Everything's under control. Why do we need monitoring systems of engineering infrastructure of data processing centers

Habr, hello!

I am a leading engineer of the company LANIT-Integration . I have been working here for over 20 years. For the last seven years I have been engaged in engineering of data centers: I install and run equipment into operation.

Every year there are more and more requirements for reliability and ease of use of data centers. However, this can not be achieved if you focus only on backup systems and the quality of individual elements. The market understands this simple idea, so companies are increasingly introducing a unified monitoring system. In short, it monitors the engineering infrastructure of the data center and helps to avoid emergency situations.

In the article I will talk about ready-made software and hardware monitoring solutions that we use with colleagues in projects.

A source

A source

To begin with, I’ll talk about what the core of the data center consists of. It is divided into three parts.

The engineering infrastructure of data centers is also divided into two subsystems: operation and security. The first includes systems of general, guaranteed and uninterrupted power supply, process air conditioning, installation constructs. The security subsystem includes burglar and fire alarms, autonomous gas fire extinguishing systems, video surveillance, access control and management.

To ensure that all systems are operating normally, constant monitoring is needed, which gives monitoring.

Source

Source

Monitoring helps data center engineers to work more comfortably. Without it, specialists must either live and work all the time next to the cabinets, or leave the office and run to them every time when there is any problem or there is a suspicion that it may happen.

Source

Source

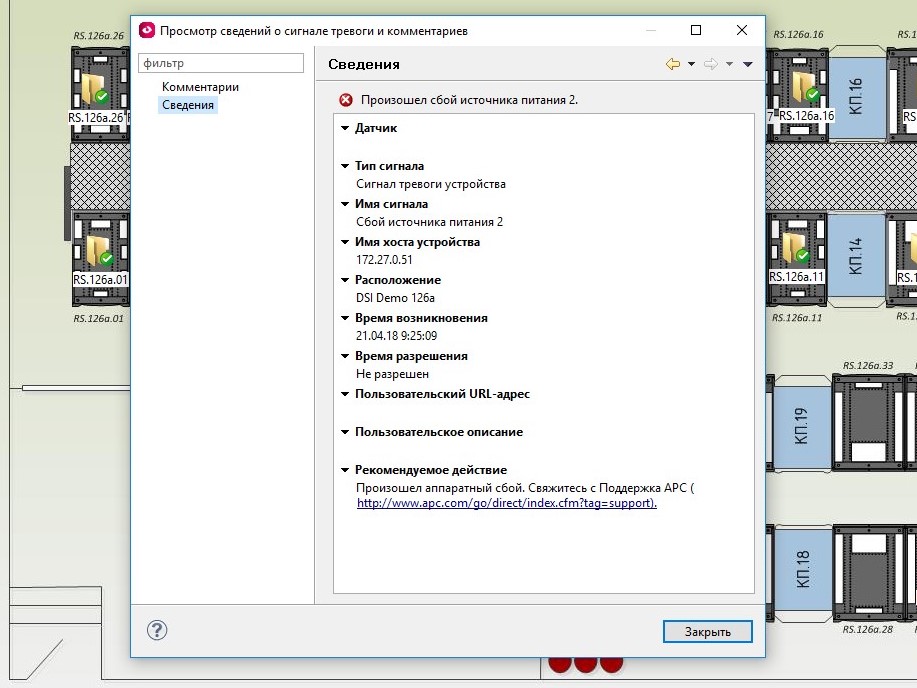

Real-time Monitoring shows how the data center infrastructure works. For indicators, as a rule, follow the duty shift. In the event of a deviation or abnormal situation, staff on duty shift can timely prevent a critical situation or reduce its consequences to a minimum. Also, the monitoring system collects data on the parameters, the status of the equipment, monitors the timing of service, accumulated hours, etc.

What exactly does the monitoring system control and what tasks does it solve?

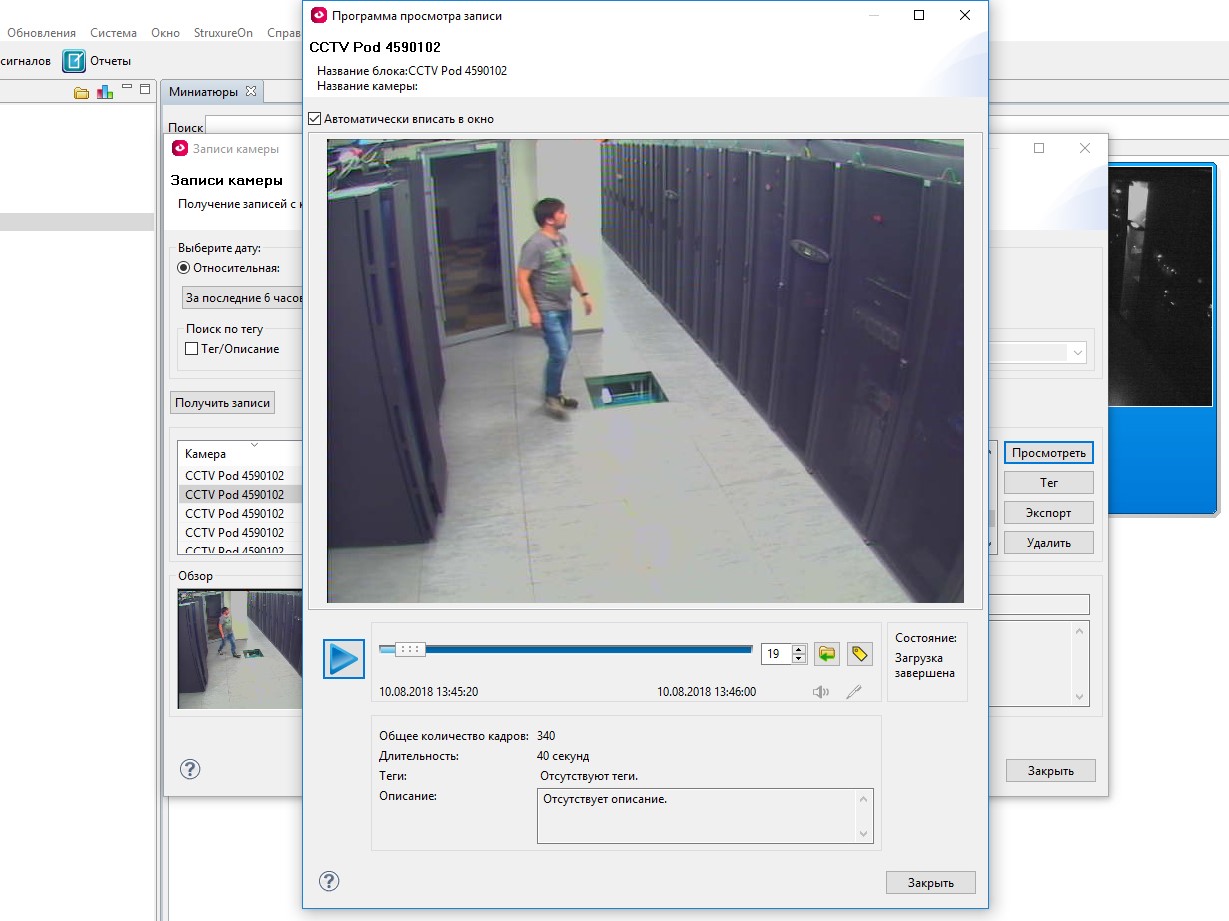

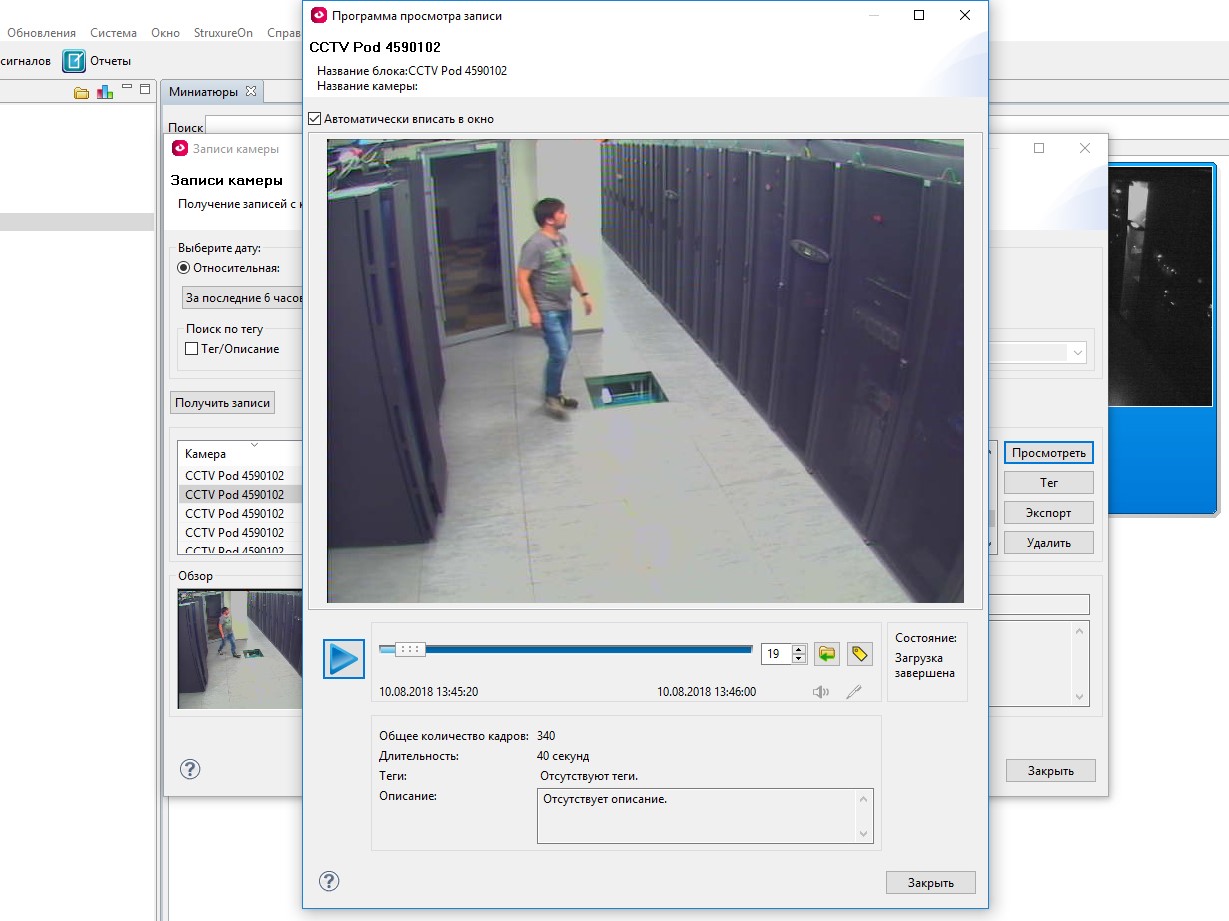

Unfortunately, statistics says that a lot of emergency situations with equipment arise through the fault of a person. That is why monitoring also monitors not only the parameters, but also those who have access to the data center and who / what it does.

A source

A source

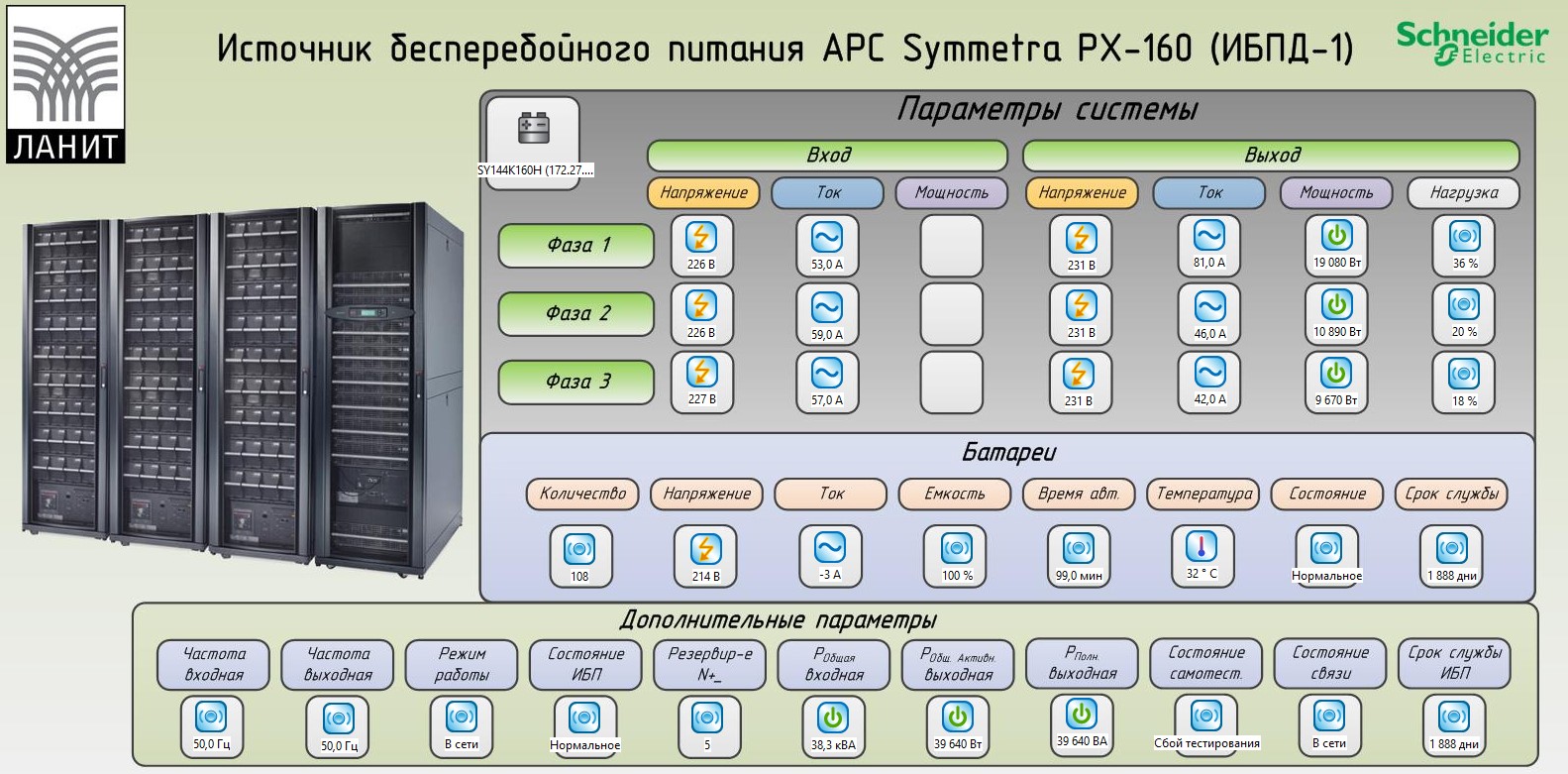

For many years, my colleagues and I have been working with the NetBotz monitoring system and the data center infrastructure management system StruxureWare Data center Expert from APC by Schneider Electric. Our team has an affiliate certification direction DCIM.

Most engineering equipment manufacturers have comprehensive solutions. With their help, you can create the engineering infrastructure of the data center "turnkey" and build a monitoring system "from cubes".

It:

However, ready-made systems have disadvantages. As a rule, each manufacturer offers a system for monitoring its equipment, that is, the one that produces itself. Of course, it is very convenient when the data center infrastructure is built on the equipment of a single brand. The introduction of such a system takes little time, there is no problem with the connection and recognition of equipment parameters.

Source It is

Source It is

predicted that the main problem of such systems is the connection of third-party equipment. It happens that such systems support some types and models of third-party equipment, but for correct connection and display of parameters very often additional actions and time are required.

For example, to connect devices of other brands that are connected via the MODBUS protocolto the Data center Expert system from APC, which are not included in the supported list, you have to contact support. In this case, you need to provide technical data on the connected equipment, fill out several forms and wait about a month. It is practically impossible to do this on your own.

From theory to practice. We installed the first monitoring system in 2010. In total, we have implemented more than 15 data center monitoring systems. On the one hand, the work is the same every time, on the other hand, each customer has their own conditions and requirements, therefore each project is remembered with something different. Below I will talk about the most interesting projects over the past few years.

Two data centers were located in Moscow and St. Petersburg. They were tied by a single monitoring system of engineering infrastructure. In this project, for the first time, it was necessary to separate user rights to access groups of devices. Like this? Specialists from Moscow monitored all devices in both data centers, and specialists in St. Petersburg controlled only their part of the equipment.

For the first time, our team had to “tie” third-party equipment, a diesel generator set, an automation shield and an air-conditioning control panel to the StruxureWare Data center Expert monitoring system. Not without the help of Western specialists of the support service of the manufacturer of the monitoring system. For a month they wrote drivers for the devices we need.

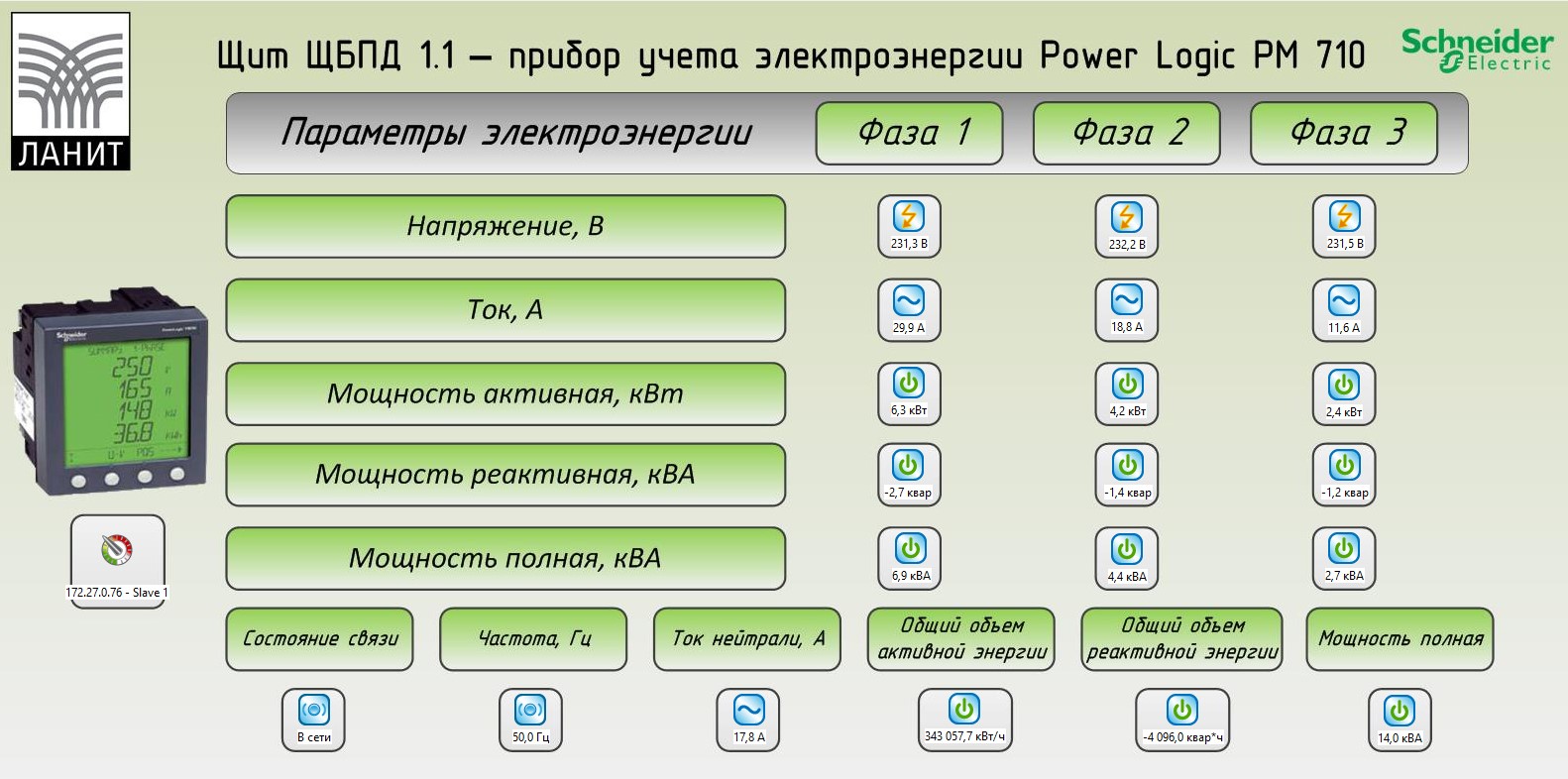

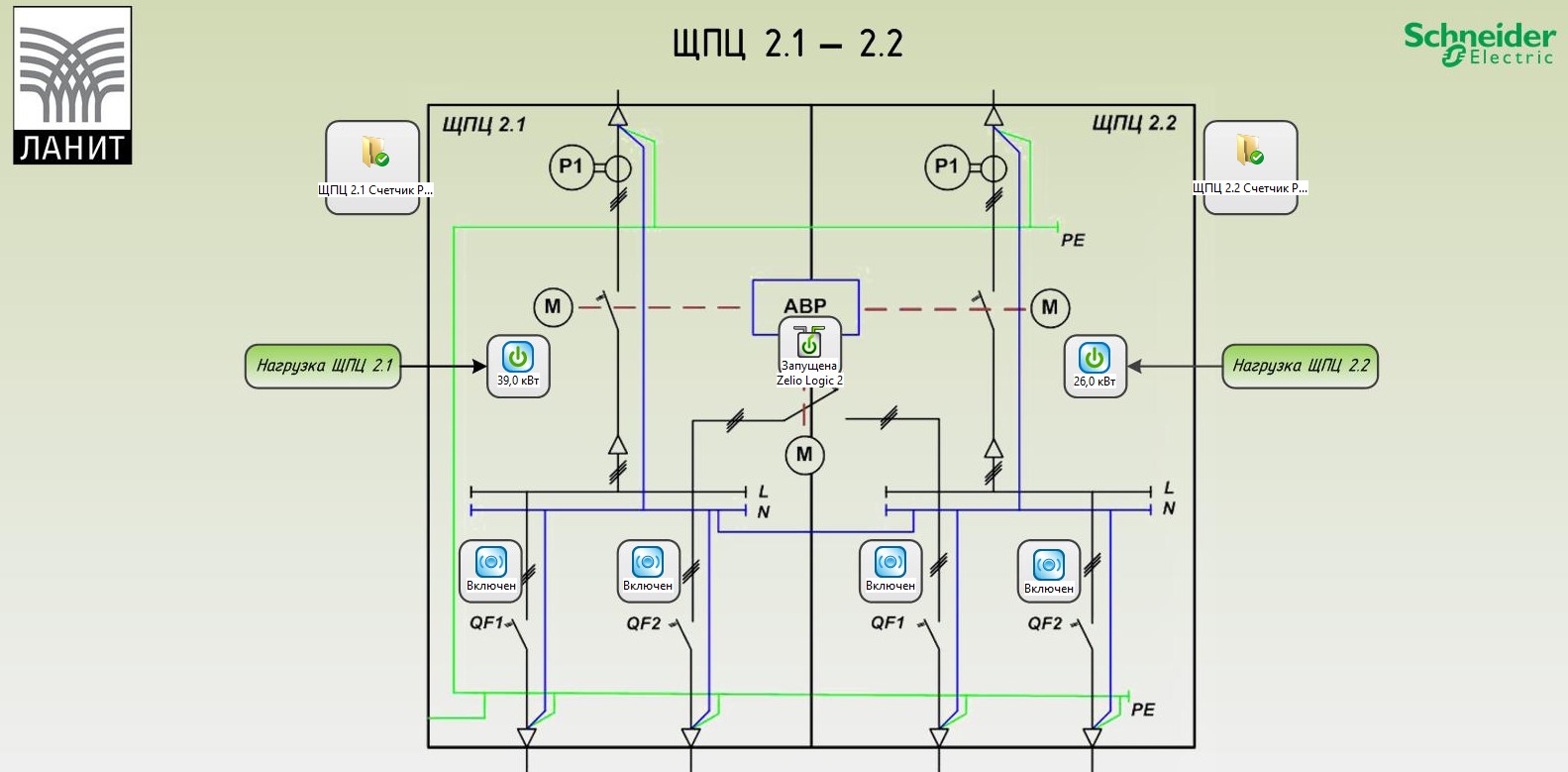

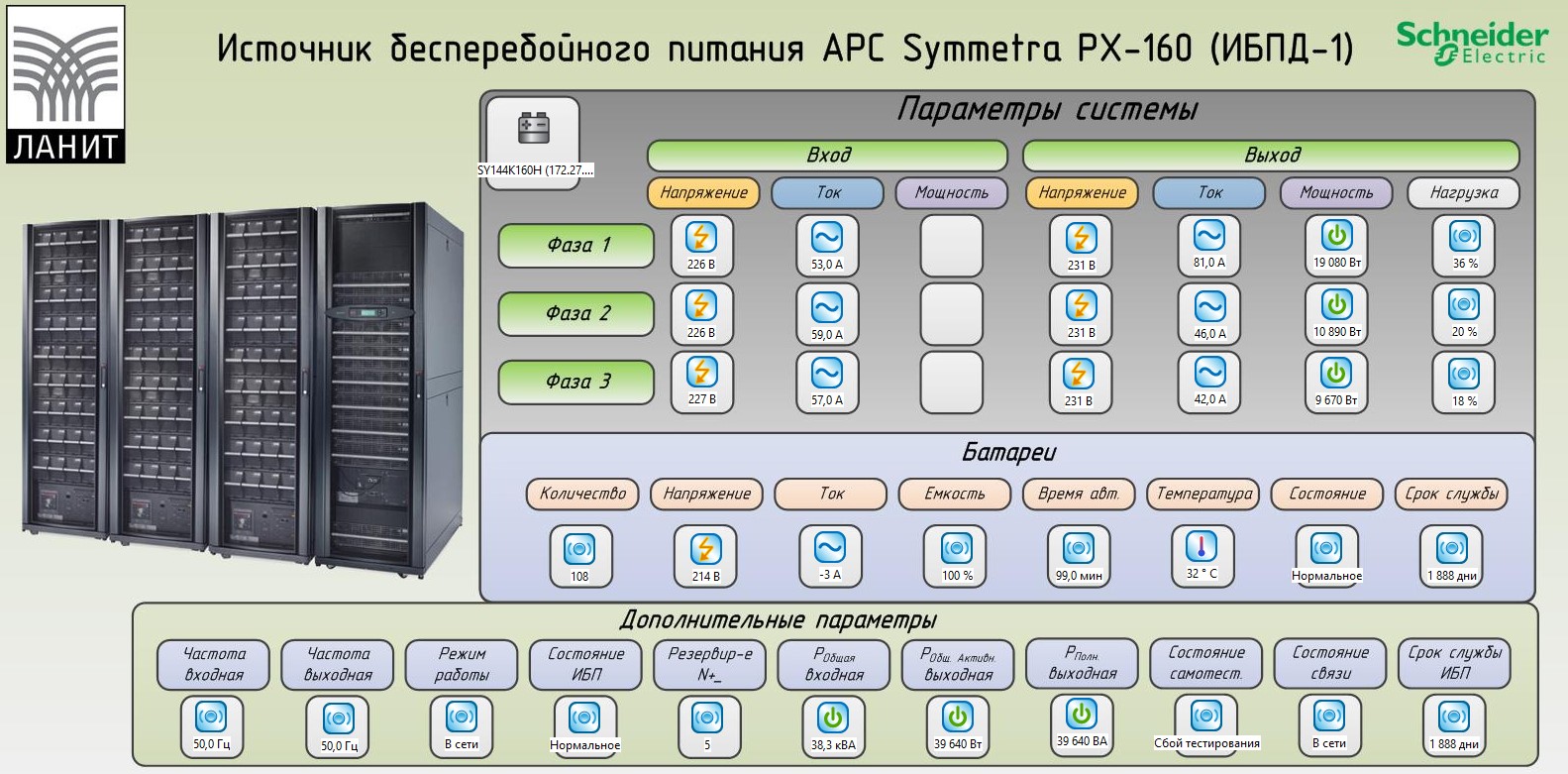

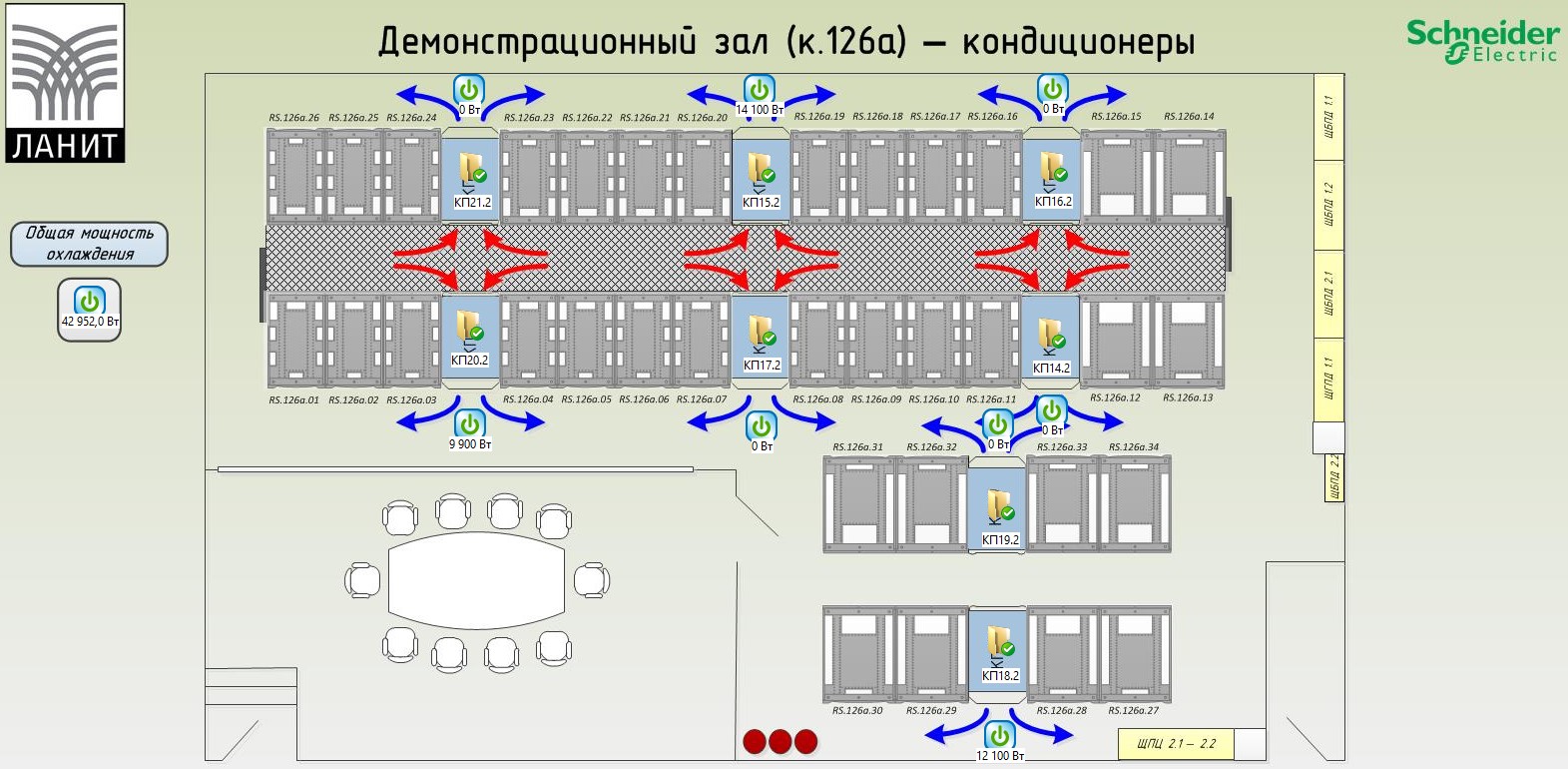

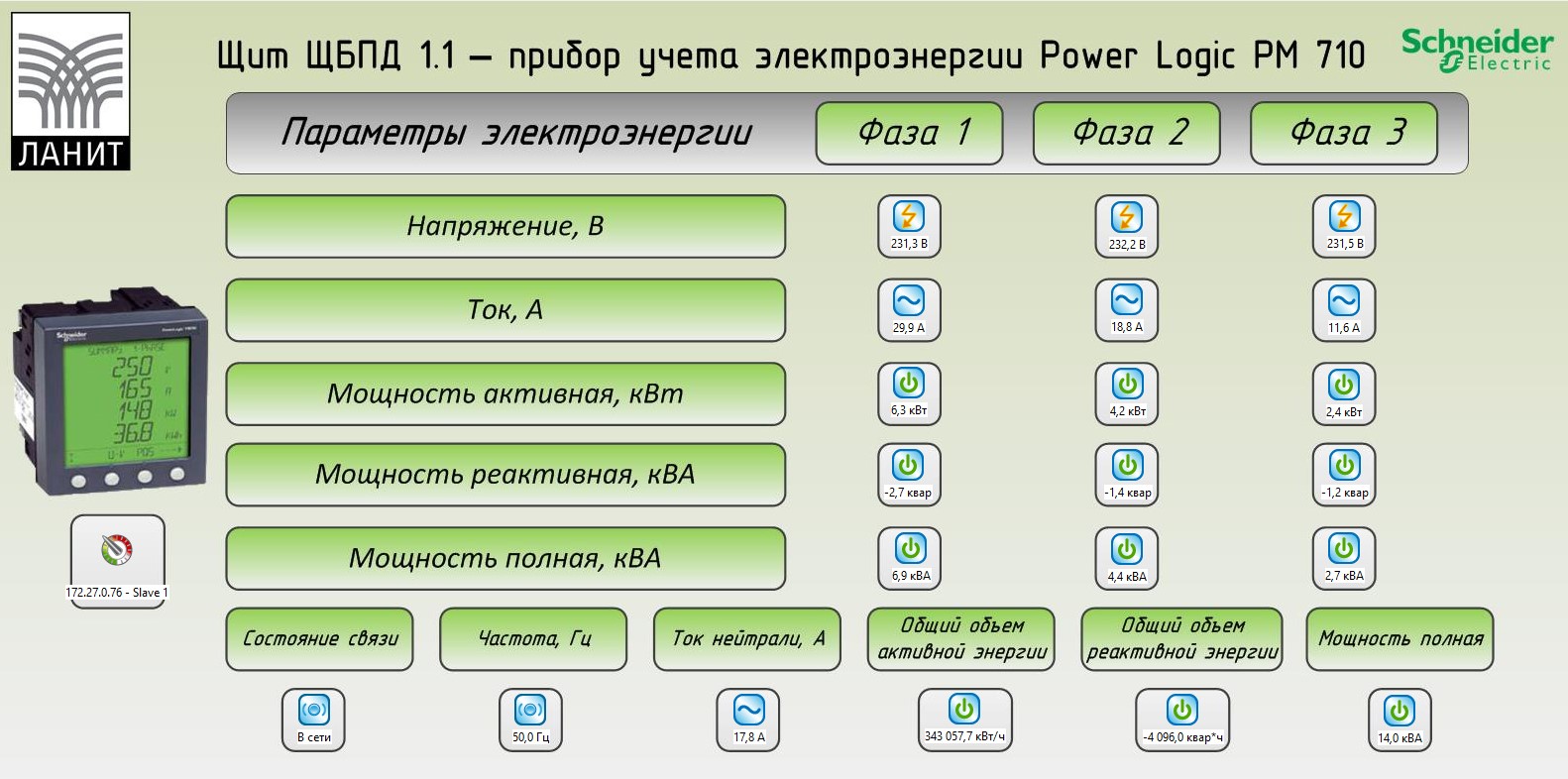

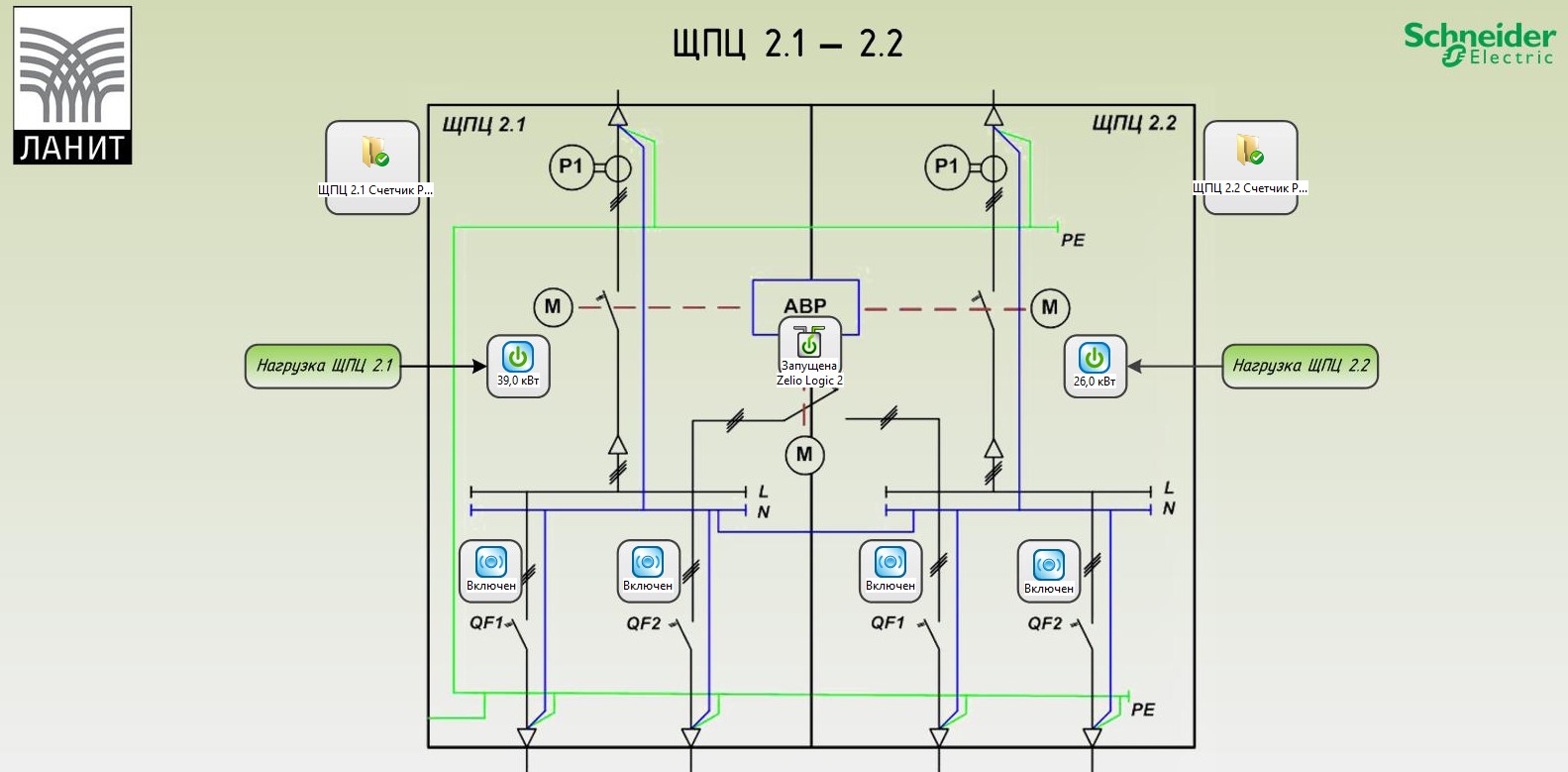

Here, in addition to the standard solution, we first monitored the switchgear shield with automatic switches, controlled by the programmable ZelioLogic relay, the power distribution board with the control of the state of the circuit breakers on the Acti-9 SmartLink controller and PowerLogic electricity meters from Schneider Electric.

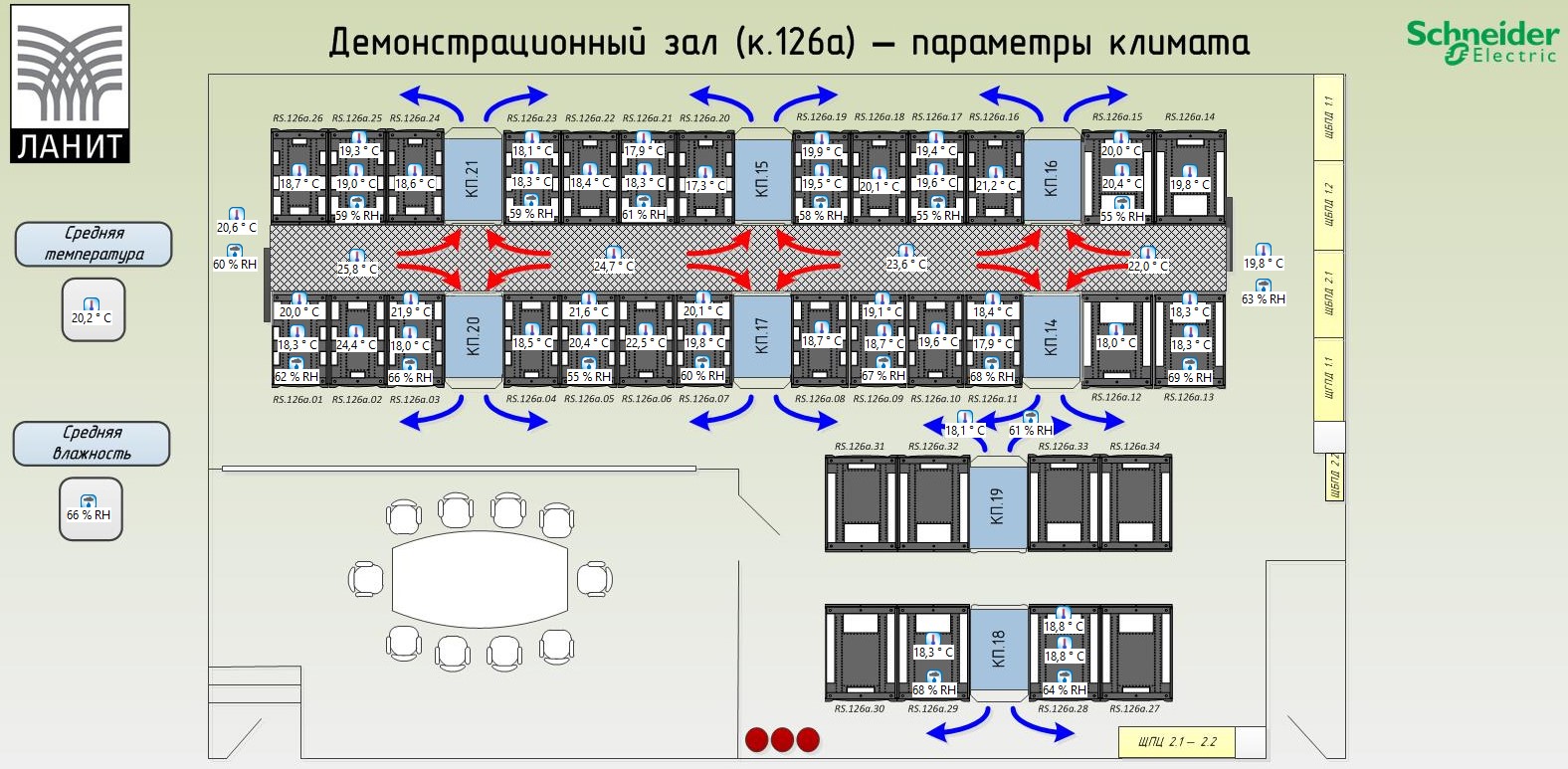

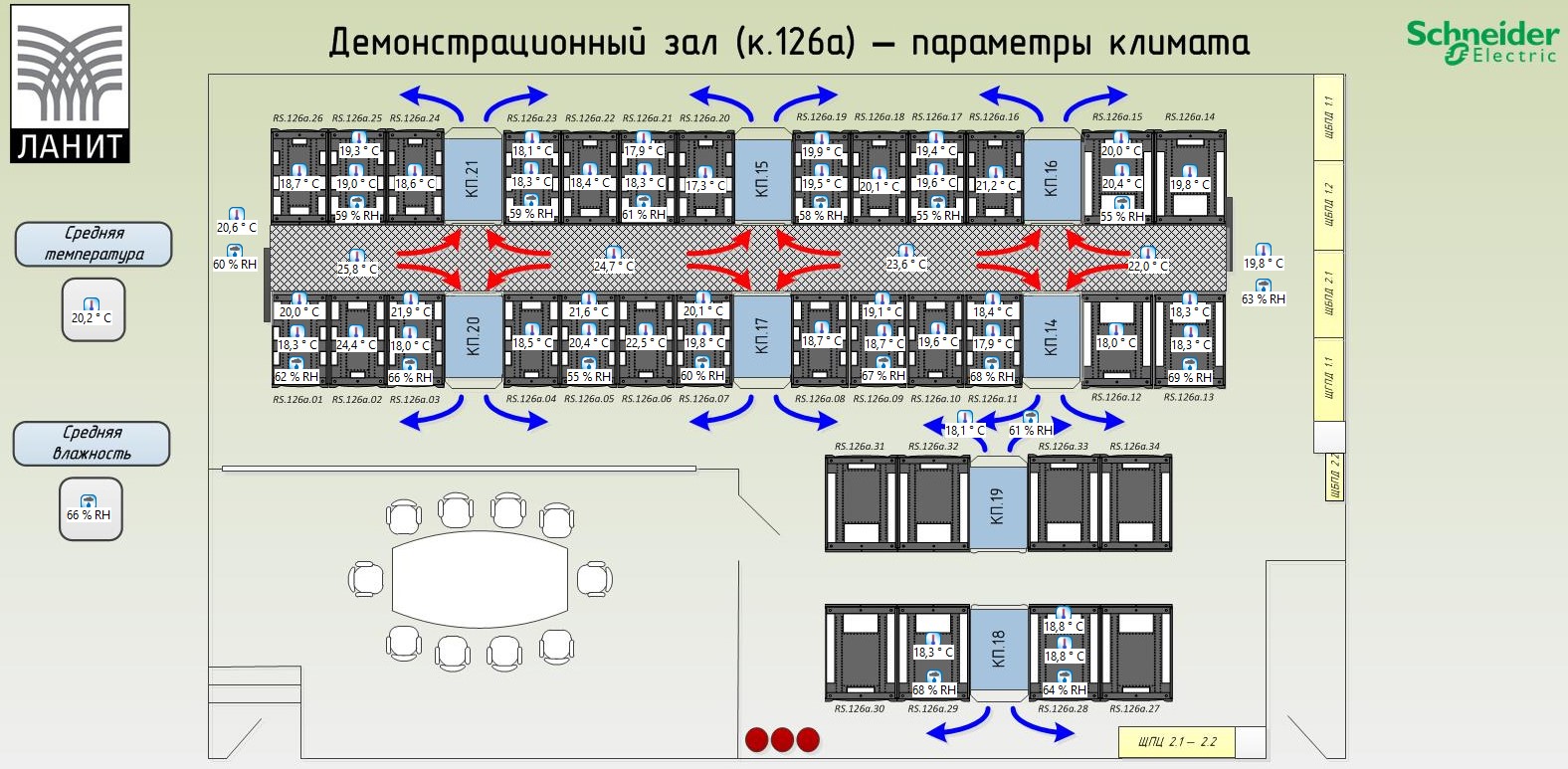

We were the first in the country to implement monitoring systems and data center infrastructure management systems using 190 wireless temperature and humidity sensors located in 6 machine rooms and 4 equipment rooms.

Another large project will start relatively soon. For us it will be a new experience. RAMOS monitoring systems and the data center infrastructure management system Aegis DCIM (Czech manufacturer CONTEG) will be introduced. Perhaps there will be a reason to tell you again.

I am a leading engineer of the company LANIT-Integration . I have been working here for over 20 years. For the last seven years I have been engaged in engineering of data centers: I install and run equipment into operation.

Every year there are more and more requirements for reliability and ease of use of data centers. However, this can not be achieved if you focus only on backup systems and the quality of individual elements. The market understands this simple idea, so companies are increasingly introducing a unified monitoring system. In short, it monitors the engineering infrastructure of the data center and helps to avoid emergency situations.

In the article I will talk about ready-made software and hardware monitoring solutions that we use with colleagues in projects.

To begin with, I’ll talk about what the core of the data center consists of. It is divided into three parts.

- The telecommunication system receives and transmits data between the data center and its users, and also connects the elements of the center.

- The technical architecture is access servers, application servers, DBMS servers, data storage systems. It is responsible for the operation of business applications and allows users to access them.

- The engineering infrastructure makes all systems work properly, that is, it maintains optimal conditions for them.

The engineering infrastructure of data centers is also divided into two subsystems: operation and security. The first includes systems of general, guaranteed and uninterrupted power supply, process air conditioning, installation constructs. The security subsystem includes burglar and fire alarms, autonomous gas fire extinguishing systems, video surveillance, access control and management.

To ensure that all systems are operating normally, constant monitoring is needed, which gives monitoring.

Monitoring helps data center engineers to work more comfortably. Without it, specialists must either live and work all the time next to the cabinets, or leave the office and run to them every time when there is any problem or there is a suspicion that it may happen.

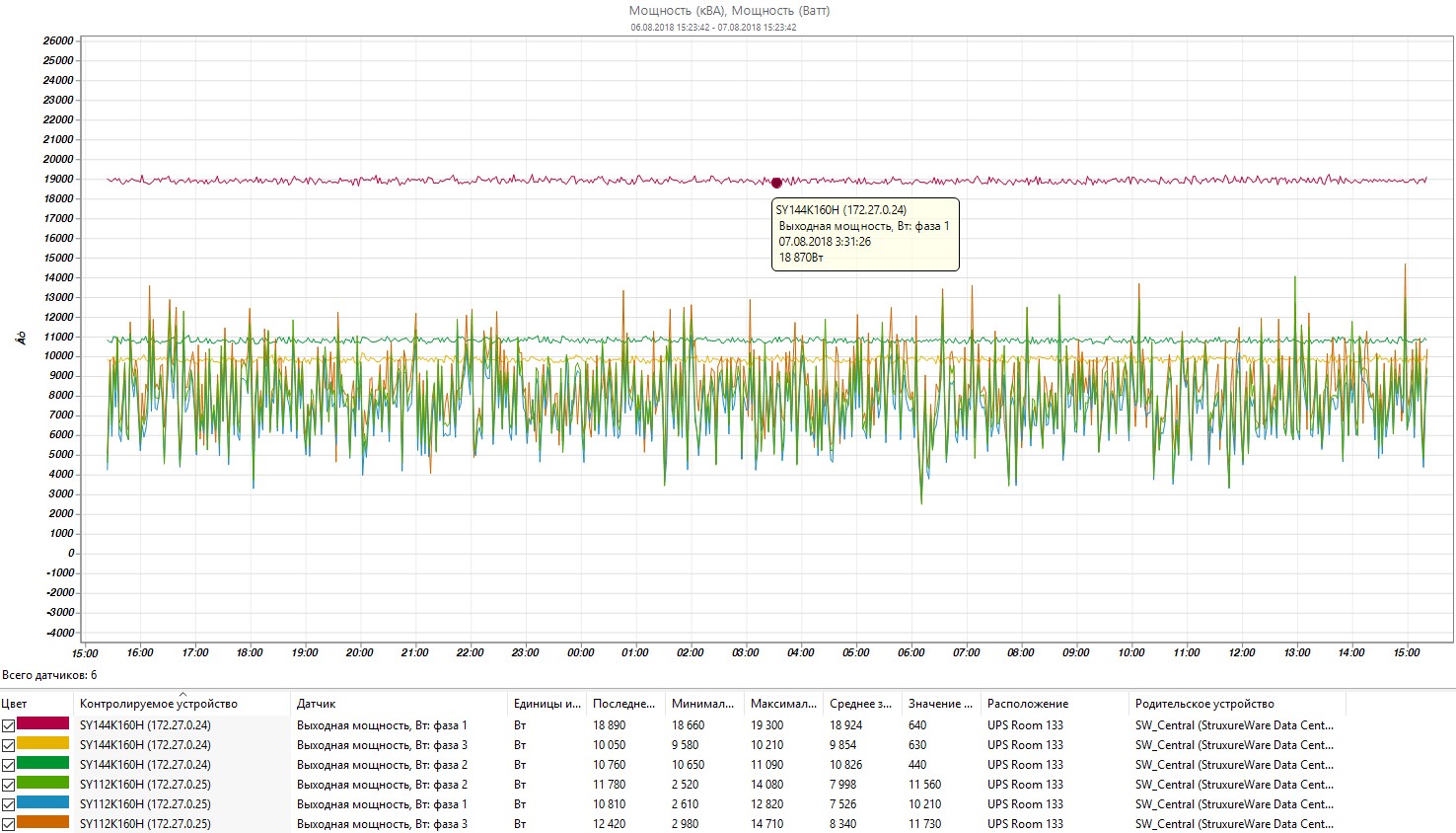

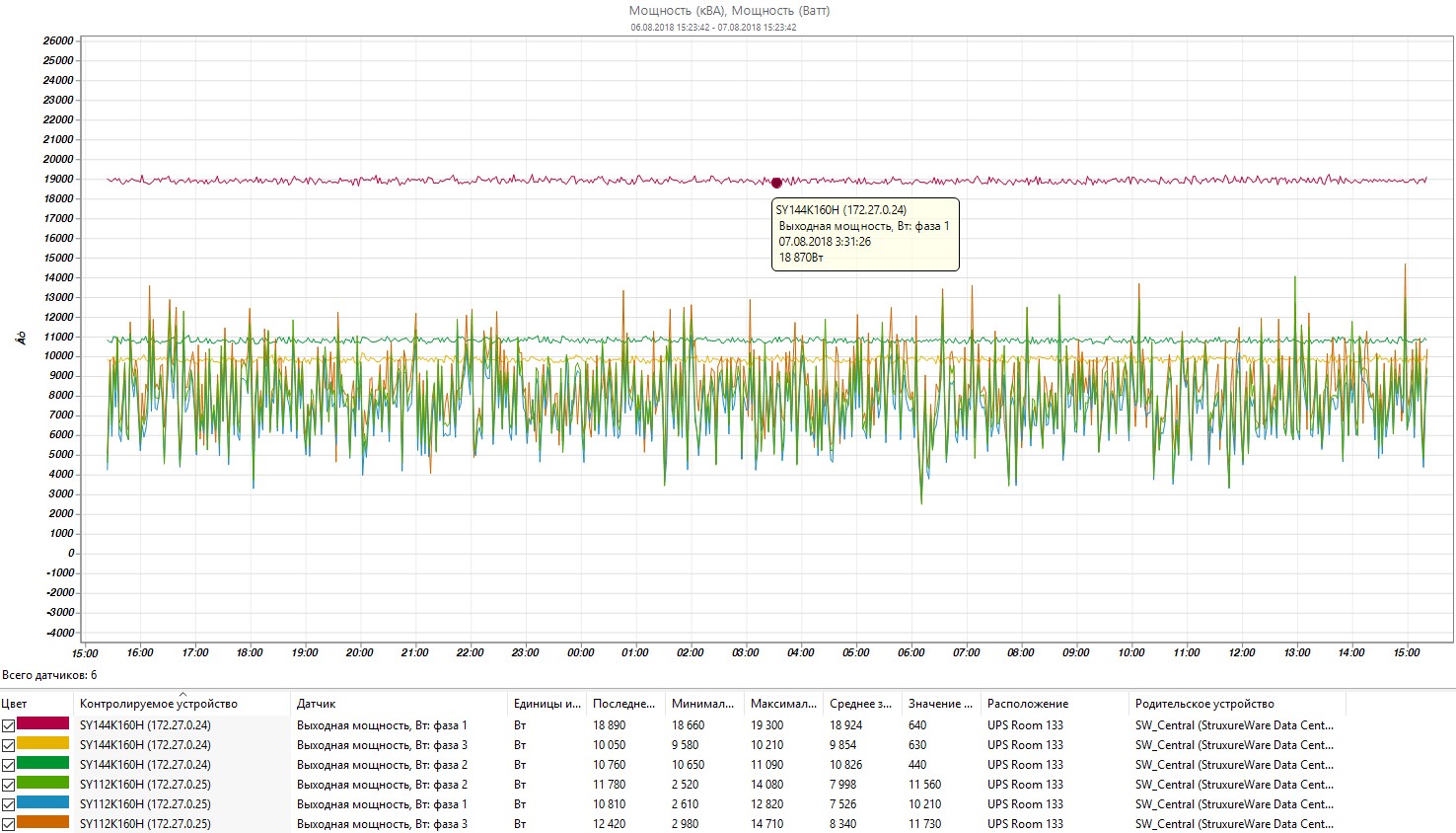

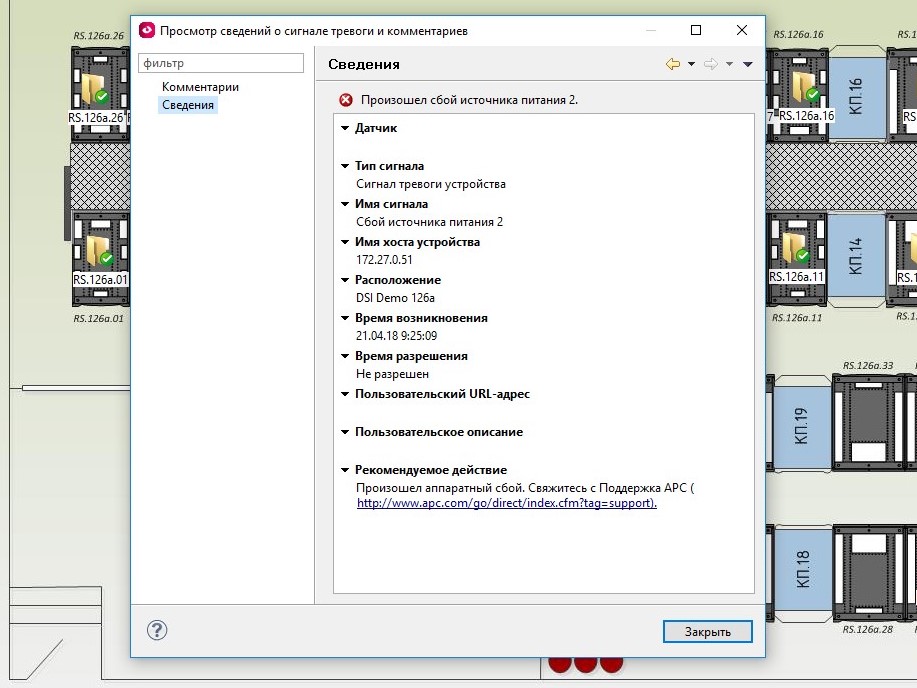

Real-time Monitoring shows how the data center infrastructure works. For indicators, as a rule, follow the duty shift. In the event of a deviation or abnormal situation, staff on duty shift can timely prevent a critical situation or reduce its consequences to a minimum. Also, the monitoring system collects data on the parameters, the status of the equipment, monitors the timing of service, accumulated hours, etc.

What exactly does the monitoring system control and what tasks does it solve?

- Monitors the parameters of the power supply network and the state of the circuit breakers;

- controls the state and parameters of the uninterruptible power supply;

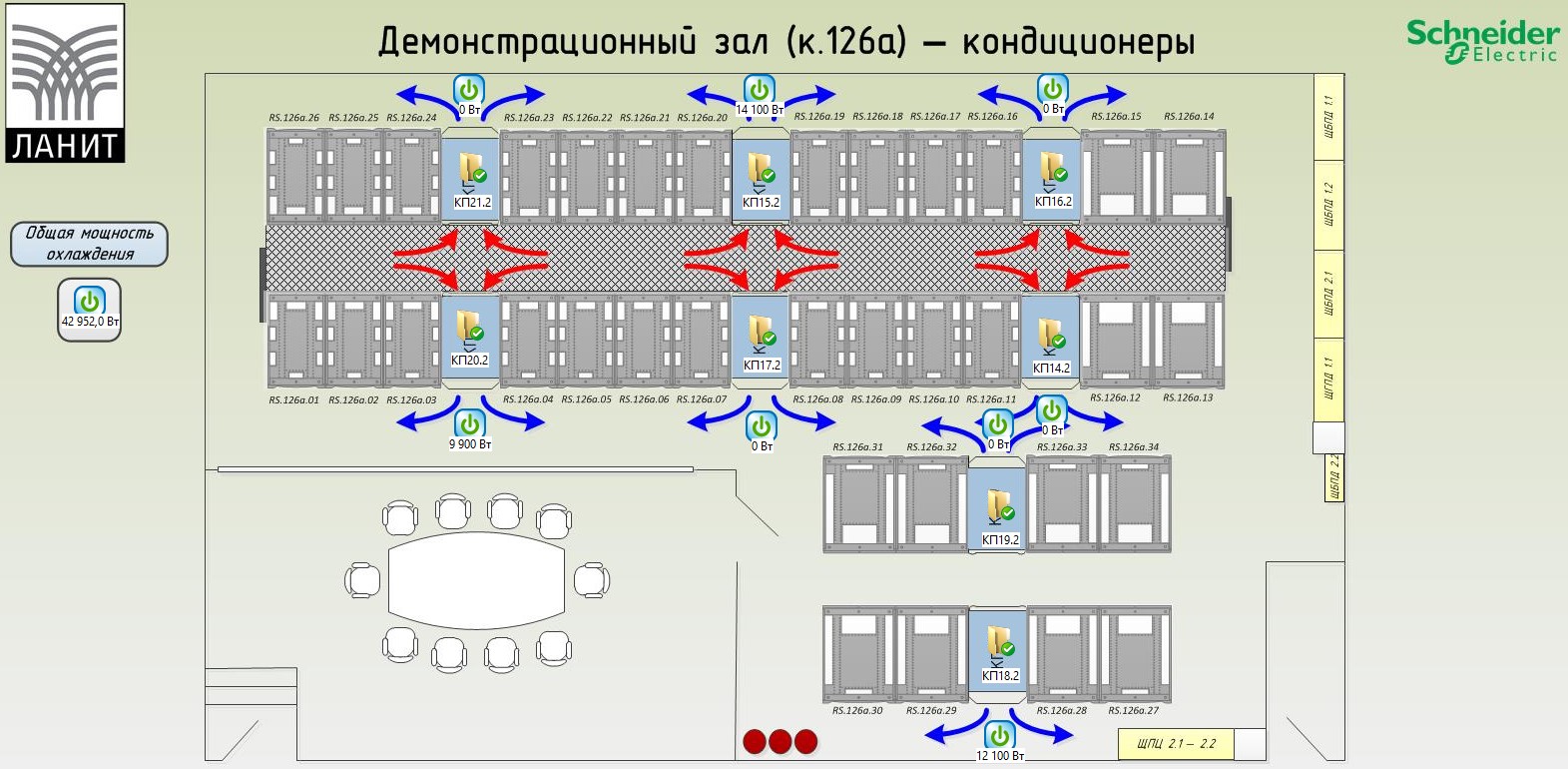

- monitors the status and parameters of the refrigeration machines, air conditioners and ventilation systems;

- collects data on temperature and humidity of the air, learns about the presence of leaks and smoke in the data center;

- creates reports and graphs on the required parameters;

- sends notifications of any events and emergency situations;

Protection from people

Unfortunately, statistics says that a lot of emergency situations with equipment arise through the fault of a person. That is why monitoring also monitors not only the parameters, but also those who have access to the data center and who / what it does.

Types of monitoring systems

Существует множество различных систем, так или иначе позволяющих контролировать параметры и работу различных типов оборудования — мониторинг IT-систем, мониторинг СКС/ЛВС, мониторинг инженерных систем и т.д.

По типу реализации системы делятся на программные, аппаратные и гибридные решения.

По уровню контроля системы мониторинга делятся на распределенные и централизованные.

Распределенные системы позволяют отслеживать состояние одного или нескольких однотипных устройств.

Централизованные системы дают возможность объединить всё контролируемое оборудование, в том числе и несколько распределенных систем, в единую систему, позволяющую наблюдать за работой всего оборудования в «одном окне».

По типу реализации системы делятся на программные, аппаратные и гибридные решения.

По уровню контроля системы мониторинга делятся на распределенные и централизованные.

Распределенные системы позволяют отслеживать состояние одного или нескольких однотипных устройств.

Централизованные системы дают возможность объединить всё контролируемое оборудование, в том числе и несколько распределенных систем, в единую систему, позволяющую наблюдать за работой всего оборудования в «одном окне».

What it consists of

For many years, my colleagues and I have been working with the NetBotz monitoring system and the data center infrastructure management system StruxureWare Data center Expert from APC by Schneider Electric. Our team has an affiliate certification direction DCIM.

Most engineering equipment manufacturers have comprehensive solutions. With their help, you can create the engineering infrastructure of the data center "turnkey" and build a monitoring system "from cubes".

It:

- monitoring controllers - devices to which various sensors are connected and which collect information from these sensors;

- port extenders for connecting sensors - additional units that connect to monitoring controllers to increase the number of connected sensors;

- temperature, humidity, leakage, smoke, door opening, motion detection, vibration sensors, analog sensors 4-20 mA and 0-5 volts, dry contacts, etc .;

- control devices and access restrictions both in communication cabinets and in premises;

- CCTV Cameras.

However, ready-made systems have disadvantages. As a rule, each manufacturer offers a system for monitoring its equipment, that is, the one that produces itself. Of course, it is very convenient when the data center infrastructure is built on the equipment of a single brand. The introduction of such a system takes little time, there is no problem with the connection and recognition of equipment parameters.

predicted that the main problem of such systems is the connection of third-party equipment. It happens that such systems support some types and models of third-party equipment, but for correct connection and display of parameters very often additional actions and time are required.

For example, to connect devices of other brands that are connected via the MODBUS protocolto the Data center Expert system from APC, which are not included in the supported list, you have to contact support. In this case, you need to provide technical data on the connected equipment, fill out several forms and wait about a month. It is practically impossible to do this on your own.

Installation and Setup

From theory to practice. We installed the first monitoring system in 2010. In total, we have implemented more than 15 data center monitoring systems. On the one hand, the work is the same every time, on the other hand, each customer has their own conditions and requirements, therefore each project is remembered with something different. Below I will talk about the most interesting projects over the past few years.

NIS GLONASS

Two data centers were located in Moscow and St. Petersburg. They were tied by a single monitoring system of engineering infrastructure. In this project, for the first time, it was necessary to separate user rights to access groups of devices. Like this? Specialists from Moscow monitored all devices in both data centers, and specialists in St. Petersburg controlled only their part of the equipment.

Project for metallurgical plant

For the first time, our team had to “tie” third-party equipment, a diesel generator set, an automation shield and an air-conditioning control panel to the StruxureWare Data center Expert monitoring system. Not without the help of Western specialists of the support service of the manufacturer of the monitoring system. For a month they wrote drivers for the devices we need.

Research department of the state corporation

Here, in addition to the standard solution, we first monitored the switchgear shield with automatic switches, controlled by the programmable ZelioLogic relay, the power distribution board with the control of the state of the circuit breakers on the Acti-9 SmartLink controller and PowerLogic electricity meters from Schneider Electric.

Technopark

We were the first in the country to implement monitoring systems and data center infrastructure management systems using 190 wireless temperature and humidity sensors located in 6 machine rooms and 4 equipment rooms.

Another large project will start relatively soon. For us it will be a new experience. RAMOS monitoring systems and the data center infrastructure management system Aegis DCIM (Czech manufacturer CONTEG) will be introduced. Perhaps there will be a reason to tell you again.

By the way, our team is always looking for talented and enthusiastic professionals.