Another step towards the end of Moore's Law

- Transfer

Samsung and TSMC switch to 5 nm process technology

The two largest manufacturers are Taiwan Semiconductor Manufacturing Co. (TSMC) and Samsung announced in April they were about to climb the next rung of Moore’s Law Ladder . First, TSMC spoke, announcing the transfer of the 5 nm process technology to the “risky production” stage - that is, the company believes that the process is ready, and the first customers take risks, hoping that the product will work in their schemes. Samsung quickly followed her with a similar statement .

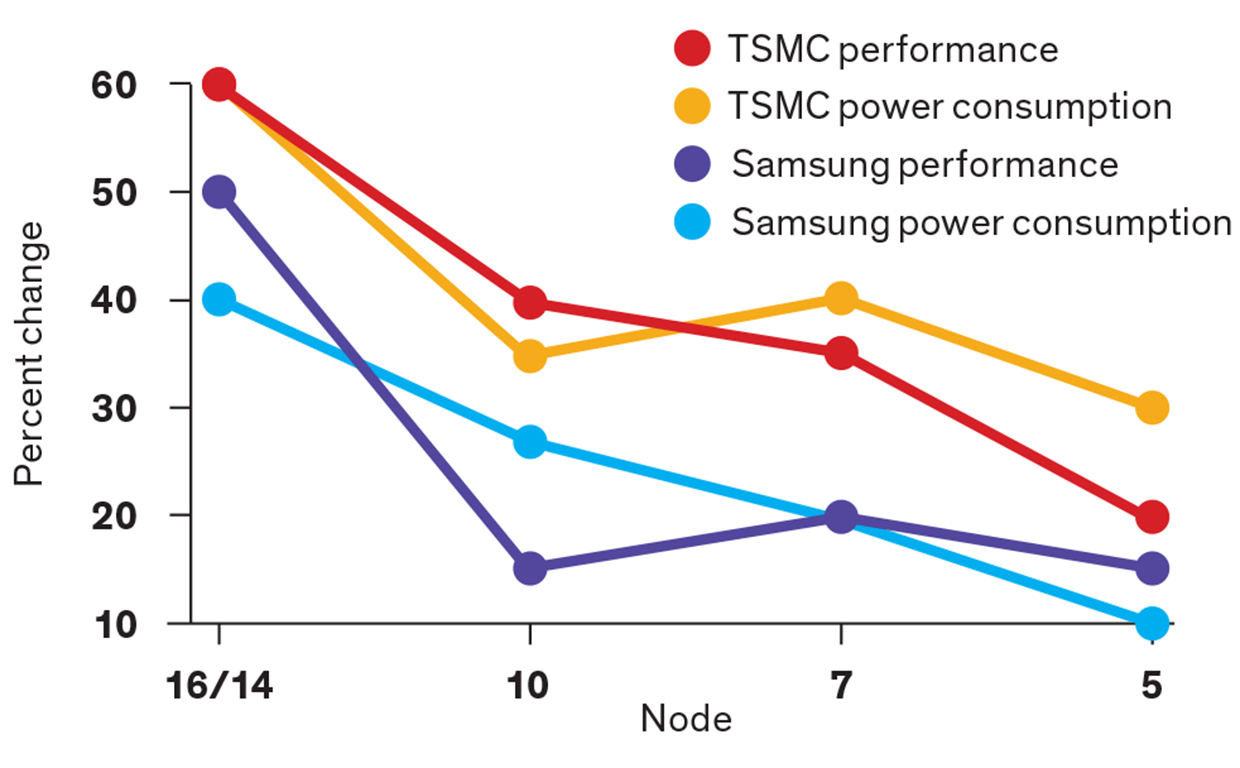

TSMC says the 5nm process provides a 15% increase in speed or a 30% increase in energy efficiency. Samsung promises an acceleration of 10% and an increase in efficiency of 20%. Analysts say these numbers are in line with expectations. However, compared with the sometimes 50% improvement that occurred 10 years ago, it is clear that Moore’s law is not the same as before. But judging by the investments of large manufacturers, customers believe that it is worth it.

What is the peculiarity of 5 nanometers?

5 nm is the first technology created from scratch using photolithography in deep ultraviolet [extreme ultraviolet lithography, EUV]. FGU with a wavelength of 13.5 nm can create extremely small parts on silicon. Some of them could be made by the previous generation of photolithography tools, however, they would need three or four passes in a row to produce the same result that the FGU achieves in one pass.

Improvements achieved during the transition to the new

manufacturing process. The factories began production at 7 nm without FGU, but then used it to reduce the number of lithographic steps and improve output. At 5 nm production, 10-12 steps of FGU are used, that is, for previous technologies it would be required to do 30 steps, if at all possible.

Since photomasks containing schemes are expensive and each lithography machine costs $ 100 million plus an investment, “FGU is more expensive per layer,” says J. Dan Hutcheson of VLSI Research. But in terms of substrates, a gap in net income is obtained, and the FSI will form the basis of all future processes.

Who will use it?

The new manufacturing process is not for everyone. At least for now. However, both companies have identified some companies that are likely to be in the forefront, including suppliers manufacturing processors for smartphones and 5G infrastructure. “We need large volumes and a need for either speed or energy efficiency,” says Len Jelinek , an analyst with semiconductors at IHS Markit.

What you compete with matters, explains Kevin Crevel of TIRIAS Research. GPU, FPGA, high-performance microprocessors used to be the first to take advantage of the front line of Moore's law. But with less competition in these markets, new technology is increasingly required for mobile processors.

Is it normal that there are only two companies left?

Only 5 companies offer 5 nm manufacturing services, Samsung and TSMC. GlobalFoundries surrendered at 14 nm, while Intel, which is years late with the release of products equivalent to its competitors at 7 nm, analysts say, is refusing production services.

Samsung and TSMC remain because they can afford the investment and expect a reasonable return on them. Samsung was the largest chip maker by revenue in 2018, but its manufacturing facilities are considered the 4th in the world , with TSMC in the first place. TSMC's capital expenditures in 2018 amounted to $ 10 billion. Samsung plans approximately the same expenses annually until 2030.

Can an industry work when only two companies are capable of delivering the most advanced manufacturing process? “The question is not whether it can work,” says Hutcheson. “She will have to.”

“As long as we have at least two viable solutions, the industry will feel comfortable,” says Jelinek.

What's next?

On assembly lines of chip makers, typically 5 nm followed 7 nm, and 3 nm followed 5 nm. But analysts say factories will begin to offer various technologies with gradual improvements that close the gaps. Indeed, Samsung and TSMC offer what they call the 6 nm process technology . Factories will need intermediate products such that customers continue to come to them at the edge of Moore’s law. After all, there are not many numbers left between 5 and 0.