Amateur radio technology: how I ordered the installation of a printed circuit board in a Chinese factory

The purpose of the publication : to tell how to prepare a simple amateur radio design for production.

As I wrote earlier , the creativity of ham radio has a limited family budget and has a limit on the time taken from the family. Not every hobbyist can afford to have at home equipment for the manufacture of printed circuit boards and their installation. In today's world, this is solved by CAD / CAM technology, and CAM can be used for the manufacture of printed circuit boards, and for mounting components on these boards.

This article describes : how to assemble printed circuit boards in production; how to prepare in CAD Eagle 7.7.0 a project for assembling a prototype on a CAM located in China.

This article does not cover: counterparty selection criteria, economic aspects, logistics issues.

Preparation for production

The automated PCB mounting process usually consists of the following steps:

- PCB fabrication.

- Drawing on a printed circuit board of solder paste.

- Installation on a printed circuit board (Pick & Place) components SMD.

- Reflow solder paste in the oven.

- (If necessary) Mounting on the underside of the SMD component board.

- (If necessary) PCB mounting of THT (Through-Hole) components.

- Washing the assembled printing unit. Drying.

- Technical quality control of component installation.

- (If necessary) Repair the assembled printing unit.

- (If necessary) Coating.

How to make a printed circuit board in a Chinese factory, I described in a previous article in the cycle. When preparing a project for production, it is necessary to remember that:

- The circuit board should be rectangular in shape. A non-rectangular printed circuit board should have a rectangular frame.

- Printed circuit boards should preferably be assembled in panels. Small and non-rectangular printed circuit boards must be assembled in the panel!

- Placing SMD components on only one side greatly simplifies and reduces the cost of the assembly process.

- The printed circuit board or panel should have enough free space around the edges for mounting in the installer and oven.

- When soldering paste is applied to a printed circuit board, a stencil is used, which can be ordered along with the manufacture of the printed circuit board.

- For the component installer to work correctly, reference marks must be applied to the printed circuit board (and / or to the technological fields of the panel).

- The nomenclature of components for downloading the installer is determined according to BOM (Bill Of Materials).

- The coordinates and orientation of the components during installation (Pick & Place) contains a special file, based on which technologists create a task for the component installer.

How I prepared my design for production

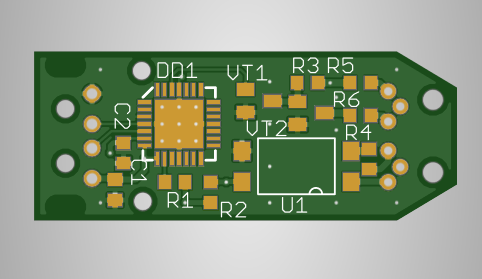

I decided to try to place an assembly order for a simple device from the article “ Weekend Design: A Simple MIDI Adapter ”.

As an adapter case, a simple and cheap SZOMK AK-S-27a was chosen . A small, non-rectangular printed circuit board can be installed in this case.

I usually order printed circuit boards for my amateur projects from pcbgogo.com . I decided to place an installation order with them. PCBA installation requirements can be found here ; sample BOM and Pick & Place files can be viewed here .

The build process in PCBGOGO looks like this:

The minimum board dimensions are 50 * 100 mm. The minimum assembly order is 5 printed circuit boards (panels), the minimum cost of work is $ 50 with the number of less than 20 printed circuit boards (panels). Stencil subject to installation order is made free of charge. If the assembled panel fits into the preferential requirements for prototype boards, the manufacture of five or 10 such panels will cost $ 5.

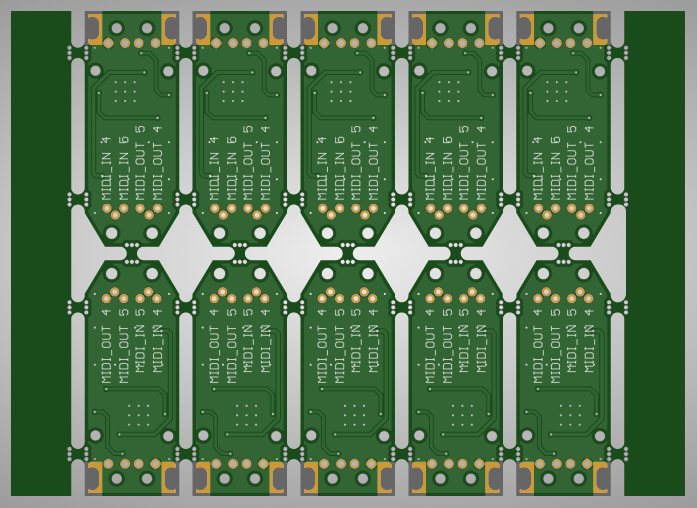

As a CAD in my amateur projects, I use the free version of Eagle 7.7.0 with a board size limit of 100 * 80 mm and the number of layers up to two. I assembled the boards in the panel according to Viktor's DIY Blog instructions . The result is:

Since non-rectangular printed circuit boards are assembled in the panel, they are separated by milling. The cutter thickness in our case is 2 mm. The thin place of the jumpers is at least 1.5 mm. Jumpers are perforated with drills with a diameter of 0.5 mm, three holes on each side. The holes do not extend beyond the circuit board, so that when the jumpers are removed, “hemp” does not form, and it would not be necessary to process the board edges before being installed in the case.

If the boards to be combined into a panel were rectangular, they could be separated by scribing (v-scoring). You can read more about scribing here .

The size of the panel is 100 * 72 mm. I placed the components of SMD on one side only. I oriented the boards in the panel in such a way as to ensure the installation of USB output connectors without disassembling the panel. Technological fields on the left and on the right are intended for fastening the panel during the production process. The manufacturer's requirement for minimum board sizes of at least 50 * 100 mm was met.

I did not put reference points on the panel: it was interesting what the Chinese technologists would say!

Warning spoiler

Chinese technologists did not say anything. They seem not the first time.

The initial data for the Pick & Place file was obtained as a result of exporting data from the panel project to the “Mount SMD” file. From there, data were taken on the positional designations of the components for the BOM.

It is necessary to pay attention to the fact that the position designations of the same components in the BOM and Pick & Place files must match exactly.

It should also be noted that the descriptions of the components (type of component, component manufacturer, face value, footprint, etc.) are entered in the Pick & Place file for a more complete understanding by technologists of what the component is and how to install it correctly on the board.

The project for the pre-fabricated MIDI adapter panel is here .

Preparation for production by the manufacturer

After checking the project files, PCBGOGO technologists asked me

I instructed the manufacturer of the order. Usually, upon approval, BOMs suggest replacing components with similar ones from other manufacturers or similar ratings. In my case, with BOM it was all simple: all the components were found in the manufacturer’s warehouse.

It should be noted that the customer can provide the components for installation himself, but according to the manufacturer’s conditions, the components must be sent in this case with a certain margin , and in our case also through customs. Unused scraps will be returned with the order.

The part of the process of preparation for production by the manufacturer, visible to the customer, was completed on this. Now that the process is running, I just have to follow the on-line order and wait for the assembled printing units and stencil to be delivered to me.

Brief Summary

This publication examines : the process of preparing a simple amateur radio design for production.

To order the manufacture of a printed circuit board and the assembly of a prototype in a Chinese factory, you need:

- Get acquainted with the requirements of the manufacturer.

- If necessary, assemble the printed circuit boards in the panel yourself or provide it to the manufacturer.

- Unload files from the gerber project.

- Prepare BOM (Bill Of Materials).

- Prepare data for the component installer.

- Send the project files to the manufacturer and agree on the details with him.

- Pay the manufacturer the production, equipment and delivery.

I really hope that the experience of ordering the installation of printed circuit boards outlined in the publication will help readers in organizing their technical work. And I also hope that any evaluation of the article will be accompanied by a comment.

73! To the connection!