Using COM Port to Recover WD My Passport Hard Drive

Western Digital is one of the few surviving HDD manufacturers on the market. And in today's article we will tell you about one interesting option related to the repair of these discs. Of course, for specialists in the field of DataRecovery this is not a revelation, but for citizens far from the subject, we hope that it will be curious.

We believe that everyone (or almost everyone) knows that WD, and not only them, following the path of minimizing the cost of production, last For several years, it has only become established in the tradition of unsoldering the USB - SATA bridge directly on the disk electronics board. This introduces some complications in the process of organizing access to user information. And with the example of the recently completed resuscitation work WD My Passport, we will tell you about some of them.

So, the WD10JMVW-11S5XS1 - a disk of the Firebird family - fell on the operating table in a coma . According to the client - at first the disk began to work extremely slowly, then it was formatted and worked fine, but as it filled with data - it died completely. Only before that, a backup of important data was not made.

After power is supplied, the disk is detected in the system, but at the slightest attempt to read anything from it, it freezes and falls off.

On any disk, during manufacturing and operation, defects are present or appear. Those that were caught at the plant, at the final stages of assembly and testing, are recorded in the so-called “Factory” defect list. Those that appear during operation fall into user defect lists.

Having seen an unstable sector being read, the disk “understands” that this sector does not have long to live and puts its address in the so-called RELO-list. If errors are repeated, then this sector will be marked as BAD and excluded from the broadcast. But it is not yet excluded - background self-testing processes will check it again and again.

Everything would be fine, but so many microcode versions of modern WDs have a funny mistake. It consists in the fact that if there are more “suspicious” sectors than the space allocated for them in RELO, then it, this very RELO, spoils. The consequences of this are very diverse - from a significant loss of performance, and ending with the inability to correctly initialize the disk (RELO is a module that is not unique, but critical for working logically).

Naturally, in order to analyze the current state of the disk, we need access to its service information. You can get it in many ways. Although modern versions of hardware and software systems for repairing HDDs support WD disks using the USB interface, there is no sense in the USB interface in cases where the firmware involved in catching and tracking bad blocks hangs.

Whenever accessing the disk via USB, there is no answer.

You can connect directly to the processor, bypassing the USB interface, soldering the SATA cable to the electronics board, but in this particular case there was no such possibility. The fact is that the disk was guaranteed and there was a sticker on the board, without damaging which there is no way to remove this board. And the customer insisted that all the stickers be in place.

How to be? The drive is not accessible via the USB interface, and there is no way to connect via SATA (see the ban on tearing off the sticker). But there is a way.

In the photo above, you see the technological connector of the WD drive, to the left of USB. Typically, these connectors are used to install jumpers that change the operating modes of the disk. But few know that this connector also implements the functions ... of a COM port diagnostic terminal. Through which you can "communicate" with the disk in technological mode, giving commands and receiving an answer to them.

Broken WD drive with COM terminal connected to it

It should be noted that this is not a COM port, in the usual sense. A TTL to RS232 level converter is required. It is most convenient to use converters based on Marvel and Silicon Image controllers that have a USB interface and form a virtual COM port in the system.

Of course, working on a COM port imposes its limitations. For example, this way you can’t access user data, but this is logical - try copying at least a gigabyte of data at 115200 bps. All operations with the disk also occur rather slowly, but as they say - one who knows life is in no hurry.

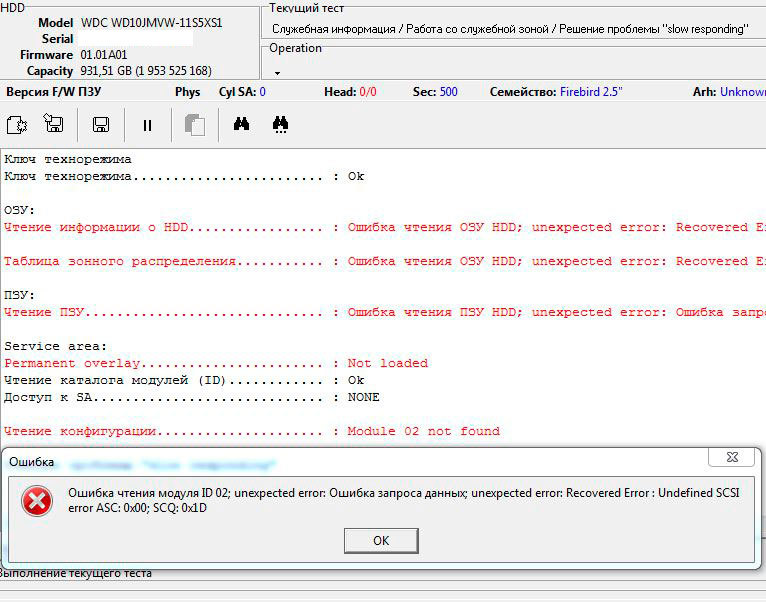

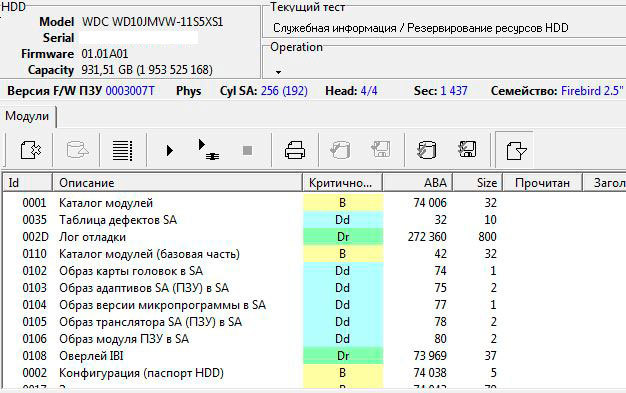

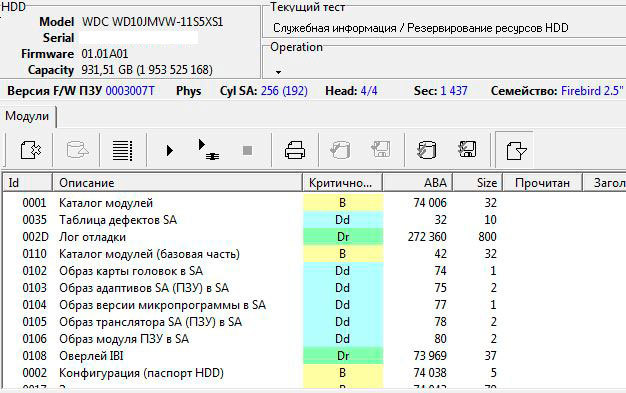

Having connected via the COM port to the diagnostic terminal and requesting Get Dir, we got a list of service information modules

That's what we tried so hard for. Access to service information received!

The rest is a matter of technology. A quick analysis only confirmed the assumption of errors in the id32 module. After fixing these errors, the disk was initialized correctly and we were able to copy information valuable to the client from it using regular means, and at the same time reserve a copy of a (now) working SA to facilitate future work.

It remains to add that the problem described above is typical not only for WD, but also for other drives. As an example, a little material from the Q & A section of the Hardmaster site about the restoration of WD My Passport .

Thanks for attention!

We believe that everyone (or almost everyone) knows that WD, and not only them, following the path of minimizing the cost of production, last For several years, it has only become established in the tradition of unsoldering the USB - SATA bridge directly on the disk electronics board. This introduces some complications in the process of organizing access to user information. And with the example of the recently completed resuscitation work WD My Passport, we will tell you about some of them.

So, the WD10JMVW-11S5XS1 - a disk of the Firebird family - fell on the operating table in a coma . According to the client - at first the disk began to work extremely slowly, then it was formatted and worked fine, but as it filled with data - it died completely. Only before that, a backup of important data was not made.

After power is supplied, the disk is detected in the system, but at the slightest attempt to read anything from it, it freezes and falls off.

A little bit about the WD microcode device

On any disk, during manufacturing and operation, defects are present or appear. Those that were caught at the plant, at the final stages of assembly and testing, are recorded in the so-called “Factory” defect list. Those that appear during operation fall into user defect lists.

Having seen an unstable sector being read, the disk “understands” that this sector does not have long to live and puts its address in the so-called RELO-list. If errors are repeated, then this sector will be marked as BAD and excluded from the broadcast. But it is not yet excluded - background self-testing processes will check it again and again.

Everything would be fine, but so many microcode versions of modern WDs have a funny mistake. It consists in the fact that if there are more “suspicious” sectors than the space allocated for them in RELO, then it, this very RELO, spoils. The consequences of this are very diverse - from a significant loss of performance, and ending with the inability to correctly initialize the disk (RELO is a module that is not unique, but critical for working logically).

And what to do?

Naturally, in order to analyze the current state of the disk, we need access to its service information. You can get it in many ways. Although modern versions of hardware and software systems for repairing HDDs support WD disks using the USB interface, there is no sense in the USB interface in cases where the firmware involved in catching and tracking bad blocks hangs.

Whenever accessing the disk via USB, there is no answer.

You can connect directly to the processor, bypassing the USB interface, soldering the SATA cable to the electronics board, but in this particular case there was no such possibility. The fact is that the disk was guaranteed and there was a sticker on the board, without damaging which there is no way to remove this board. And the customer insisted that all the stickers be in place.

If the mountain does not go to Mohammed ...

How to be? The drive is not accessible via the USB interface, and there is no way to connect via SATA (see the ban on tearing off the sticker). But there is a way.

In the photo above, you see the technological connector of the WD drive, to the left of USB. Typically, these connectors are used to install jumpers that change the operating modes of the disk. But few know that this connector also implements the functions ... of a COM port diagnostic terminal. Through which you can "communicate" with the disk in technological mode, giving commands and receiving an answer to them.

Broken WD drive with COM terminal connected to it

It should be noted that this is not a COM port, in the usual sense. A TTL to RS232 level converter is required. It is most convenient to use converters based on Marvel and Silicon Image controllers that have a USB interface and form a virtual COM port in the system.

Of course, working on a COM port imposes its limitations. For example, this way you can’t access user data, but this is logical - try copying at least a gigabyte of data at 115200 bps. All operations with the disk also occur rather slowly, but as they say - one who knows life is in no hurry.

Having connected via the COM port to the diagnostic terminal and requesting Get Dir, we got a list of service information modules

That's what we tried so hard for. Access to service information received!

The rest is a matter of technology. A quick analysis only confirmed the assumption of errors in the id32 module. After fixing these errors, the disk was initialized correctly and we were able to copy information valuable to the client from it using regular means, and at the same time reserve a copy of a (now) working SA to facilitate future work.

It remains to add that the problem described above is typical not only for WD, but also for other drives. As an example, a little material from the Q & A section of the Hardmaster site about the restoration of WD My Passport .

Thanks for attention!