The use of additive technologies in the production of complex non-standard products

Today I want to talk about one interesting process of manufacturing a non-standard product - an anechoic waveguide chamber. At the first meeting with the customer, the main requirement became clear - the deadlines. Foreign performers of non-standard units contacted by the customer indicated from six months to eight months. In the process of communication with the customer, the product concept gradually emerged: the appearance was determined in three versions, depending on the manufacturing technology. A marketing study was conducted, so to speak, of placing orders for parts and components of a product. The main problem was immediately identified: factories and small firms, without fundamentally abandoning a single product, delayed the process itself to the ridiculous. That is, already at the stage of agreeing on particulars, we understood that here, in Russia, history would drag on for months. I do not think it is necessary to explain this well-known fact; many have come across. We wanted to hand over the finished product in the summer. Therefore, they decided, paradoxically as it sounds, to apply plastics and additive manufacturing technology.

The contradiction is that the chamber must provide the conductivity required by the technical specifications. Again, engineers, for example, fundamentally refused to take up this development (simply say: think on this topic). They did not tell me in person that I was an amateur and that I was talking nonsense, no. They patiently explained: “such things should be metallic. Such products can be made only at a pair of number factories in Moscow and the Moscow region. And in general, “there is no equipment in the country, no equipment, and idiots go around”. In general, this was the psychological situation in which we decided to make a conductive chamber from plastic with the sixth class according to the roughness of internal cavities.

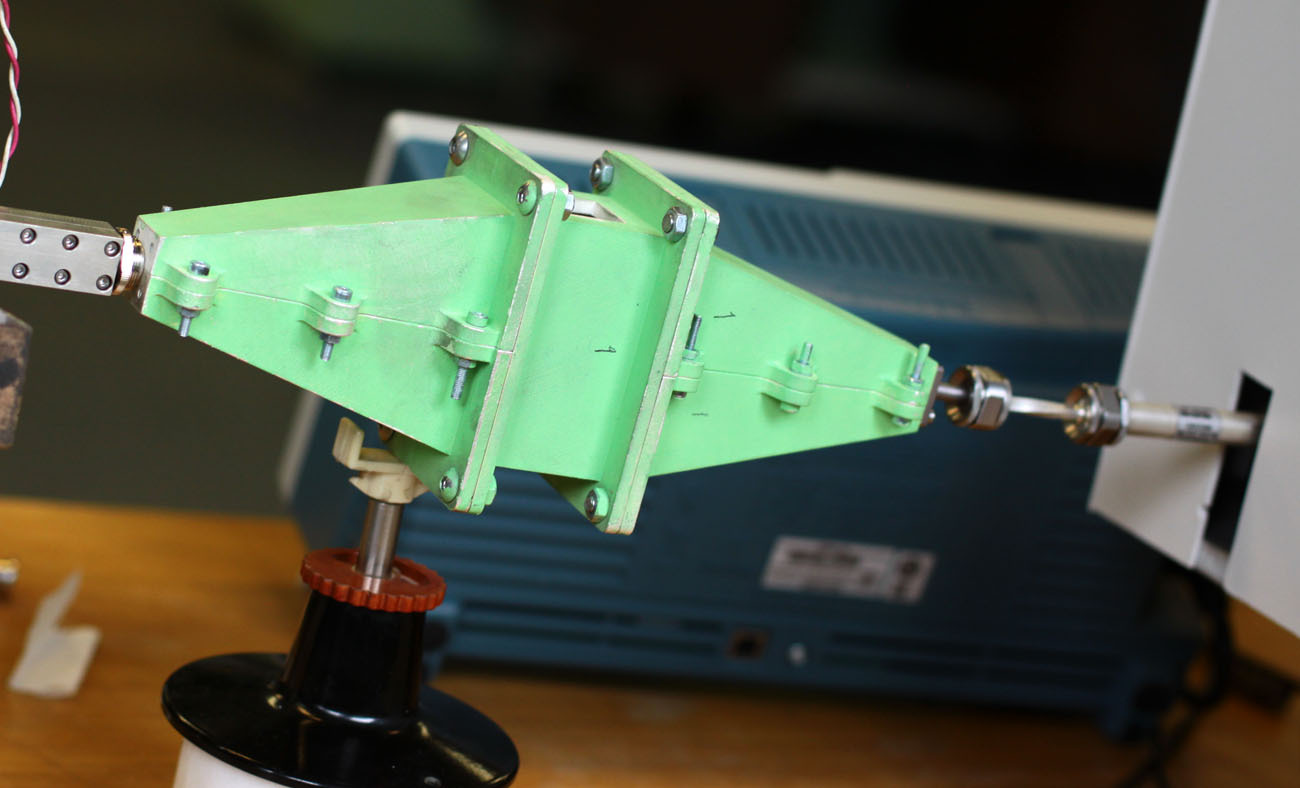

According to the customer’s working sketches, we made drawings and a 3D model. The sizes in the drawings were agreed by telephone and by e-mail. It took three days (drawings were incomplete). We thought, thought, and launched the product: it was very curious to see what kind of thing it would be. They printed part on Ultimaker 2 and half on Picasso (Russian manufacturer of 3D printers).

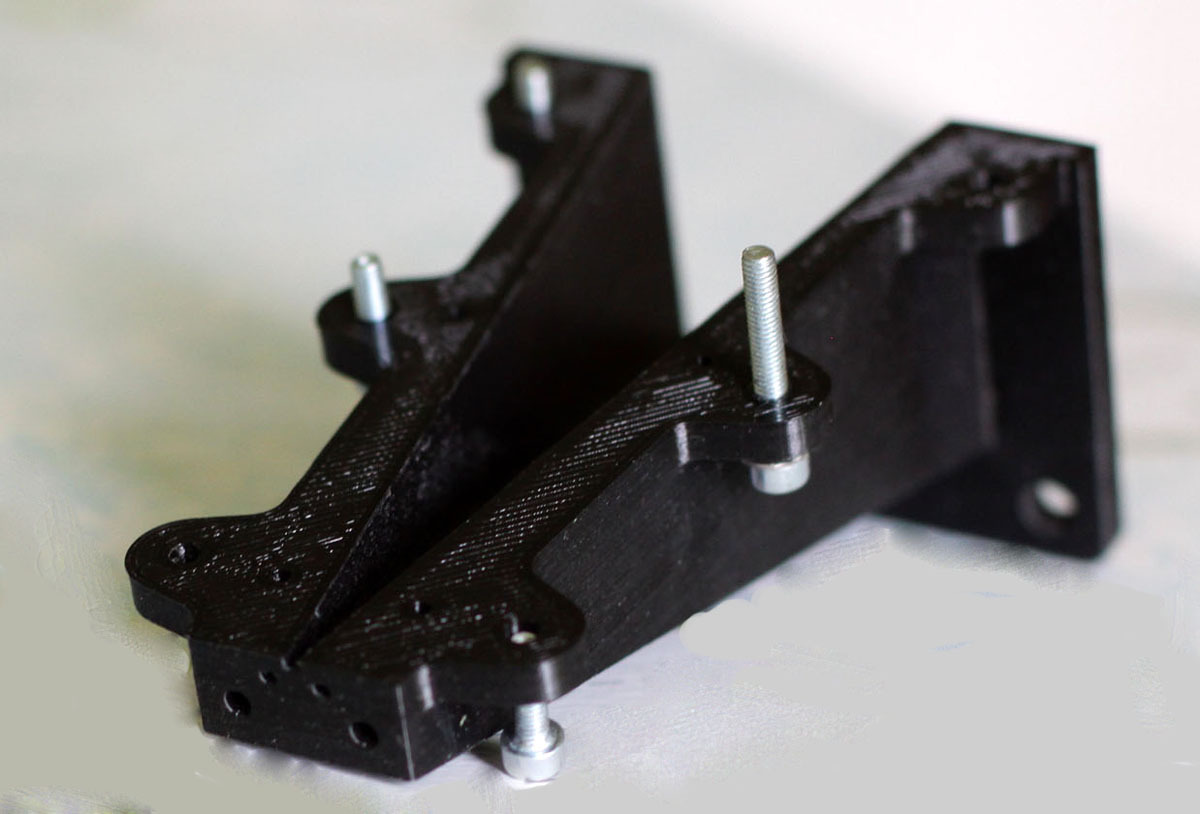

Printed, collected. The product looked intimidating: unexpectedly large and a bunch of bolts in black plastic. Plastic was used by ABS of REC company - also ours, a Russian manufacturer.

They took the thing to the customer - to show, suddenly what was wrong. Zavlab took this AVS-ku from my hands into his own ... After a couple of minutes, eight people looked at the layout, gathered in a circle. Here I witnessed once again how great a 3D printer helps at the design stage. They asked me to leave the layout for a couple of days - try on the spot and all that. A day later they called - everything is fine, all the holes in place and sizes are okay.

And we started the experiments. We can say that there was a certain period of throwing. Responsibility crushed, and I was looking for options to make a model of metal. I must say that we decided on the technological process of manufacturing our metal products (and the performers of the work, which is the most important thing), although this took almost two months. But during this time a composite sample was already ready.

Samples from 9 types of plastic were printed. It also turned out that no one undertook to metallize plastic, based on the terms of reference for the technical specifications. Traveled all over Moscow and the region, negotiations were held with Tomsk and Nizhny Novgorod. I especially remember one state-owned plant, which quietly asked for "three to four million rubles" to restore technology. It turns out that in Soviet times, French equipment was imported to solve our case, but it was overgrown with moss and shrubs, and the bathtubs with chemicals were empty. Alas.

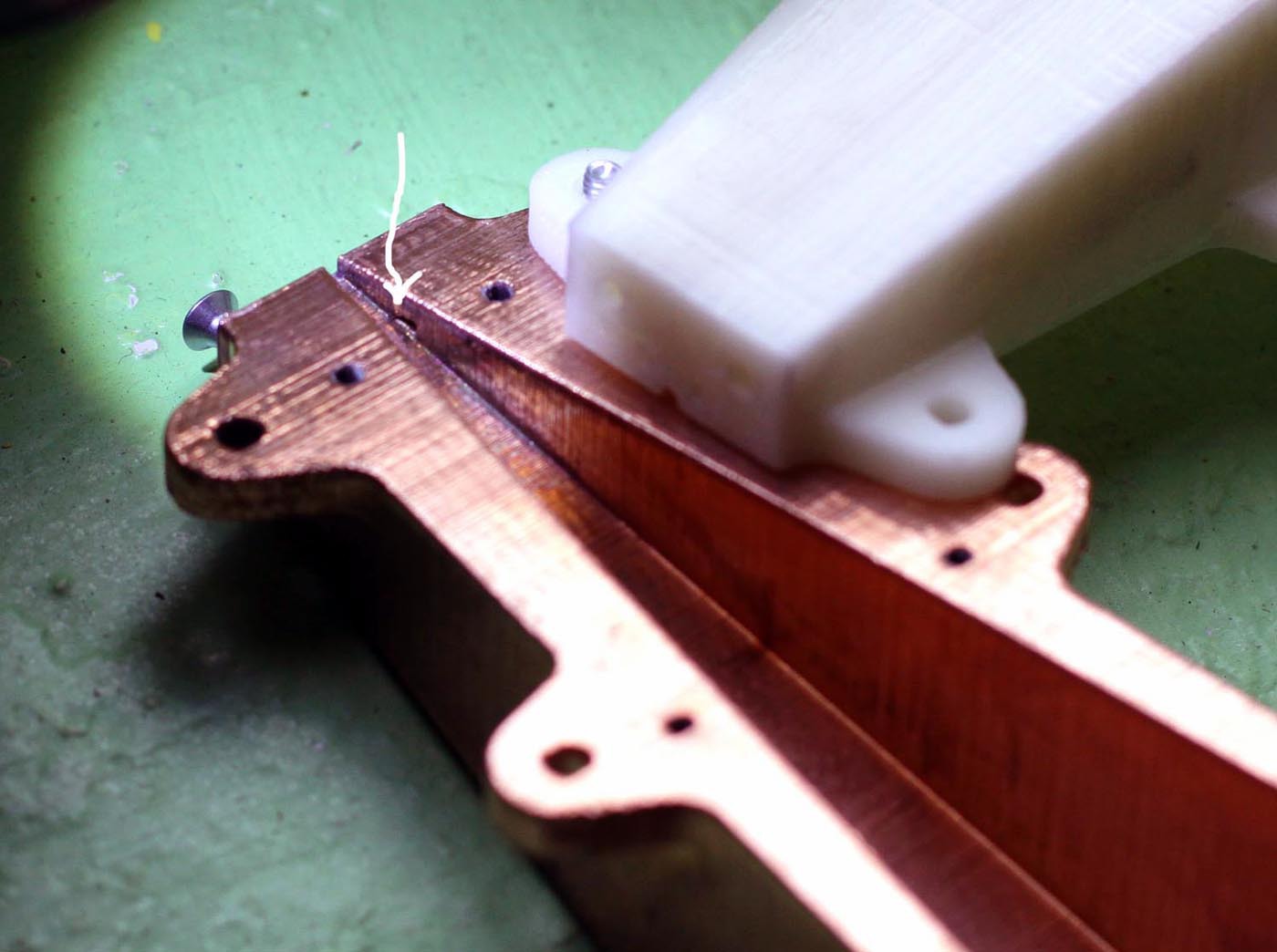

Electroplating, so to say, "garage sense", basically did not want to deal with a single product and a chain of experiments before the finish operation. But in the end, options were found. Intensive experiments led from a weak, prickly foil to a polished monolith. Along the way, an error occurred in the 3D model: the recesses for the mounting bolts at the ends almost came into contact with the edges of the channel. When printing, a fistula was inevitably formed, so small that it became noticeable only after metallization. The modeling engineer was very surprised, like all of us, muttered, but quickly figured out the problem and fixed the 3D model. Here is another definite plus of using 3D printing at the prototyping stage: if we didn’t notice this error, at the next stage the losses on the move would be 30 thousand rubles for money and two weeks for the deadlines.

Then began the process (the Japanese would call this process an "incident") grinding. Or rather, in the beginning there was a task: to achieve a polished finish surface. I cherished the hope that it would be possible to attach our part to the CNC machine, turn on the program and the machine would make us candy. This hope is still alive, since in general the problem remains: bring the finished part to the workshop with cross-sectional dimensions of 1.2 by 2.4 mm and put it on grinding. At this stage, to be honest, my hands fell more than once. Firstly, there are endless, hoarse, disputes with engineers who voluptuously kept repeating: “this is impossible, it’s easier to order from scratch somewhere, make it and grind it there”.

- Well, what if the five-coordinate?

- Well, the five-coordinate must handle it ... although, no, it’s unlikely

- But why?

- No one has such equipment

. And so on. In our case, on our own, we solved the problem by manufacturing a slipway and conical bodies. A little used grinders. They were polished and polished, installing parts in a slipway and gluing emery onto cones. It was a very complicated, nervous process, but in a month we found a technology that combines a sequence of grinding, electroplating and polishing cycles. Again, the use of 3D printing helped a lot: we would design and manufacture slipways of wood and metal for ten days, instead of three in fact.

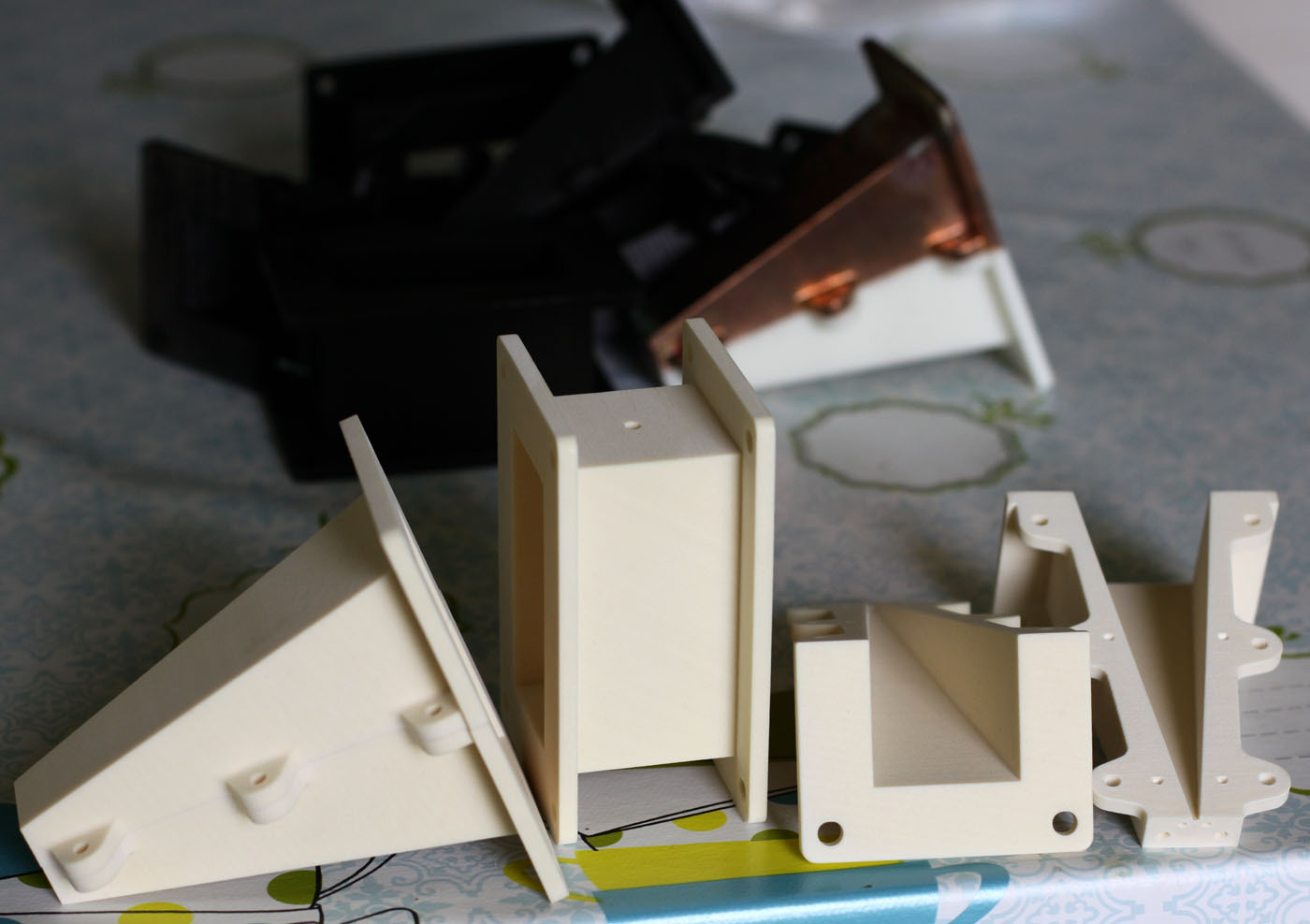

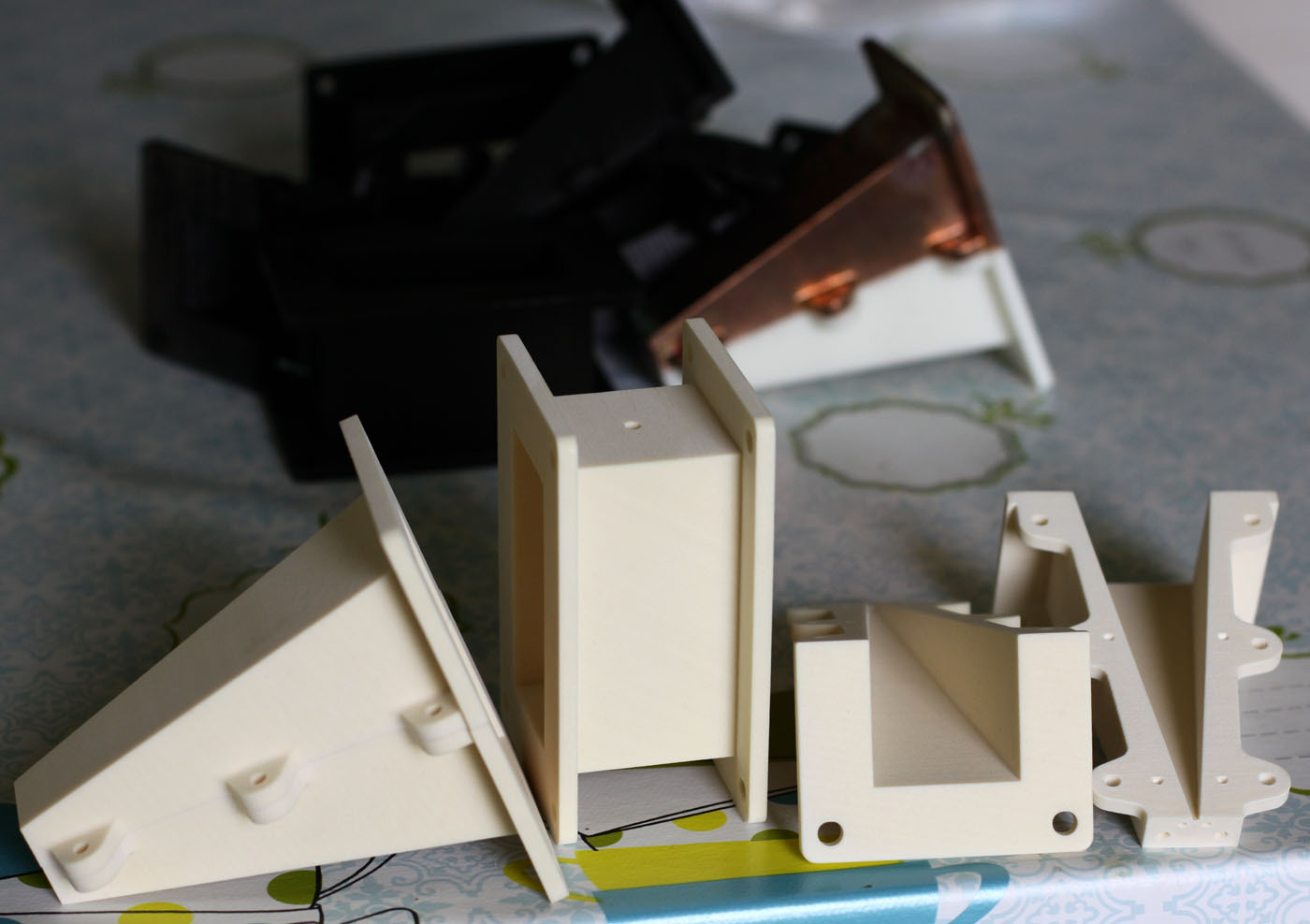

I remember that at that time I was addicted to carrying at least two or three sets of convenience foods in my backpack. One of such moments is depicted in the photo: he came home, dumped a bunch on the table and I sit and look at it ... Kaif!

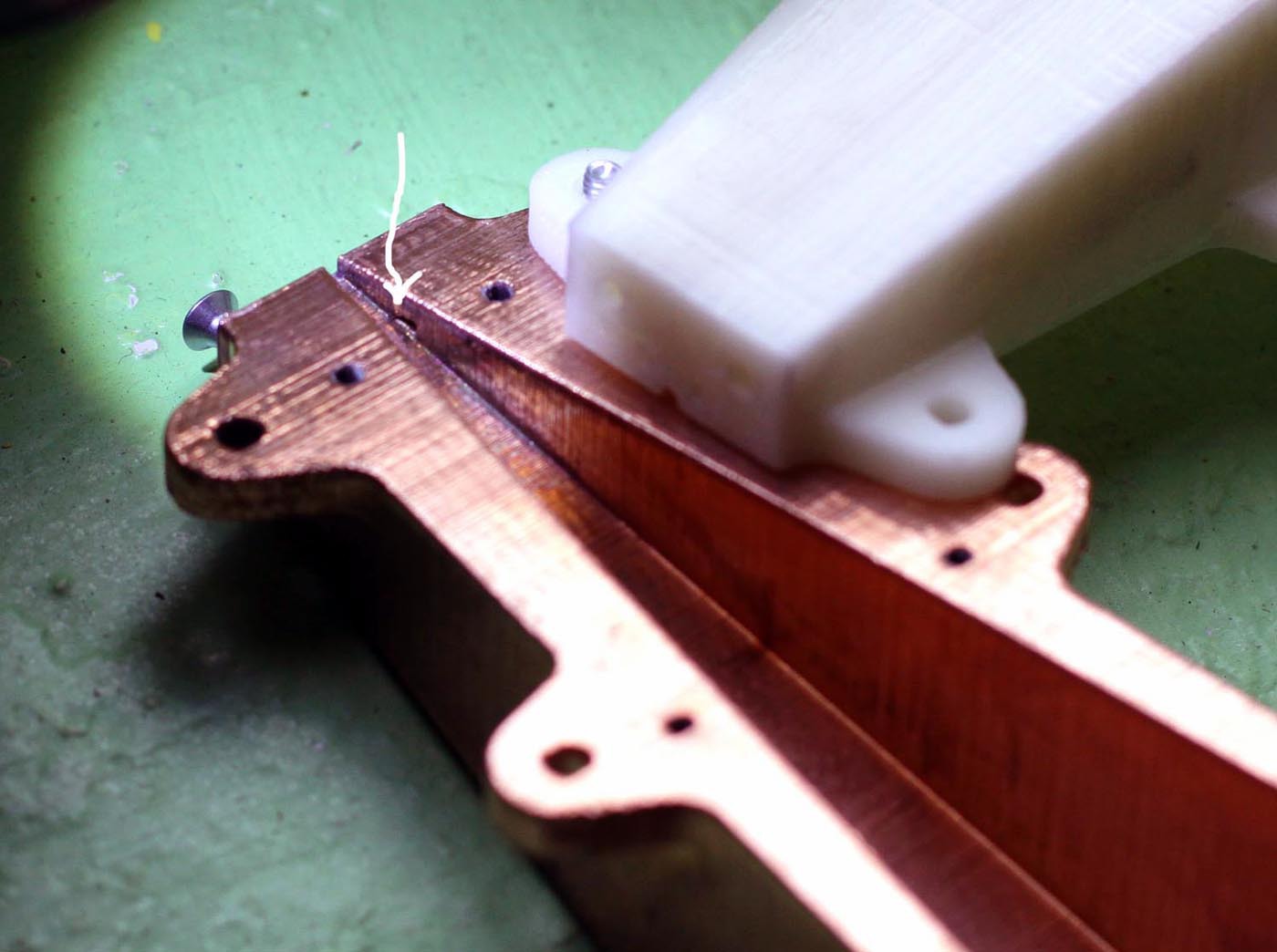

The reference part is at the copper plating stage. In addition to the difficulty of selecting a pair of plastic-electroplated, the problem of the unevenness of the galvanic coating was fully drawn. It turned out that the outer surfaces are galvanized much better than what we need, the inner ones. In the inner channel, the side walls are galvanized better than the bottom of the channel. The electroplating specialist, realizing what he had gotten into, looked with a cold intelligent squint ...

Also, the thorns of the crystalline structure of the electroplated coating caused a lot of trouble. They grew in the most “necessary” places, especially at the ends. They also coped with this phenomenon by constructing a "galvanic armature" in place. This terrible name was invented by our engineer. Electroplating, before that with ease, like an artist, who operated with a round silver wand, fell ill from a nervous breakdown.

It was, obviously, a classic catharsis, since, having recovered, the galvanist was involved in the process of technical creativity. He gave the mountain galvanization technology on a metal block. In fact, the process is a little more complicated, but we decided, publicly, to designate it in this way. The process is based on a USSR patent from 1942. Yes Yes! There was a difficult war, but creative thought dawned on our ancestors! I remember discussing the process, reviewing the first prototype, and then one of the engineers says:

“So what is it, now we can do the waveguides as you want ...

” “Where do we get them,” I ask mechanically.

- How to where? Starting from the microwave and ending with the radars on airplanes!

- ...

And in parallel, we worked out yet another direction - the manufacture of waveguides using the method of "electroplating on a metal block". But that's another story.

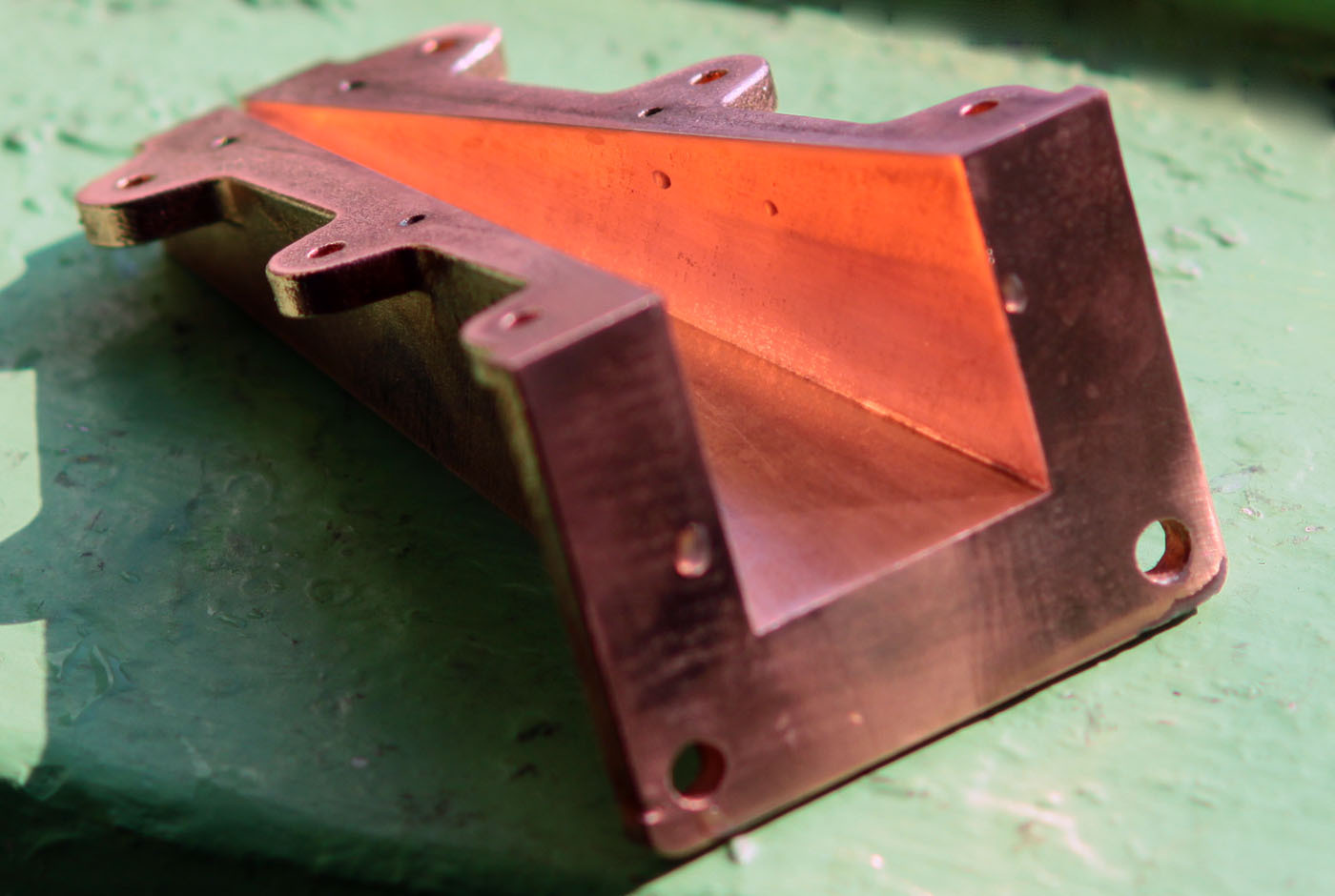

Finished part of the product before assembly. Water droplets are visible on the walls. This was followed by the finish assembly, which presented the next surprises. Looking back, we are sure that almost everything had to be done differently. It was possible to provide more pins, a different configuration of the body, to design the ends and flanges in a different way. This knowledge was achieved at the cost of almost three months of intense collective design thought, as they say, “Russian ingenuity” and three screwed-up finishing details.

It was on this project that I felt like a fish in water, I cannot but say about the true sense of satisfaction when I managed to unite different people (and the guys got together as one - talents, but creepy individualists), sometimes in different places, into a team capable of not not only solve the formed technical problem, but also generate a creative idea.

And the final episode. We handed over the product, the representative of the customer three days later said that everything was fine and the work was accepted. But flanges are still needed: eight, or better, ten pieces.

I went to Volgograd for a visit and on the third day I realized that the flanges should be done here. On the Avito site, I found two owners of milling machines, with one, Igor, quickly phoned, exchanged information and he said he would do it in a couple of days. Igor purchased the material on the local “Bird” market, and a day later I came to pick up the goods. We talked, Igor led me into the workshop: a private house, in a spacious garage there are a couple of lathes, a milling machine, something else for little things, and a handsome red-haired cat guarded it all. Plus, the complete readiness of the owner to discuss any technologically possible one-time orders. Now I know that it’s not necessary to go to China for any small things.

The contradiction is that the chamber must provide the conductivity required by the technical specifications. Again, engineers, for example, fundamentally refused to take up this development (simply say: think on this topic). They did not tell me in person that I was an amateur and that I was talking nonsense, no. They patiently explained: “such things should be metallic. Such products can be made only at a pair of number factories in Moscow and the Moscow region. And in general, “there is no equipment in the country, no equipment, and idiots go around”. In general, this was the psychological situation in which we decided to make a conductive chamber from plastic with the sixth class according to the roughness of internal cavities.

According to the customer’s working sketches, we made drawings and a 3D model. The sizes in the drawings were agreed by telephone and by e-mail. It took three days (drawings were incomplete). We thought, thought, and launched the product: it was very curious to see what kind of thing it would be. They printed part on Ultimaker 2 and half on Picasso (Russian manufacturer of 3D printers).

Printed, collected. The product looked intimidating: unexpectedly large and a bunch of bolts in black plastic. Plastic was used by ABS of REC company - also ours, a Russian manufacturer.

They took the thing to the customer - to show, suddenly what was wrong. Zavlab took this AVS-ku from my hands into his own ... After a couple of minutes, eight people looked at the layout, gathered in a circle. Here I witnessed once again how great a 3D printer helps at the design stage. They asked me to leave the layout for a couple of days - try on the spot and all that. A day later they called - everything is fine, all the holes in place and sizes are okay.

And we started the experiments. We can say that there was a certain period of throwing. Responsibility crushed, and I was looking for options to make a model of metal. I must say that we decided on the technological process of manufacturing our metal products (and the performers of the work, which is the most important thing), although this took almost two months. But during this time a composite sample was already ready.

Samples from 9 types of plastic were printed. It also turned out that no one undertook to metallize plastic, based on the terms of reference for the technical specifications. Traveled all over Moscow and the region, negotiations were held with Tomsk and Nizhny Novgorod. I especially remember one state-owned plant, which quietly asked for "three to four million rubles" to restore technology. It turns out that in Soviet times, French equipment was imported to solve our case, but it was overgrown with moss and shrubs, and the bathtubs with chemicals were empty. Alas.

Electroplating, so to say, "garage sense", basically did not want to deal with a single product and a chain of experiments before the finish operation. But in the end, options were found. Intensive experiments led from a weak, prickly foil to a polished monolith. Along the way, an error occurred in the 3D model: the recesses for the mounting bolts at the ends almost came into contact with the edges of the channel. When printing, a fistula was inevitably formed, so small that it became noticeable only after metallization. The modeling engineer was very surprised, like all of us, muttered, but quickly figured out the problem and fixed the 3D model. Here is another definite plus of using 3D printing at the prototyping stage: if we didn’t notice this error, at the next stage the losses on the move would be 30 thousand rubles for money and two weeks for the deadlines.

Then began the process (the Japanese would call this process an "incident") grinding. Or rather, in the beginning there was a task: to achieve a polished finish surface. I cherished the hope that it would be possible to attach our part to the CNC machine, turn on the program and the machine would make us candy. This hope is still alive, since in general the problem remains: bring the finished part to the workshop with cross-sectional dimensions of 1.2 by 2.4 mm and put it on grinding. At this stage, to be honest, my hands fell more than once. Firstly, there are endless, hoarse, disputes with engineers who voluptuously kept repeating: “this is impossible, it’s easier to order from scratch somewhere, make it and grind it there”.

- Well, what if the five-coordinate?

- Well, the five-coordinate must handle it ... although, no, it’s unlikely

- But why?

- No one has such equipment

. And so on. In our case, on our own, we solved the problem by manufacturing a slipway and conical bodies. A little used grinders. They were polished and polished, installing parts in a slipway and gluing emery onto cones. It was a very complicated, nervous process, but in a month we found a technology that combines a sequence of grinding, electroplating and polishing cycles. Again, the use of 3D printing helped a lot: we would design and manufacture slipways of wood and metal for ten days, instead of three in fact.

I remember that at that time I was addicted to carrying at least two or three sets of convenience foods in my backpack. One of such moments is depicted in the photo: he came home, dumped a bunch on the table and I sit and look at it ... Kaif!

The reference part is at the copper plating stage. In addition to the difficulty of selecting a pair of plastic-electroplated, the problem of the unevenness of the galvanic coating was fully drawn. It turned out that the outer surfaces are galvanized much better than what we need, the inner ones. In the inner channel, the side walls are galvanized better than the bottom of the channel. The electroplating specialist, realizing what he had gotten into, looked with a cold intelligent squint ...

Also, the thorns of the crystalline structure of the electroplated coating caused a lot of trouble. They grew in the most “necessary” places, especially at the ends. They also coped with this phenomenon by constructing a "galvanic armature" in place. This terrible name was invented by our engineer. Electroplating, before that with ease, like an artist, who operated with a round silver wand, fell ill from a nervous breakdown.

It was, obviously, a classic catharsis, since, having recovered, the galvanist was involved in the process of technical creativity. He gave the mountain galvanization technology on a metal block. In fact, the process is a little more complicated, but we decided, publicly, to designate it in this way. The process is based on a USSR patent from 1942. Yes Yes! There was a difficult war, but creative thought dawned on our ancestors! I remember discussing the process, reviewing the first prototype, and then one of the engineers says:

“So what is it, now we can do the waveguides as you want ...

” “Where do we get them,” I ask mechanically.

- How to where? Starting from the microwave and ending with the radars on airplanes!

- ...

And in parallel, we worked out yet another direction - the manufacture of waveguides using the method of "electroplating on a metal block". But that's another story.

Finished part of the product before assembly. Water droplets are visible on the walls. This was followed by the finish assembly, which presented the next surprises. Looking back, we are sure that almost everything had to be done differently. It was possible to provide more pins, a different configuration of the body, to design the ends and flanges in a different way. This knowledge was achieved at the cost of almost three months of intense collective design thought, as they say, “Russian ingenuity” and three screwed-up finishing details.

It was on this project that I felt like a fish in water, I cannot but say about the true sense of satisfaction when I managed to unite different people (and the guys got together as one - talents, but creepy individualists), sometimes in different places, into a team capable of not not only solve the formed technical problem, but also generate a creative idea.

And the final episode. We handed over the product, the representative of the customer three days later said that everything was fine and the work was accepted. But flanges are still needed: eight, or better, ten pieces.

I went to Volgograd for a visit and on the third day I realized that the flanges should be done here. On the Avito site, I found two owners of milling machines, with one, Igor, quickly phoned, exchanged information and he said he would do it in a couple of days. Igor purchased the material on the local “Bird” market, and a day later I came to pick up the goods. We talked, Igor led me into the workshop: a private house, in a spacious garage there are a couple of lathes, a milling machine, something else for little things, and a handsome red-haired cat guarded it all. Plus, the complete readiness of the owner to discuss any technologically possible one-time orders. Now I know that it’s not necessary to go to China for any small things.