Energy saving at the enterprise. Solution option

One of the readers of our newsletter asked us a question: what could we advise to save energy in the warehouse? After considering various options, we decided to propose to automate the process of managing warehouse lighting at night, since the activity of loaders at that time is small, and with a large warehouse area, lighting costs eat up a lot of money that is quite worthwhile during a crisis.

To solve our problem, it was proposed to use MP324M kits, MP146 power modules and PW1245 power supplies.

MP324M - is a wireless superheterodyne receiver with a remote control at a frequency of 433 MHz. Since it is designed to work in conditions of strong interference, the choice fell on him.

MP146- It is a power relay with three operating modes: button, pulse, trigger. The module provides a place for installing the receiver from the MP324M set. The relay mounted on the module allows you to control electrical appliances with power up to 6.5 kW.

PW1245 - is a built-in power supply voltage of 12V, with a working current of 500 mA. The power supply module is equipped with all types of protection, which indicates its reliability.

The essence of the proposed solution:

Since the lighting was divided into squares of several lamps, we proposed installing MP146 modules with receivers from the MP324M set at the nodal points.

During installation, you will not need a special tool, since all units are equipped with screwdriver terminals, which will favorably affect the ease of installation and operation. Before installation, using the installed jumpers, the power relays must be configured in the "button" mode. Since relays with a switching current of 30A are installed on the MP146 module, additional starters will not be needed.

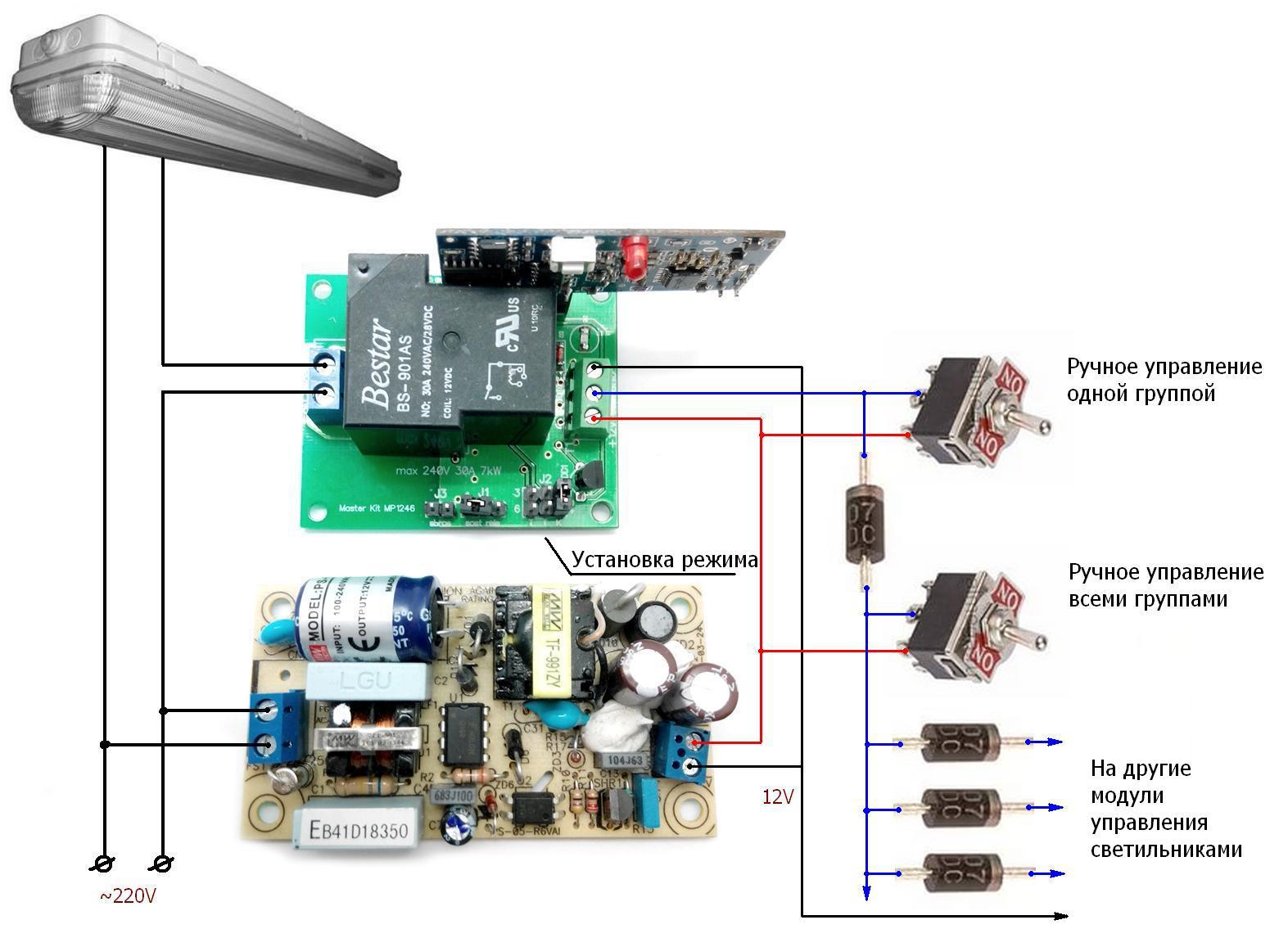

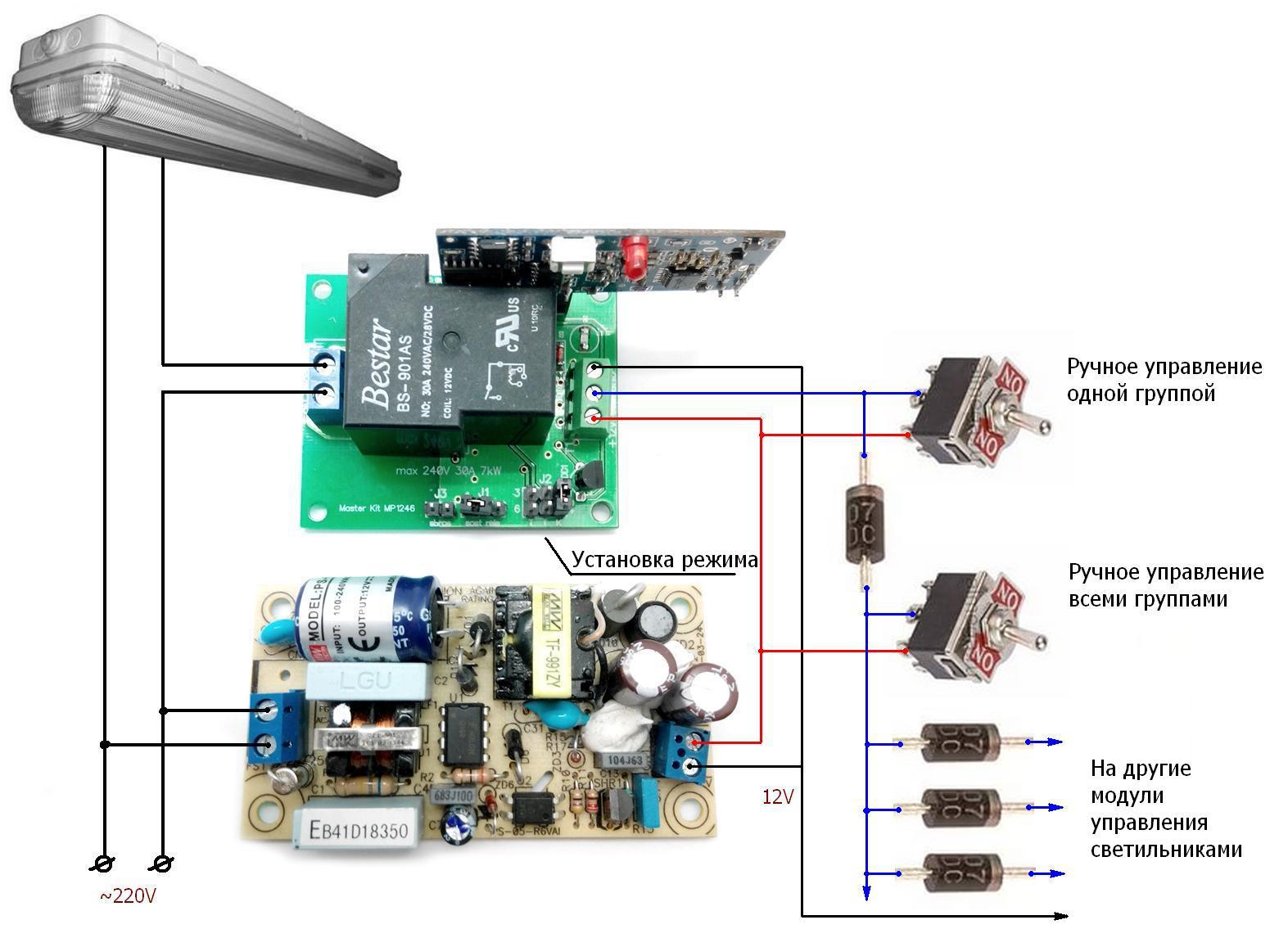

To work in normal mode or in the event of an accident, automatic shutdown has been introduced. For this, it is necessary to install toggle switches for separate and general control of all groups. To obtain independent control, the toggle switch for general switching is decoupled by diodes.

Wiring diagram:

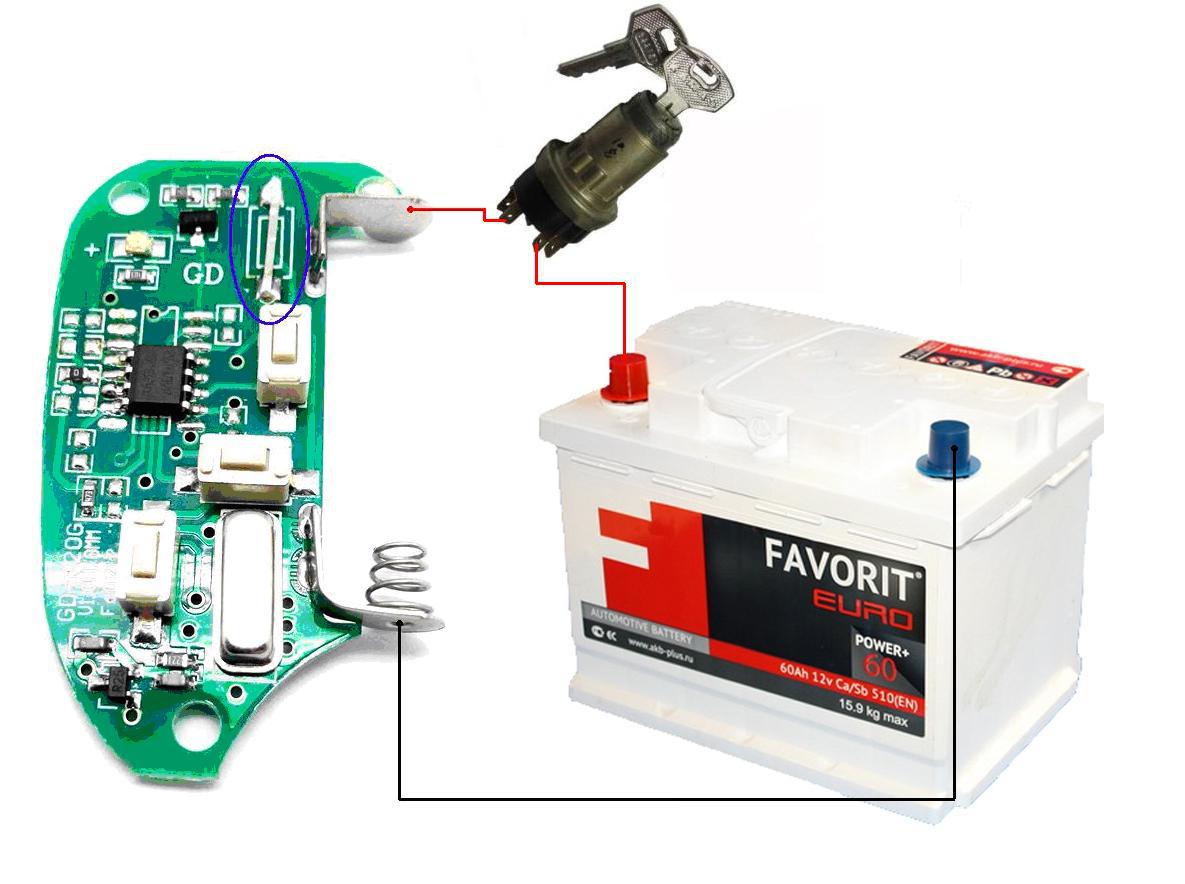

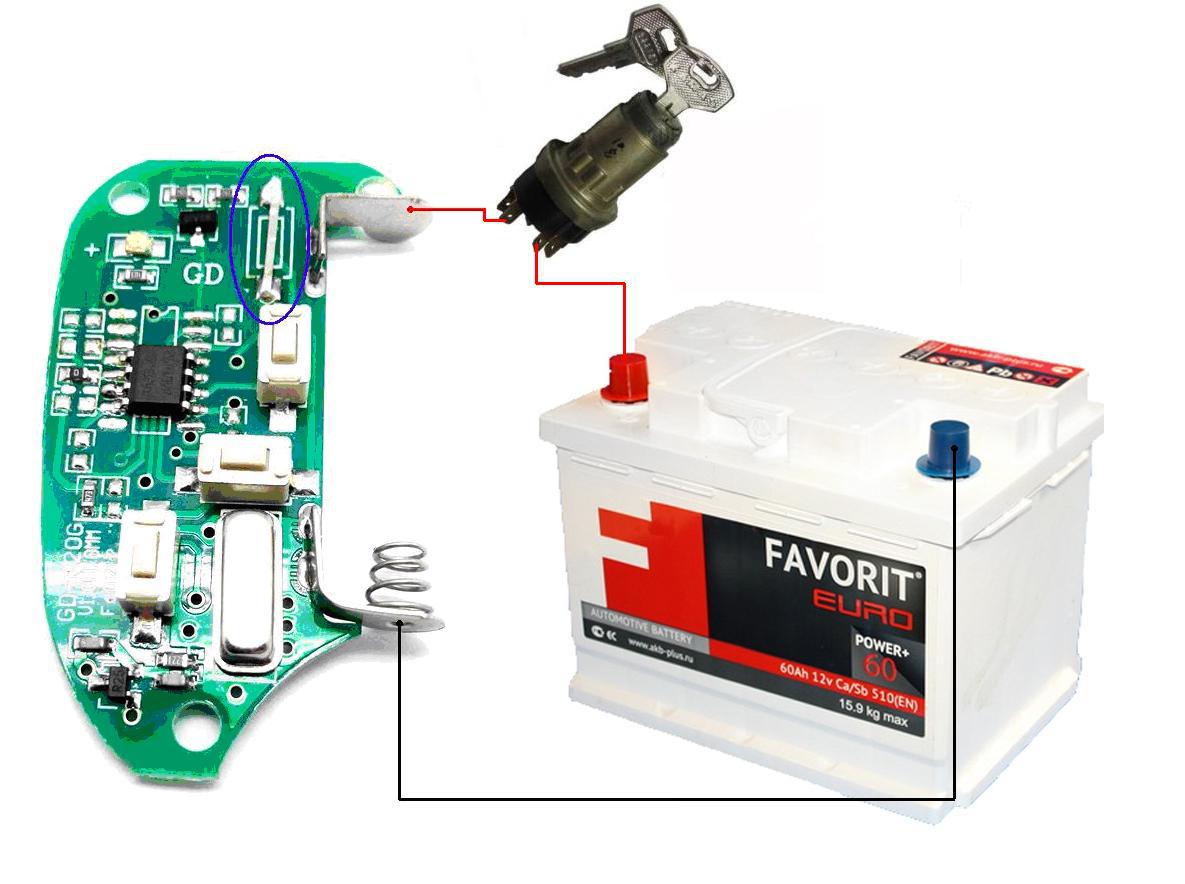

In turn, we install the transmitters in the loaders working on the night shift. Since the transmitters are powered by 12V and it is possible to take 12V from this loader, we connect the transmitters to the battery of the trucks without a DC / DC converter. Before installing the transmitters must be modified. To do this, remove the first button and place a jumper in its place. Power is supplied to the transmitters along with the ignition of the loader. When installing the transmitter, you must try to ensure that it is at the maximum possible distance from the metal structures of the loader. The connection diagram and the installation location of the transmitter can be seen in the thumbnails below.

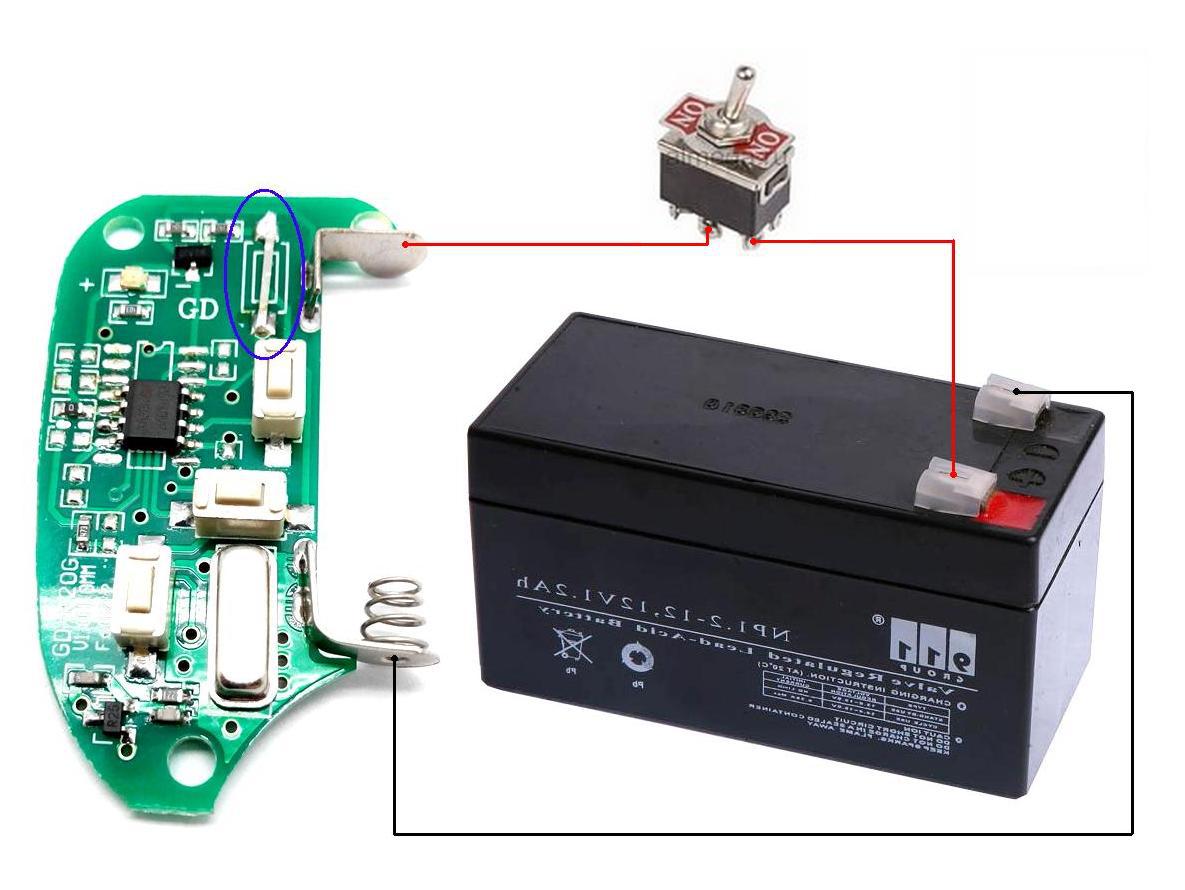

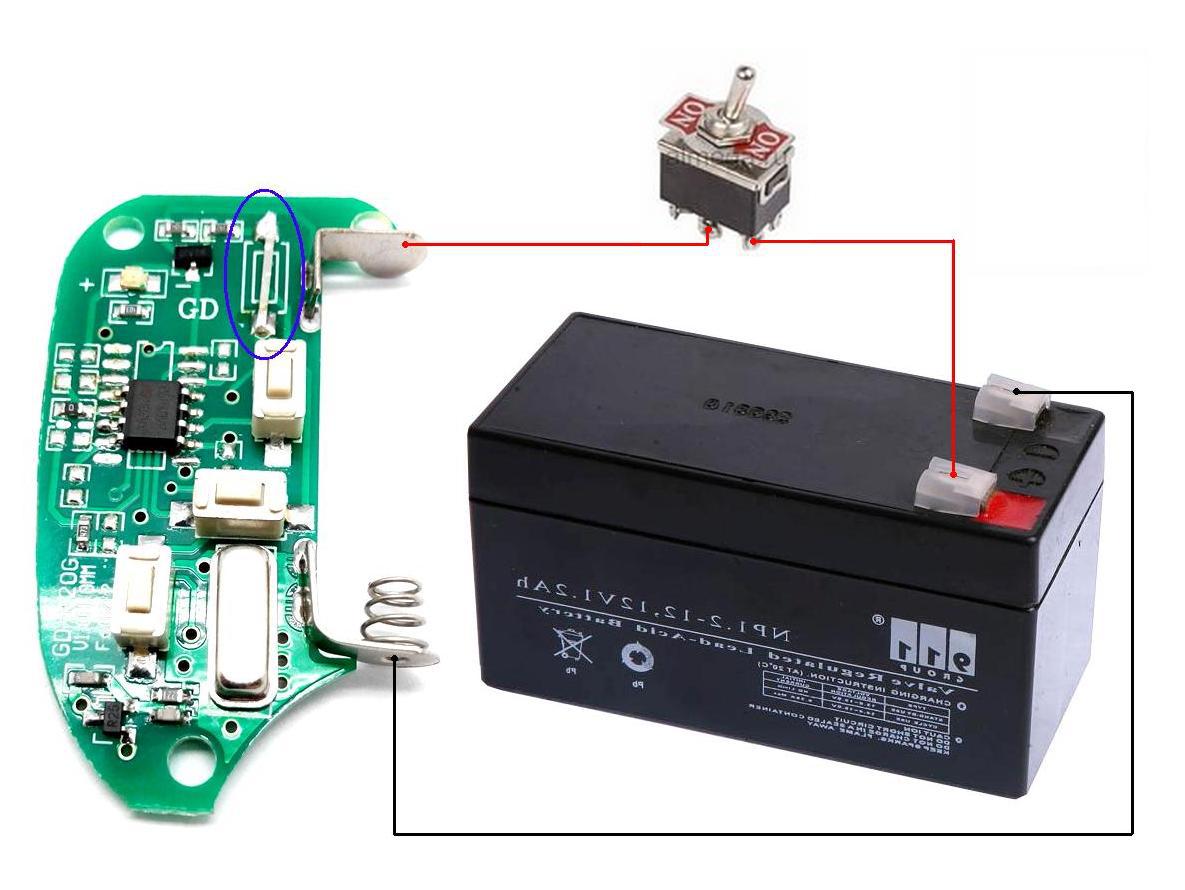

Transmitters can also be used for walking, for example, for a guard. To do this, take a housing of a suitable size, in which we place the transmitter module. We install a switch in the case. It is powered by a 12V battery. To increase the operating time of the transmitter, you can take a larger case, and put a 12V battery from the cash register into it. Then in the case it is necessary to install a socket for charging the battery:

How it all works.

When the loader’s ignition is turned on, the transmitter begins to emit. When radiation enters the zone of a given receiver, a power module is activated that includes a group of lamps. When the signal leaves the receiver area, the lamps go out. Similarly with a transmitter for walking.

Since this system has a large operating distance, up to 150 m, the sensitivity of the receivers must be adjusted by the length of the antenna, which will be a 17-cm-long section of wire.

Perhaps someone will want to repeat or improve this solution. Or maybe he will offer his own?

Posted by: Vladimir Rublev (UA4LOU)

To solve our problem, it was proposed to use MP324M kits, MP146 power modules and PW1245 power supplies.

MP324M - is a wireless superheterodyne receiver with a remote control at a frequency of 433 MHz. Since it is designed to work in conditions of strong interference, the choice fell on him.

MP146- It is a power relay with three operating modes: button, pulse, trigger. The module provides a place for installing the receiver from the MP324M set. The relay mounted on the module allows you to control electrical appliances with power up to 6.5 kW.

PW1245 - is a built-in power supply voltage of 12V, with a working current of 500 mA. The power supply module is equipped with all types of protection, which indicates its reliability.

The essence of the proposed solution:

Since the lighting was divided into squares of several lamps, we proposed installing MP146 modules with receivers from the MP324M set at the nodal points.

During installation, you will not need a special tool, since all units are equipped with screwdriver terminals, which will favorably affect the ease of installation and operation. Before installation, using the installed jumpers, the power relays must be configured in the "button" mode. Since relays with a switching current of 30A are installed on the MP146 module, additional starters will not be needed.

To work in normal mode or in the event of an accident, automatic shutdown has been introduced. For this, it is necessary to install toggle switches for separate and general control of all groups. To obtain independent control, the toggle switch for general switching is decoupled by diodes.

Wiring diagram:

In turn, we install the transmitters in the loaders working on the night shift. Since the transmitters are powered by 12V and it is possible to take 12V from this loader, we connect the transmitters to the battery of the trucks without a DC / DC converter. Before installing the transmitters must be modified. To do this, remove the first button and place a jumper in its place. Power is supplied to the transmitters along with the ignition of the loader. When installing the transmitter, you must try to ensure that it is at the maximum possible distance from the metal structures of the loader. The connection diagram and the installation location of the transmitter can be seen in the thumbnails below.

Transmitters can also be used for walking, for example, for a guard. To do this, take a housing of a suitable size, in which we place the transmitter module. We install a switch in the case. It is powered by a 12V battery. To increase the operating time of the transmitter, you can take a larger case, and put a 12V battery from the cash register into it. Then in the case it is necessary to install a socket for charging the battery:

How it all works.

When the loader’s ignition is turned on, the transmitter begins to emit. When radiation enters the zone of a given receiver, a power module is activated that includes a group of lamps. When the signal leaves the receiver area, the lamps go out. Similarly with a transmitter for walking.

Since this system has a large operating distance, up to 150 m, the sensitivity of the receivers must be adjusted by the length of the antenna, which will be a 17-cm-long section of wire.

Perhaps someone will want to repeat or improve this solution. Or maybe he will offer his own?

Posted by: Vladimir Rublev (UA4LOU)