Overview of plastic for 3D printing Carbon Fiber

Good day. When testing Wanhao Duplicator 6, we used many exotic types of plastic. We are especially interested in carbon-based plastic nylon. We decided to talk about it in more detail.

Now there are many different types of plastic with the addition of carbon, but they all differ in their characteristics.

We used to print "carbon" firm Fiber Force. Carbon Fiber uses nylon as the base.

The cost of the coil weighing 500 grams - 4 500 rubles.

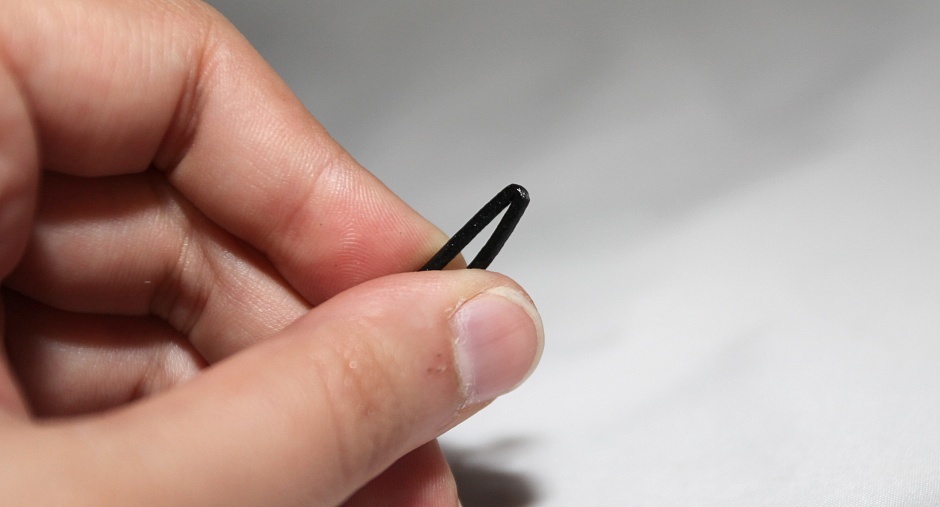

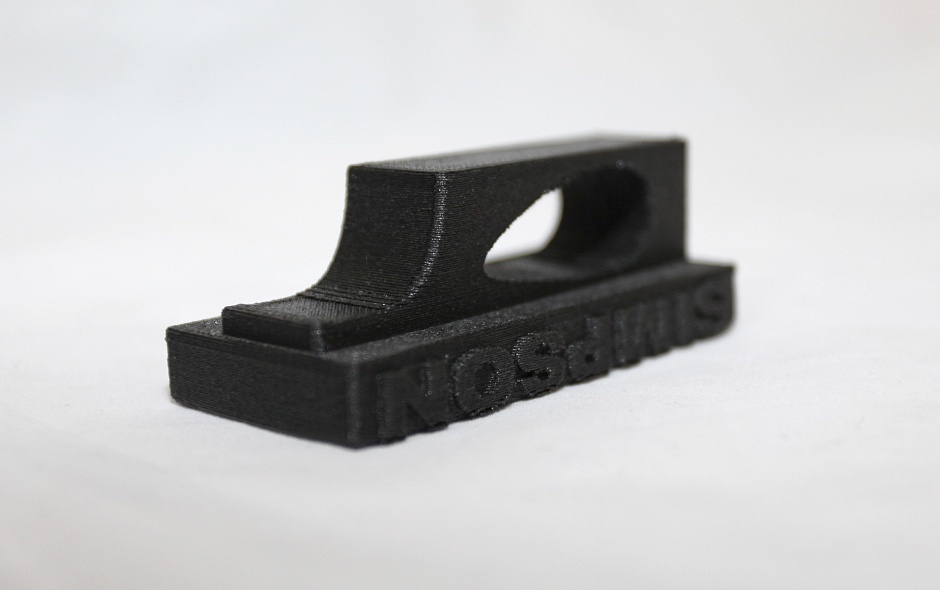

The first thing that surprised this color is a black, matte bar.

To the touch bar slightly rough. The stiffness is very similar to the usual ABS, but I did not manage to break off a piece with my hands.

After a dozen bends in different directions, the place of the bend was certainly jammed, but it did not break off. This is in principle not surprising. Not for nothing as the basis of the manufacturer indicates nylon.

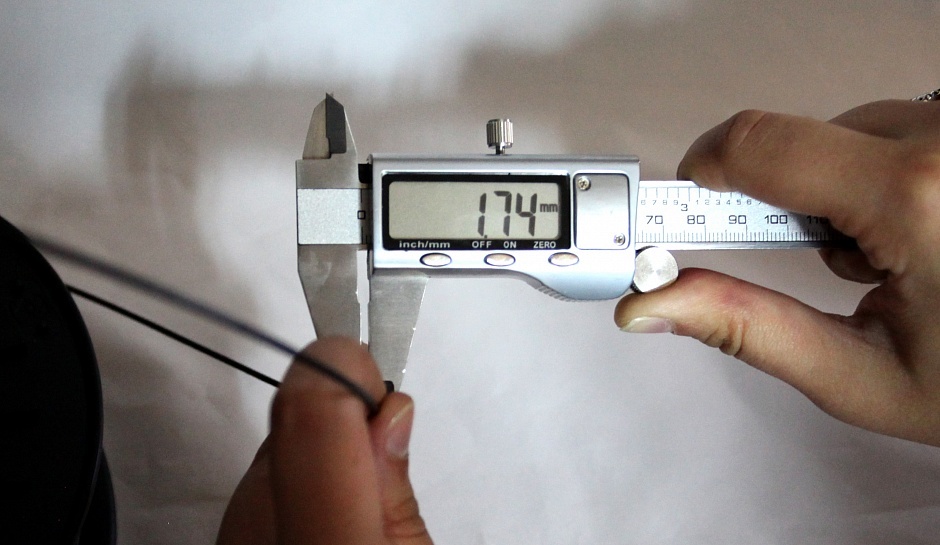

Be sure to check the diameter of the rod. Everything is quite within the declared 0.05mm manufacturer.

The recommended print settings from the manufacturer is a nozzle of 240 degrees, a table of 20 degrees or no heat at all. Although it turned out that the sintering of the layers is very good on the range from 230 to 260 degrees. Of course, as the temperature rises, the material becomes very fluid and the overhanging elements begin to sag.

Printed parts are slightly softer than ABS, but much more flexible.

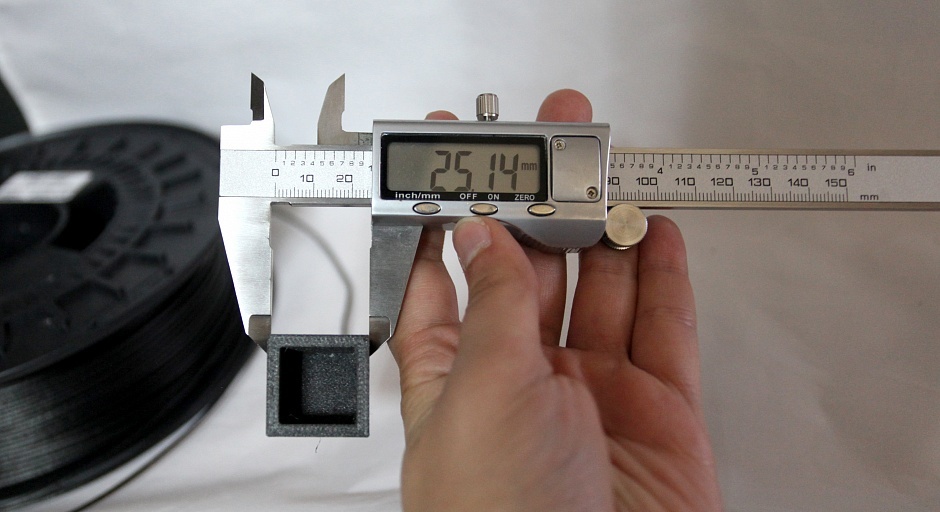

The material almost does not shrink. The manufacturer claims only 2%. Cube 25x25mm.

The most interesting feature is resistance to fire. The material of course melts, but does not flow and does not ignite.

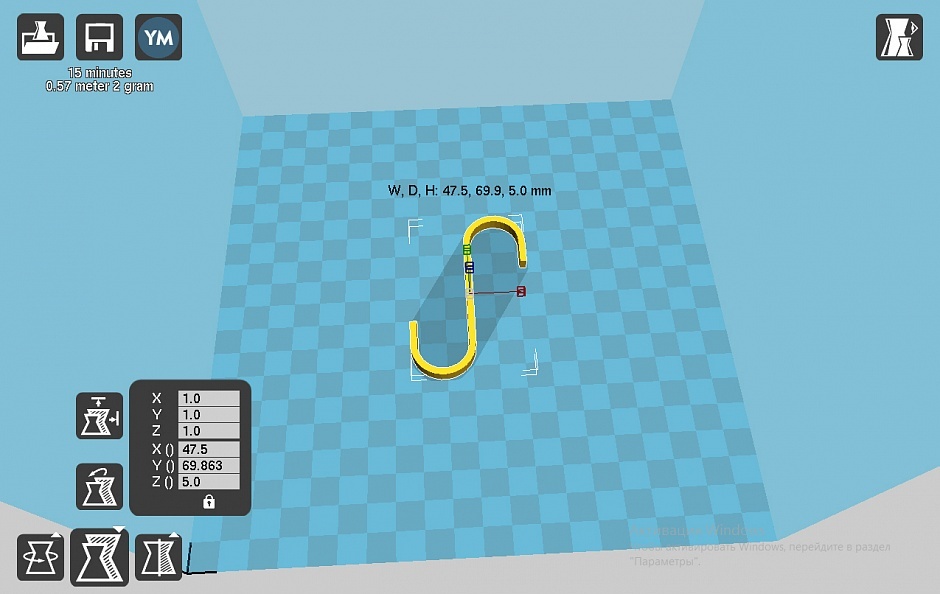

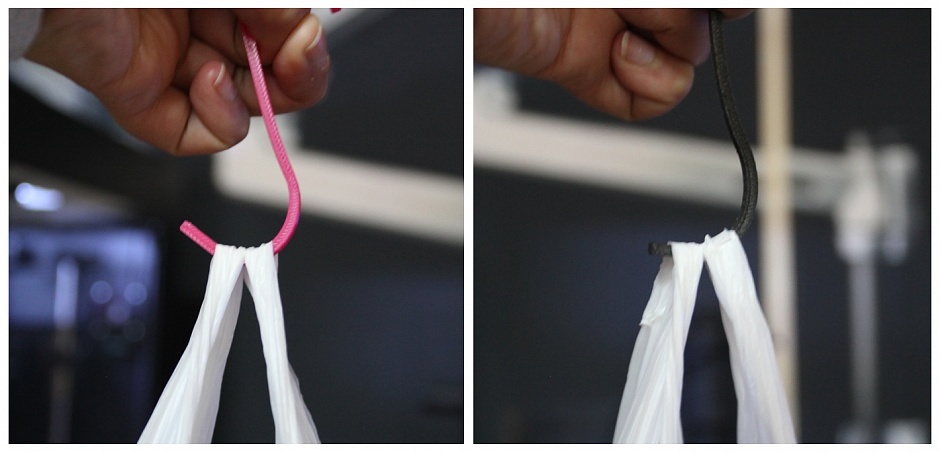

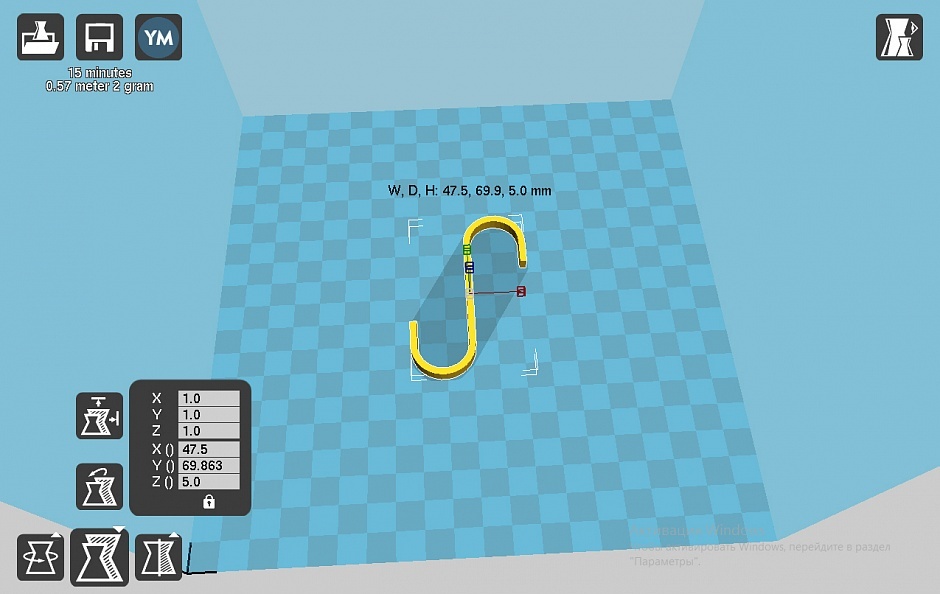

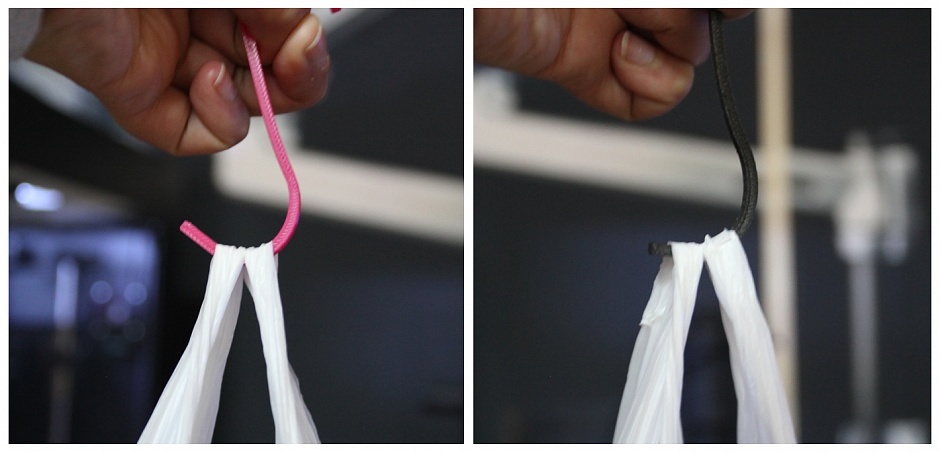

The stiffness of the material is in the middle between the ABS and PLA. We printed the hooks with 100% filling and hung a package with a load on them.

As a load used kilogram coils with plastic. One coil weighs an average of 1400 grams.

The weight of one coil all the hooks weathered well.

On 2x ABS coils dropped out. PLA and Carbon hold on. But it is clear that if Carbon is even tougher, then ABS is not much.

On 3 coils Carbon could not stand it. Hook is not broken, but straightened.

Results

The material was very interesting in its properties. Trouble-free in printing, it will undoubtedly be useful for the manufacture of functional prototypes for which tensile strength, flexibility and durability are important.

For example, while preparing an article for our employee, a trifling sleeve broke in the car. The detail was quickly modeled and printed out from several materials. It was the carbon sleeve that showed its best.

Or let's say they printed Mag Pull (loop of quick retrieval) for G3 stores. The guys asked to print from the very-most durable plastic, so that the loop could survive more than one game.

By tradition, a minute of advertising)

Buying equipment in our company, you get 10 advantages:

1. The ability to use Trade In.

2. Warranty - 12 months

3. Instructions in Russian

4. Technical support during the whole period of operation

5. You buy a 3D printer from an official distributor in Russia.

6. Free shipping.

7. Free training in our office.

8. The ability to buy a printer on credit through the banks TKS, OTP, Renaissance.

9. 10% discount on plastic forever.

10. The opportunity to get acquainted with the printer in our demo room.

The review was prepared by the specialist in 3D printing of Color World company, Anna Panfilova.

Subscribe to our groups on Facebook , VK and YouTube to keep abreast of the latest developments.

Now there are many different types of plastic with the addition of carbon, but they all differ in their characteristics.

We used to print "carbon" firm Fiber Force. Carbon Fiber uses nylon as the base.

- Firm Fiber Force was founded in 2013 in Italy. In addition to ABS and PLA Fiber Force produces several types of special plastics. One of them is CARBON FIBER.

The cost of the coil weighing 500 grams - 4 500 rubles.

The first thing that surprised this color is a black, matte bar.

Looking ahead I will say due to the dullness of the bar ready-made "prints" look almost like cast.

To the touch bar slightly rough. The stiffness is very similar to the usual ABS, but I did not manage to break off a piece with my hands.

After a dozen bends in different directions, the place of the bend was certainly jammed, but it did not break off. This is in principle not surprising. Not for nothing as the basis of the manufacturer indicates nylon.

Be sure to check the diameter of the rod. Everything is quite within the declared 0.05mm manufacturer.

The recommended print settings from the manufacturer is a nozzle of 240 degrees, a table of 20 degrees or no heat at all. Although it turned out that the sintering of the layers is very good on the range from 230 to 260 degrees. Of course, as the temperature rises, the material becomes very fluid and the overhanging elements begin to sag.

Printed parts are slightly softer than ABS, but much more flexible.

The material almost does not shrink. The manufacturer claims only 2%. Cube 25x25mm.

The most interesting feature is resistance to fire. The material of course melts, but does not flow and does not ignite.

The stiffness of the material is in the middle between the ABS and PLA. We printed the hooks with 100% filling and hung a package with a load on them.

As a load used kilogram coils with plastic. One coil weighs an average of 1400 grams.

The weight of one coil all the hooks weathered well.

On 2x ABS coils dropped out. PLA and Carbon hold on. But it is clear that if Carbon is even tougher, then ABS is not much.

On 3 coils Carbon could not stand it. Hook is not broken, but straightened.

Results

The material was very interesting in its properties. Trouble-free in printing, it will undoubtedly be useful for the manufacture of functional prototypes for which tensile strength, flexibility and durability are important.

For example, while preparing an article for our employee, a trifling sleeve broke in the car. The detail was quickly modeled and printed out from several materials. It was the carbon sleeve that showed its best.

Or let's say they printed Mag Pull (loop of quick retrieval) for G3 stores. The guys asked to print from the very-most durable plastic, so that the loop could survive more than one game.

By tradition, a minute of advertising)

Buying equipment in our company, you get 10 advantages:

1. The ability to use Trade In.

2. Warranty - 12 months

3. Instructions in Russian

4. Technical support during the whole period of operation

5. You buy a 3D printer from an official distributor in Russia.

6. Free shipping.

7. Free training in our office.

8. The ability to buy a printer on credit through the banks TKS, OTP, Renaissance.

9. 10% discount on plastic forever.

10. The opportunity to get acquainted with the printer in our demo room.

The review was prepared by the specialist in 3D printing of Color World company, Anna Panfilova.

Subscribe to our groups on Facebook , VK and YouTube to keep abreast of the latest developments.