Need a small keyboard - do it yourself

- Transfer

If you need a keyboard, you can purchase one. If you need a small keyboard, then everything is more complicated. In addition to the Blackberry keyboard alteration options or fuss with tiny tactile switches, there are no normal solutions for getting small, thin and specialized keyboards. However, there is one option: silicone keyboards. Nobody has done this yet, so I decided - why not give it a try.

Unfortunately, there is no ready-made information on the design, creation or production of their own silicone keyboards. There is very little documentation, and all the factories that manufacture them seem to copy information from each other. To ask a Chinese company how to do this is the same as playing in a "damaged telephone." But, despite all this, I managed to make my own silicone keyboard, and now I am sharing information on how this is done.

The goal of the project is to create a very small computer keyboard for wearable devices, electronic badges, playing Fortnite on a portable computer, or simply for use as a USB keyboard. This has already been done before. BadgeFor the 2018 conference, the Hackaday Belgrade Conference used 55 standard tactile switches arranged in the form of a keyboard. Another project with Hackaday.io called (Pi) QWERTY also used dozens of standard clock switches. However, such devices have their drawbacks.

PiMiniQWERTY - the best of homemade miniature keyboards

Firstly, standard 4mm tactile buttons are quite expensive. This is not a problem if you use a small number of them for one project, but if you need 60-70 buttons per device, the cost starts to rise. The cheapest of those that I found cost $ 70 per roll of 4000, or a couple of cents apiece. Take 70 pieces and get $ 1.25 per device - just for the buttons. It may turn out that the buttons will cost more than the microcontroller.

Secondly, tactile buttons must be put together. The number of failures may not be very large, but if you assemble entire boards from switches, it will be more than if they were single devices. Compared to SMD resistors and caps, the buttons are large and thick, which increases the number of scraps when they are placed. Also, since it takes a lot of time to assemble such a keyboard, you have to pay more for the assembly of buttons than for installing a finished device. This increases the cost of the keyboard based on tactile switches.

Finally, the buttons are not labeled. If you will assemble a keyboard of 4 mm buttons, you will have to do the marking on the board. At the Belgrade conference, this was done quite well, while mini (Pi) QWERTY did it brilliantly, because they used two boards, one for electronics and one for signatures. One can imagine inscribing the buttons, but their surface is already very small.

Solution: use injection-molded silicone keyboards. Such keyboards are in almost all remote controls, they were used in old Nokia phones such as "brick". Silicone keyboards are everywhere, and there are factories making them to order.

Silicone Keyboards with TaoBao and AliExpress. The companies selling them also make them to order.

There are many advantages to using silicone keyboards. First, most of them use button labels. Secondly, you are not limited to 4 mm buttons. Buttons can be of any size and any shape. Collecting them is easy; to use such a keyboard with a board, you just need to place it on the board; everything else has already been done for you. Finally, the silicone keyboard looks cooler than any buttons. So why don't they use them? Mostly due to cost, however, there are some engineering problems.

Different types of silicone and membrane switches

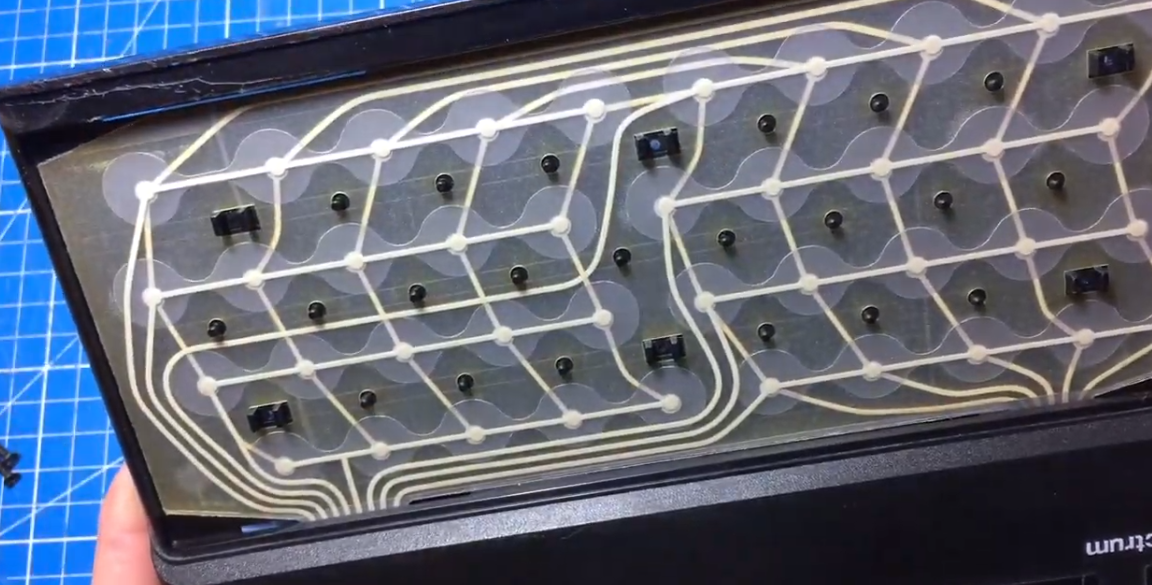

ZX Spectrum Membrane Keyboard

Before delving into the design of silicone keyboards, you need to discuss the layout of small keyboards and key sets. The first are Metal Dome keyboards, or membrane keyboards. The best examples of such tactile membrane buttons are keyboards from popular home computers of the 1980s, ZX Spectrum or Atari 400. If you look elsewhere in the apartment, you may have such a keyboard in the microwave.

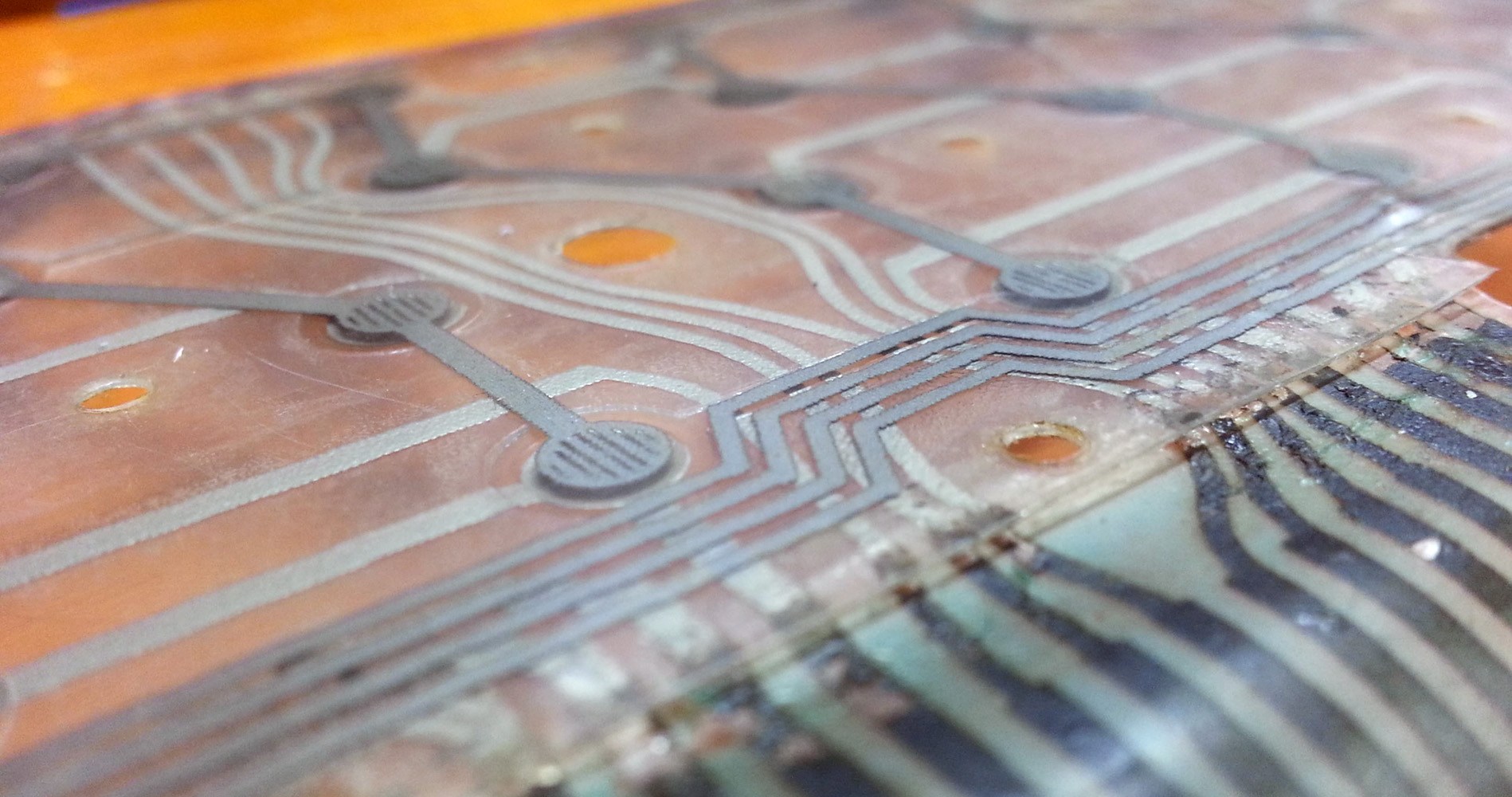

Such keyboards have a matrix buttons. The electrical circuit consists of tracks drawn with conductive ink on two sheets of polyester. A stainless steel dome is located under each button. Pressing the button compresses the dome, and closes two layers of polyester.

The best membrane keyboard images can be taken withone of his projects . Such membranes do not care how the metal dome was pressed. The simplest option is to place buttons and letters directly on top of the membrane. A piece of plastic can be glued onto an array of tactile switches. This is exactly how keyboards are made in Speak N Spell and Big Trak toys [in the USSR there was an analogue of such a toy, “Lunokhod” / approx. transl.]. This is how you can make a keyboard for a three-year-old baby, protected from peanut butter.

However, pure membrane switches to the touch are very cheap and do not provide tactile feedback. One option is to place the plastic buttons above the membrane switch. Metal Dome keyboards (with a metal dome) use hard plastic keys that press on small metal domes sandwiched between two layers of conductive ink polyester:

But membrane keyboards are not required hard plastic buttons. You can use soft silicone, on top of the membrane keyboard, as is done on the ZX Spectrum. Instead of rigid plastic rectangles, as in my Metal Dome project, Speccy used a single canvas of silicone buttons. The ZX Spectrum used silicone buttons on its keyboard, but it was still a membrane keyboard. It makes no difference how to press a metal dome - through a sheet of plastic with printed characters, or silicone rectangles.

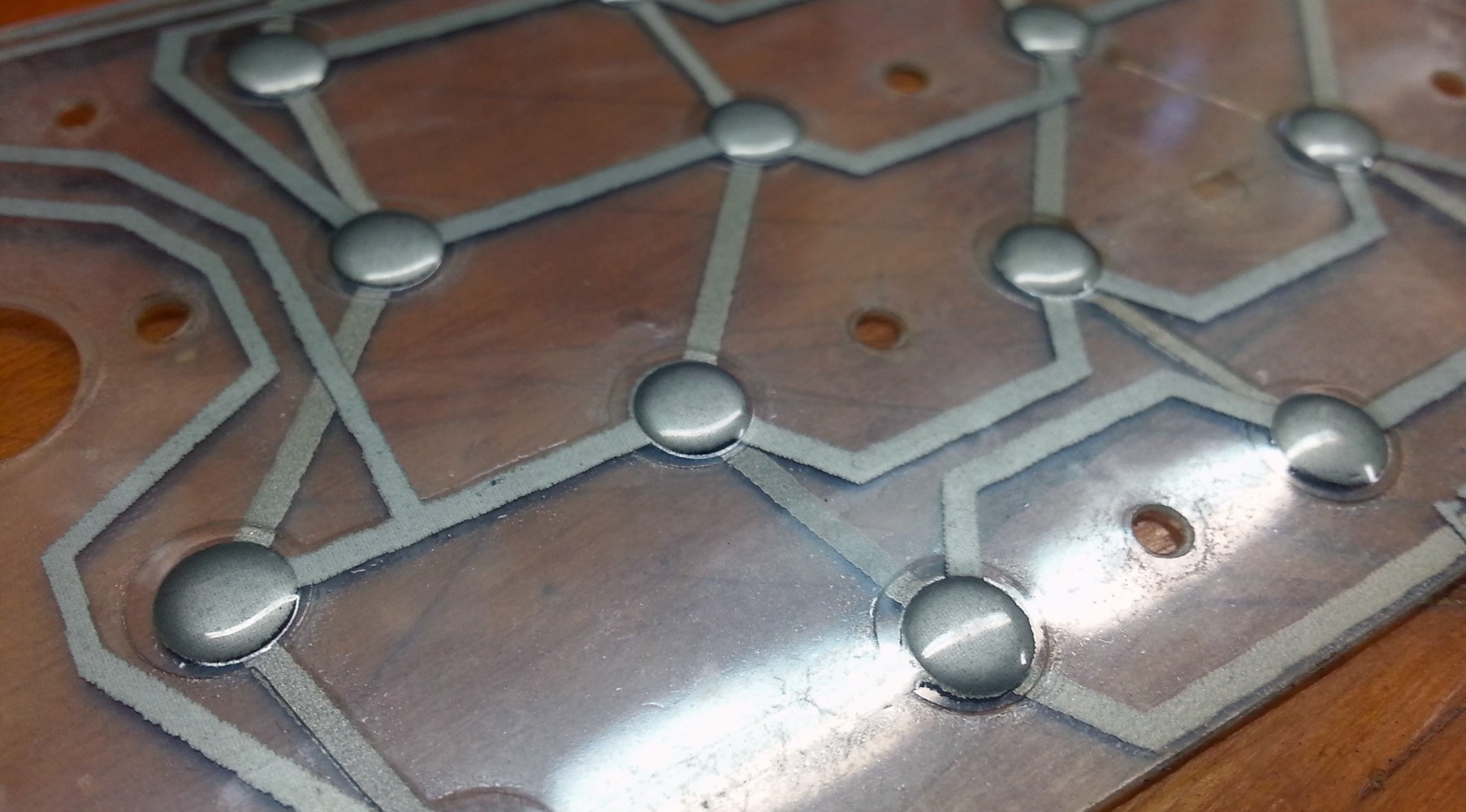

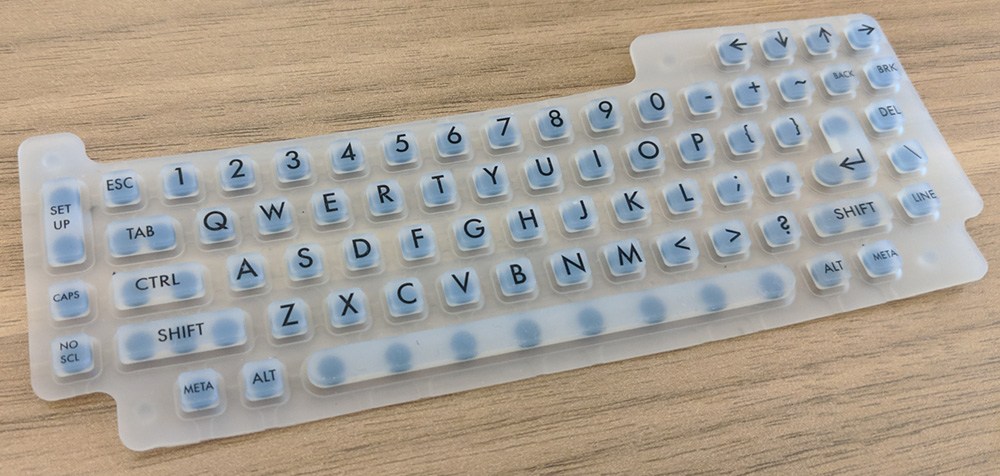

Another type of keyboard — the one I made for this article — is a silicone or rubber keyboard .

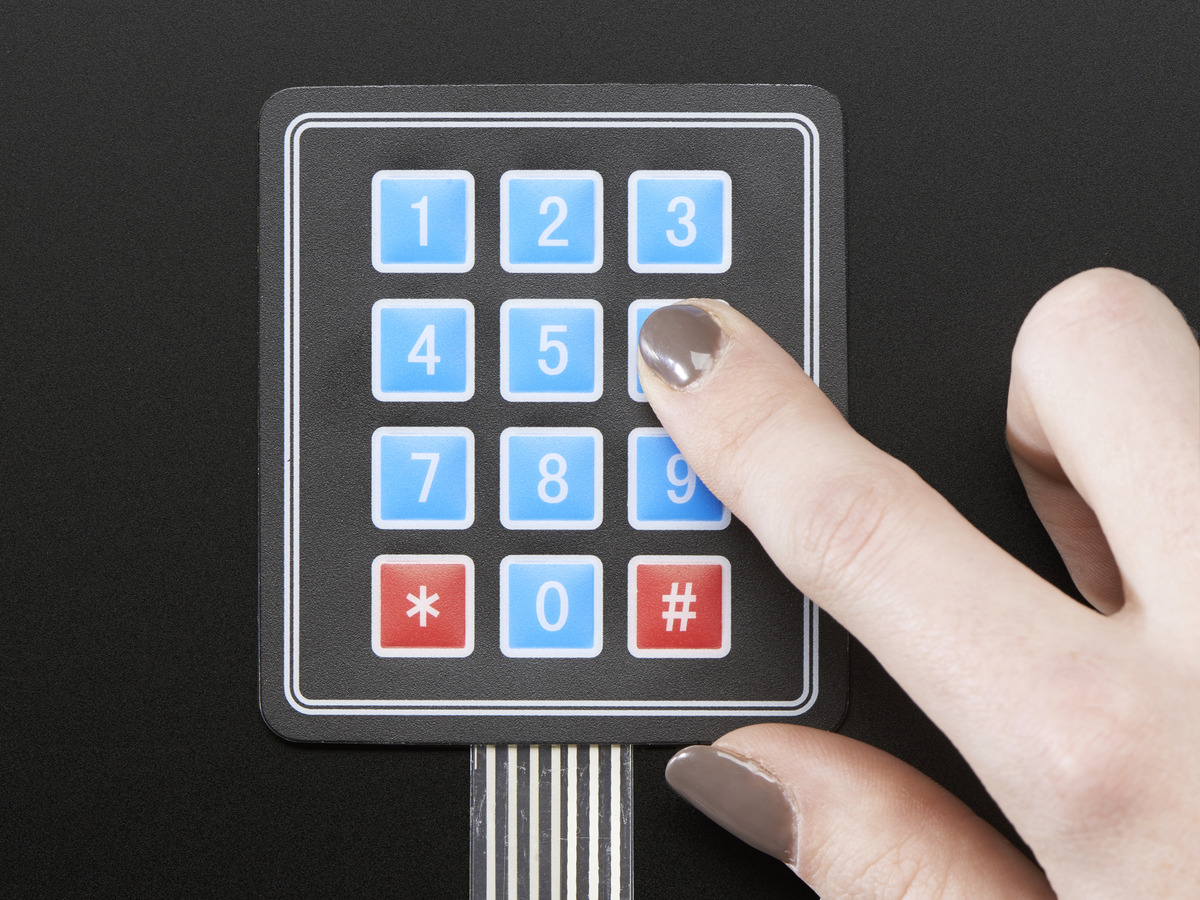

The ubiquitous membrane keypad for Arduino

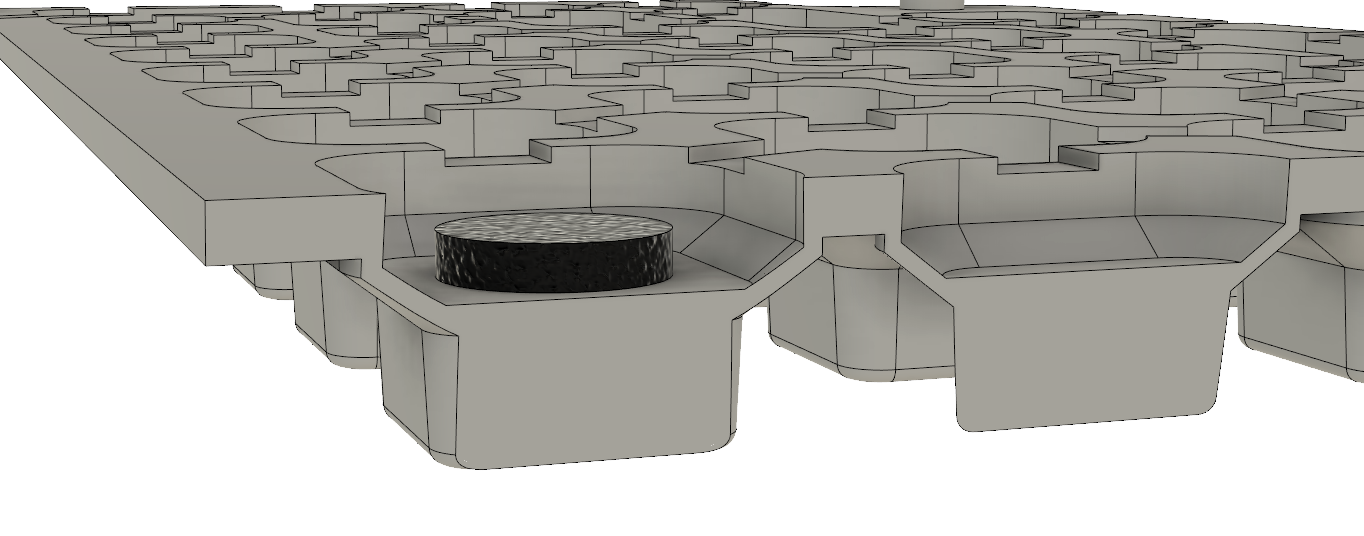

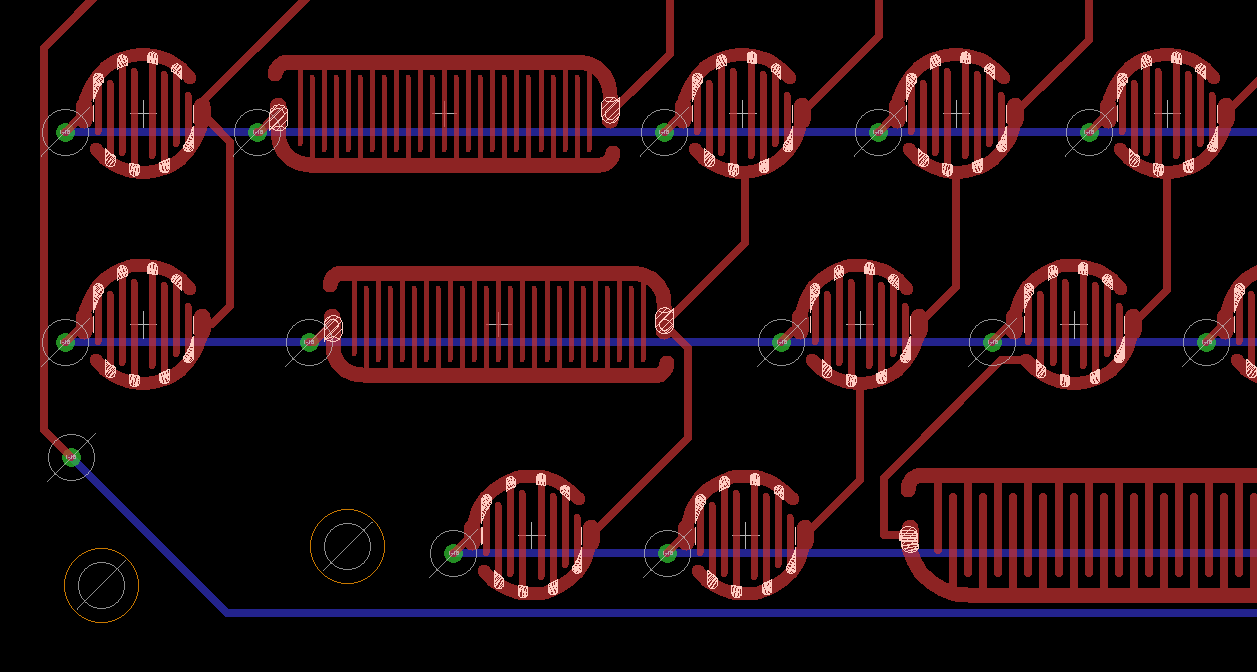

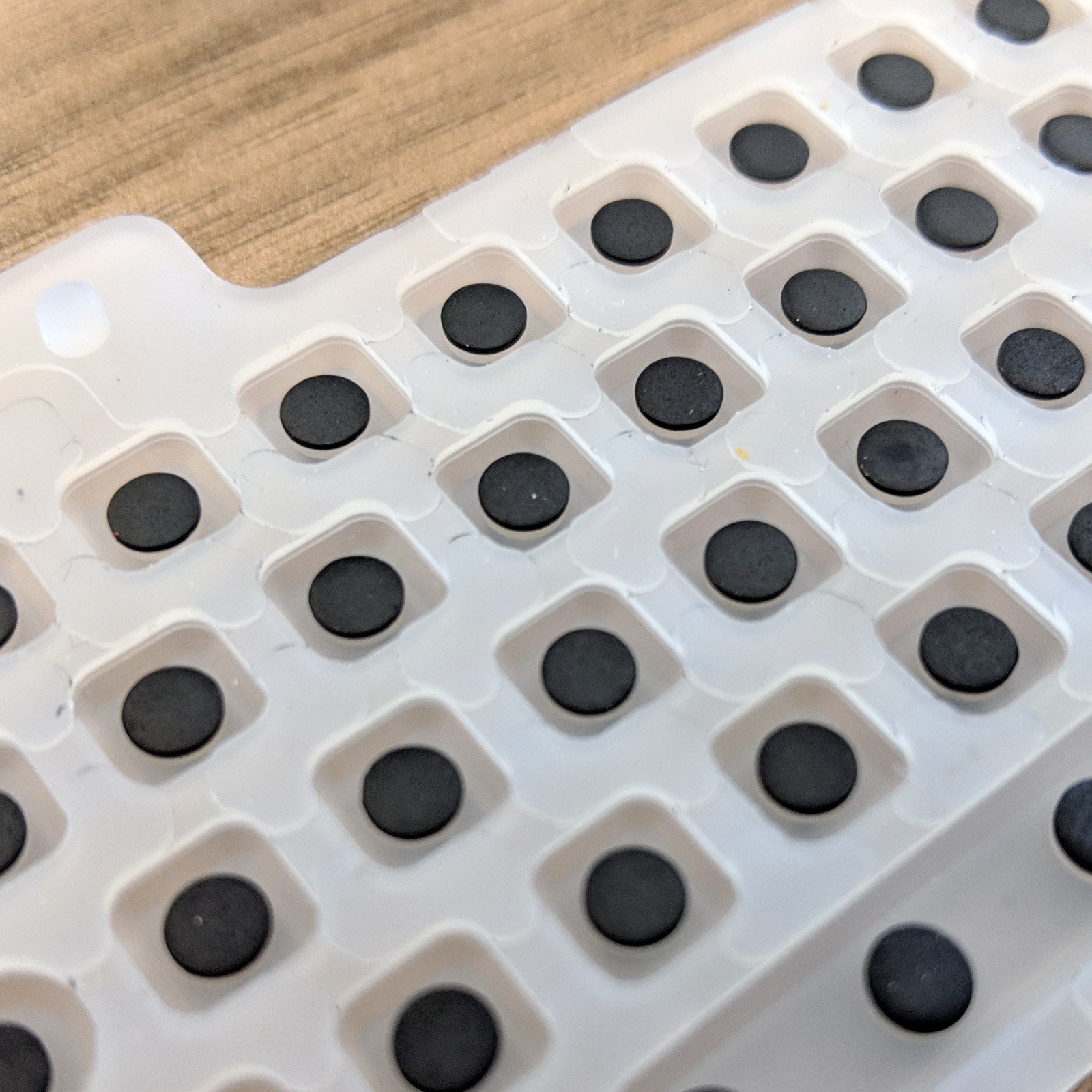

The rubber keyboard uses injection-molded silicone buttons that press the contacts. A carbon contact (“tablet”) is built into the silicone button, and the contacts for the keyboard matrix are created from the tracks on the printed circuit board. Contacts can be integrated into the board (ENIG technology recommended) or printed on top of conductive inks. In any case, the keyboard consists of a printed circuit board, silicone buttons with conductive contacts under each button, small conductive carbon contacts in each button, and sockets for attaching silicone to the board.

Choosing between a membrane and rubber keyboard, it is worth considering a few points, and many of them are able to outweigh the scales in favor of a membrane. Although rubber keyboards can be made in many colors, the characters on the membrane keyboard are essentially printed; on the membrane keyboard you can make any characters of any color. Membrane keyboards are cheaper because they do not need a mold. Rubber keyboards require a strip containing a monolithic block of silicone keys, which means the additional cost of a second mold for casting. And the rubber keyboard wins only on tactile sensations. If you have ever tried using the Atari 400, you will agree: it is much easier to type on rubber keyboards. And they are more stylish than membrane ones.

Ongoing projects

Not a specialized rubber keyboard that can be used even now

. Today I do not know cases of using specialized rubber keyboards in small runs. Of course, they exist in the DIY community: Adafruit sells 4x4 keyboards (Sparkfun has the same thing ), and similar buttons can be ordered on AliExpress and eBay. Yes, of course, Sparkfun and Adafruit spent on the development of boards, but the buttons themselves are likely to do somewhere far, far away. These are not specialized keyboards; These are standard ready-made keyboards for specialized projects.

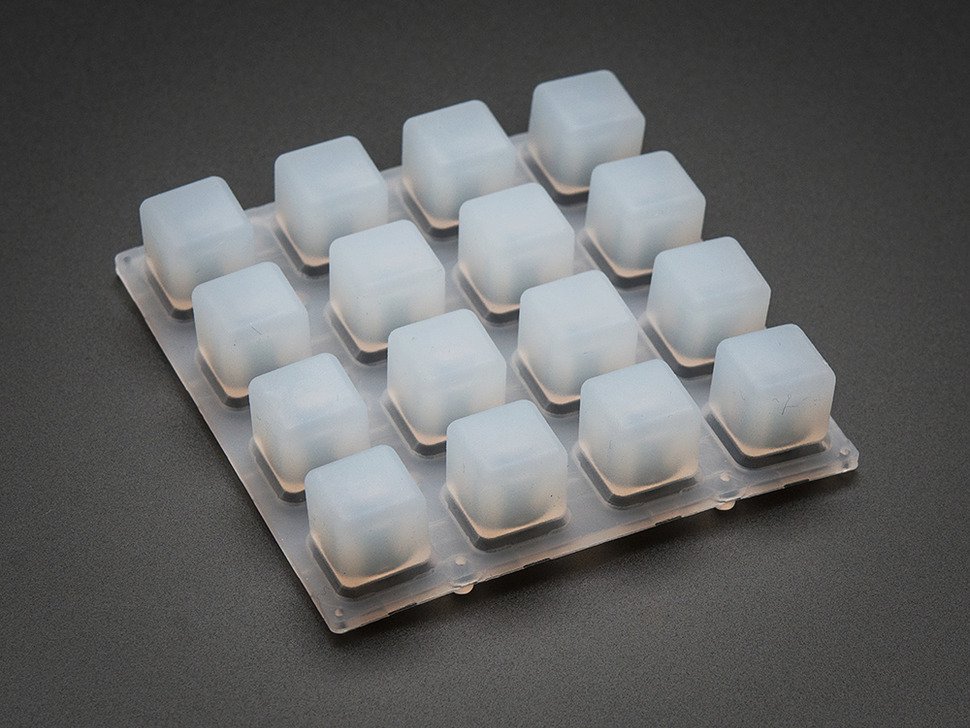

And these rubber buttons were used a lot where: to create a Monome clone , a step sequencer , a MIDI device. It is for this that the backlit silicone buttons were developed: they make cool MIDI controllers. But since there are no tags on them, they are of little use for anything else.

And these are the only, as far as I know, DIY projects that use 4x4 silicone keyboards. People, of course, are trying to do something else. Some of them are looking for rubber keyboards on the forums , and some are experimenting with aluminum molds, but so far no one has succeeded. Dave Jones rejected the idea of rubber keyboards for his uSupply project and switched to specialized membrane switches.

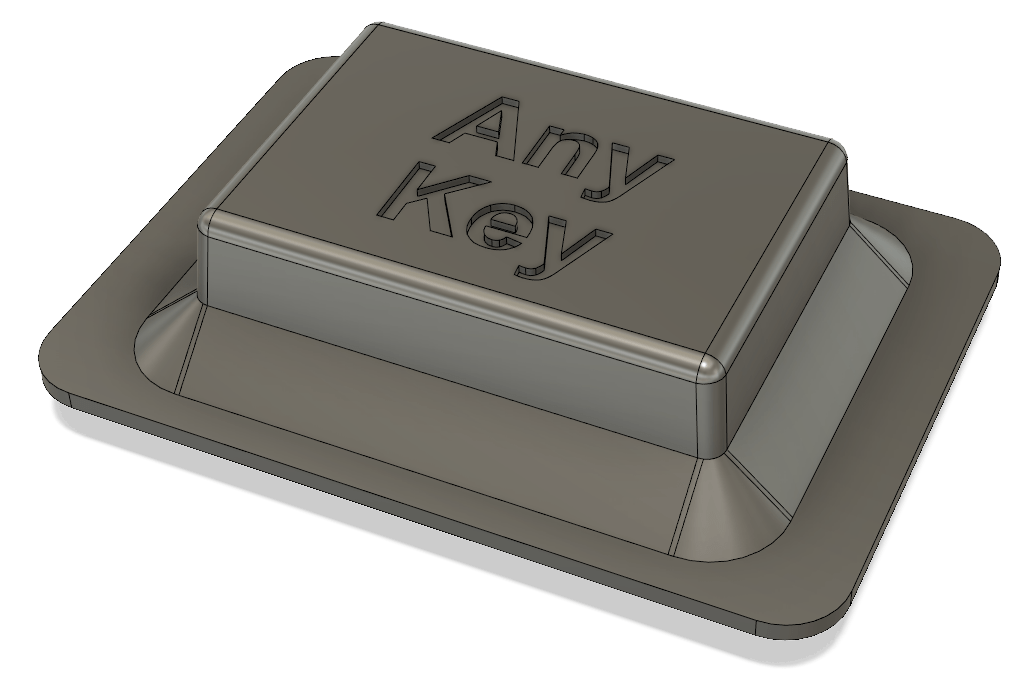

Design keyboard, boss and air holes

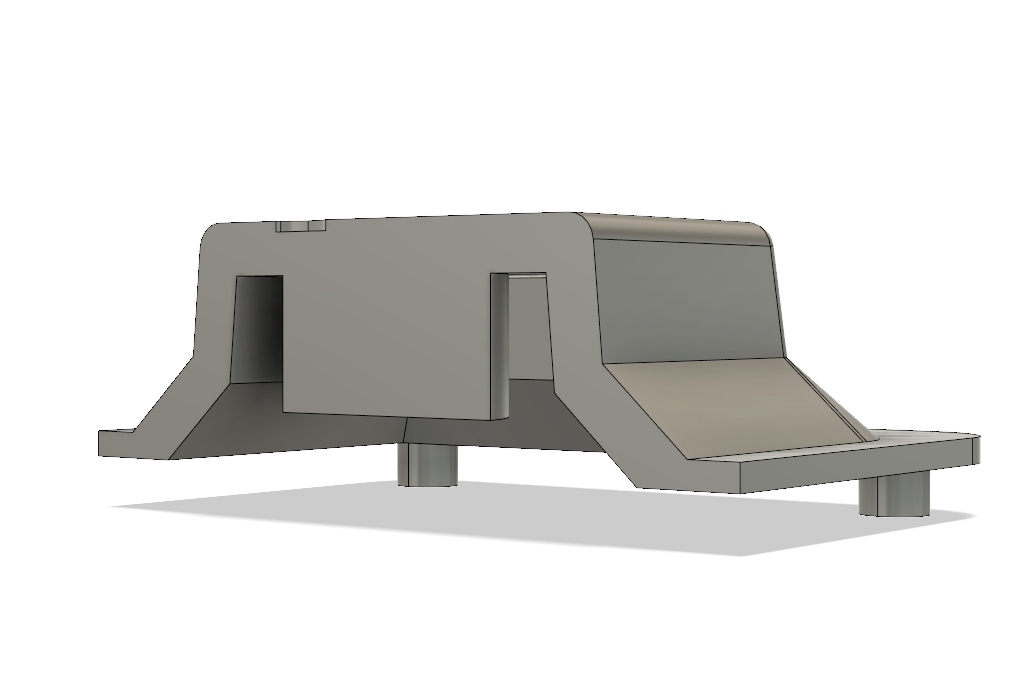

So what is the creation of a rubber keyboard made of? In fact, we are developing a steel or aluminum casting mold. The mold is sent to an injection molding machine, where it is filled with carbon balls, filled with hot silicone, which is then vulcanized. Further processing of the buttons is possible - laser marking, silk-screen printing or epoxy coating. Designing a rubber keyboard is designing a mold, but the basic components are pretty simple. Below is an example - a keyboard from a single key - which I made in Fusion360 in a few minutes.

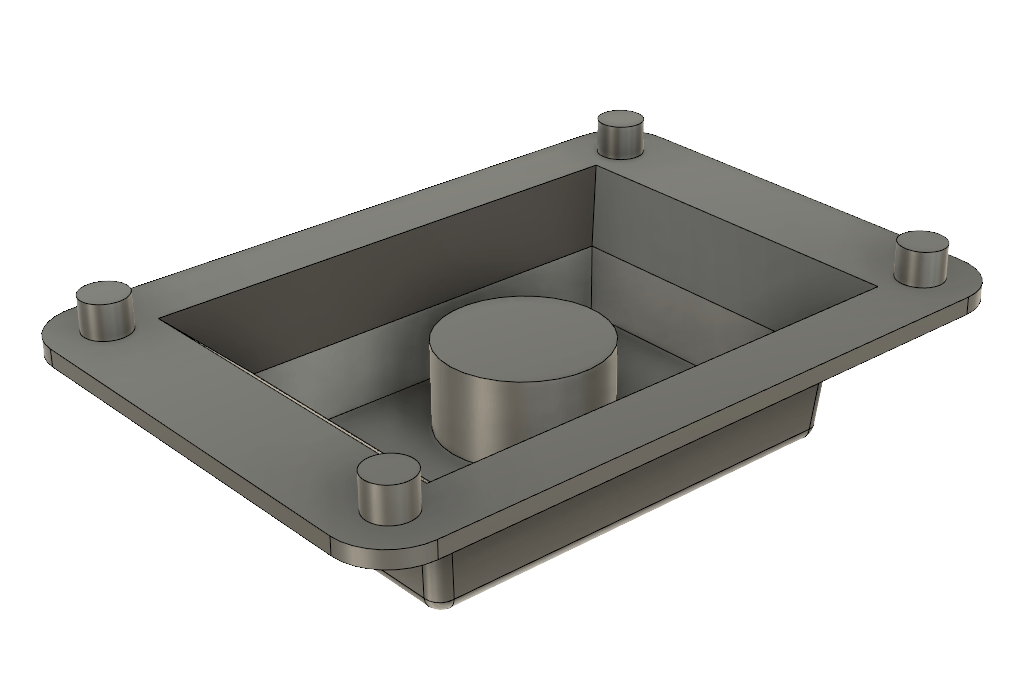

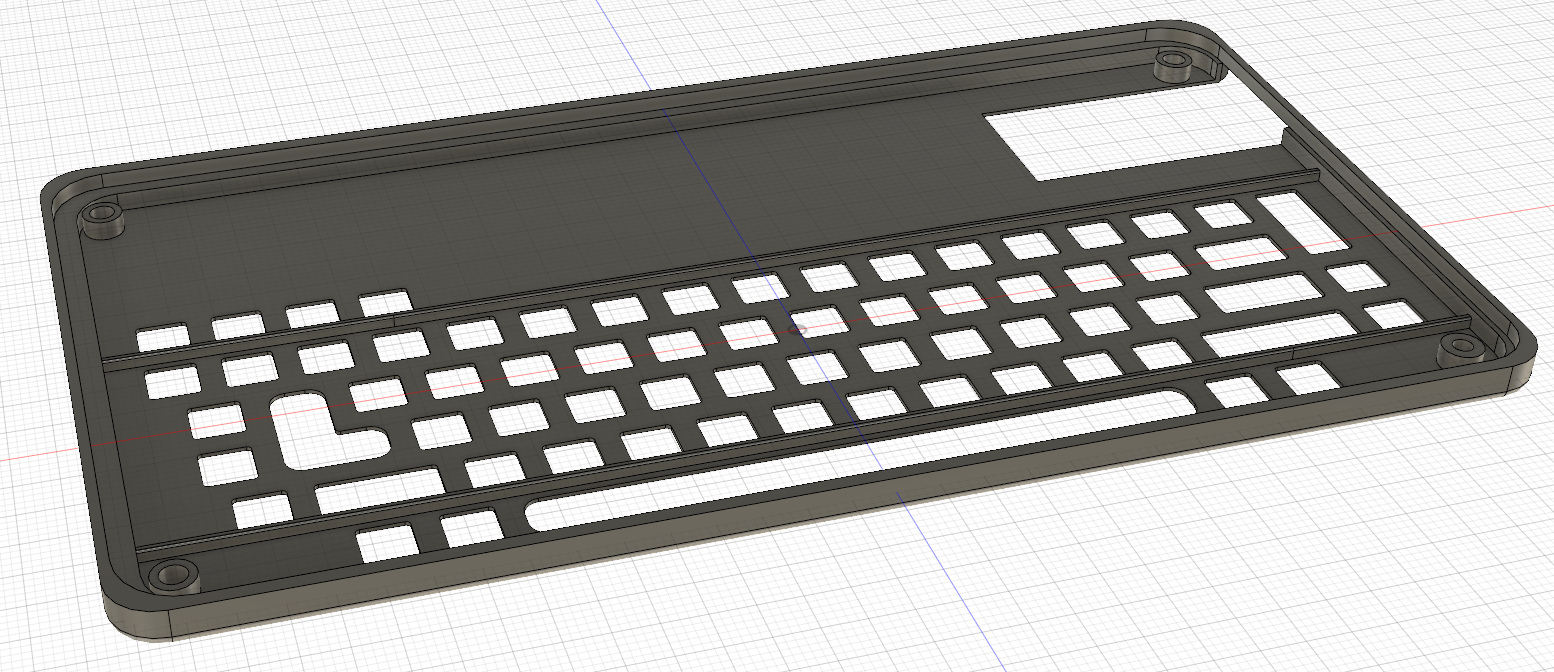

The external shape of the keyboard depends on the purpose, and the base is a layer of silicone. At the corners of the base there are four bosses for mounting on a circuit board. They are needed to align the button and prevent it from sliding.

The internal structure of the key consists of a large carbon tablet, the contact that will click on the board. There are simply more keys on the keyboard, but the shape of one key is essentially the same. Mark the spaces at the bottom of the key allowing air to pass underneath. If they are not made, the keyboard will flick when pressed.

Cutaway silicone key. A black object is a carbon tablet that serves as a bridge between two pins on the board.

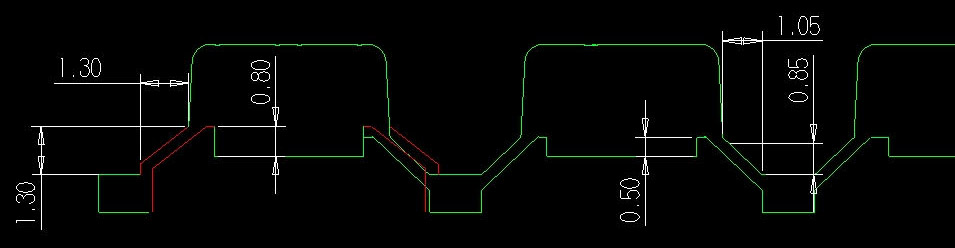

The dimensions of my keyboard are in mm.

After the keyboard project was ready, and the files were sent to the factory for the manufacture of molds and the production of several test samples, it was time to develop a printed circuit board. For my project, the circuit did not matter much - the main thing is that the board had two tracks closely connected to the opposite sides of the keyboard matrix. For this, ENIG technology is recommended. Production restrictions also matter: the standard minimum of the track width and the distance between them is 0.15-0.20 mm, and I developed a board with tracks of 0.25 mm and the same distance between them.

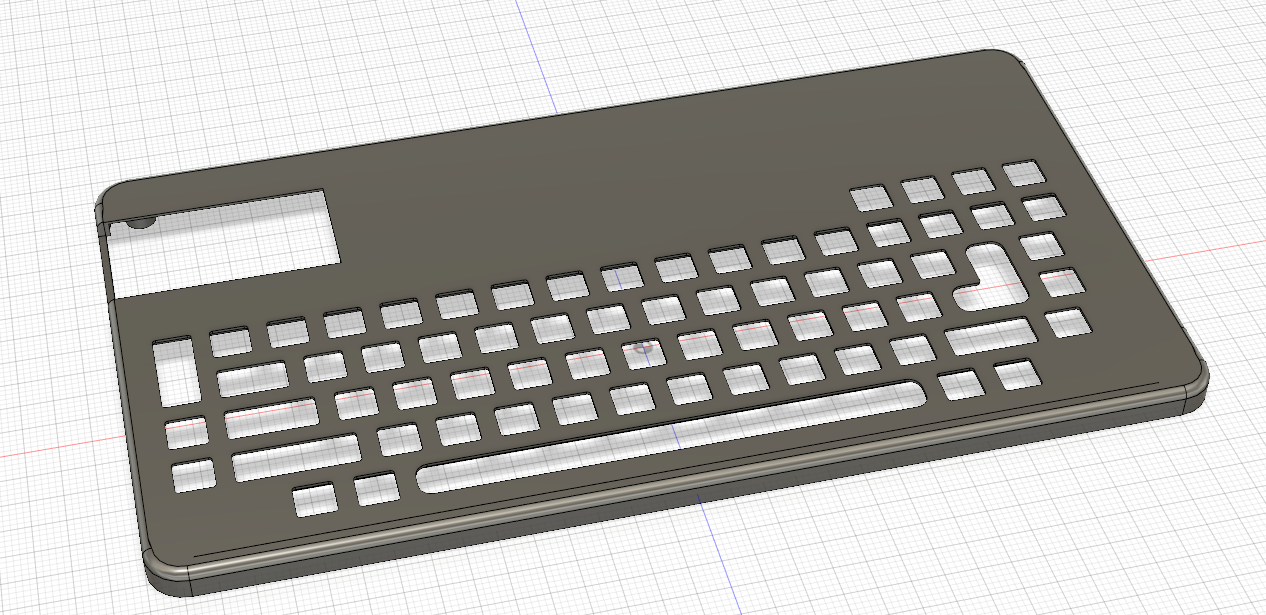

Having finished the keyboard and the board, you can proceed to the mounting strip. This is perforated plastic screwed to the board. A rubber keyboard is pinched between it and the board. I made the following prototype, just to test the keyboard. Electronics is just a Teensy LC (I had it at hand), with a cutout giving access to the prototyping board:

I sent this model to Shapeways and the keyboard was assembled. The firmware on Teensy uses the standard Keypad library and appears to the computer as a USB HID device. It turned out a specialized rubber keyboard of exactly the form that I need. This is not the final option, as the USB keyboard is just a working concept for checking rubber keys, but it really works.

I will reveal the cost of the project; it should be borne in mind that the sample here is very small - I turned to only one manufacturer with only one model. However, due to strong competition in the market, I think that these prices will be representative enough for the average cost of a specialized rubber keyboard.

The cost is as follows:

| Manufacture | $ 2 219 |

| Design | $ 600 |

| Bank commission | $ 58 |

| TOTAL | $ 2 877 |

From an economic point of view, all this makes sense with circulations of the order of 10,000

The total cost of a small number of samples was equal to $ 2877. This is the cost of a mold for casting and checking by an engineer for CAD files. Ten keyboards for three thousand bucks.

However, after all the stages of design and preparation, the factory is able to issue packs of keyboards. After that, the cost of one piece becomes equal to $ 1.3 for a circulation of 1000 to $ 0.79 for a circulation of 5000. So a total of a thousand keyboards will cost me $ 4,177, that is, $ 4.18 per piece. Five thousand keyboards will cost $ 6,827, or $ 1.36 apiece. This price, less than $ 1.5, makes this technology viable for small-scale production.

Rubber keyboards are suitable for large manufacturers: Samsung sells millions of TVs, and they all have one remote control. The issue of making a rubber keyboard for a DIY project has always remained open. Small-scale projects do not use this technology, so there was no one to ask if specialized silicone switches make sense. I say that it makes sense if you make a thousand keyboards. At a circulation of five thousand, the cost of a rubber keyboard and plastic fasteners may drop below the cost of a microcontroller.

→ All project sources are available on GitHub