Advanced CNC machine

I would like to tell you about my project in order to get an opinion about it. Reasoned criticism and suggestions are welcome with open arms. If interest arises, I will write a series of articles about how the project was created, I will share a grain of my experience. So, let's begin.

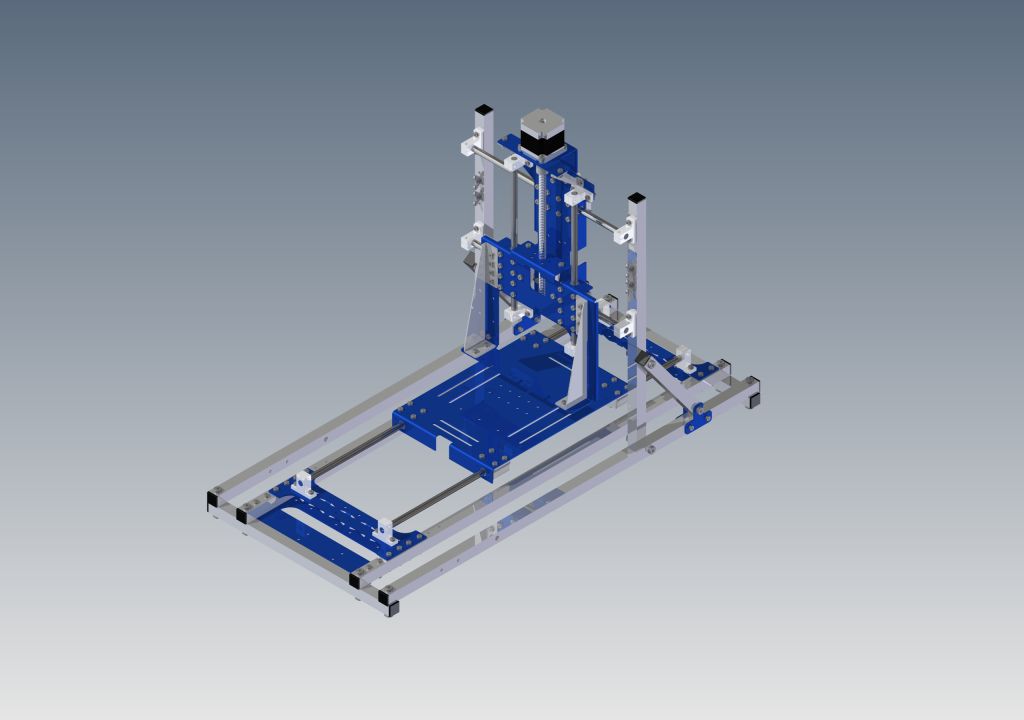

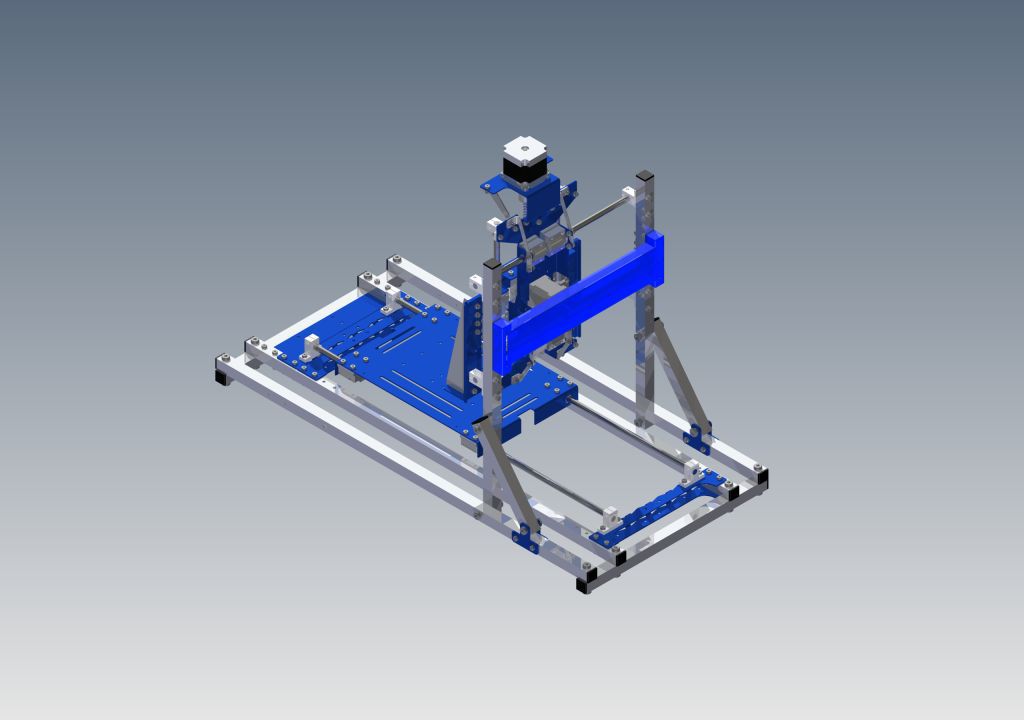

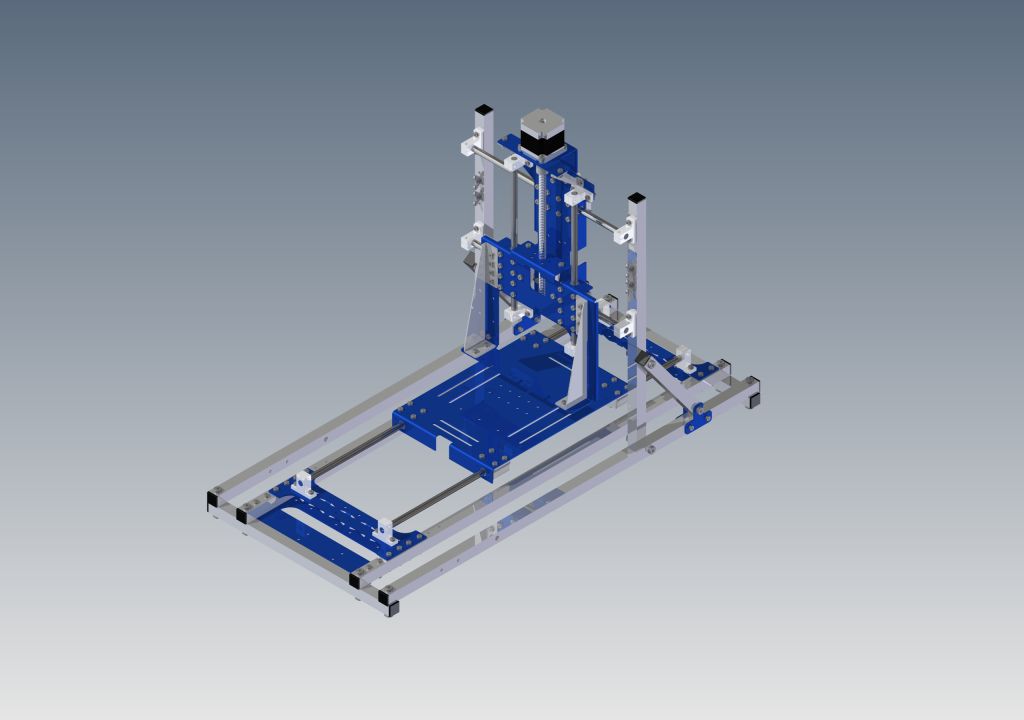

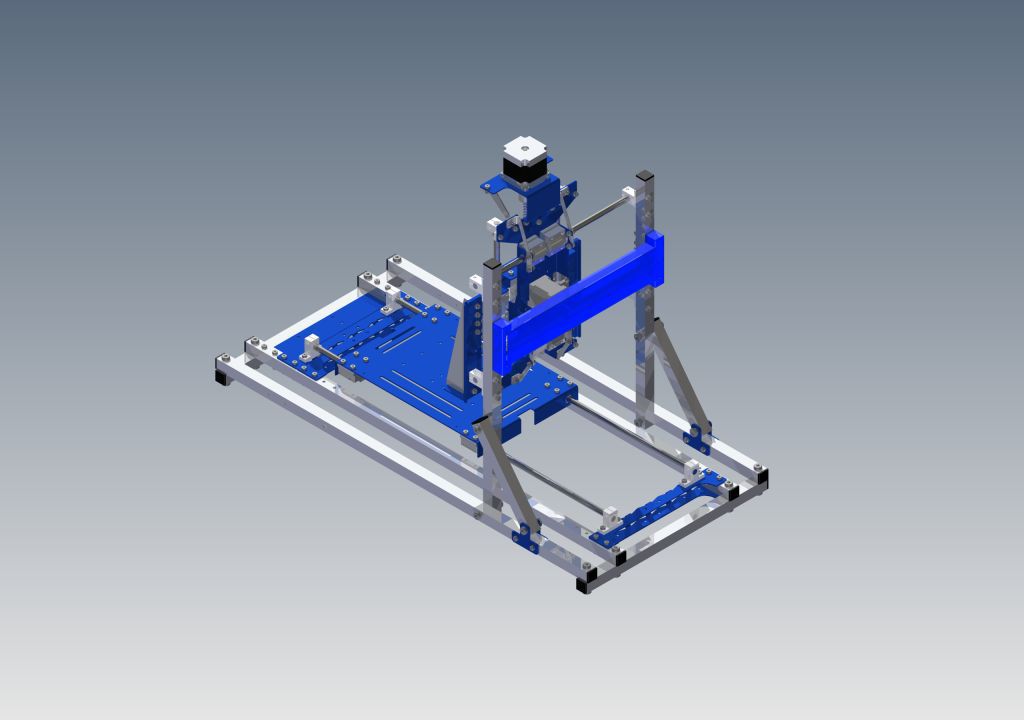

Recently, an idea came up to create a completely open project of a universal 3-coordinate platform, which can perform the functionality of both a 3D printer and a milling machine for processing plastic and much more. The platform is built on a modular type. This means that it has a completely interchangeable carriage drive and tool. We called this thing "RRaptor Platform." In the future, I will give a number of images and photographs of design models and what has already been implemented.

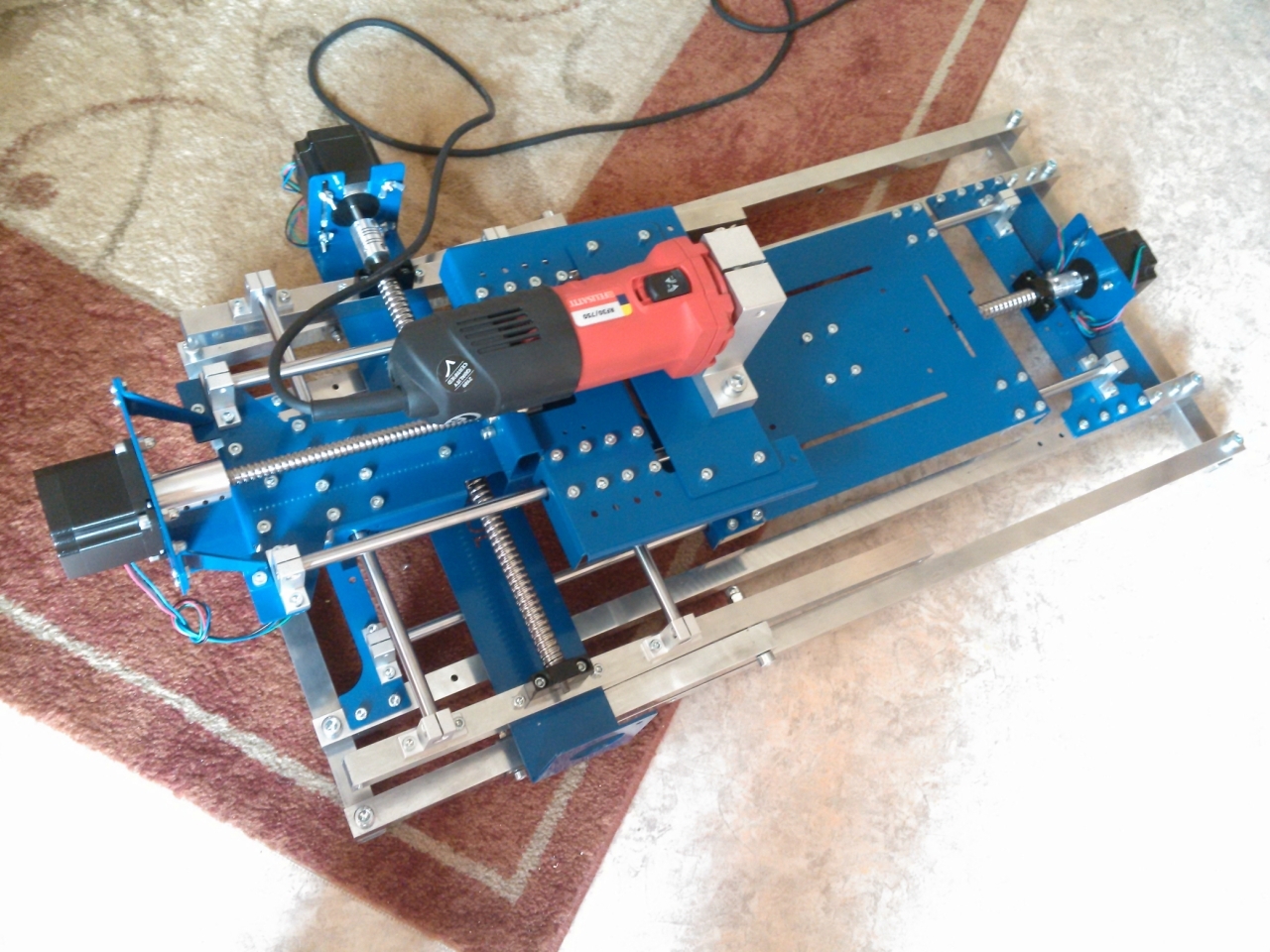

But what happened in reality. And yes. The screw on the Y coordinate is not fixed.

Let's see what modularity means in the context of the project. For example, we want to get a 3d printer: put the appropriate drive + print unit (you can put 3 units at the same time) - and you're done. We can print your details. For various reasons, platform-gear gears with a stepper motor are used to print on the platform.

The model shows the installed gear-rack drive to the Y coordinate

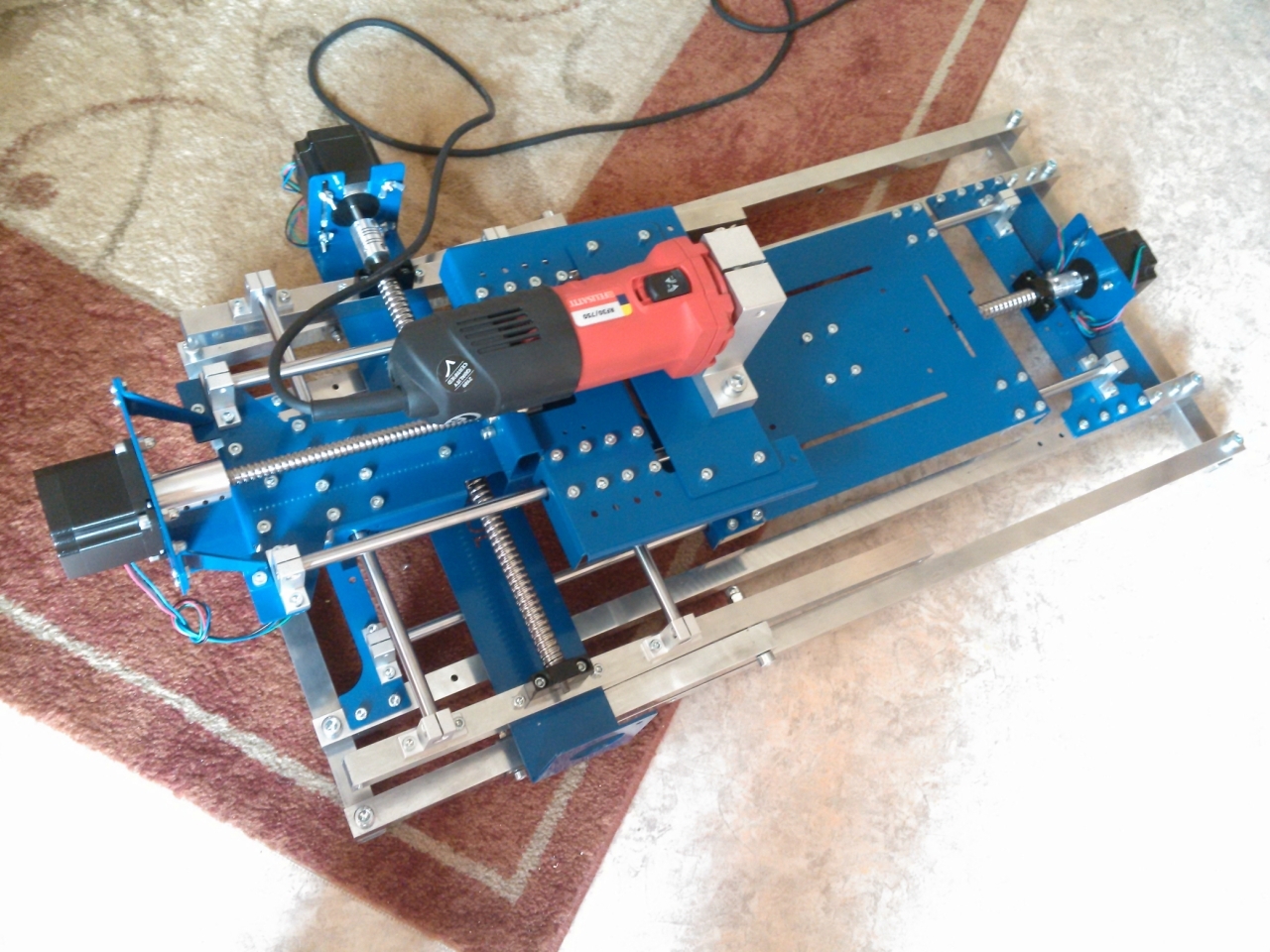

Or we needed to mill something. Then install a screw-nut drive with a NEMA23 ball motor and a milling cutter. Done! We experimented with various screws. Starting from the "collective farm", such as the usual studs and ending with high-quality ball screws. It is possible to install various types of screws on the platform. Depends on the budget of the machine. The options for the milling spindle also range from standard drills to our version of a small and compact spindle for milling plastic (which is still only at the drawing stage). At the moment, in our tests we use a 650W aluminum stand drill.

So much for the plastic milling machine.

It also folds.

As I said above, we want to make the project open to third-party developers. Put all drawings and patents in the public domain, including software. But more about that later.

The next important component of the project is the control unit. All electronic filling is located there. Without going into details what is there (as I already said, there will be interest - I will write everything in separate articles), I will note its main feature. This control unit can “steer” several platforms simultaneously. This will allow you to create a small infrastructure of devices (more precisely platforms) that perform various functions, centrally controlling them (probably loudly said, but still ...). The block is also modular. Its filling varies. You can add various communication interfaces: wi-fi, Bluetooth, ethernet, etc. Whatever your heart desires.

Photo of the control unit housing.

Software is a separate saga. We wrote it (and are writing) from scratch. Absolutely everything, starting from step-by-step rotation algorithms, ending with an application on an android smartphone, is our job. I am not saying that we came up with something innovative and new. Although there are key differences from analogues (for example, Marlin firmware). I just want to focus on the fact that we took the project and the idea as a whole very seriously. And I hope that we can fully realize it. Namely, to mass-produce such platforms.

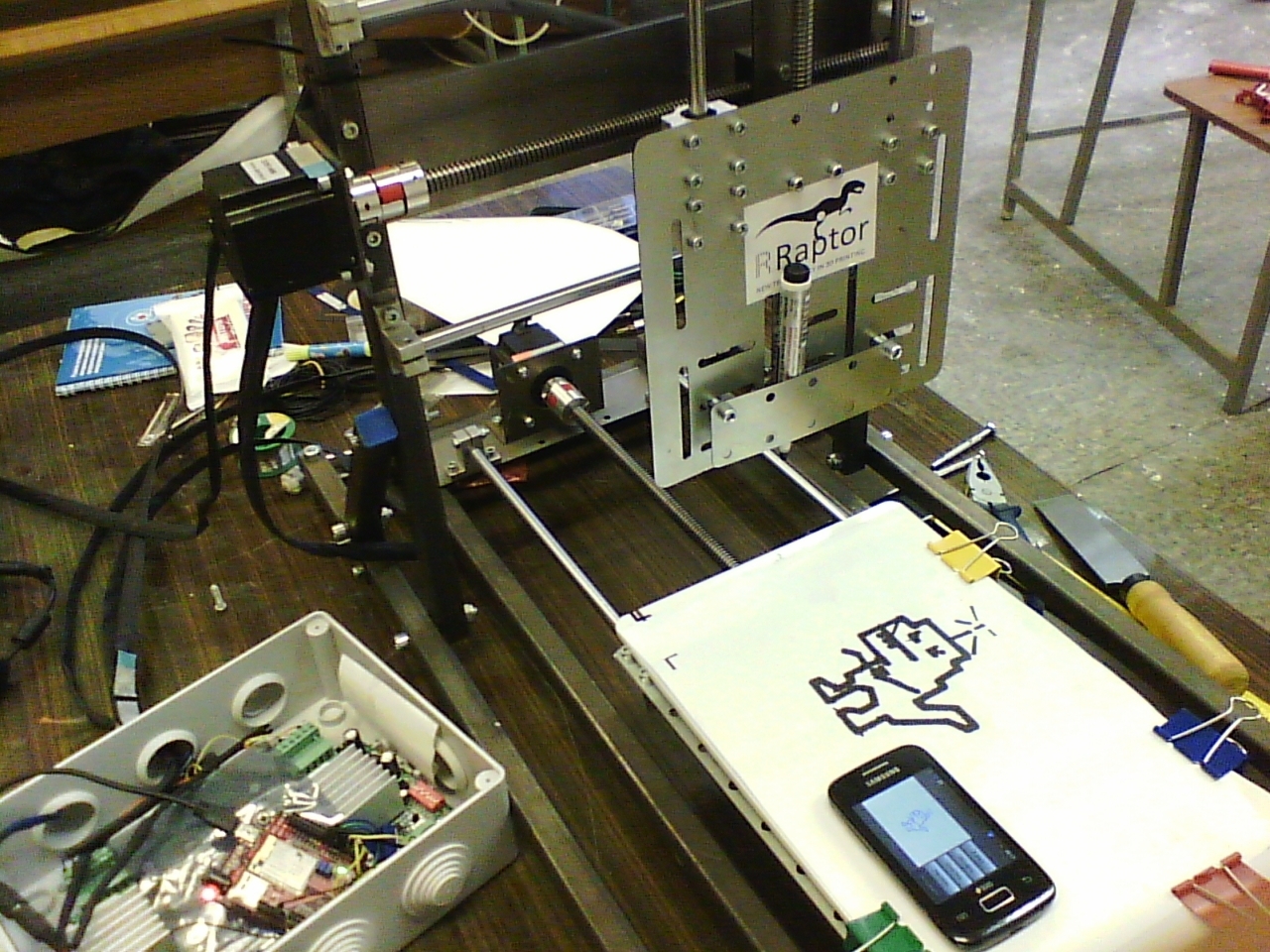

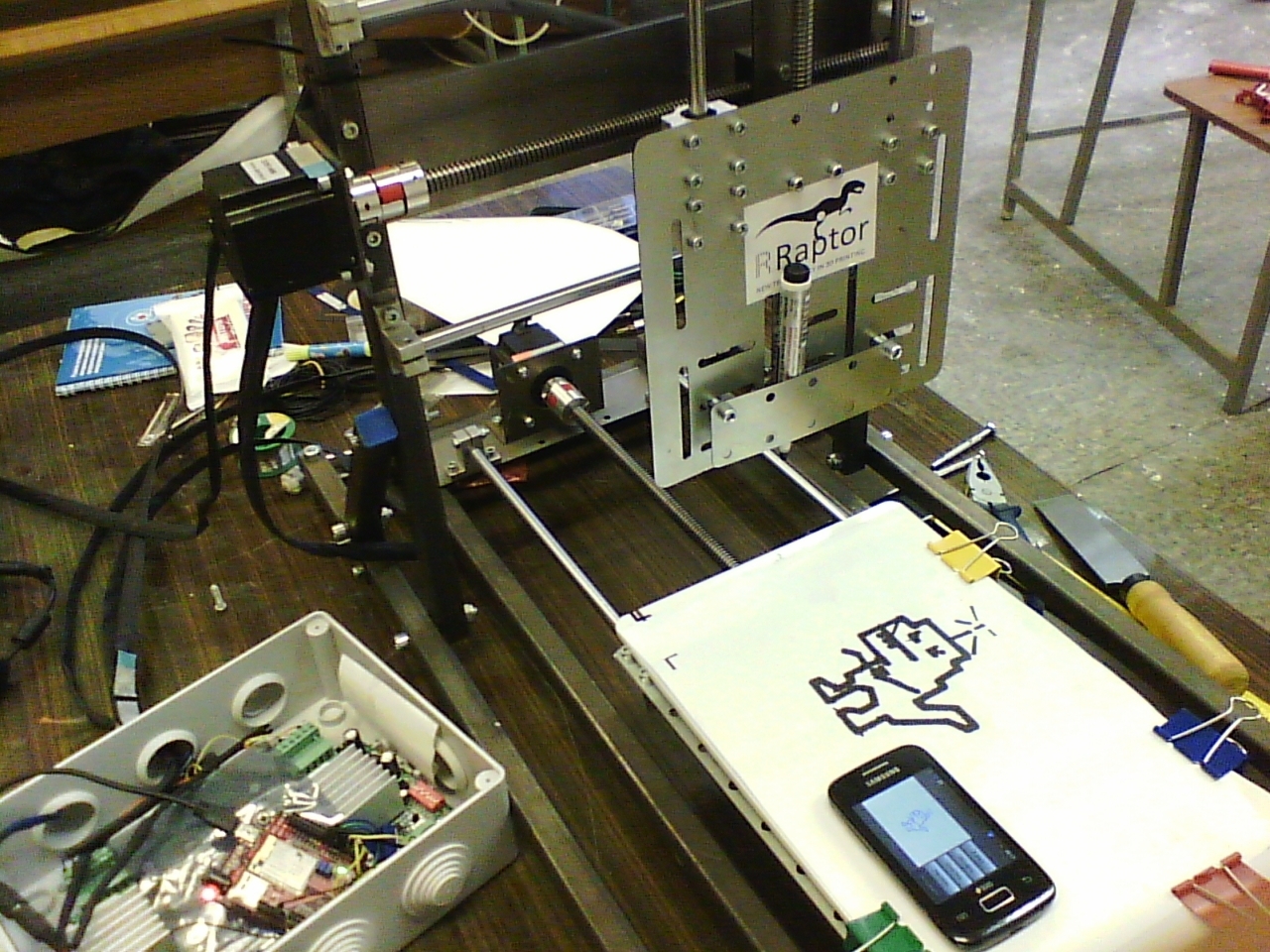

This is our first prototype. They made a plotter based on it for the very first tests.

Although it is still necessary to grow and finalize both the shortcomings in mechanics and software before mass production. Nevertheless, we already have a little experience.

The first series of 5 pieces

I hope (or rather sure) your feedback, opinions and comments will help us. Unfortunately, to describe and show many details of the project in one article is simply unrealistic. But you have to start somewhere.

Thanks for attention.

Recently, an idea came up to create a completely open project of a universal 3-coordinate platform, which can perform the functionality of both a 3D printer and a milling machine for processing plastic and much more. The platform is built on a modular type. This means that it has a completely interchangeable carriage drive and tool. We called this thing "RRaptor Platform." In the future, I will give a number of images and photographs of design models and what has already been implemented.

But what happened in reality. And yes. The screw on the Y coordinate is not fixed.

Let's see what modularity means in the context of the project. For example, we want to get a 3d printer: put the appropriate drive + print unit (you can put 3 units at the same time) - and you're done. We can print your details. For various reasons, platform-gear gears with a stepper motor are used to print on the platform.

The model shows the installed gear-rack drive to the Y coordinate

Or we needed to mill something. Then install a screw-nut drive with a NEMA23 ball motor and a milling cutter. Done! We experimented with various screws. Starting from the "collective farm", such as the usual studs and ending with high-quality ball screws. It is possible to install various types of screws on the platform. Depends on the budget of the machine. The options for the milling spindle also range from standard drills to our version of a small and compact spindle for milling plastic (which is still only at the drawing stage). At the moment, in our tests we use a 650W aluminum stand drill.

So much for the plastic milling machine.

It also folds.

As I said above, we want to make the project open to third-party developers. Put all drawings and patents in the public domain, including software. But more about that later.

The next important component of the project is the control unit. All electronic filling is located there. Without going into details what is there (as I already said, there will be interest - I will write everything in separate articles), I will note its main feature. This control unit can “steer” several platforms simultaneously. This will allow you to create a small infrastructure of devices (more precisely platforms) that perform various functions, centrally controlling them (probably loudly said, but still ...). The block is also modular. Its filling varies. You can add various communication interfaces: wi-fi, Bluetooth, ethernet, etc. Whatever your heart desires.

Photo of the control unit housing.

Software is a separate saga. We wrote it (and are writing) from scratch. Absolutely everything, starting from step-by-step rotation algorithms, ending with an application on an android smartphone, is our job. I am not saying that we came up with something innovative and new. Although there are key differences from analogues (for example, Marlin firmware). I just want to focus on the fact that we took the project and the idea as a whole very seriously. And I hope that we can fully realize it. Namely, to mass-produce such platforms.

This is our first prototype. They made a plotter based on it for the very first tests.

Although it is still necessary to grow and finalize both the shortcomings in mechanics and software before mass production. Nevertheless, we already have a little experience.

The first series of 5 pieces

I hope (or rather sure) your feedback, opinions and comments will help us. Unfortunately, to describe and show many details of the project in one article is simply unrealistic. But you have to start somewhere.

Thanks for attention.