Wanhao Duplicator 7 changes the rules of the game

Most recently, sales of the long-awaited Wanhao Duplicator 7 3D printer started .

This is the first Wanhao DLP printer. The Chinese company Wanhao

today is the world leader in the production of desktop 3D-printers

working on FDM technology, last year the company produced 67,000 printers. The goal of

Wanhao is to create low-cost 3D printers available even to students, because only 5 years

ago, the creators of the company themselves were students who were passionate about 3D printing.

The DLP method is an alternative to the SLA technology, where instead of laser installations

LED projectors are used. DLP printing is based on photopolymer resins,

hardening when irradiated with ultraviolet light. DLP printers project an

image of the whole layer until the polymer resin hardens, after which the

next layer is applied and the image of the new digital model is projected. In comparison with SLA,

one can distinguish such an advantage as lower cost of projectors compared to

laser emitters. Accordingly, the price of DLP-printers below stereolithography.

Nevertheless, Wanhao Duplicator 7 is not exactly a DLP printer, since it

uses an integrated LCD screen as a light source to illuminate the photopolymer, this solution

reduced the cost of the printer by an order of magnitude and made this model accessible to all

wishing to try a completely different technology of 3D printing, which makes it possible to

create more complex models with a higher quality surface model.

The recommended retail price of the printer is 36 900 rubles!

For a high-precision 3D printer printing photopolymers, this is a fantastically low price.

Completion and appearance of the

D7 is made in a concise, simple design with a removable massive lid. The 3D printer is

small, weighs only 12 kg.

Grade may seem ascetic, but as practice has shown - this is quite enough.

Work table

Constructive

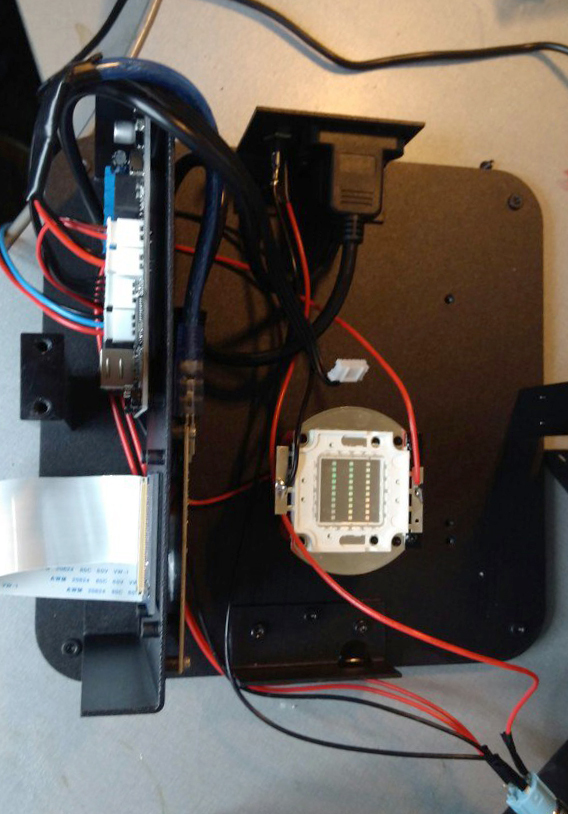

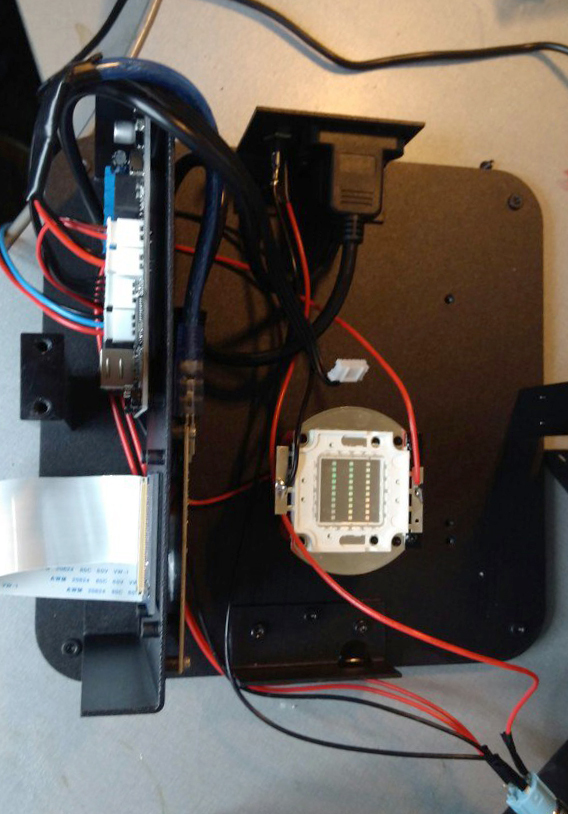

An LED matrix with an LCD screen is used as a projector. The principle is very simple

- the light from the matrix is sent to the screen and, depending on the picture, either passes light or

not. For printing, any photopolymer that hardens at 405 nm UV wave is suitable.

Control board:

LED matrix:

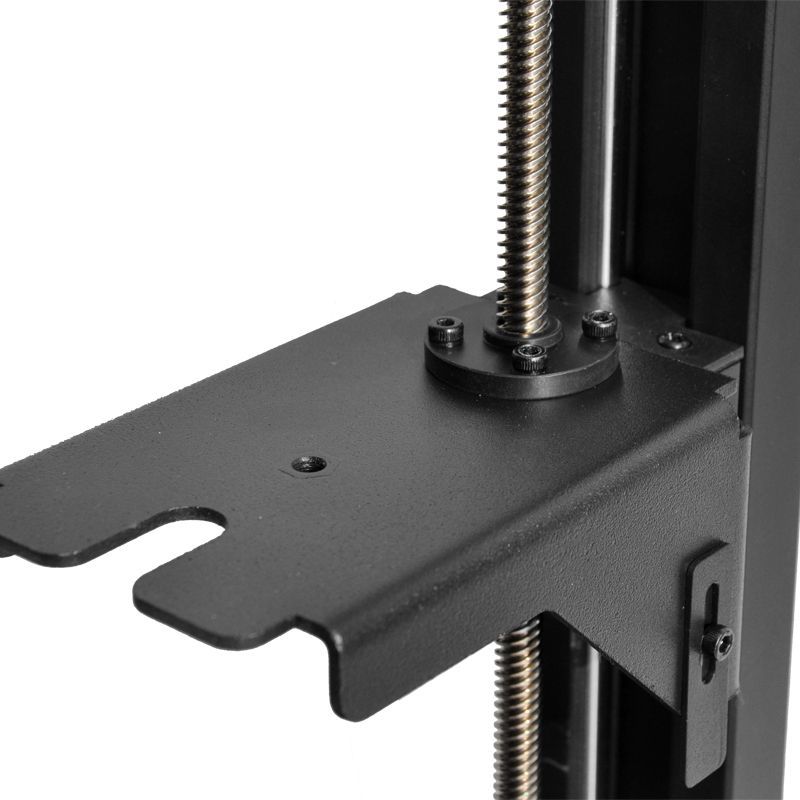

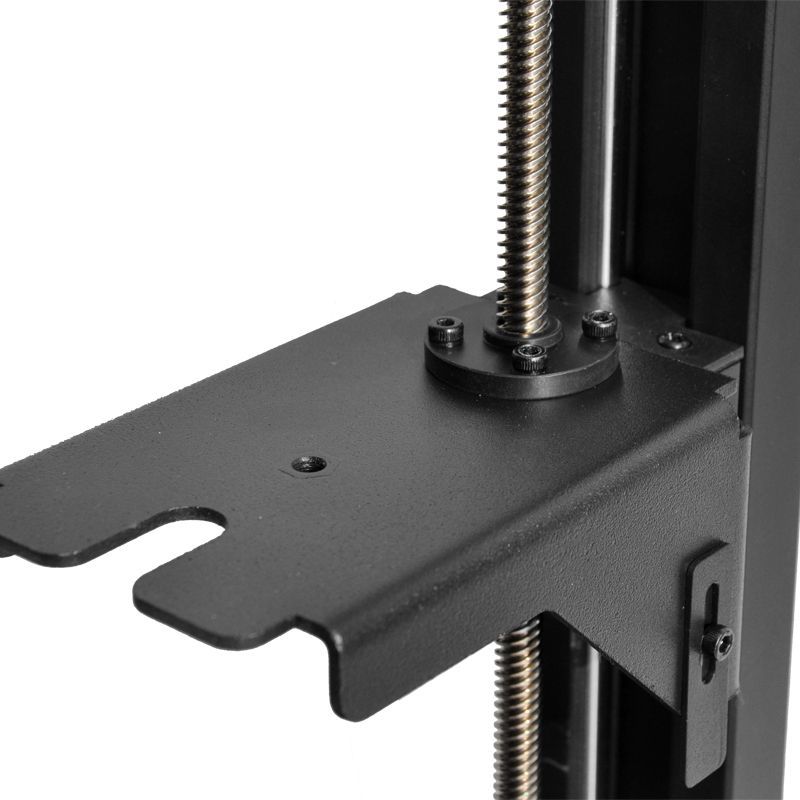

Already trapezoidal screw along the Z axis.

Printed bath is a bit atypical. It is a metal frame on

which the film is stretched below.

This design allows you to simply replace the film. Although you have to

twist / twist as much as 22 bolts! Fortunately, replacing the film is required less frequently. For all

the time of our use of the Duplicator 7 replacement was needed only once after a bad

print.

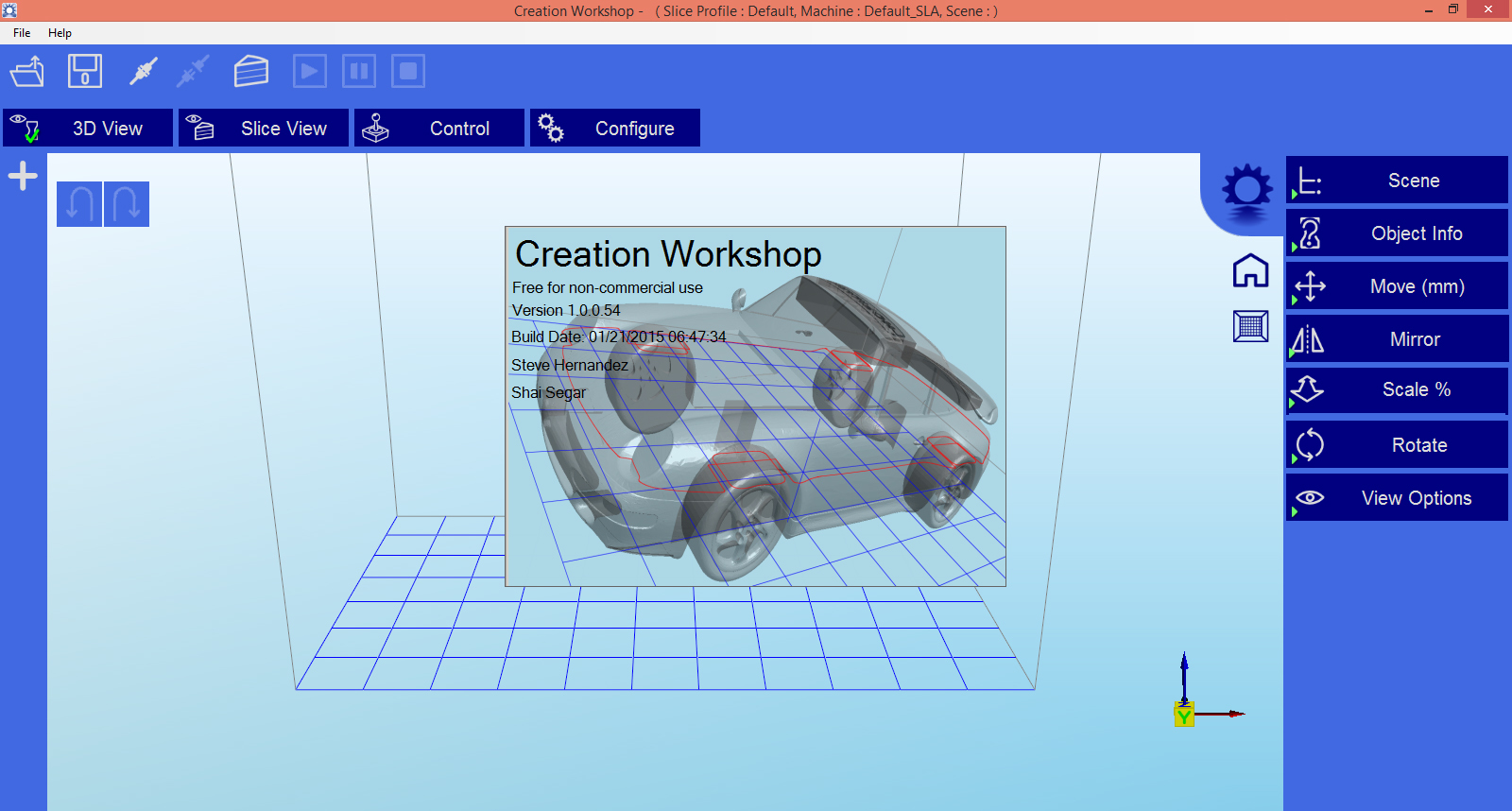

Software

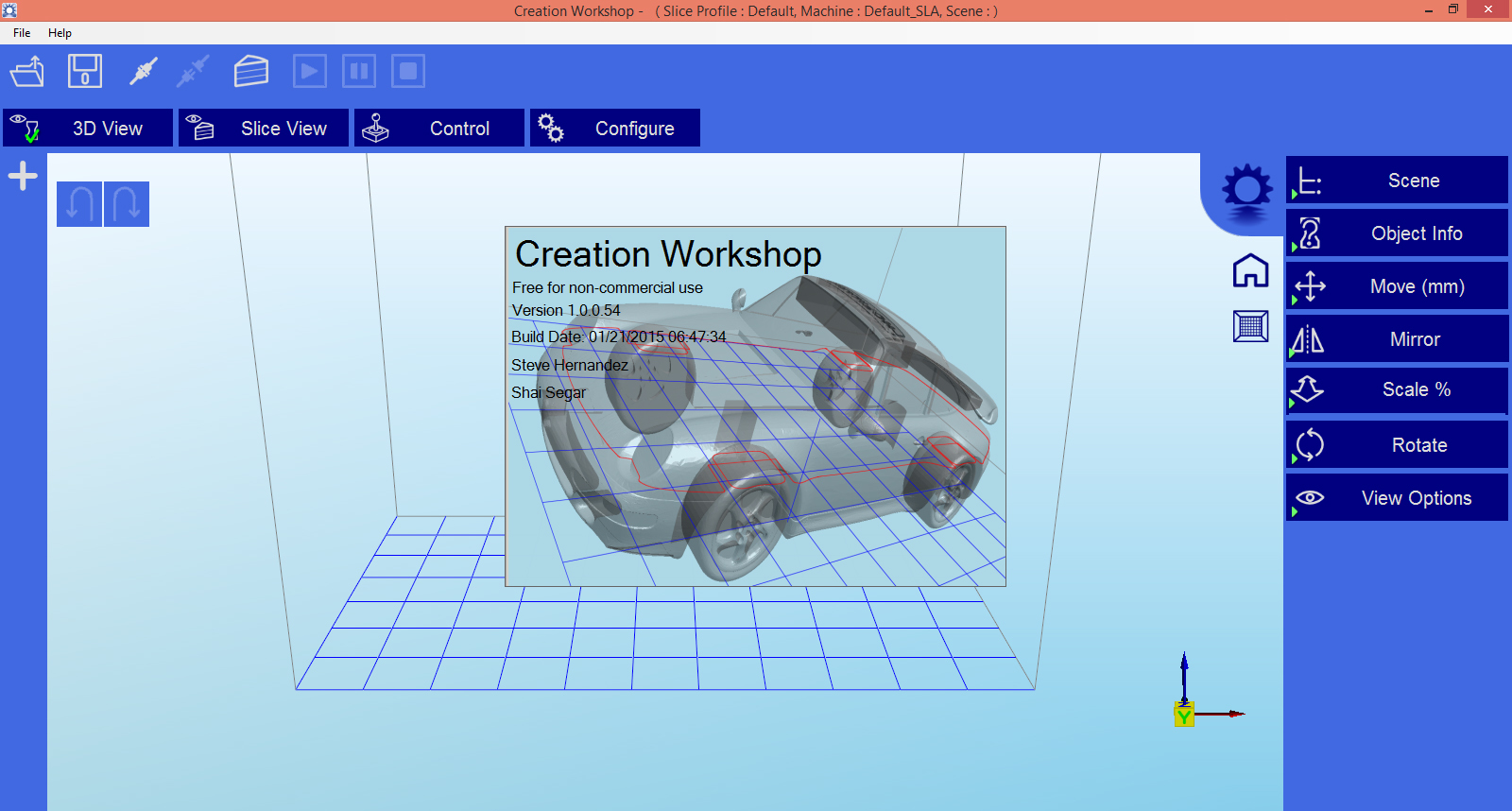

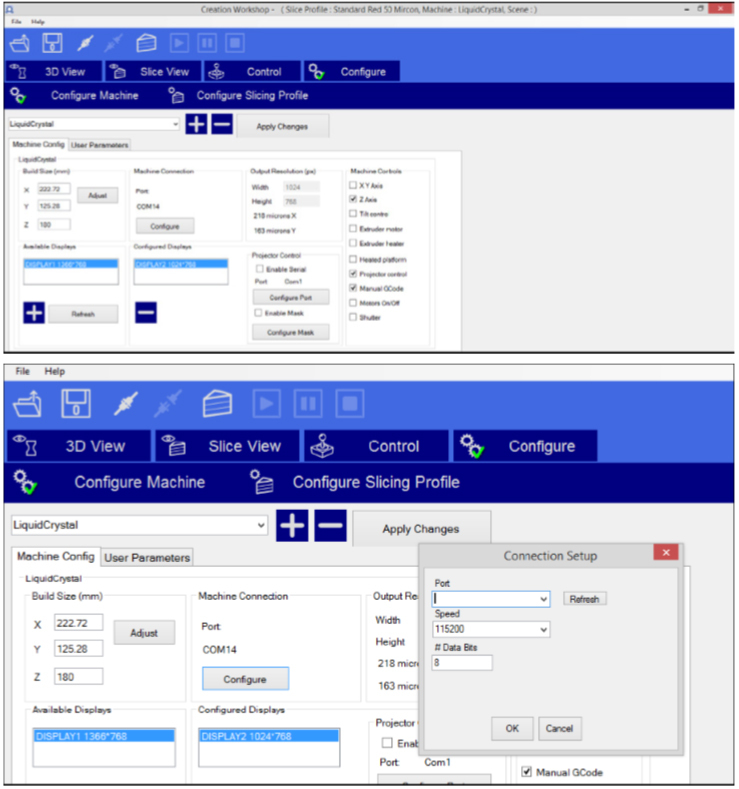

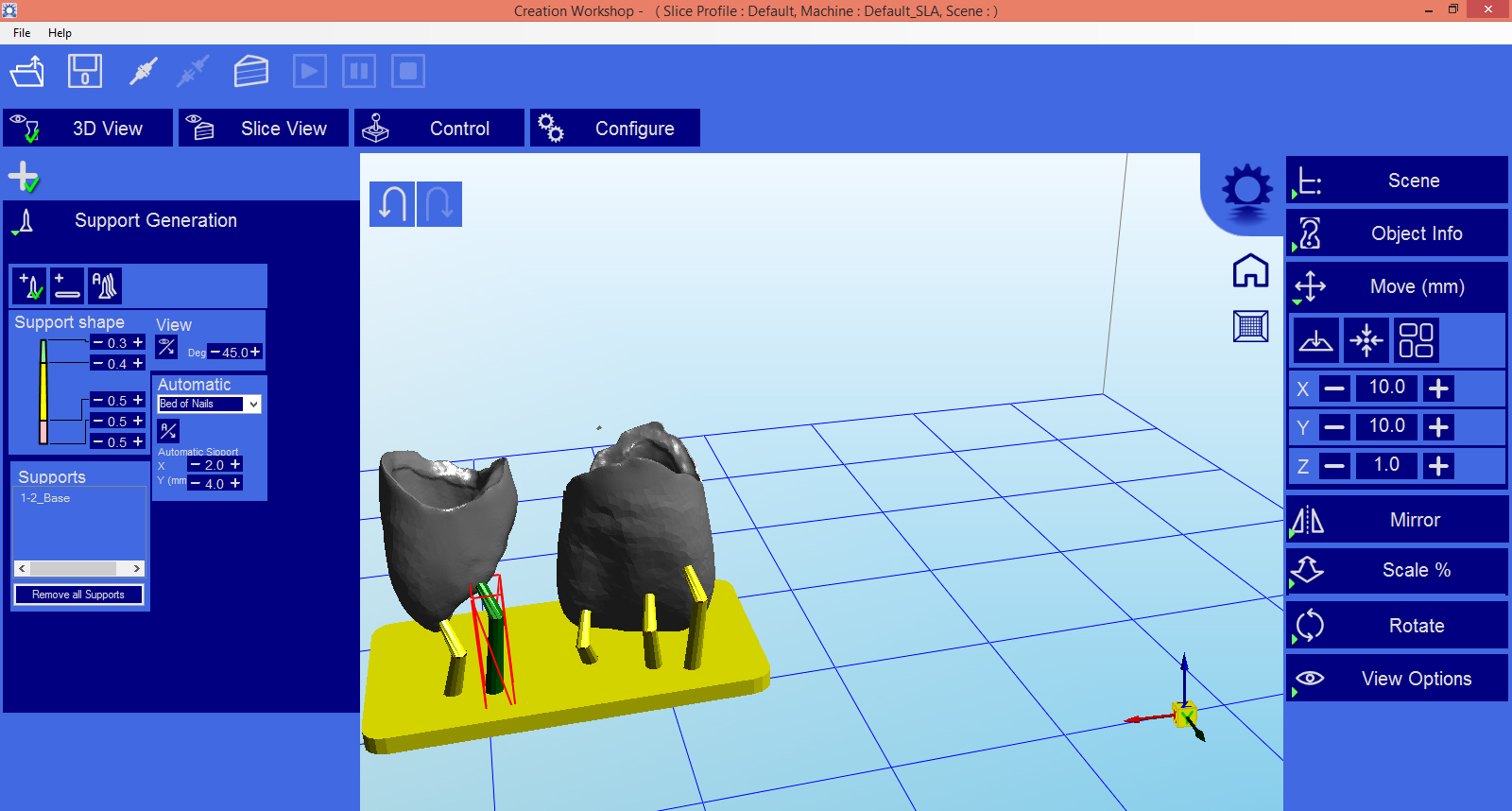

As a default slicer, it is proposed to use the Creation Workshop.

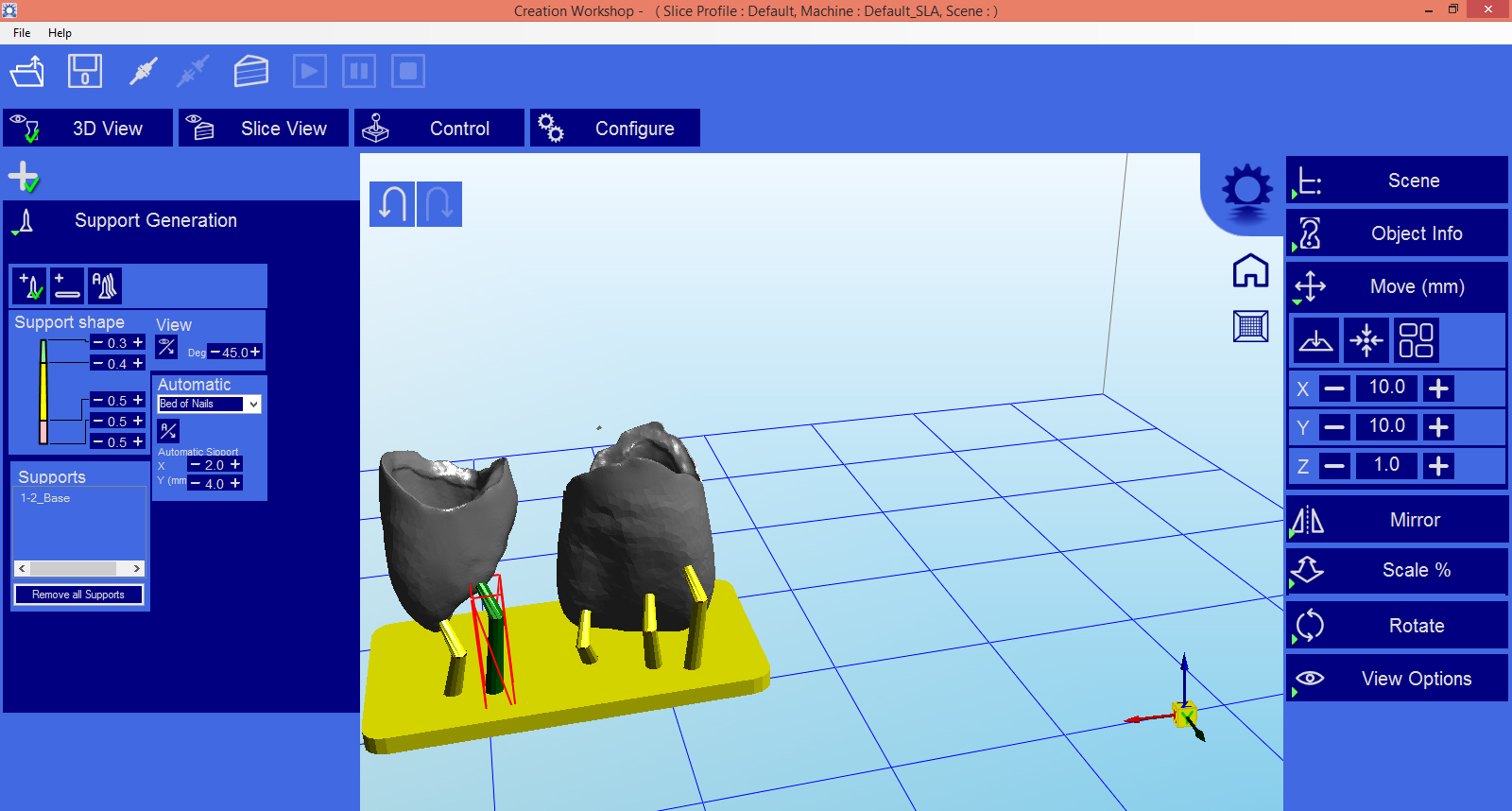

At first, the Creation Workshop seemed a bit unusual, but overall, the slicer is good enough. Of the main advantages I want to highlight the possibility of manual editing supports. Often it helps a lot.

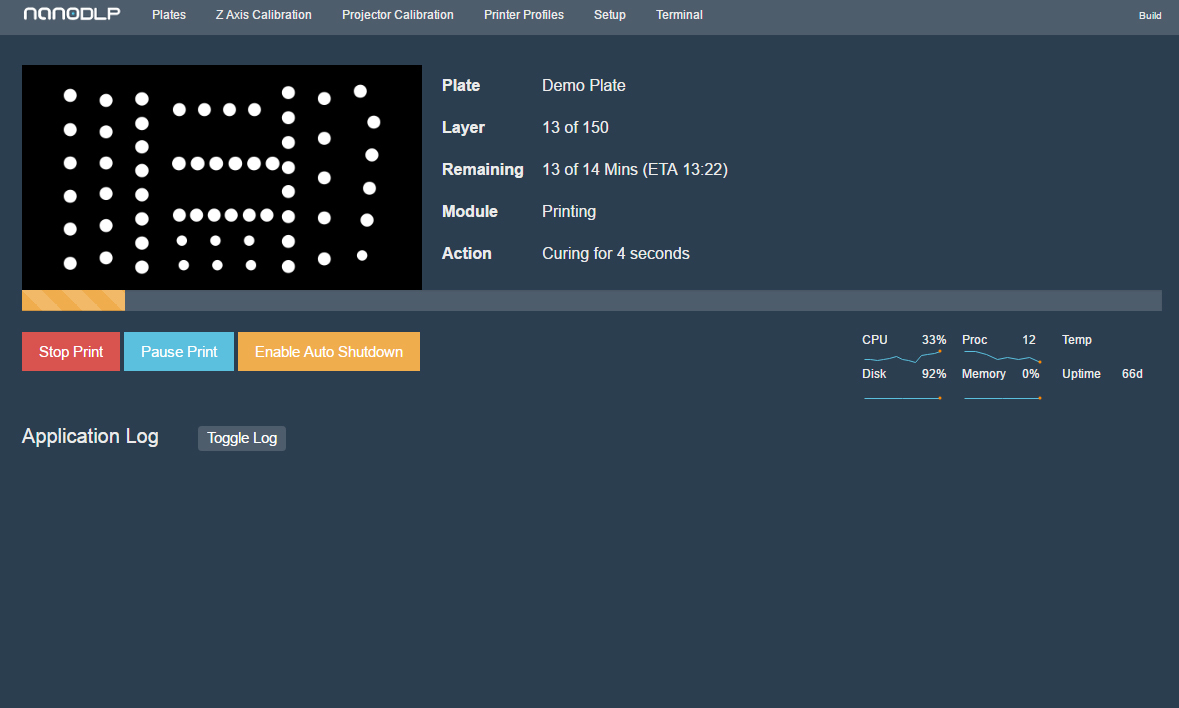

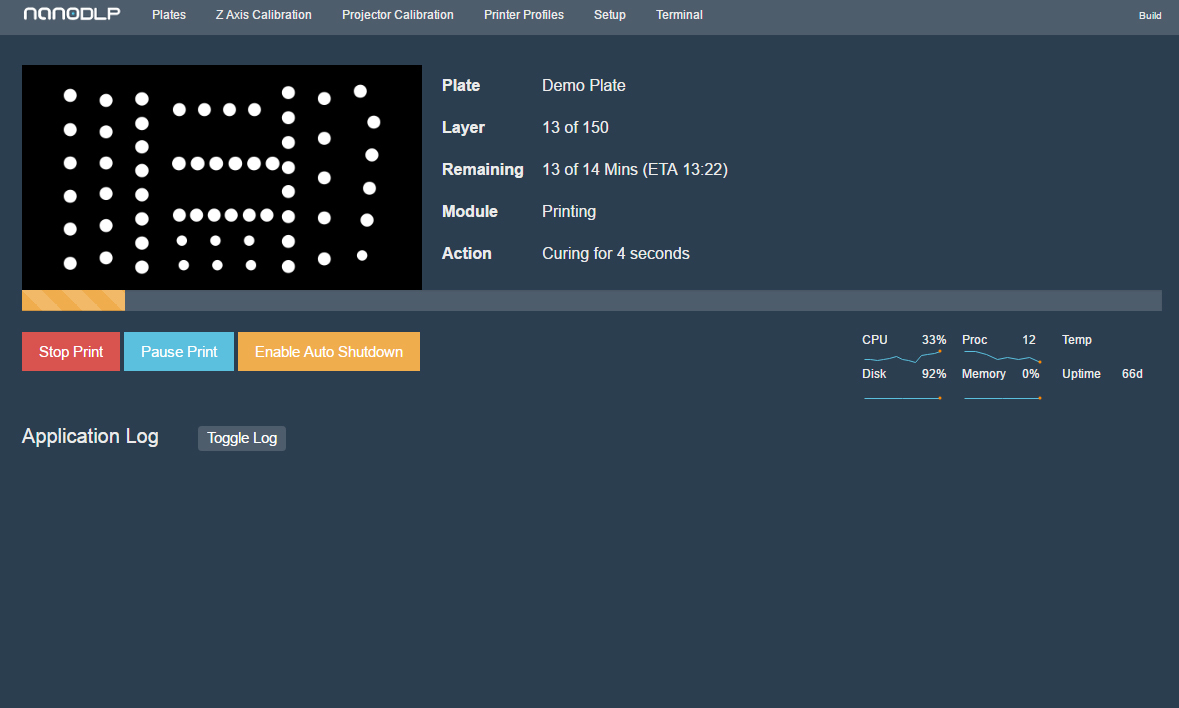

Can also be used as a NanoDLP slicer.

To do this, you need to download the firmware on the Wanhao website to use the NanoDLP and “flash” the

printer. This can be easily done with CURA. Detailed instructions can be

found on the official website of Wanhao.

Preparation for printing

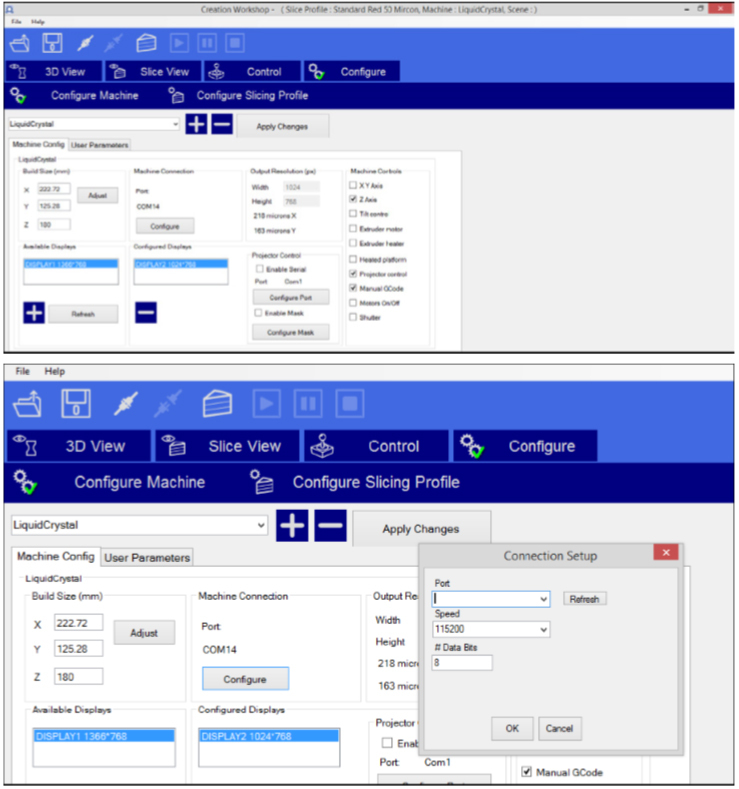

To connect Duplicator 7, you need a video card with two HDMI outputs. We connect the 3D-

printer, which is defined as the “second monitor”. Additionally, we connect the printer via

USB. Next, run the slicer.

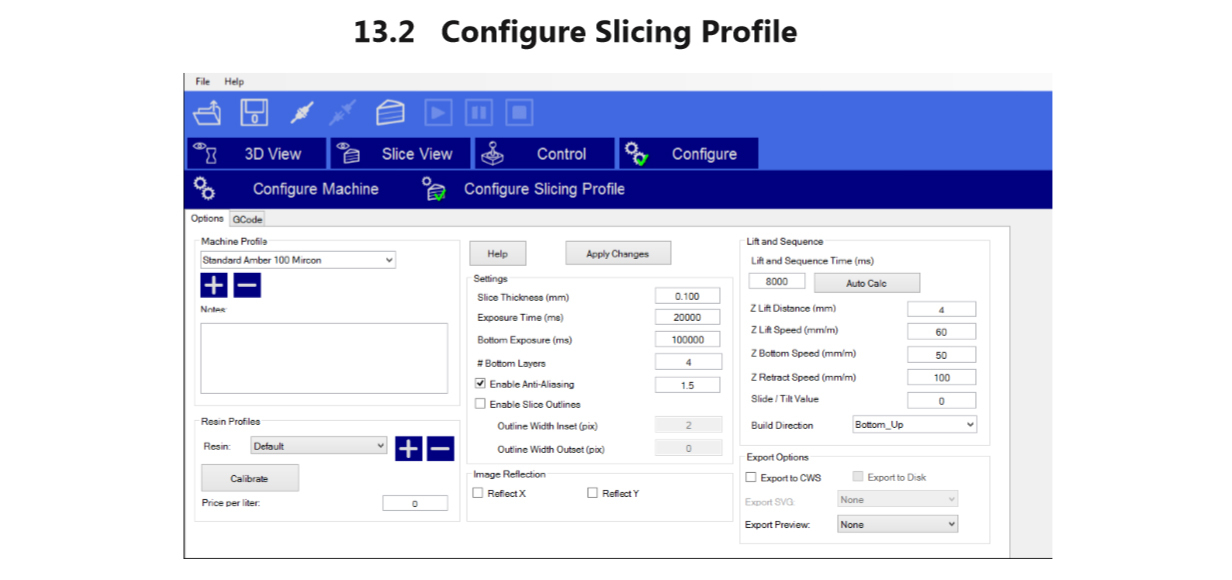

Before connecting, you need to configure the slicer using screenshots from the instructions.

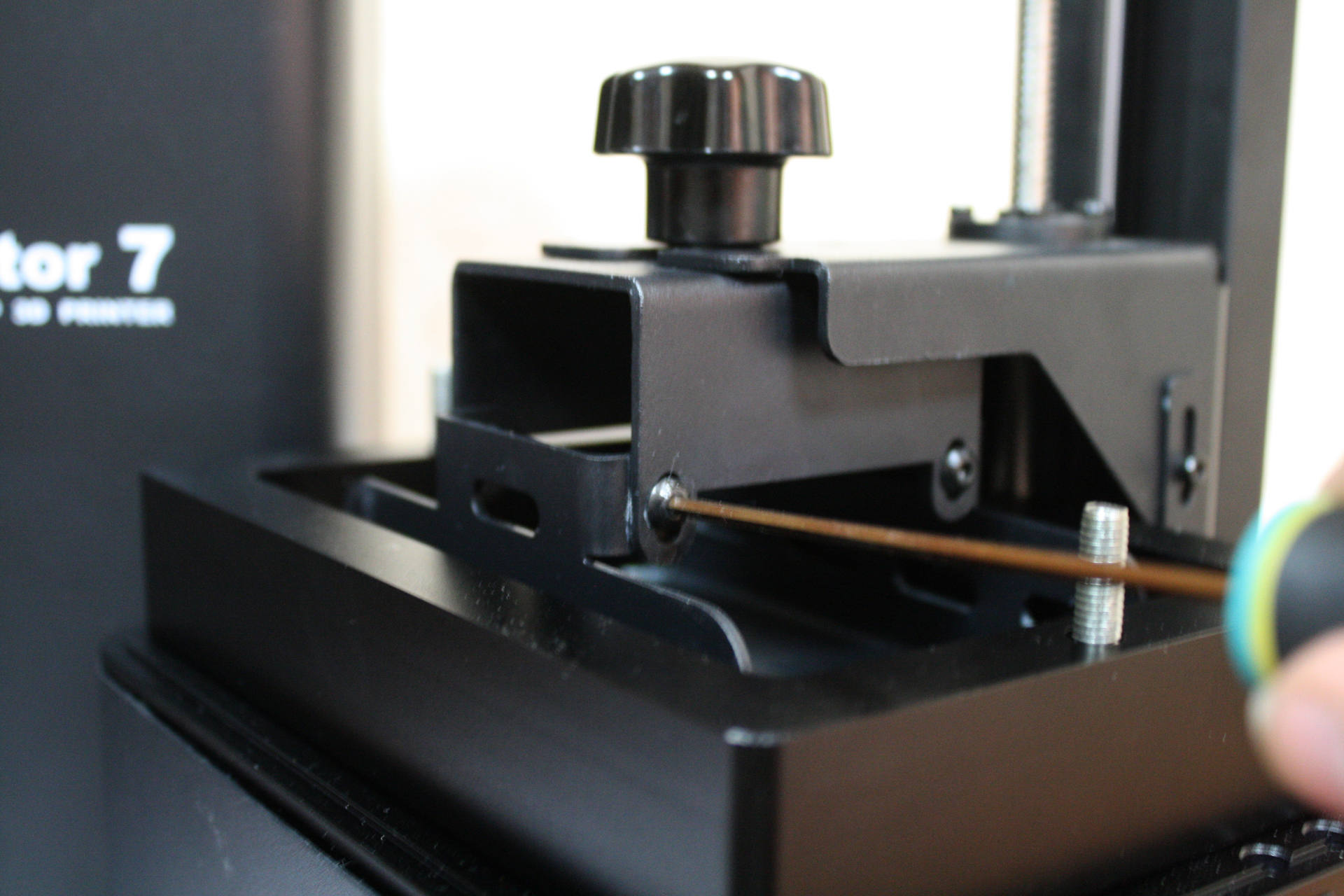

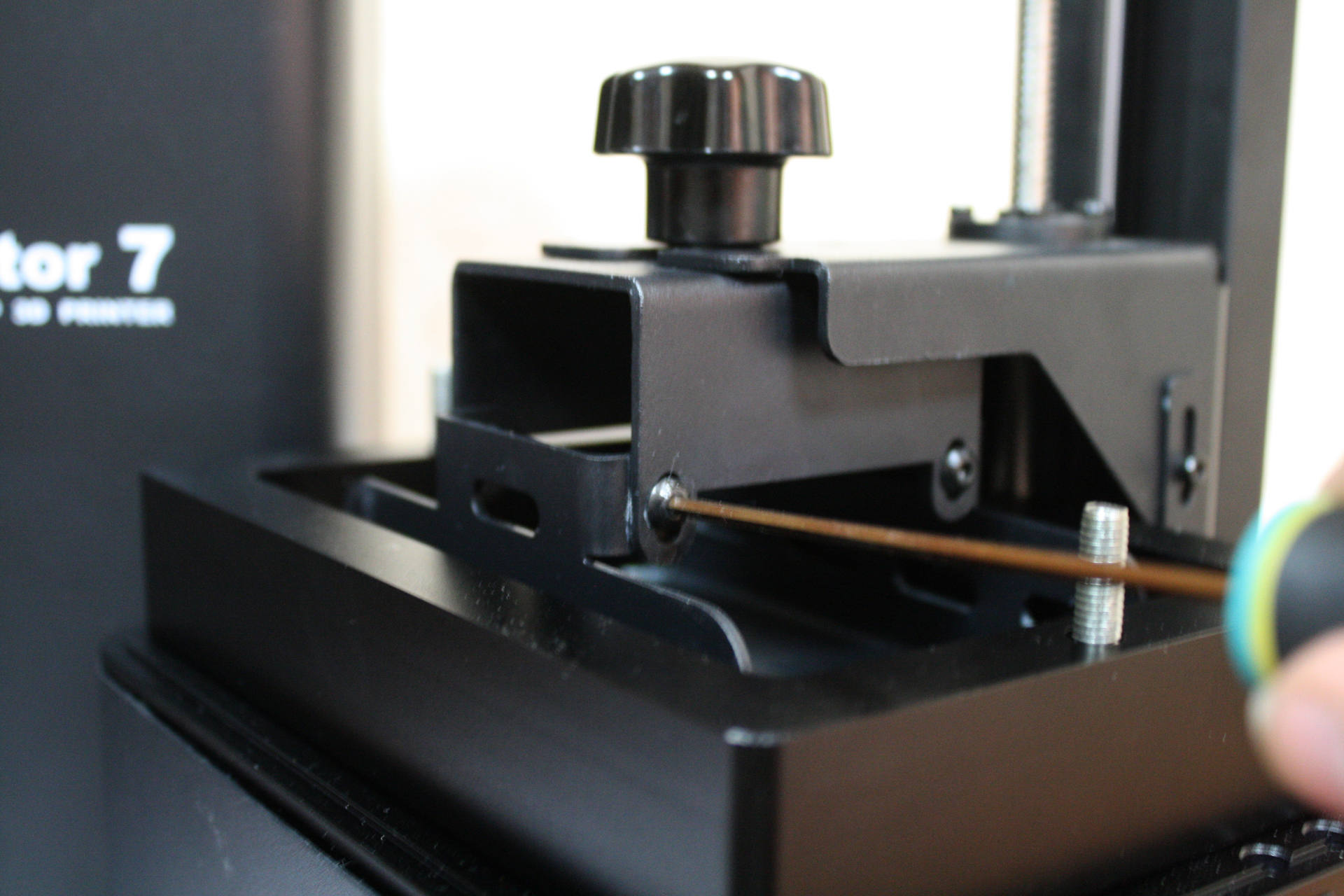

Calibration was very simple. We unscrew the 4 bolts securing the platform and

send the printer to the “house”. Then we firmly

press the platform to the display (but without fanaticism, so as not to push the display through!) And tighten the bolts.

Before printing, the platform must be sent to the "house". Do not forget to pour the

polymer into the printed bath before this =) We

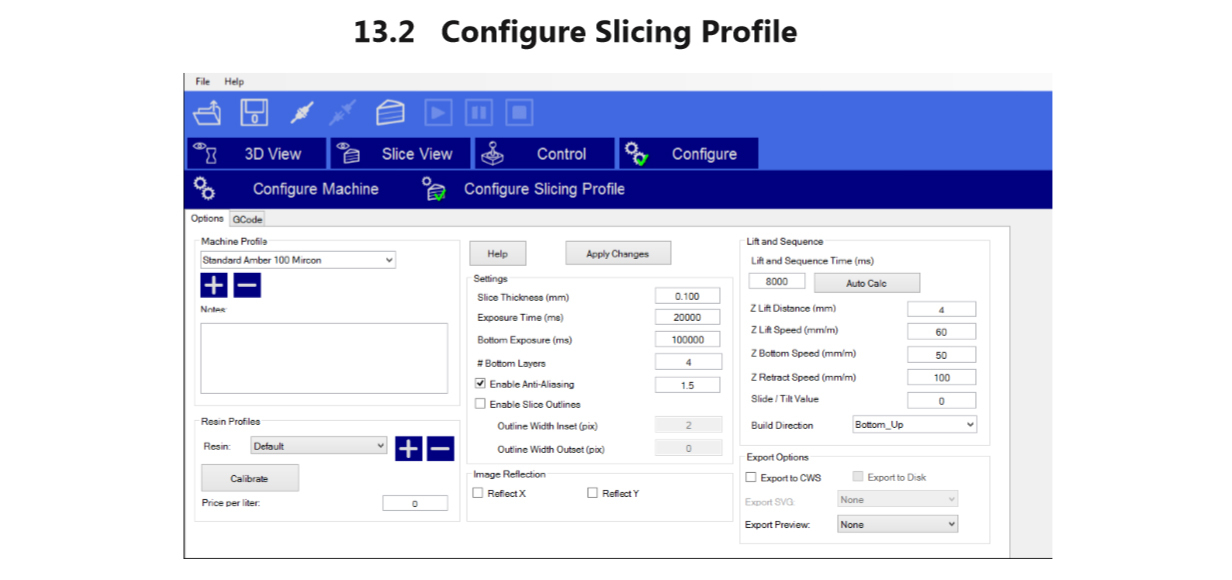

set up the slice profile on the screenshots from the instructions and experience the delight that

the printer immediately earned!

Resin Selection and Printing Results

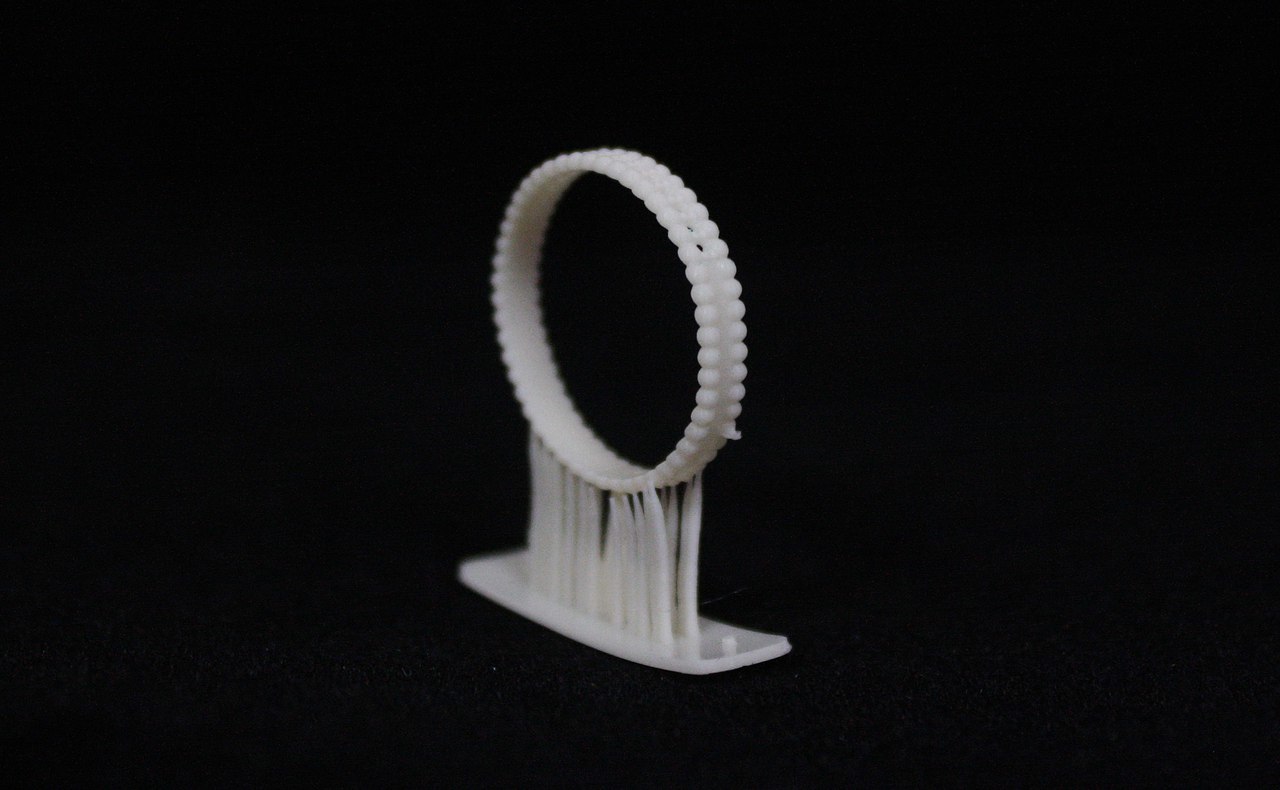

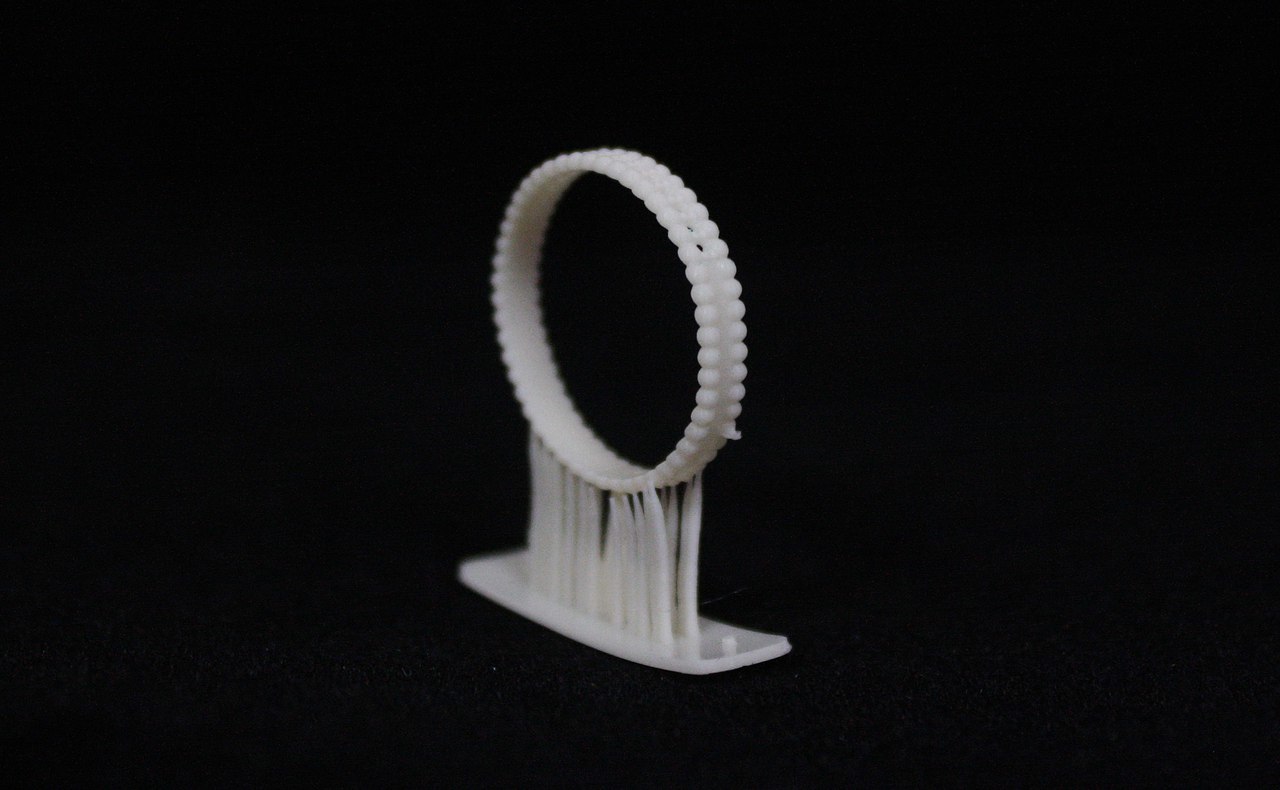

As a result of our first printing, we received such beauty. Thickness of a layer is 100 microns.

Partially painted and assembled figure:

With photopolymer resin that comes with the printer, no problems have arisen,

unfortunately until Wanhao produces only one type of resin Wanhao Gray (5700 rubles per liter), but in the future we hope to expand the range of resins.

We also managed to try Photocentric resin! We had to suffer for a long time with the selection

of print parameters, the result was worth it. The layer is 50 microns, the exposure time is 20 seconds per layer. By

Unfortunately until Wanhao not provide information on the print settings for different types of

resins

Photopolymer resin from the German company Detax showed itself perfectly, with which

we achieved perfect print quality. Even the smallest micro

details of the models are printed . The layer is 50 microns, the exposure time is 25 seconds per layer.

Results

Wanhao Duplicator 7 - certainly a very worthy representative of high-precision 3D-printers.

The unique technology of DLP printing allows you to achieve a minimum layer thickness of 35 microns,

which is unthinkable for FDM printers. Very pleased with the price of the device. Finding a 3D printer with such printing accuracy, intended for the production of small and smooth parts and elements, is cheaper than for 200,000 rubles.

Duplicator 7 will be an excellent auxiliary tool for jewelry workshops,

dental clinics. Also, a 3D printer will be interesting for people who are fond of

miniatures or modeling, design or production of souvenirs.

By tradition, a minute of advertising. Buying equipment in our company, you get 10 advantages:

The review was prepared by the team of the company Color World.

Subscribe to our groups on Facebook , VK and YouTube to keep up with the latest events.

This is the first Wanhao DLP printer. The Chinese company Wanhao

today is the world leader in the production of desktop 3D-printers

working on FDM technology, last year the company produced 67,000 printers. The goal of

Wanhao is to create low-cost 3D printers available even to students, because only 5 years

ago, the creators of the company themselves were students who were passionate about 3D printing.

The DLP method is an alternative to the SLA technology, where instead of laser installations

LED projectors are used. DLP printing is based on photopolymer resins,

hardening when irradiated with ultraviolet light. DLP printers project an

image of the whole layer until the polymer resin hardens, after which the

next layer is applied and the image of the new digital model is projected. In comparison with SLA,

one can distinguish such an advantage as lower cost of projectors compared to

laser emitters. Accordingly, the price of DLP-printers below stereolithography.

Nevertheless, Wanhao Duplicator 7 is not exactly a DLP printer, since it

uses an integrated LCD screen as a light source to illuminate the photopolymer, this solution

reduced the cost of the printer by an order of magnitude and made this model accessible to all

wishing to try a completely different technology of 3D printing, which makes it possible to

create more complex models with a higher quality surface model.

The recommended retail price of the printer is 36 900 rubles!

For a high-precision 3D printer printing photopolymers, this is a fantastically low price.

Completion and appearance of the

D7 is made in a concise, simple design with a removable massive lid. The 3D printer is

small, weighs only 12 kg.

Grade may seem ascetic, but as practice has shown - this is quite enough.

Work table

- Plastic spatula for removing models (used only to clean the film in the printing bath)

- Jar for washing models from polymer residues after printing (for washing we used isopropyl alcohol)

- Fluoroplastic film and spare nuts for baths

- HDMI cable

- USB cable

- Hex screwdriver

- Photopolymer Wanhao 250 ml.

Constructive

An LED matrix with an LCD screen is used as a projector. The principle is very simple

- the light from the matrix is sent to the screen and, depending on the picture, either passes light or

not. For printing, any photopolymer that hardens at 405 nm UV wave is suitable.

Control board:

LED matrix:

Already trapezoidal screw along the Z axis.

Printed bath is a bit atypical. It is a metal frame on

which the film is stretched below.

This design allows you to simply replace the film. Although you have to

twist / twist as much as 22 bolts! Fortunately, replacing the film is required less frequently. For all

the time of our use of the Duplicator 7 replacement was needed only once after a bad

print.

Software

As a default slicer, it is proposed to use the Creation Workshop.

At first, the Creation Workshop seemed a bit unusual, but overall, the slicer is good enough. Of the main advantages I want to highlight the possibility of manual editing supports. Often it helps a lot.

Can also be used as a NanoDLP slicer.

To do this, you need to download the firmware on the Wanhao website to use the NanoDLP and “flash” the

printer. This can be easily done with CURA. Detailed instructions can be

found on the official website of Wanhao.

Preparation for printing

To connect Duplicator 7, you need a video card with two HDMI outputs. We connect the 3D-

printer, which is defined as the “second monitor”. Additionally, we connect the printer via

USB. Next, run the slicer.

Before connecting, you need to configure the slicer using screenshots from the instructions.

Calibration was very simple. We unscrew the 4 bolts securing the platform and

send the printer to the “house”. Then we firmly

press the platform to the display (but without fanaticism, so as not to push the display through!) And tighten the bolts.

Before printing, the platform must be sent to the "house". Do not forget to pour the

polymer into the printed bath before this =) We

set up the slice profile on the screenshots from the instructions and experience the delight that

the printer immediately earned!

Resin Selection and Printing Results

As a result of our first printing, we received such beauty. Thickness of a layer is 100 microns.

Partially painted and assembled figure:

With photopolymer resin that comes with the printer, no problems have arisen,

unfortunately until Wanhao produces only one type of resin Wanhao Gray (5700 rubles per liter), but in the future we hope to expand the range of resins.

We also managed to try Photocentric resin! We had to suffer for a long time with the selection

of print parameters, the result was worth it. The layer is 50 microns, the exposure time is 20 seconds per layer. By

Unfortunately until Wanhao not provide information on the print settings for different types of

resins

Photopolymer resin from the German company Detax showed itself perfectly, with which

we achieved perfect print quality. Even the smallest micro

details of the models are printed . The layer is 50 microns, the exposure time is 25 seconds per layer.

Results

Wanhao Duplicator 7 - certainly a very worthy representative of high-precision 3D-printers.

The unique technology of DLP printing allows you to achieve a minimum layer thickness of 35 microns,

which is unthinkable for FDM printers. Very pleased with the price of the device. Finding a 3D printer with such printing accuracy, intended for the production of small and smooth parts and elements, is cheaper than for 200,000 rubles.

Duplicator 7 will be an excellent auxiliary tool for jewelry workshops,

dental clinics. Also, a 3D printer will be interesting for people who are fond of

miniatures or modeling, design or production of souvenirs.

By tradition, a minute of advertising. Buying equipment in our company, you get 10 advantages:

- Ability to use the program Trade In.

- Warranty - 12 months

- Instructions in Russian

- Technical support throughout the lifetime

- You buy a 3D printer from an official distributor in Russia

- Free shipping.

- Free training in our office.

- The ability to buy a printer on credit through banks TKS, OTP, Renaissance.

- 10% discount on plastic forever.

- The opportunity to get acquainted with the printer in our demo room.

The review was prepared by the team of the company Color World.

Subscribe to our groups on Facebook , VK and YouTube to keep up with the latest events.