How we build lean production (Lean) in our company

About what?

As a manager, I became interested in lean manufacturing and after reading the book “Lean Thinking” I decided to transfer my vision from the field of factory production to the IT industry.

What lean and useful we do in our studio, and what can be scaled to other companies, is described in this article.

Statistics analysis

Like many companies in the IT industry, we measure project work in man-hours and from this we form the cost of developing a project. We have a CRM system where we track the hours spent on a particular task. At some point, we decided to track statistics on the hours spent in the following vein:

- Hours spent on tasks within the assessment

- Hours spent on tasks beyond assessment

- Company internal tasks

Next, let's turn on lean manufacturing.

As the theory goes, we need to divide all the processes in production into three types:

- Increasing customer value

- Not increasing value, but necessary for production ( muda of the first kind)

- And processes that do not increase the value of the product, which are direct losses ( muda of the second kind)

The first item needs to be constantly improved, the second - to be regulated and kept at a certain level, the third - to completely eradicate the company.

And, it would seem, you need to merge two paragraphs and success, but ... not everything is so simple. After several iterations, we increased the number of groups. Here are some of the groups we divide tasks into:

- Hours inside project appraisal

- Hours outside the project estimate

- Warranty Work

- Hours for separately allocated directions (Tech. Support, Internet marketing, etc.)

- Company internal tasks

- Self-development + Planers + Standups + Retrospectives

- Project Evaluation (for potential customers)

Already from such parameters we were able to collect more reliable statistics. According to her, it became clear that the guarantee is a wise 2nd kind. And you need to configure the processes to reduce it to zero. If you have a lot of project assessments coming down on you, then this process may be even better regulated so that it does not grow much ( muda of the first kind). As a result, only hours within project evaluations bring value. Their share needs to be maximized and at some point to understand where your ceiling is for this parameter.

Today we are talking only about lean, but in general it is difficult to overestimate the benefit of collecting such statistics for business. In the case of each company, the set of parameters may be different, but dividing it into three key types will help you understand what to do to increase profits.

We move machines

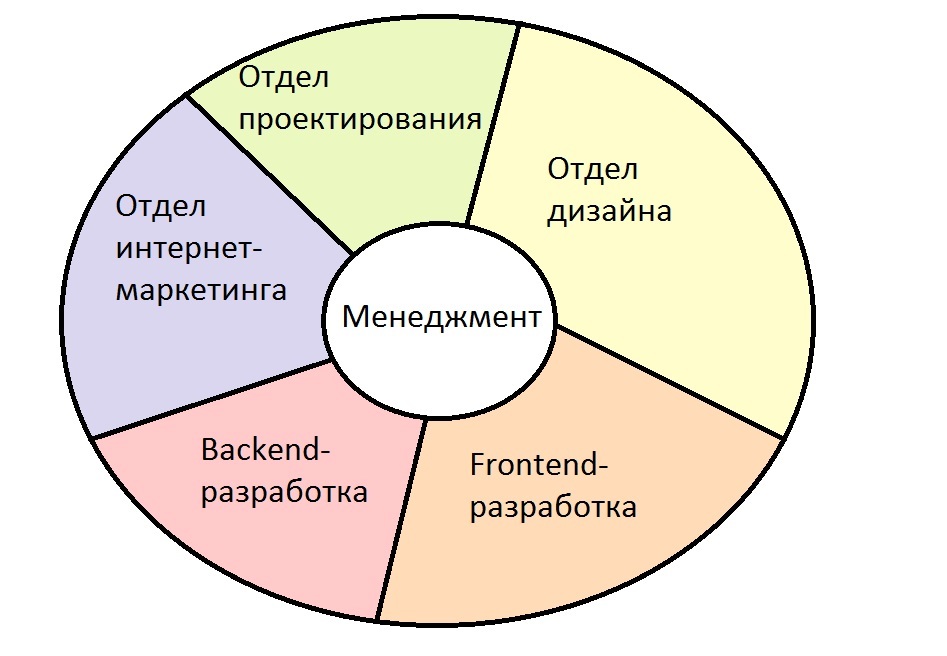

In our company, frontend and backend developers are in the same office, the rest of the employees, respectively, separately. Naturally, over time, a sufficient mutual understanding arose between them in which form it is better to transfer work from one stage to another. This understanding is deep enough and the leadership for this has done nothing but define them in one office. From this we conclude:

"If you seat all employees related to production in the direction of the flow of product creation, this will significantly strengthen the ties at the junctions of the stages."

The converse is also true, if the employees of the neighboring stages of development will not sit in close proximity, it will be difficult to achieve a high level of understanding between them.

In all the stories of transforming the company into lean manufacturing, the first thing the Japanese sensei did was move the machines , rearranging them in the right order. Moreover, such rearrangements, with a change in technology, took on a permanent character. In IT, you can find your analogue to this process. Even if you don’t have the opportunity to create a continuous stream, even the temporary (1-2 months) presence of employees in the “alien” department will be useful. Although the neighborhood, of course, gives results much higher.

In the specific situation of our company, designers should have a good understanding of designers, designers - frontend, frontend - backend. You can close the circle, because at the beginning and at the end of the process, Internet marketers are added.

Break cocoons

Have you ever heard such a phrase from the manager: “This employee is just doing his job well”? Lean manufacturing seeks to remove the word “simple” from this phrase. An ideal employee of lean manufacturing not only does his job well, but also understands how his activities affect the value of the final product. This is a very important emphasis, because in the eyes of the company, the employee understands how it affects its profit. Here you need to clarify a bit, let's see a way to expand the review of the employee.

Step 1

After deciding to switch to lean manufacturing, you need to break the cocoons around all the employees. First you need to reach a situation where the employee will begin to better understand what his immediate bosses require of him, that is, the head of the unit and pm (so be it). As a result, they should have an excellent understanding on working issues.

Step 2

Understanding the adjacent stages of development. Here we are talking about the neighborhood, where the movement of machine tools helps remarkably.

Step 3

Understanding all stages of development. It is necessary for the employee to have a clear idea of how value is created at all stages to which it does not apply (design, prototyping, etc.). The magnitude of this step depends on how many development steps you have.

Step 4

The final stage is an understanding of what the end client / user needs. Ideally, this is a comprehensive understanding of the result of the work and the generation of ideas for improving the product, through which the sales team can gain advantages relative to competitors.

If an employee understands all the stages of the value stream, its benefits for the company are difficult to evaluate. He, looking at any task, will understand how to make it so that the end user is as satisfied as possible with the result.

What is the result

I built all the ideas in this article, simulating what I know about lean manufacturing, on the processes of the studio in which I work. Having introduced innovations and, rushing to embark on the path of lean manufacturing, we received several interesting improvements. This is a more controlled development process and streamlined, versatile employee training. Moreover, the training of employees is 100% necessary things.

Naturally, this is not all that can be done in the framework of lean production in your company. And if you have thoughts that can complement the article, write in comments. For my part, I will try to collect more of my observations and share with you.