Natural wear of the hard disk heads. Detection and evaluation

Introduction

Failure of the hard disk heads is a fairly frequent problem faced by data recovery specialists. The reasons for the failure of the heads of several, the most common:

- Damage to the heads in the event of a disk crashing (sticking on the surface, incorrect parking entry, etc.).

- Damage to the heads during a physical impact on the disc (a fall of the disc, a blow to the disc, strong vibrations during operation, etc.).

- Damage to the heads during electric shock (burned power supply, power supply voltage surge, polarity reversal when power is connected (do not ask me how, the connector somehow manages to plug the other side) to the drive, etc.).

- Manufacturing defects.

- Natural wear.

In this article I would like to talk about the latter reason. This reason for the failure of the magnetic head unit of hard drives ( normal wear and tear ) personally seems to me the most interesting, since it is rather difficult to diagnose. Usually, for the first four reasons, everything is more or less clear almost at the first glance at the heads, often even without a microscope. Natural wear with the naked eye is practically invisible.

What is it for? Isn't it easier, having found that the heads are faulty, just replace them and subtract the data? Unfortunately no. The way we approach the data recovery restoration procedures depends on what exactly caused the failure of the magnetic heads block. Let me explain by example.

If the heads failed as a result of the impact, then before installing a serviceable node in the disk, a detailed study of the magnetic plates would be needed: did they suffer as a result of the impact? Are there any scratches, chips? Could not the installation of a new unit of magnetic heads without preliminary preparation lead to new damage? As a result, a significantly increased list of preparatory procedures, including the application of special chemicals to surface damage.

Another example. If the heads are out of order if the emergency parking is incorrect, then another study will be required. It will be necessary to assess how the heads are damaged, whether their slider has not bent, whether this has led to the loss of block fragments inside the containment, etc. Accordingly, the order of work in restoring information, again, will be different, up to the refinement of the parking element inside the containment area and significant modifications to the firmware of the drive.

Well, if the heads fail as a result of normal wear and tear, in the overwhelming majority of cases it will be sufficient to simply replace the heads and proceed to reading the information (of course, provided that serviceable compatible ones are used).spare parts). That is why the task of determining the degree of wear of a block of magnetic heads seems to me quite important.

Some theory

A hard disk head is a node that hovers above the disk surface while the drive is running, using the aerodynamic properties of its slider. To ensure maximum efficiency of aerodynamics, the surface of the MR-element of the head is perfectly flat and has a certain pattern of grooves and bumps.

The rotational speed of a modern hard disk spindle engine can vary from 5,400 to 15,000 revolutions per minute depending on the purpose of the drive. Many notebook drives are made to increase energy efficiency low speed; drives for servers and high-performance platforms are made high-speed. At such a speed of rotation inside the disk, a powerful air flow is formed, which is used for the aerodynamics of the heads.

However, this air flow has another effect - the gradual knocking out of the ceramic and plastic parts of the block of magnetic heads that are in direct contact with it, small particles. Banal weathering , if we talk in terms of school natural history. In order to prevent these particles from damaging the surface (although, of course, this cannot be completely avoided), a fine dust filter catcher is installed in the disk, which is located in a place where it can cover the maximum amount of passing air flow. The fight against surface microdamages, which did occur, occurs through defect-management of the hard disk microprogram: defective sectors are entered into a growing list of defects and reassigned to the healthy sectors from the disk reserve.

Natural wear: how manifested

As a rule, the natural wear of the magnetic head assembly begins to manifest itself long before the hard disk finally fails. Only those who do not monitor the state of their computer hardware in principle overlook it. The hard disk has a subsystem SMART, which accumulates error statistics (reassigned sectors, unsuccessful attempts to start, the number of attempts to reassign a sector, etc.), based on which an approximate prediction of disk failure is made. When you start the computer, the SMART subsystem is polled, and if everything is fine, the computer starts; if any of the attributes of SMART "subsided" so much that it went beyond the bounds of normality, you will see a message on the second POST BIOS of this type: Hard Disk Drive XX SMART Status BAD, or similar in meaning. Starting the computer will be possible only by pressing one of the function keys (usually F1).

Unfortunately, quite a few users who have problems with the initial assembly of the computer (for example, incorrect installation of CPU FAN), which leads to the constant appearance of such messages (something like "CPU FAN speed error") and the need to press a function key to continue to start the computer disable this feature in the BIOS. In this case, when you start the machine, all notifications are ignored, and it becomes impossible to see if there was a notification about the bad SMART status of the disk at startup.

True, Windows also recognizes disks with a poor SMART status, but it may be too late for an actually dying disk. And this mechanism does not always work out, as practice shows: quite often, drives with one or two attributes that “sagging” may not cause any suspicion in Windows for a very long time. Therefore - see the statistics accumulated SMART, it is useful. You can follow it with the help of a mass of free utilities, for example - Victoria.

The wear of the disc starts from the moment it starts to operate, but at first it starts with low intensity. After a certain time, when the degree of wear reaches a certain, critical, value, the wear goes from linear to exponential growth, and the disk goes into a faulty state rather quickly.

The main signs of a disk transition to the exponential wear stage are: a rapid increase in the number of reassigned sectors in a SMART report, an increase in the number of errors when trying to reassign a sector, “slowing down” a disk, the appearance of “tying” sounds when accessing certain files or folders. At the final stage of wear, a large number of defective sectors appear (the defect management system can no longer cope with the flow of emerging defects), and serious brakes in the operation of the disk. The failure of the head (or several heads) due to wear is the apotheosis of this process. The computer stops loading or loads very slowly, you can not copy any of your files, everything is terribly slow, and, finally, it just stops working. Everything. The heads are worn out and can no longer read anything.

To be fair, it must be said that some drives have a microprogram lock system activated in the event of its problems (including defect management). In this case, the disk refuses to work (either it is not detected at all, or it is detected, but does not give up capacity, or is determined by the “factory” name, etc.). The lock prevents critical wear if the disk went directly to this face, provided that the user does not try to “start” the disk with multiple inclusions (“suddenly it starts”), dances with a tambourine and dubious recommendations from the Internet (“on On the full moon, place your disk on the system unit, spit three times in the processor fan and, when you fly back, say 'Information, return, hard disk boot up' ”and similar anti-scientific heresy). There is only one correct advice:

Diagnosis of normal wear of a magnetic head assembly with a microscope

Microscopic analysis of the hard disk heads has long been the standard in the data recovery industry. Examination of the heads under a microscope makes it possible to identify surfaces on which there are serious damages (dust on the heads, polished surface of the head, etc.), to identify the nature of the damage to the heads, etc. However, there is no generally accepted method for detecting natural wear of the heads.

Taking into account the fact that head wear is primarily a knockout of microparticles from its surface as a result of exposure to a strong air current (microdamage to the surface), it is quite logical that we can assess the degree of wear by its relief state. However, with standard lighting, you can only see large flaws in the working surface of the MR element; In order to “reveal” the micro-relief completely, two sources of light are required: the main one, directed perpendicular to the surface, and some similarity of backlight, directed at a small angle (20 - 30 degrees) to the surface. To enhance the "manifestation" of the microrelief, we used ordinary white light from an annular halogen lamp as the main source of light, and the LED of a cold blue glow was used as an additional ("back") light.

A setup for research, therefore, consists of: a MS-VP trinocular microscope; an adapter for Canon EF bayonet, a Canon EOS 5D Mark II camera, a Model 2401 annular lamp, a “backlight” light source — a regular microscope illuminator with a replaced LED.

Installation for the study of the degree of wear of the magnetic heads of the hard disk.

Under normal illumination with direct light, only major terrain damage is visible on the surface of the MR element. This is understandable: the light goes from top to bottom at a right angle, the light source - from all sides (annular illuminator); while the shadows are almost not discarded. The introduction of a “backlight” light source into the light scheme makes it possible to see the shadows from the numerous micro unevenness of the surface and to assess the nature of damage to the MR element.

Example

As an example, we take two identical old drives, in which the wear process has been going on for a long time, but one disk is in a critical (“death”) state, and the second is in a state where the SMART status is just starting to warn of a possible disk failure. (the disk only goes to an exponential increase in wear). Disks Seagate ST3160215AS, family Seagate Barracuda 7200.10, capacity 160 GB. The design of the containment uses 2 heads. The shooting conditions are the same: ISO 320, shutter speed 1/30, F 0 (the aperture is fully open, as the shooting goes through the microscope).

The disk in the “death state” has extremely sad SMART attributes and a huge number of defects. The disk, whose SMART just started to show an error, has a smooth reading schedule and less sad indicators of SMART attributes.

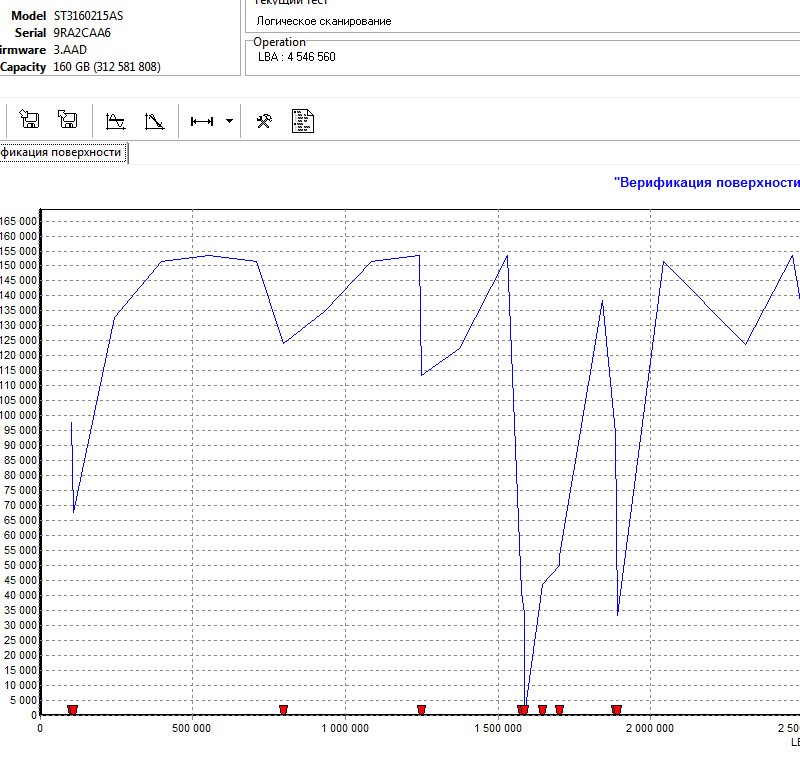

Graph of reading an experimental disc in critical state of wear, first 3 million sectors

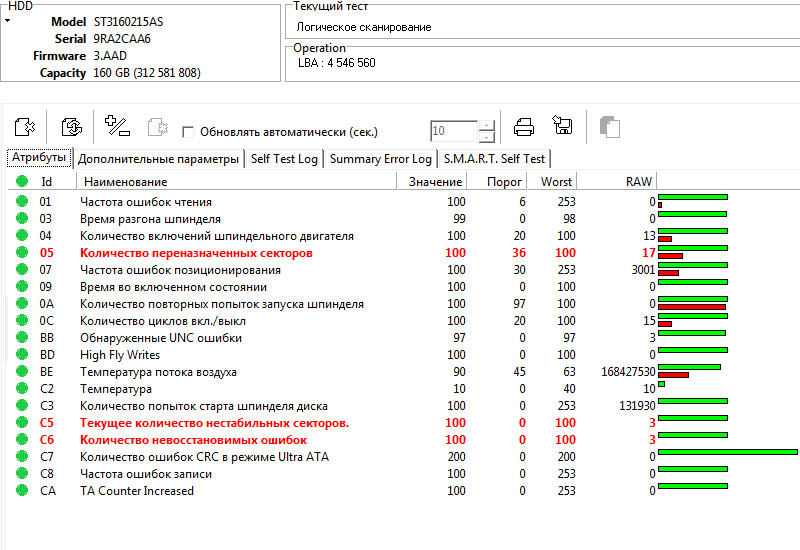

Attributes of SMART experimental disc in critical state of wear

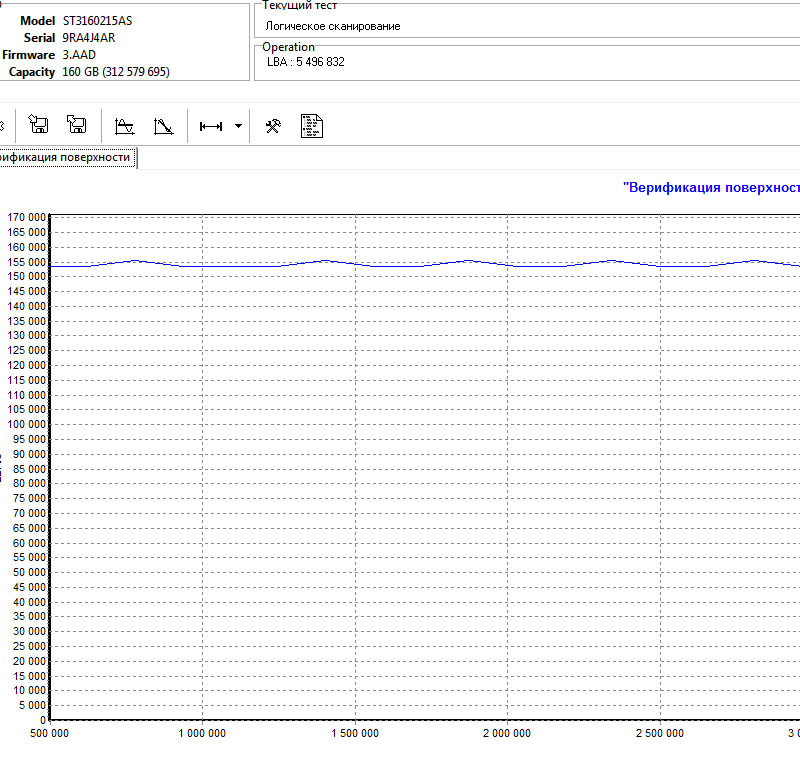

Graph of reading an experimental disc in precritical state of wear, first 3 million sectors

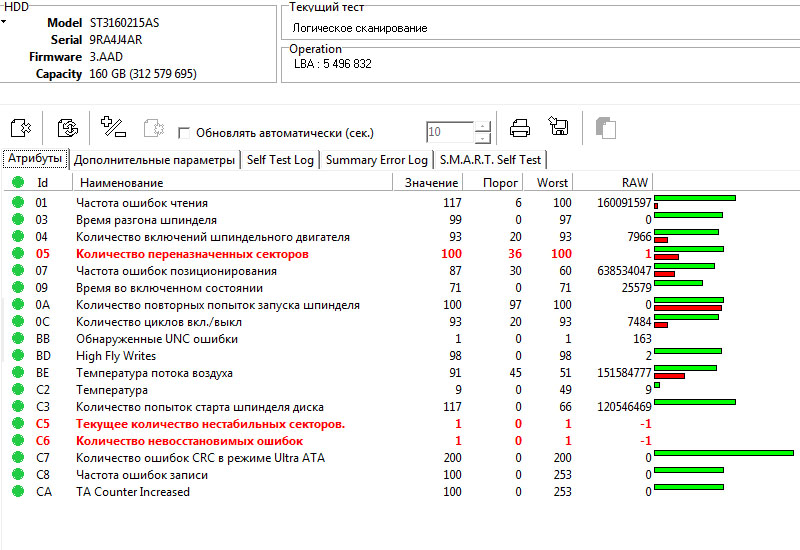

Attributes of SMART experimental disc in a precritical state of wear

Let's look at the heads first with a normal illuminated from above. The surface of the MR element looks flat.

General view of the microrelief of the MR-element head Seagate ST3160215AS disc, under a direct light source.

Now let's turn on the “backlit” light. The relief picture has changed: where we see indentations in ordinary light, in double light they look like bulges, and the “grain” of the surface is noticeably increased.

The disc with less wear on the surface of the MR-element has a relatively smaller grain size, but most importantly, there are no large holes. A disc with a greater degree of wear has a relatively larger grain and has clearly visible large gouges on the surface of the MR element.

Different degree of graininess of the microrelief of one surface area of the MR-element of the heads of the Seagate ST3160215AS accumulators with varying degrees of wear, scale 100%.

General view of the surface micro-relief of the MR-element of the heads of the Seagate ST3160215AS drives with varying degrees of wear

Conclusion

The use of the described technique allows, with a high degree of reliability, to determine the hard disk heads that failed as a result of natural wear. My technique is used for all disks arriving with a diagnosis of a “faulty block of magnetic heads,” since the examination of heads under a microscope is an indispensable part of diagnostics. However, I want to make a reservation: it is highly undesirable to use a point lamp as a source of main light, in particular - bright LEDs. For the perfect manifestation of the surface relief, we need uniform illumination of the surface.