How it all began: optical discs and their history

In general, optical compact discs appeared in 1982, the prototype saw the light even earlier - in 1979. Initially, compacts were developed as a replacement for vinyl discs, as a better and more reliable carrier. It is believed that laser discs are the result of the joint work of teams of two technology corporations - Japanese Sony and Dutch Philips.

At the same time, the base technology of “cold lasers”, which made the appearance of laser discs possible, was developed by Soviet scientists Alexander Prokhorov and Nikolai Basov.. For their invention, they were awarded the Nobel Prize. In the future, technology has evolved, and in the 70s, Philips developed a method for recording CDs, which initiated the CD. First, the company's engineers created ALP (audio long play) as an alternative to vinyl records.

The diameter of the ALP disks was approximately 30 centimeters. A little later, the engineers reduced the diameter of the discs, while the playback time dropped to 1 hour. Laser discs and playback devices for them were first demonstrated by Philips in 1979. After that, the company began to search for a partner for further work on the project - the technology was seen by developers as international, and it was difficult to develop it to the necessary level and popularize on its own.

The beginning of everything

Management decided to try to establish contacts with technology companies from Japan, while this country was at the forefront of hi-end technology. To do this, Philips delegates went to the country, they managed to meet with the President of Sony, who became interested in technology.

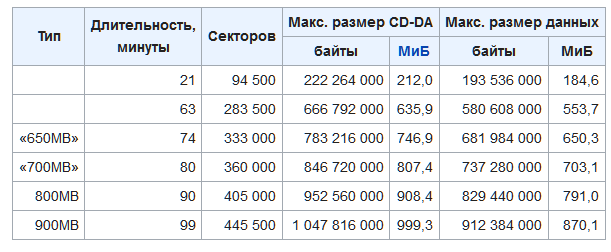

Almost immediately was formedPhilips-Sony engineering team, they developed the first specifications of the technology. Sony Vice President insisted on increasing the disk volume, he wanted the compact to accommodate Beethoven’s ninth symphony, for which the disk volume was expanded from 1 hour to 74 minutes (there is also an opinion that this is just a beautiful marketing story). The amount of data that fit on such a disk was 640 MB. Engineers have developed sound quality parameters. For example, the sampling frequency of stereo signals was regulated at the level of 44.1 kHz (for one channel 22.05 kHz) with a bit width of 16 bits each. This is how the standard Red Book appeared.

The name of the new technology did not appear suddenly - it was chosen from several options, including Minirack, Mini Disc, Compact Rack. As a result, the developers have combined the two names, getting a hybrid Compact Disc. Last but not least, this name was chosen because of the growing popularity of audio cassettes ( Compact Cassette technology ).

Philips and Sony also played a crucial role in the development of the first digital CD specification, called the Yellow Book or CD-ROM. The new specification made it possible to store not only audio, but also text and graphic data on disks. The disc type was determined in automatic mode when reading the header. The problem was that a CD that conforms to the Yellow Book standard could only work with a certain type of drives that were not universal.

On August 17, 1982, the first CD was released at the Philips factory in Langenhagen, Germany. The Visitors album was recorded on it.ABBA groups. It is worth noting that the lacquer coating of the first discs was not of very high quality, so that compact buyers often spoiled them. Over time, the quality of the disks has improved. The first few years they were used exclusively in hi-fi equipment, they were used as a replacement for vinyl records and cassettes.

Since 2000, 700 MB discs began to appear on the market, making it possible to record audio with a total duration of up to 80 minutes. They have completely ousted 650 MB disks from the market. There are also 800 MB carriers, but they were not suitable for all drives, so such discs were not particularly popular. It was possible to increase the amount of storage space available by reducing the distance between tracks. So, for example, for discs with a capacity of 650 MB, the distance between tracks is 1.7 microns, and for 800 MB discs, this indicator is reduced to 1.5 microns. Also at the first speed is 1.41 m / s, and the second is 1.39 m / s.

How it works

The disk consists of several layers. The substrate is polycarbonate, its thickness is 1.2 mm, diameter - 120 mm. On the substrate is placed another layer - metal (it can be gold, silver, or, most often, aluminum). Next, the metal layer is protected with a varnish, which is applied graphics. The substrate reliably protects the metal layer, so that very deep scratches interfere with the reading. The diameter of the hole in the disk - 15 mm.

The format of data storage for disks is Red Book (it was mentioned above). Reading errors are corrected using the Reed-Solomon code, so that light scratches do not reduce the readability of the disk.

The data on the disc is recorded in the form of a spiral track of the so-called pits (recesses), which are squeezed into the polycarbonate base. The depth of each pit is about 100 nm, width - 500 nm. Pita length from 850 nm to 3.5 μm. Pitas scatter or absorb light, the substrate reflects. Thus, a recorded disc is an excellent example of a reflective diffraction grating.

The disk is read using a laser beam with a wavelength of 780 nm, which is emitted by a semiconductor laser. The principle of reading is to register changes in the intensity of the reflected light. So, the laser beam converges on the information layer, the diameter of the light spot in this case is 1.2 μm. The maximum signal is recorded between pitas. In the case of contact with the pit, a lower light intensity is recorded. Changes in intensity are converted into an electrical signal with which the equipment operates.

How to create a disc

- The first step is to prepare the data for launch in the series;

- Photolithography - the second stage, is the process of creating a disk stamp. First, a glass disc is created, onto which a layer of photoresistive material is applied, and information is recorded on it. The material changes the physico-chemical properties under the action of light;

- Data recording is performed using a laser beam. With increasing laser power (when you need to create a pit), the chemical bonds of the molecules of the photoresistive material are destroyed, and it freezes;

- The photoresist is etched (in different ways, from plasma to acid), areas not affected by the laser are removed from the matrix;

- The disk is placed in a galvanic bath, where a nickel layer is deposited on its surface;

- The discs are molded by injection molding, the original glass disc is used as the source code;

- Next, metal is sprayed onto the information layer;

- A protective varnish is applied to the outside, on which a graphic image is already applied.

What about CD-RW?

CD-RW is a kind of CD that appeared in 1997. Initially, the standard was called CD-Erasable (CD-E, erasable CD).

It was a real breakthrough in the field of recording and storing information. After all, getting an inexpensive and capacious information carrier was a dream of thousands of engineers and users. CD-RW is similar in structure and operation to a regular CD, but the recording layer is different - it is a specialized alloy of chalcogenides. Silver indium antimony tellurium is most commonly used. When heated above the melting point, such an alloy changes from a crystalline to an amorphous state.

The phase transition in this case is reversible, which is the basis for the rewriting process. The thickness of the active layer of the disk is only 0.1 μm, so that the laser is easy to act on the substance. The recording process takes place when exposed to a laser beam, the active layer in this case goes into the melt (those areas that were affected by the laser). Then the heat diffuses into the substrate, and the melt passes into the amorphous state. In amorphous segments, such characteristics as the dielectric constant, the reflection coefficient and, consequently, the intensity of the reflected light change. It carries information about recording on disk. The reading is performed using a laser of lower power, which cannot affect the active layer. When recording, the active layer heats up to 200 degrees Celsius,

Repeated use of CD-RW leads to mechanical fatigue of the working layer. Therefore, the engineers who developed the technology used substances with a low fatigue rate. A CD-RW can sustain about a thousand rewriting cycles.

DVD - even more capacity!

The first DVDs appeared in Japan in 1996, they appeared as a response to the request of users and businesses who needed more and more capacious media. Initially, high-capacity drives were developed by several companies at once. Two independent development directions have emerged: Multimedia Compact Disc (Philips and Sony), - Super Disc (8 large corporations, including Toshiba and Time Warner). A little later, both directions merged into one under the influence of IBM. She convinced partners not to repeat the events of the “war of formats” times, when there was a battle for the priority between the standards of videotapes “Video Home System” and “Betamax”.

The technology was announced in September 1995, and in the same year, the developers published specifications. The first DVD burner was released in 1997.

It was possible to increase the recording capacity while maintaining the previous dimensions by using a red laser with a wavelength of 650 nm. The track pitch is two times less than that of the CD and is 0.74 μm.

Blu-ray - the most modern optical media

Another type of optical media with much higher data recording density than a CD or DVD. The standard was developed by an international consortium of BDA. The first prototype appeared in October 2000.

The technology involves the use of a short-wave laser (wavelength of 405 nm), hence the name. The letter “e” was removed because the expression blue ray is commonly used in English and cannot be patented. The use of a blue (blue-violet) laser made it possible to narrow the track to 0.32 μm, increasing the data recording density. Media reading speed increased to 432 Mbps.

UDF - Universal Disk Format

UDF is a file system format specification that is independent of the OS. It is designed to store files on optical media - both CD, and DVD and Blu-Ray. UDF does not have a limit of 2 and 4 GB for recordable files, so this format is ideal for high-capacity drives - DVD and Blu-Ray.

Optical discs and the Internet

Technology companies continue to improve optical discs. So, Sony and Panasonic in 2016 were able to increase the capacity of optical media up to 3.3 TB. At the same time, disk performance remains, according to Sony representatives, up to 100 years.

Nevertheless, all types of optical discs are gradually losing popularity - with the development of the Internet, the need for users to accumulate data on disks disappears. Information can be stored in the cloud, which is much more convenient (how much safer it is - another question). Compact discs are not nearly as popular as they were several years ago, but they are most likely not threatened with complete oblivion (as in the case of audio cassettes) - they will be used to create archives of information important for business.

If terabyte optical discs go into a series, their use will be limited - maybe with their help they will distribute films in 4K and modern games with a set of various bonuses. But most actively they will be used to create backups. And if Sony is telling the truth about the age-old preservation of recorded data, the business will use very new technology.