Fatal errors in hardware integration

Good day! Today we talk about what mistakes are in the integration of digital equipment in the business, manufacturing and education, as well as how to avoid them. The material was prepared on the performance of Maxim Zhuravlev at the “Top 3D Expo. Digital Education 2018 ” and includes a video recording of the speech.

Exhibition-Conference “Top 3D Expo. Digital Education 2018 ”, as the name suggests, is dedicated to education, and this presentation was intended to address the issue of the inclusion of additive equipment in the learning process.

Tasks </ h3

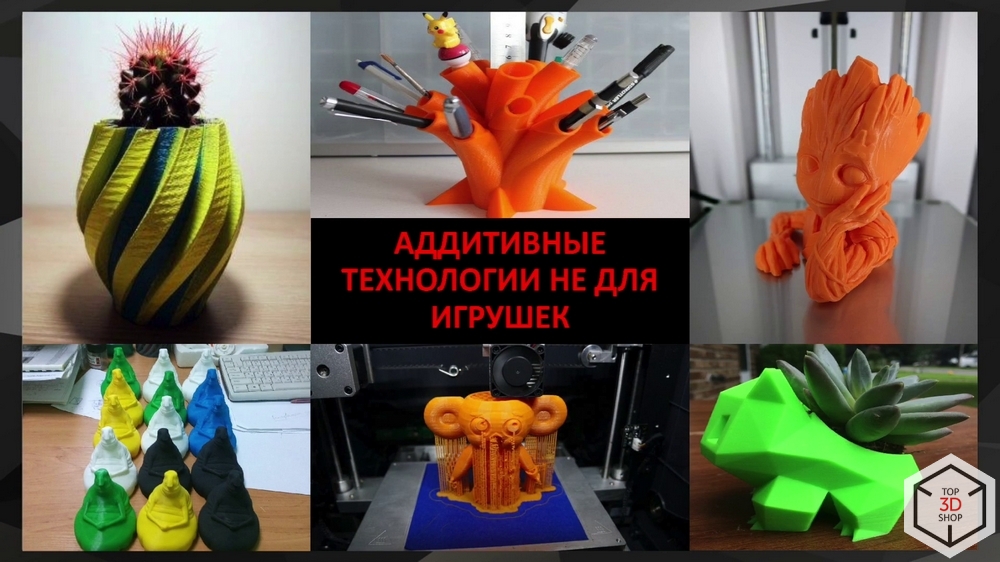

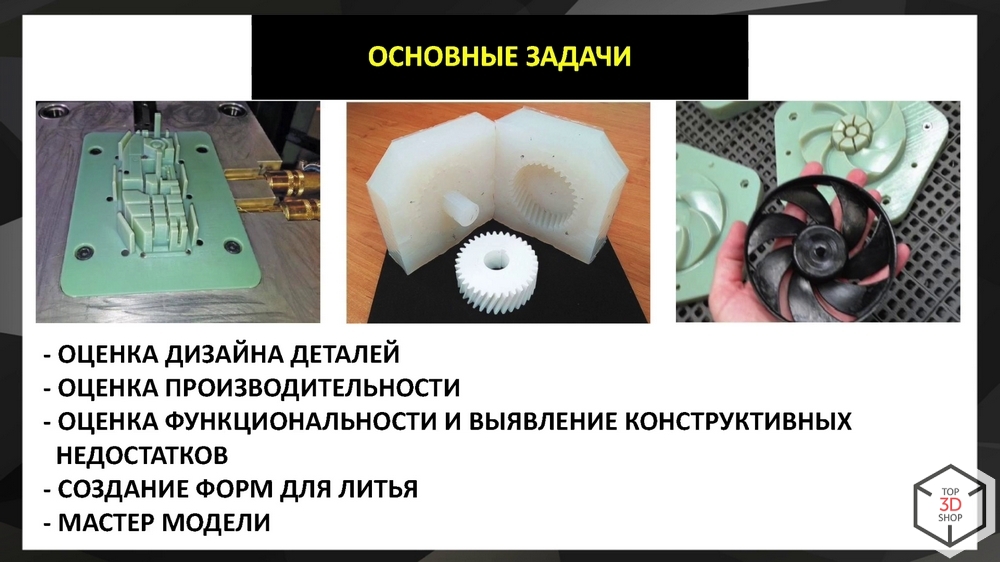

Correct task setting is half the success. Nowadays, 3D printers are not designed for toys, figurines, pots and other decorations, or rather, they can print all of this, but the main tasks of additive technologies are much more global now: this is reducing production costs.

All this must be understood when integrating additive technologies into the learning process.

Scanners are usually used for the following purposes: reverse engineering, quality control, rapid prototyping, virtual assembly, analysis of shapes and sizes, preparation of design documentation.

One of the problems of digital technology in Russia right now is a shortage of qualified specialists who can solve these problems.

In the field of education, the crisis with the training of specialists capable of working with modern equipment, one of the most important tasks of the industry is the training of qualified personnel that are so scarce in production.

To prepare these professionals, you need the appropriate equipment for their training.

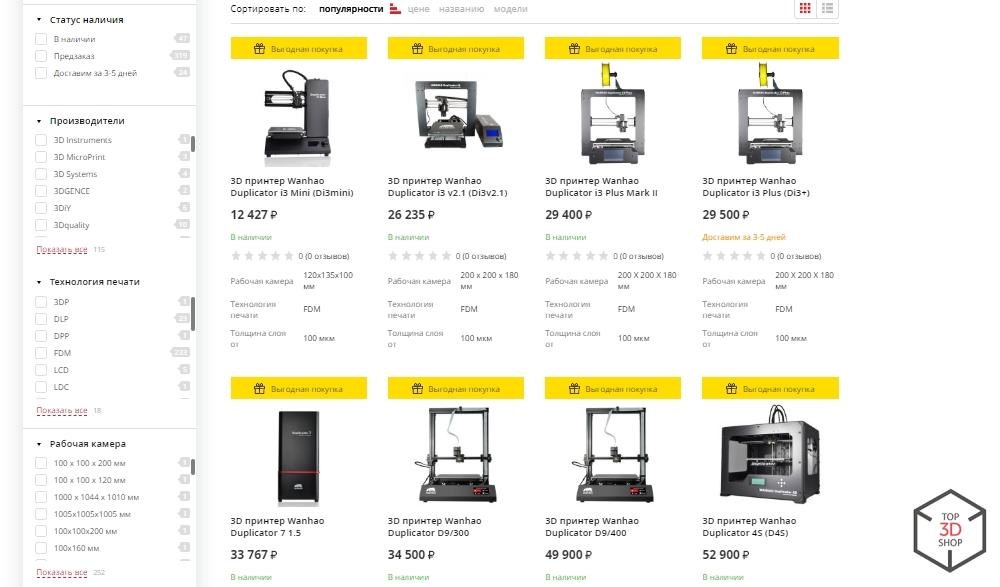

Before we talk about the appropriate equipment, we will talk about the fact that there is no sense to acquire for educational purposes. Many consider it as a purchase option as a textbook, which is facilitated by low prices, but it will bring little benefit. Further - more about it.

What equipment can not buy for vocational training and production

The vast majority of printers worth up to 100 000 rubles. These include various assembly kits and other Chinese printers that do not have the necessary structural rigidity and reliability.

A cheap 3D printer is endless settings, calibrations, crashes, all this violates the training plan and reduces the quality of the issued specialists.

A similar situation with 3D-scanners - scanners costing less than 150,000 rubles, as a rule, are also unsuitable for educational processes.

Having bought this equipment for the organization of educational process, you just throw money down the drain, it can be confirmed by those who have already purchased it. In our experience of communicating with various educational institutions that unknowingly acquired these scanners and tried using them to teach scanning, reverse engineering and quality control organizations, we can confidently say that these scanning systems could not.

Then they turned to us and we solved their problem.

Suitable equipment

This is what the equipment used in production looks like from the inside, suitable for education and business:

Here we see a PolyJet printing printer, which provides high-precision printing and is used to create prototypes.

This is how equipment in enterprises looks outside.

Nothing to do with household amateur 3D-printers, which unknowingly sometimes buy to solve problems that they are not designed for.

The production operator is busy printing, not setting up or repairing the printer, this is the main difference between professional equipment.

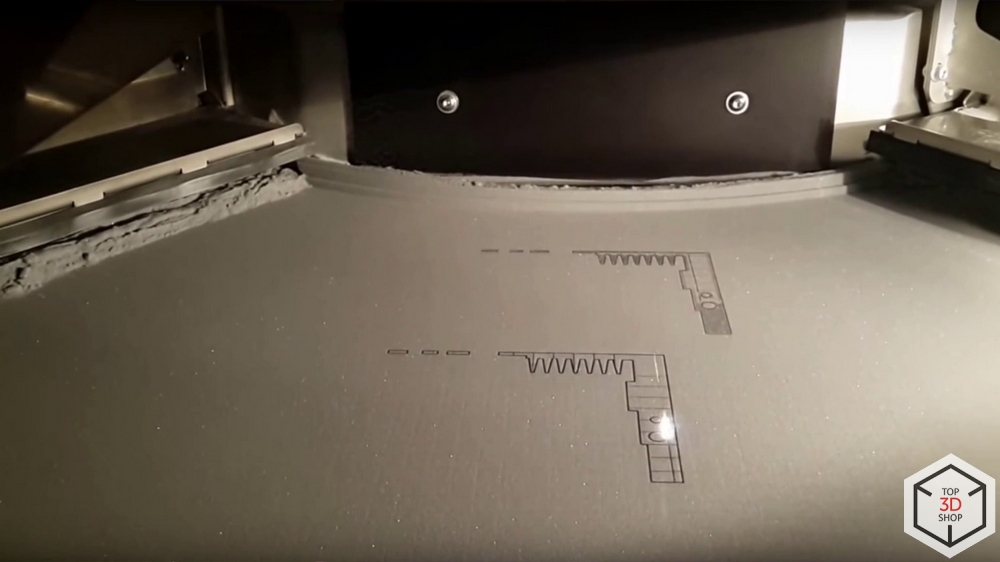

SLS

The SLS technology is one of the most sought-after and used in industry, in particular in the engineering and foundry industries.

Its main advantage is that there is no need for support elements, because the surrounding powder - print material - serves as a support for the model. Due to this, many of the most sophisticated forms become available that are impossible to print on printers with other technology. In addition, the technology allows you to fill the entire volume of the working chamber with prints, as there is no need for their contact with the platform.

Products after printing can be used as a final product, as their strength characteristics are as close as possible to cast and molded specimens.

The cost of this solution previously started from 10 million rubles, so that it was not available for most educational institutions.

The first SLS printer available for education: Sinterit Lisa.

Sinterit lisa

- Power supply: 100/130 V or 220/240 V

- Sizes, mm: 620 x 400 x 660

- Weight, kg: 41

- Laser: IR, 5W

- Maximum power consumption: 1.6 kW

- The maximum size of the workpiece: PA12 - 90x110x130 mm, flexa Black - 110x130x150 mm

- Minimum wall thickness: 0.4 mm

- Power consumption: 0.9 kW

- Working chamber: 150 x 200 x 150 mm

- Chamber temperature: 105 ° C

- The temperature of the printing table: 190 ° C

- Printing technology: SLS

- Layer thickness from: 0.075 mm

- Accuracy on axes X, Y, mm: 0.1

- File Format: STL, OBJ, 3DS, FBX

- Supported materials: PA12 smooth, flexa Black

- Interfaces: Wi-Fi

- Print speed: 15 mm / hour

The cost of the complex Lisa is about 1,300,000 rubles. The package includes a printer, a screening station for powder and a sandblasting chamber for processing prints.

This is a turnkey solution at the industrial level. It can be used in medicine, for printing prototypes of implants and parts of prostheses, exoskeletons, splints.

A good solution is also for TsMITA - they are now actively developing and receiving support from the state, and for a technical college.

Sinterit also recently introduced a new printer, the Sinterit Lisa Pro.

Sinterit Lisa Pro

It differs from its predecessor by an enlarged camera and a seal in the gas atmosphere - the printer is equipped with a built-in nitrogen system, which allows the use of more materials.

- Working chamber: 150 x 200 x 260 mm

- Chamber temperature: 192 ° C

- Printing technology: SLS

- Layer thickness from: 75 microns

- Accuracy of the press XY: 50 microns

- Supported materials: PA11, PA12 Smooth, Flexa

The cost of the printer is less than two million rubles. It is well suited to a large industrial enterprise for running in the use of SLS in the production cycle and making a decision on the purchase of larger and more expensive equipment.

SLA

SLA is a common name for technology. It has several proprietary analogs from different manufacturers, such as PolyJet and MJP, as well as variations on the light source used - DLP, LED.

The essence of the technology is layer-by-layer curing of photopolymer resins with ultraviolet light.

By virtue of its main advantage, the highest printing accuracy, has the widest application: medicine, dentistry, jewelry production, printing foundry equipment, master models, burnable models.

Due to its popularity in production, this technology is also in demand in education. Since there are specialized SLA-printers for the dentistry and jewelry industry, and it can be very expensive to purchase several such devices in an educational institution, we offer you the most versatile and applicable printer for training.

DWS XFab

- Operating temperature and humidity: 20-25 ° С / 60%

- Power supply: AC 240 / 100V / 50-60 Hz

- Sizes, mm: 400 x 606 x 642

- Software: Fictor, Nauta

- File Formats: .stl, .slc, .nauta, .fictor, .mkr, .3dm, .3ds, .ply, .obj, .lwo, .x

- Light source: BlueEdge solid state laser

- Operating system: Windows7 and above

- Working chamber: Ø 180x180 mm

- System requirements: 2 GB of memory, OpenGL I / O compatible video card, USB port, 1 active Internet connection,

- Specialization: Design, Souvenir industry, Jewelery, Education, Production

- Printing technology: SLA

- Layer thickness, from: 10 microns

- Interfaces: USB

It is suitable for both production and education. It costs about 700,000 , and exceeds all printers of its class and price range in accuracy, most printers are up to two million rubles, and some models cost about five million. In addition, the printers of the series have a significantly larger working chamber than the analogs of other companies that are similar in price.

The manufacturer himself develops consumables and a laser printer system, thanks to which the quality of his prints surpasses the analogs, in particular, in terms of the strength of the models obtained, among other SLA printers, he has no competitors.

A wide range of materials significantly increases the scope of the models printed on this printer.

The weakest point of all SLA printers is the elements responsible for radiation, which is why DWS gives a lifetime warranty on the laser system of its 3D printers.

Fdm

FDM is the most popular and widely used 3D printing technology. Its accuracy is constantly increasing and it gets more and more applications.

Increasing the temperature of the print increases the list of available materials that previously could only be processed in large-scale industries and plants with a cost of 10 million rubles or more. These are ULTEM, PEEK, PEI and other refractory engineering plastics.

Competition for industrial equipment is ready to make a printer of the Latvian company MASS PORTAL, working with these materials and costing much cheaper.

MASS PORTAL

- Dimensions, mm: 480x620x855

- Software: FabCloud, Simplify3D, FabControl

- Country of manufacture: Latvia

- File Formats: .stl, .obj, .3mf, .gcode

- Working chamber: 300x300x300 mm

- Movement speed: 250 mm / s

- Specialization: Design, Architecture, Packaging, Advertising, Layout design, Souvenir industry, Education, Production

- The temperature of the printing table: up to 120 ° C

- Extruder temperature: 75 - 475 ° C

- Printing technology: FDM

- Layer thickness from: 150 microns

- Supported materials: ABS, ASA, BVOH, CPE, HIPS, PA (Nylon), PC, PEI, PEEK, PET, PETG, PLA, PMMA, POM, PP, PPSU, PVA, PVB, TPE, TPU

- Thread Diameter: 1.75

- Diameter of nozzle, mm: 0.4

- Interfaces: USB 2.0, Ethernet, Wi-Fi

- Platform: heated

- Compatible operating systems: Linux, MacOS, Windows

- Price: 1 145 155 rubles

One of our clients had a choice: to buy a printer easier, without the possibility of printing with high-temperature plastics, plus a vacuum molder to later replace the printer with a more advanced one, or immediately buy a 3D printer corresponding to all the specified parameters, and a molder to buy later.

We recommended the second option, as it provides more options immediately and removes the issue of replacing the printer in the future.

One of the most accessible, noteworthy in the context of the topic called 3D printers is the printer of the Krasnoyarsk company Imprint Hercules 2018.

Hercules 2018

- Shipping Weight: 26.8 kg

- Warranty: 1 year

- Dimensions with packaging: 471x460x553 mm

- Power supply: 220 ± 15% / 50 Hz, 12 / 20.8 A

- Power Consumption: 500 W

- Productivity: 34-50 cm3 / h

- Dimensions, mm: 391x380x496

- Weight, kg: 18.9

- Shell Material: Steel

- Software: Slic3r

- Country of manufacture: Russia

- File Formats: STL, OBJ

- Worktop Calibration: Mechanical

- Maximum temperature of the printing platform: 125 ° C

- Extruder maximum temperature: 260 ° C

- Heated table: yes, removable glass

- Working chamber: 200x200x210 mm

- Travel speed: up to 150 mm / s

- Specialization: Aerospace industry, Design, Architecture, Packaging, Advertising, Layout design, Defense industry, Automotive industry, Education, Manufacturing

- Printing technology: FDM

- Layer thickness, from: 20 microns

- Noise level: 48 dB

- Supported materials: ABS, PLA, Flex, Rubber, SBS, BF Bronze, Carbon, Nylon, HIPS, PETG

- Thread Diameter: 1.75

- The diameter of the nozzle, mm: 0.2, 0.3, 0.5, 0.8, 1

- Interfaces: USB, SD card

- Number of print heads: 1

- Print speed: 100 mm / s

- Compatible operating systems: Windows, Linux, MacOS

- Price: 104 000 rubles

The printer, with the dimensions of the working chamber 200 by 200 by 210 millimeters, has the necessary rigidity and sufficient weight, which positively affects the print quality, and the Russian assembly gives us an attractive price and affordable warranty service.

Scanning

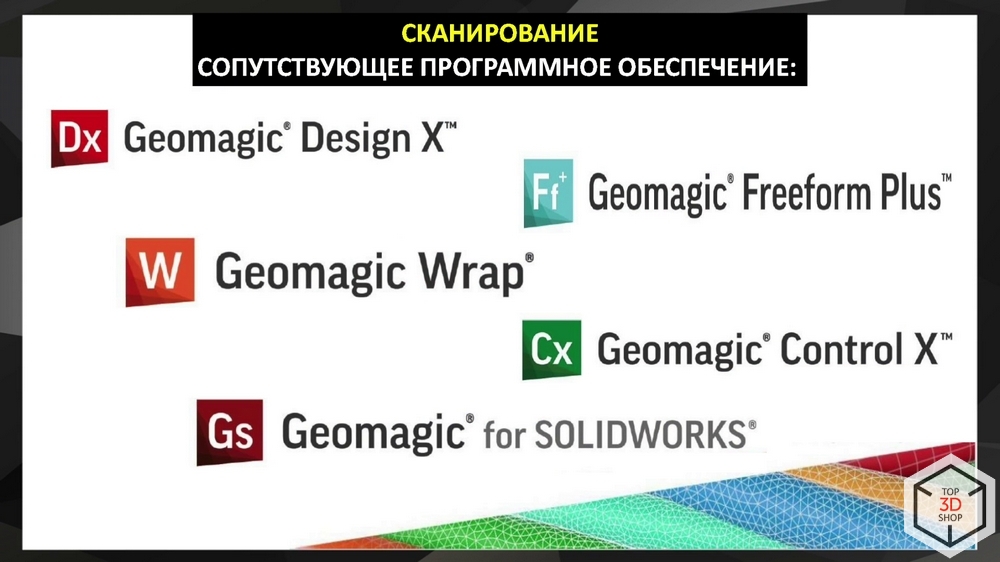

Many people who want to buy a 3D scanner for reverse engineering or control are not even aware that a scan — the result of a 3D scanner — is not yet a complete 3D model with all the known parameters; special software.

Reverse engineering

The applied software of the Geomedic series is widely used in many enterprises, since It has proven itself and is in fact an industrial standard.

Geomagic Design X costs about 1,400,000 rubles, and not every educational institution is ready to spend such sums on software, but it is a very powerful tool that no modern industrial enterprise can do without.

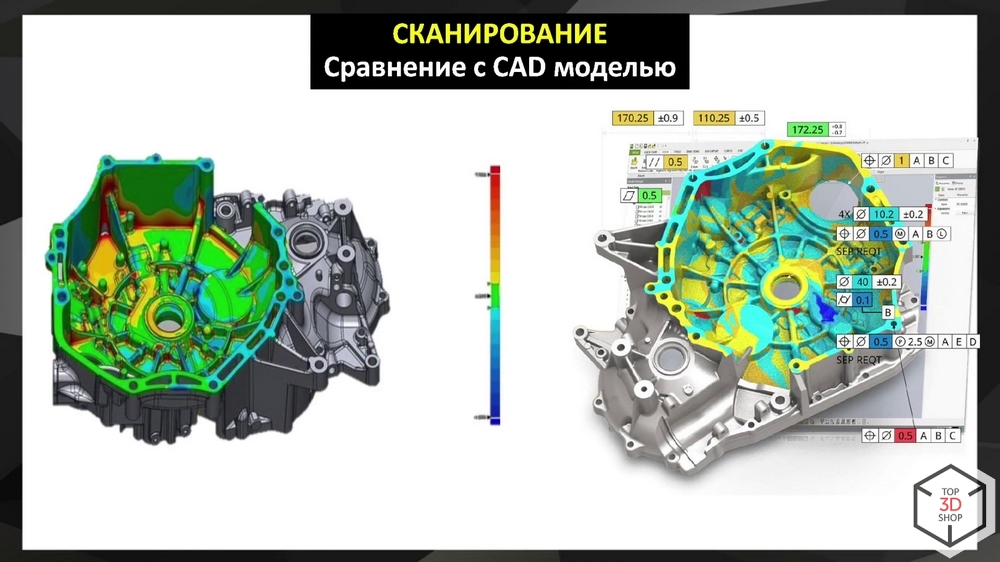

Control

Control is carried out at different stages of production - it can be input, output, intermediate, and so on. We scan, get a scan and compare the results with the CAD model to see the degree of compliance and all possible deviations. This is done using Geomagic X Control . This software costs one million rubles, which not every educational institution can afford either.

There is a ready-made educational solution: hardware-software complex CREAFORM Academia.

CREAFORM Academia

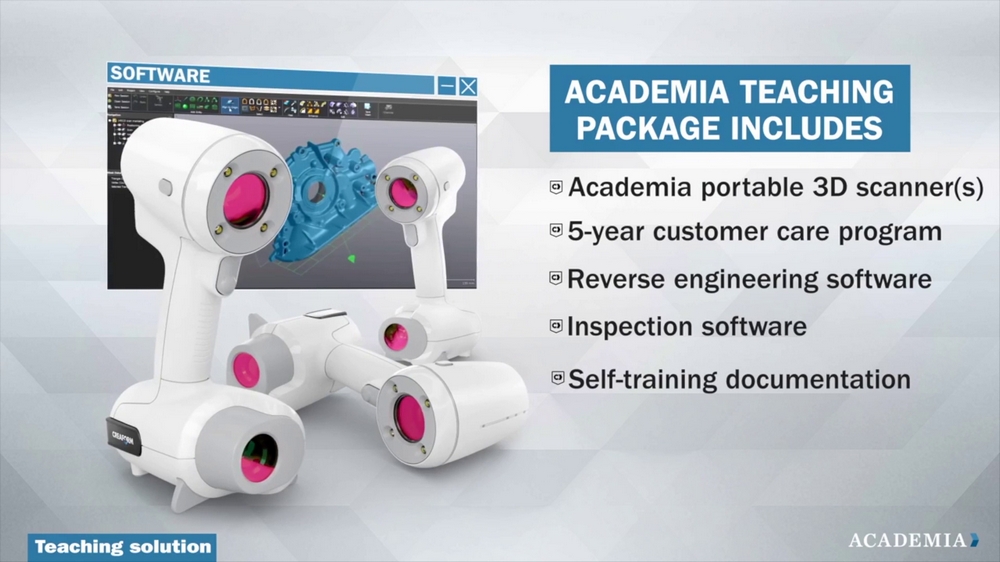

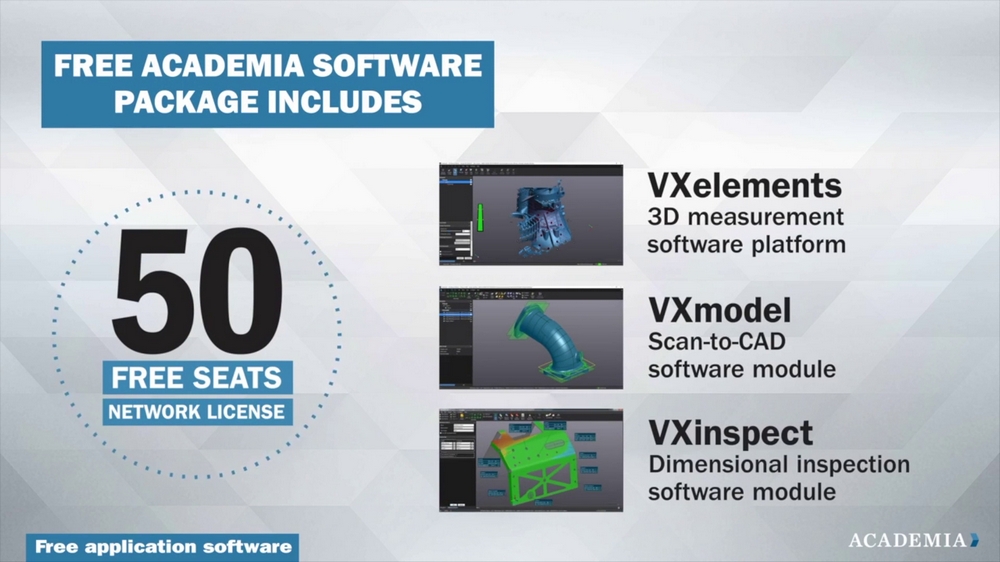

The kit includes not only a 3D scanner, it also comes with:

software for scanning, reverse engineering and quality control, with a license for 50 working / training places and support for five years.

Teaching materials for teaching, video tutorials and custom presentations.

The cost of the educational package, Teaching package , begins with an amount of less than a million rubles.

Also available is an engineering version of the complex - Research package.

Its cost starts from 4 million rubles. It differs in the complete scanner model - in the training set it is the Academy scanner, in Research Research the options are possible; a set of software and the availability of certification as a calibration metrology equipment.

findings

If you want to save time and money, and usually these factors are very closely related, then you should contact the selection of equipment from professionals.

Not so terrible is the loss of some sums from the budget of the institution in connection with the purchase of inappropriate equipment, such as failure of the curriculum or irrelevant knowledge in the program. We will help to avoid both.

For individual selection of equipment and software for an educational institution, TsMIT or enterprises, contact Top 3D Shop .

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: