M5BAT - A New Approach to Industrial Energy Storage

Today's development of the electric power industry provides for the increasing introduction of renewable energy sources. Development also continues in the field of improving the quality and reliability of power supply.

As one of the options for solving these problems, the idea of creating substations with large-capacity batteries near consumers is used. This article presents one of the solutions that is scheduled for commissioning in 2016 in Germany.

The development of such projects began in the 1980s. At that time, West Berlin had a completely autonomous power supply system and, in order to maintain frequency, the Batterie-Speicherkraftwerk Berlin-Steglitz was built in 1986, which means “battery-powered power plant”. This station was closed in 1994, after the merger of power systems.

The station had the following characteristics:

The station consisted of 7080 lead batteries in 12 parallel branches of 590 batteries each.

Today, the lead-acid batteries or lithium-ion batteries mentioned above are used in large quantities on the market for such solutions. Of the latter, one can recall such decisions in Germany:

But as with any technology, there are always flaws. For all storage technologies, the following is true: either we get a lot of power and a small amount of stored energy, or vice versa. This is true both when comparing different technologies, and in the middle of one group of the same chemical principle (although here the difference is often not so great). Pricing and operating costs are also important.

Therefore, ideas have arisen and continue to arise on the combination of various types of batteries. For example, in Braderup, a hybrid installation of lithium-ion batteries (2 MW, saved energy 2 MWh) and a vanadium redox battery (Vanadium-Redox-Flow-Batteriespeicher, 330 kW and 1 MWh) were commissioned. The lithium-ion battery was created by Sony, the vanadium - Vanadis Power, the design and control system - Bosch [5].

The purpose of the article is to describe one of these hybrid projects, namely a combination of lithium-ion and lead-acid batteries.

For stationary installations, weight and volume are not the most important factor, because here the advantage of lithium-ion batteries does not play a big role. At the same time, the currents with which these batteries can be charged and discharged are higher than those applicable for lead-acid batteries of the same capacity. The main drawback is the installation cost and operating costs.

It is important to remember here that we are talking about energy, where it is not about 5-6 years, but about 10 and above, up to 30 years for medium voltage networks (where similar installations are used today). In this case, the benefits of a lithium-ion battery are offset by the fact of cheaper (albeit more frequent) maintenance of lead batteries. I note that the service is not a replacement. In fact, in such systems, a lead-acid battery lasts up to 9 years without replacement, at least under extremely adverse conditions (low temperatures in the Alps), which is already comparable to the life of lithium-ion batteries.

Therefore, it was decided to implement a hybrid installation to cover both unplanned jumps and those planned to smooth out the consumption schedule.

The characteristics of the installation are contained in its name - M5BAT. It is planned that the peak capacity will be 5 MW, the maximum amount of stored energy - 5 MWh. The number 5 is also used to abbreviate the following name: Modularer multi-Megawatt multi-Technologie Mittelspannungsbatteriespeicher - Modular multi-megawatt medium voltage energy storage system using several technologies (the English version is also good in terms of five M in a row - Modular Multimegawatt, Multitechnology Medium-Voltage Battery Storage System).

The technical goal is to develop an approach to the creation of modular systems.

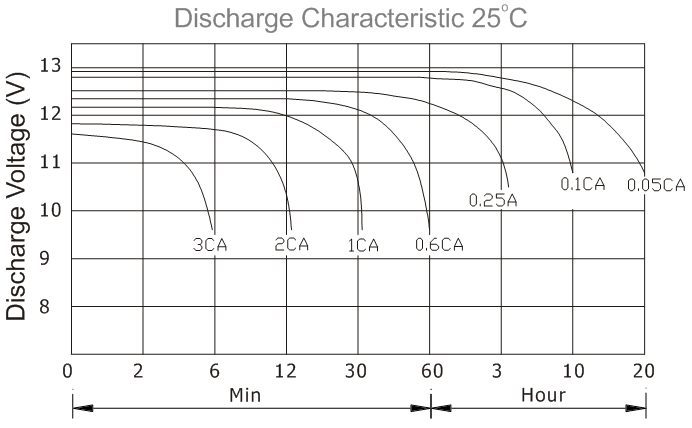

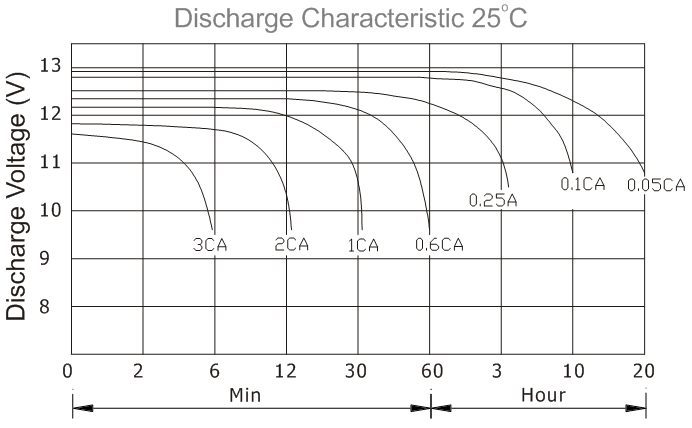

Here I will also make a small digression-reminder. The faster the battery runs out, the less energy you can get from it. This is true for all types of chemical batteries. On the Internet there are lots of pictures showing this relationship. Below is one of them:

The second, no less important goal, economic - to create an optimal system, cheaper than pure lithium-ion, but not inferior in efficiency in real work in the electric network.

The manufacturer was Beta-motion. The company is a systems developer, but not a manufacturer. Unfortunately, it was not possible to find reliable information about the type of cells, except for information on the use of a ceramic separator.

The following Exide production models were used:

More complete specifications can be found here: 16 OCSM 2320 LA and 602 1960C Solar .

Left 16 OCSM 2320 LA, Right 602 1960C Solar

SMA manufacturer, two 630 kVA inverters each. They were designed with more features than standard. But the basic characteristics as a whole should not have changed. Since it did not work out to verify this information, I give detailed data on standard models by reference .

After commissioning, work is planned for a year. Both the testing of the technical part will be carried out, in particular the reliability and overall ability to work in the required mode for smoothing peaks, and work in the energy market. Based on the research, a decision will be made on the fate of the project.

Based on the project, an approach to a modular system for use in electrical networks will be developed.

Institute for Power Generation and Storage Systems RWTH Aachen University - Institute of Power Generation and Storage Systems of the Rhine-Westphalian Technical University of Aachen.

Institut für Elektrische Anlagen und Energiewirtschaft RWTH Aachen - Institute of Electrical Systems and Energy of the Rhine-Westphalian Technical University of Aachen.

E.On is one of the largest backbone network operators in the EU.

Exide Technologies is a manufacturer of VRLA gel and Kupferstreckmetalltechnologie (expanding copper technology) batteries.

SMA Solar Technology AG is a supplier of inverters.

Beta-motion is a manufacturer of lithium-ion batteries. Not listed in the list of partners on the main site.

1. Official site of the M5BAT project

2. Battery power station 5 MWh in Schwerin

3. Battery power station 2 MWh in Dresden

4. Regional regulatory power station Feldheim, 6.5 MWh

5. Hybrid LiIon-RedOx battery in Braderup

As one of the options for solving these problems, the idea of creating substations with large-capacity batteries near consumers is used. This article presents one of the solutions that is scheduled for commissioning in 2016 in Germany.

A bit of history

The development of such projects began in the 1980s. At that time, West Berlin had a completely autonomous power supply system and, in order to maintain frequency, the Batterie-Speicherkraftwerk Berlin-Steglitz was built in 1986, which means “battery-powered power plant”. This station was closed in 1994, after the merger of power systems.

The station had the following characteristics:

| Peak power | 17 MW |

| Peak power output | 20 minutes |

| Maximum stored energy | 14.4 MWh |

The station consisted of 7080 lead batteries in 12 parallel branches of 590 batteries each.

Existing technology

Today, the lead-acid batteries or lithium-ion batteries mentioned above are used in large quantities on the market for such solutions. Of the latter, one can recall such decisions in Germany:

- In Schwerin, Samsung installed a 5 MWh battery with a peak power of 5 MW. The battery consists of 25600 batteries with a chemical composition of lithium oxide-manganese. Claimed lifetime 20 years [2]

- In Dresden, a battery of LG Chem batteries with characteristics of 2 MW / 2.7 MWh was installed. JH2 type batteries. Unfortunately, marketing here also took its toll and LG naps these polymer batteries, although they are the most common lithium-ion ones in a non-rigid case (pouch bag cells). Claimed lifetime 10 years [3]

- In Feldheim, the largest in Europe (10 MW peak, 6.5 MWh of energy) regulatory power station was commissioned. Made from 3360 modules spawn by LG Chem [4]

But as with any technology, there are always flaws. For all storage technologies, the following is true: either we get a lot of power and a small amount of stored energy, or vice versa. This is true both when comparing different technologies, and in the middle of one group of the same chemical principle (although here the difference is often not so great). Pricing and operating costs are also important.

Therefore, ideas have arisen and continue to arise on the combination of various types of batteries. For example, in Braderup, a hybrid installation of lithium-ion batteries (2 MW, saved energy 2 MWh) and a vanadium redox battery (Vanadium-Redox-Flow-Batteriespeicher, 330 kW and 1 MWh) were commissioned. The lithium-ion battery was created by Sony, the vanadium - Vanadis Power, the design and control system - Bosch [5].

The purpose of the article is to describe one of these hybrid projects, namely a combination of lithium-ion and lead-acid batteries.

Project Motivation

For stationary installations, weight and volume are not the most important factor, because here the advantage of lithium-ion batteries does not play a big role. At the same time, the currents with which these batteries can be charged and discharged are higher than those applicable for lead-acid batteries of the same capacity. The main drawback is the installation cost and operating costs.

It is important to remember here that we are talking about energy, where it is not about 5-6 years, but about 10 and above, up to 30 years for medium voltage networks (where similar installations are used today). In this case, the benefits of a lithium-ion battery are offset by the fact of cheaper (albeit more frequent) maintenance of lead batteries. I note that the service is not a replacement. In fact, in such systems, a lead-acid battery lasts up to 9 years without replacement, at least under extremely adverse conditions (low temperatures in the Alps), which is already comparable to the life of lithium-ion batteries.

Therefore, it was decided to implement a hybrid installation to cover both unplanned jumps and those planned to smooth out the consumption schedule.

Specifications

The characteristics of the installation are contained in its name - M5BAT. It is planned that the peak capacity will be 5 MW, the maximum amount of stored energy - 5 MWh. The number 5 is also used to abbreviate the following name: Modularer multi-Megawatt multi-Technologie Mittelspannungsbatteriespeicher - Modular multi-megawatt medium voltage energy storage system using several technologies (the English version is also good in terms of five M in a row - Modular Multimegawatt, Multitechnology Medium-Voltage Battery Storage System).

The technical goal is to develop an approach to the creation of modular systems.

Here I will also make a small digression-reminder. The faster the battery runs out, the less energy you can get from it. This is true for all types of chemical batteries. On the Internet there are lots of pictures showing this relationship. Below is one of them:

The second, no less important goal, economic - to create an optimal system, cheaper than pure lithium-ion, but not inferior in efficiency in real work in the electric network.

Components Used

Lithium ion batteries

The manufacturer was Beta-motion. The company is a systems developer, but not a manufacturer. Unfortunately, it was not possible to find reliable information about the type of cells, except for information on the use of a ceramic separator.

Lead acid batteries

The following Exide production models were used:

| Title | 16 OCSM 2320 LA | 602 1960C Solar |

| Technology | CSM (Copper Stretch Metal) | VRLA gel |

| Number of cycles | n.d. | 2400 |

| Lifetime | 20 years | n.d. |

| Nominal capacity, 1 pc. | 4180 Wh | 3670 Wh |

More complete specifications can be found here: 16 OCSM 2320 LA and 602 1960C Solar .

Left 16 OCSM 2320 LA, Right 602 1960C Solar

Inverter

SMA manufacturer, two 630 kVA inverters each. They were designed with more features than standard. But the basic characteristics as a whole should not have changed. Since it did not work out to verify this information, I give detailed data on standard models by reference .

The future of the project

After commissioning, work is planned for a year. Both the testing of the technical part will be carried out, in particular the reliability and overall ability to work in the required mode for smoothing peaks, and work in the energy market. Based on the research, a decision will be made on the fate of the project.

Based on the project, an approach to a modular system for use in electrical networks will be developed.

Project participants

Designers

Institute for Power Generation and Storage Systems RWTH Aachen University - Institute of Power Generation and Storage Systems of the Rhine-Westphalian Technical University of Aachen.

Institut für Elektrische Anlagen und Energiewirtschaft RWTH Aachen - Institute of Electrical Systems and Energy of the Rhine-Westphalian Technical University of Aachen.

Industry partners

E.On is one of the largest backbone network operators in the EU.

Exide Technologies is a manufacturer of VRLA gel and Kupferstreckmetalltechnologie (expanding copper technology) batteries.

SMA Solar Technology AG is a supplier of inverters.

Beta-motion is a manufacturer of lithium-ion batteries. Not listed in the list of partners on the main site.

Sources

1. Official site of the M5BAT project

2. Battery power station 5 MWh in Schwerin

3. Battery power station 2 MWh in Dresden

4. Regional regulatory power station Feldheim, 6.5 MWh

5. Hybrid LiIon-RedOx battery in Braderup