3D printing rules where you need maximum customization and serial production would be totally unprofitable. Therefore, she is very fond of DIY fans in various fields, etc. In essence, a 3D printer is a DIY tool.

Household 3D printing is now experiencing explosive growth. The FDM technology is quite simple, and the community of enthusiasts has already developed several typical designs of such printers, differing in the methods of bar feeding and kinematics. On the basis of these standard designs, both branded printers and dozens, if not hundreds of home-made designs, individual parts or even complete kit-sets to which you can buy on Ebay or AliExpress are created.

It would seem that technology is running around, getting cheaper, while there is already a serious demand for it. Isn’t this a guarantee of imminent grandiose success in the mass market (as it already happened with mobile phones, digital cameras, and a little bit earlier - with computers)? Is it time to buy?

It seems to us not to hurry. FDM technology is quite capricious, and so far it is far from becoming a kind of “digital camera” or “washing machine” in the hands of an unknowing user. Almost every corner here has to apply engineering thought. In fairness it should be noted that if your engineering is okay, then the possibilities of 3D printing are really huge. But it is better to know in advance what you "subscribe" to.

Layer-by-layer application requires special preparation of the models and the surface on which printing is carried out, plus post-processing of parts will be needed.

The printer comes with a glass or metal table - not any material will stick on them without additional tweaks (and not any then will come off without disturbing the geometry of the model). PLA-plastic can be printed on the table without heating, using a coating of blue adhesive tape - a very durable painting tape from 3M, which now enterprising users have been re-trained in "adhesive tape for 3D printing." The overwhelming majority of thermoplastics need at least a heated table, and sometimes additional adhesive coatings (varnish, glue, beer, acetone syrup, etc. - there are lots of user-tested options). Finding the right coating for this printer (and plastic) is the way of experiments and errors. We'll have to spoil more than one model before there is the best option.

But the seal of the first layer of the problem is not limited. The molten plastic thread cannot hang in the air, respectively, on strongly protruding parts (for example, parts with a reverse bias) support is needed, which at the end of printing will need to be cut, somehow processing the cut point so that there are no sharp edges. It should be noted that the most ordinary vertical wall after the 3D printer will not be perfectly smooth (at least the layer boundaries will be noticeable, and maybe other defects). So post-processing will be required for almost all parts for which surface qualities are important.

Not all plastics lend themselves well to post-processing. Those who print a lot and different materials will have to have a whole set of solvents, hand tools, etc. at home. (as well as those who are actively entertained DIY). By the way, at the same time part of the plastics is also toxic when printing - so we need closed shells, hoods, etc.

Characteristics of the result are highly dependent on consumables.

Quality problems can be determined not only by factory defects, but also by completely “regular” features of the material used: for example, some types of plastic are hygroscopic (absorb water from the environment). If you do not store such plastic in tightly closed bags of silica gel, the bar becomes fragile, can break when serving, produce strange sounds when printing, it is not good to lie on the model, etc.

In general, even if the quality of the material is high (no obvious problems), not any model is suitable for printing with a certain plastic. Some materials are fragile and do not allow thin walls to be printed, others, on the contrary, are well stratified in volume.

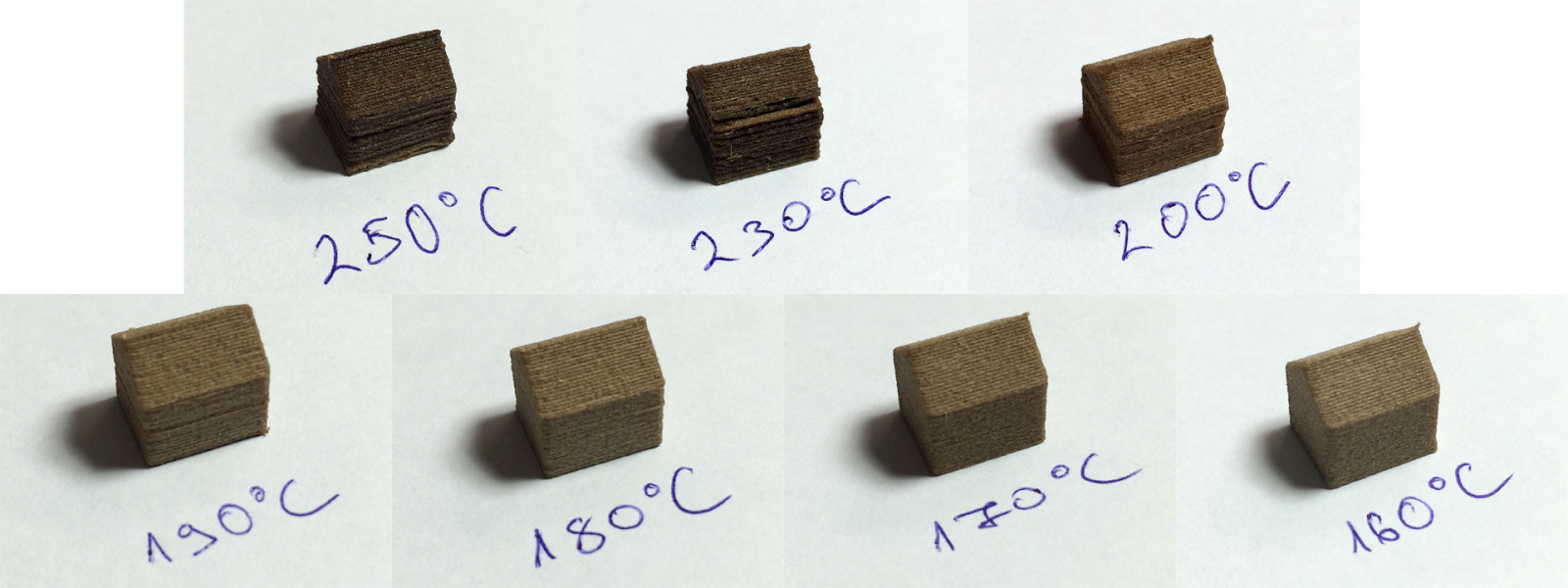

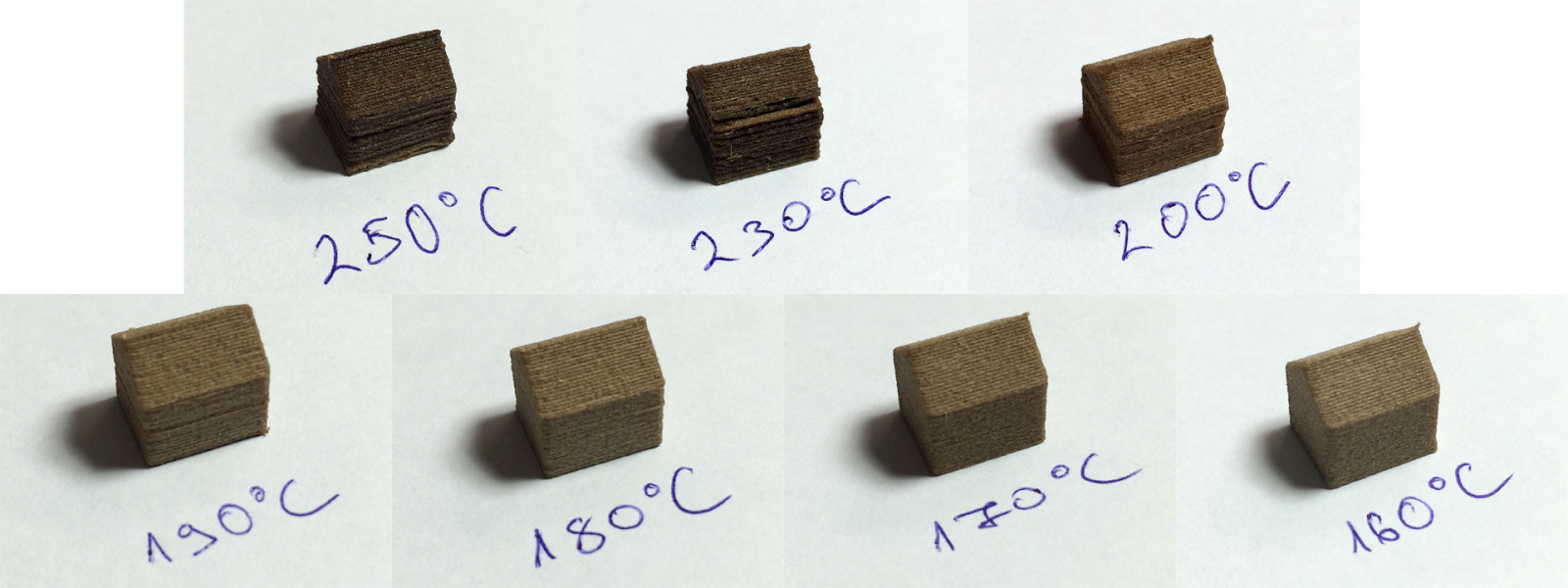

Each plastic has its own optimum print temperature. If it is exceeded, the detailing deteriorates and surface defects appear. In the reverse situation, layers are poorly sintered. Similarly, there are optimal layer thickness, retract parameters (reverse movement of the thread) and other similar parameters.

Many print flaws can be “compensated” by reducing speed. But it is rightly said that the main problem is not to print the object, but to do it in a reasonable time. Therefore, for objects more than a matchbox, you will have to deal with the optimal settings for each plastic.

The difficulty is added by the fact that the detailed settings are not prompted by the “colleagues” on the forum - the optimal parameters are largely determined by the printer itself: how well the temperature sensor is calibrated; whether remote feed is used, etc. Plus, the final figures may differ for the same plastic from different manufacturers, as well as for coils of different colors from the same manufacturer.

The printer itself is able to be capricious. Each of the existing structures on the market has its drawbacks. Somewhere the motors, which need to be perfectly synchronized, work a little wrong; somewhere - the table oscillates while printing at high speed; somewhere too much of a contribution comes from the weight of the printhead. Similarly, there are "sore spots" that will come out regardless of whether it is a self-assembled printer, a whale printer, or purchased as a "black box from the manufacturer." In the first two cases, the probability of getting glitches is somewhat higher, but the corporate origin does not eliminate the device from “typical” diseases.

In an average 3D printer, there are quite a few moving parts, and mechanics have their own working resource. In some devices, plastic gears are worn off, in others, a Teflon tube is being gradually eaten by a fitting, etc. Sooner or later, such small flaws begin to affect the print result. Alas, but there is no universal FAQ that helps to catch the problem by the final result. Here, as in old cars - you need to look for colleagues in misfortune, study the forums and hope that someone has already encountered this problem. Or - as an option - find out which node is to blame for the problem, and shake it up completely. But this is more like building your own printer from scratch.

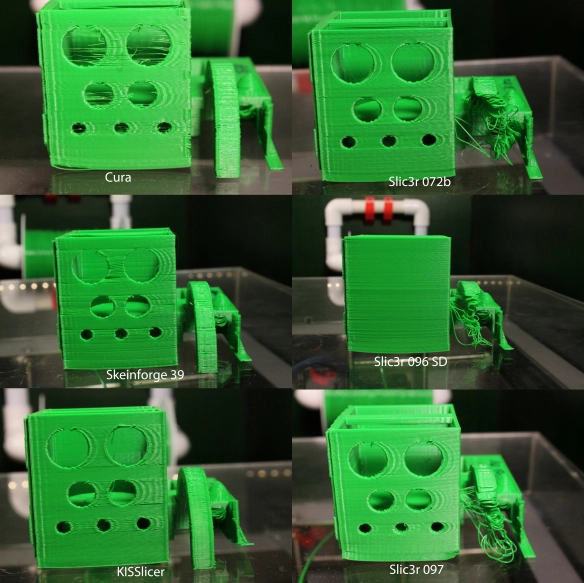

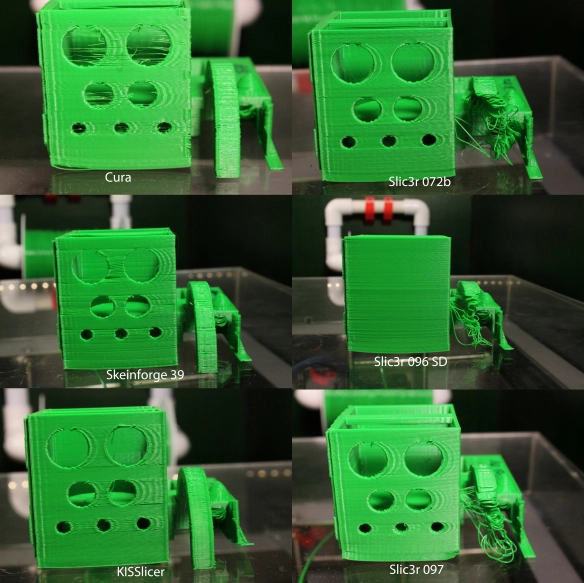

Before tens of meters of the bar become a viable object, the model must undergo a slitting procedure — cutting into layers, taking into account the technical characteristics of the printer — nozzle size, layer thickness, etc. A slicer can “break wood” if the original model is not closed (it happens that the simplest model produces holes - in the most direct sense). For the "treatment" of models, there are online services and tools in specialized software, but they do not always cope with the task. At the same time, they themselves may well “lose” some details.

Frankly, the slicer can be wrong, even if the model is completely normal, and the reason is rounding. If the shaft pitch on some axis is not proportional to the layer thickness, when slicing, the rounding error will accumulate, which on the model manifests itself in the form of a corrugated surface.

If we talk more globally, the main problem of consumer 3D printing in the existing version is the lack of feedback when growing the model: the printer simply does not see what it is printing. There are temperature sensors, thread jams and other tools, but the appearance of the model is not evaluated in any way. The only feedback goes through the user, who interprets what is happening in his own way.

As a result, a 3D printer today is not exactly a household appliance. It can not be compared with a conventional printer and even more so with any washing machine. Can you imagine if for a successful washing of clothes you had to select the frequency of rotation of the drum of the machine during the experiments, changing it through the firmware? Yes, for some it was really interesting, but hardly for the majority.

3D printer closest to power tools. This is a great tool for creating objects, but you need to know how to use them. Unfortunately, at the moment this idea is not quite readable in the advertising of some 3D printers - as a result, a quite noticeable share of disappointed customers appears, who have been waiting for miracles from science fiction, and who have received an unused junk stand at home.

In my opinion, in the future, 3D printing technology still has a chance to become truly domestic. First of all, FDM is developing rapidly: firmware is being improved, new sensors are being added, etc. At the same time, volumes of Russian-language documentation, which is quite understandable to non-specialists, are growing exponentially.

Secondly, printers using a different technology, the laser sintering method (SLS), began to enter the consumer market in the past and the year before, since patent restrictions on SLS ended in 2014. However, while the cost of devices exceeds 5 thousand dollars. So for now, speaking of consumer 3D printing, we still mean FDM with all the attendant problems.

FDM or Fused deposition modeling (as well as FFF or Fused Filament Fabrication) is an additive method of “growing” objects, on the basis of which almost all modern “household” 3D printers are built. The technique implies a layer-by-layer “growing” of an object from molten plastic fed in the form of a rod.

The idea was originally patented, but the patent expired and after that inexpensive 3D printers of various manufacturers — from eminent Americans to nameless Chinese — rushed onto the market for every taste and budget. Someone chooses by brand - however, if you have knowledge of electronics and the desire to solve emerging problems on your own (without technical support from the manufacturer), you can save money by purchasing a kit or even assembling a printer from scratch on one of the hundreds of published models.

A barrel of honey

FDM technology is really impressive. Today it is no longer just a tool for rapid prototyping for designers and architects. In fact, having a three-dimensional model of the object, we can reproduce it at home, if necessary, change the scale or slightly modify it in the editor. For example, you can download the model of attachment for the phone in the car and scale it for your own device. Or from scratch to draw any household detail - from the lampshade on the lamp to the door handle, not to mention all sorts of trivialities like homemade mounts to the GoPro, elements of children's designers, etc.

Of course, 3D printing cannot replace a conveyor with mass production - the speed of layer-by-layer formation of plastic parts is low, so one “typical” printer can serve, at best, only the requests of its owner. But the task obzkakat existing production technology and not worth it. 3D printing rules where you need maximum customization and serial production would be totally unprofitable. Therefore, she is very fond of DIY fans in various fields, etc. In essence, a 3D printer is a DIY tool.

Household 3D printing is now experiencing explosive growth. The FDM technology is quite simple, and the community of enthusiasts has already developed several typical designs of such printers, differing in the methods of bar feeding and kinematics. On the basis of these standard designs, both branded printers and dozens, if not hundreds of home-made designs, individual parts or even complete kit-sets to which you can buy on Ebay or AliExpress are created.

Tar ... also a barrel?

It would seem that technology is running around, getting cheaper, while there is already a serious demand for it. Isn’t this a guarantee of imminent grandiose success in the mass market (as it already happened with mobile phones, digital cameras, and a little bit earlier - with computers)? Is it time to buy?

It seems to us not to hurry. FDM technology is quite capricious, and so far it is far from becoming a kind of “digital camera” or “washing machine” in the hands of an unknowing user. Almost every corner here has to apply engineering thought. In fairness it should be noted that if your engineering is okay, then the possibilities of 3D printing are really huge. But it is better to know in advance what you "subscribe" to.

Table processing and models

Layer-by-layer application requires special preparation of the models and the surface on which printing is carried out, plus post-processing of parts will be needed.

The printer comes with a glass or metal table - not any material will stick on them without additional tweaks (and not any then will come off without disturbing the geometry of the model). PLA-plastic can be printed on the table without heating, using a coating of blue adhesive tape - a very durable painting tape from 3M, which now enterprising users have been re-trained in "adhesive tape for 3D printing." The overwhelming majority of thermoplastics need at least a heated table, and sometimes additional adhesive coatings (varnish, glue, beer, acetone syrup, etc. - there are lots of user-tested options). Finding the right coating for this printer (and plastic) is the way of experiments and errors. We'll have to spoil more than one model before there is the best option.

But the seal of the first layer of the problem is not limited. The molten plastic thread cannot hang in the air, respectively, on strongly protruding parts (for example, parts with a reverse bias) support is needed, which at the end of printing will need to be cut, somehow processing the cut point so that there are no sharp edges. It should be noted that the most ordinary vertical wall after the 3D printer will not be perfectly smooth (at least the layer boundaries will be noticeable, and maybe other defects). So post-processing will be required for almost all parts for which surface qualities are important.

Not all plastics lend themselves well to post-processing. Those who print a lot and different materials will have to have a whole set of solvents, hand tools, etc. at home. (as well as those who are actively entertained DIY). By the way, at the same time part of the plastics is also toxic when printing - so we need closed shells, hoods, etc.

Features of consumables

Characteristics of the result are highly dependent on consumables.

Quality problems can be determined not only by factory defects, but also by completely “regular” features of the material used: for example, some types of plastic are hygroscopic (absorb water from the environment). If you do not store such plastic in tightly closed bags of silica gel, the bar becomes fragile, can break when serving, produce strange sounds when printing, it is not good to lie on the model, etc.

In general, even if the quality of the material is high (no obvious problems), not any model is suitable for printing with a certain plastic. Some materials are fragile and do not allow thin walls to be printed, others, on the contrary, are well stratified in volume.

Each plastic has its own optimum print temperature. If it is exceeded, the detailing deteriorates and surface defects appear. In the reverse situation, layers are poorly sintered. Similarly, there are optimal layer thickness, retract parameters (reverse movement of the thread) and other similar parameters.

Many print flaws can be “compensated” by reducing speed. But it is rightly said that the main problem is not to print the object, but to do it in a reasonable time. Therefore, for objects more than a matchbox, you will have to deal with the optimal settings for each plastic.

The difficulty is added by the fact that the detailed settings are not prompted by the “colleagues” on the forum - the optimal parameters are largely determined by the printer itself: how well the temperature sensor is calibrated; whether remote feed is used, etc. Plus, the final figures may differ for the same plastic from different manufacturers, as well as for coils of different colors from the same manufacturer.

Printer Tricks

The printer itself is able to be capricious. Each of the existing structures on the market has its drawbacks. Somewhere the motors, which need to be perfectly synchronized, work a little wrong; somewhere - the table oscillates while printing at high speed; somewhere too much of a contribution comes from the weight of the printhead. Similarly, there are "sore spots" that will come out regardless of whether it is a self-assembled printer, a whale printer, or purchased as a "black box from the manufacturer." In the first two cases, the probability of getting glitches is somewhat higher, but the corporate origin does not eliminate the device from “typical” diseases.

In an average 3D printer, there are quite a few moving parts, and mechanics have their own working resource. In some devices, plastic gears are worn off, in others, a Teflon tube is being gradually eaten by a fitting, etc. Sooner or later, such small flaws begin to affect the print result. Alas, but there is no universal FAQ that helps to catch the problem by the final result. Here, as in old cars - you need to look for colleagues in misfortune, study the forums and hope that someone has already encountered this problem. Or - as an option - find out which node is to blame for the problem, and shake it up completely. But this is more like building your own printer from scratch.

Software errors

Before tens of meters of the bar become a viable object, the model must undergo a slitting procedure — cutting into layers, taking into account the technical characteristics of the printer — nozzle size, layer thickness, etc. A slicer can “break wood” if the original model is not closed (it happens that the simplest model produces holes - in the most direct sense). For the "treatment" of models, there are online services and tools in specialized software, but they do not always cope with the task. At the same time, they themselves may well “lose” some details.

Frankly, the slicer can be wrong, even if the model is completely normal, and the reason is rounding. If the shaft pitch on some axis is not proportional to the layer thickness, when slicing, the rounding error will accumulate, which on the model manifests itself in the form of a corrugated surface.

If we talk more globally, the main problem of consumer 3D printing in the existing version is the lack of feedback when growing the model: the printer simply does not see what it is printing. There are temperature sensors, thread jams and other tools, but the appearance of the model is not evaluated in any way. The only feedback goes through the user, who interprets what is happening in his own way.

As a result, a 3D printer today is not exactly a household appliance. It can not be compared with a conventional printer and even more so with any washing machine. Can you imagine if for a successful washing of clothes you had to select the frequency of rotation of the drum of the machine during the experiments, changing it through the firmware? Yes, for some it was really interesting, but hardly for the majority.

3D printer closest to power tools. This is a great tool for creating objects, but you need to know how to use them. Unfortunately, at the moment this idea is not quite readable in the advertising of some 3D printers - as a result, a quite noticeable share of disappointed customers appears, who have been waiting for miracles from science fiction, and who have received an unused junk stand at home.

Future

In my opinion, in the future, 3D printing technology still has a chance to become truly domestic. First of all, FDM is developing rapidly: firmware is being improved, new sensors are being added, etc. At the same time, volumes of Russian-language documentation, which is quite understandable to non-specialists, are growing exponentially.

Secondly, printers using a different technology, the laser sintering method (SLS), began to enter the consumer market in the past and the year before, since patent restrictions on SLS ended in 2014. However, while the cost of devices exceeds 5 thousand dollars. So for now, speaking of consumer 3D printing, we still mean FDM with all the attendant problems.