Underwater cable management. How it's done

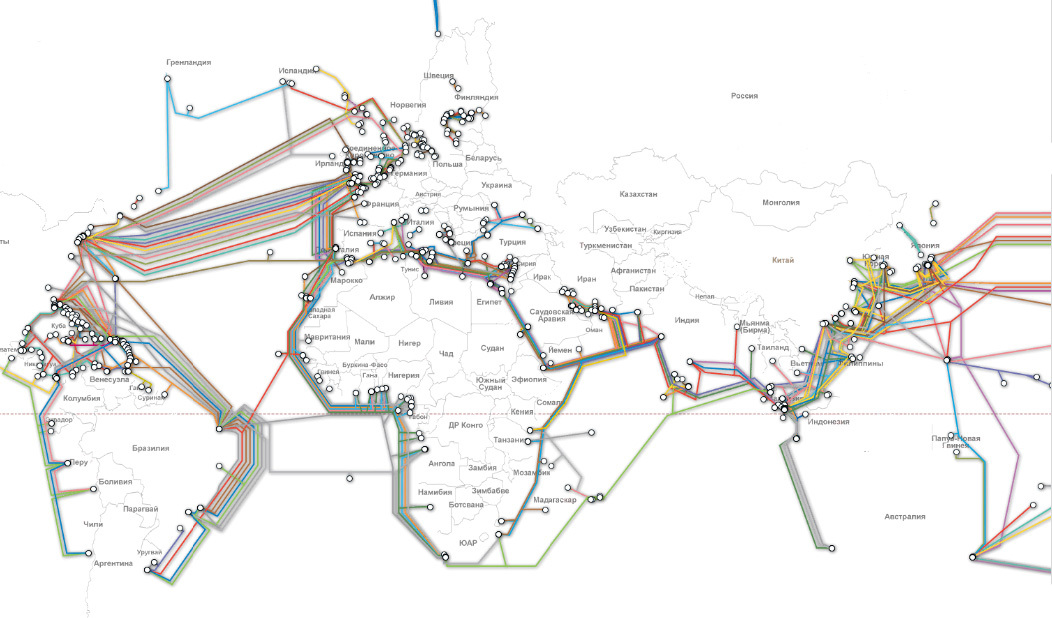

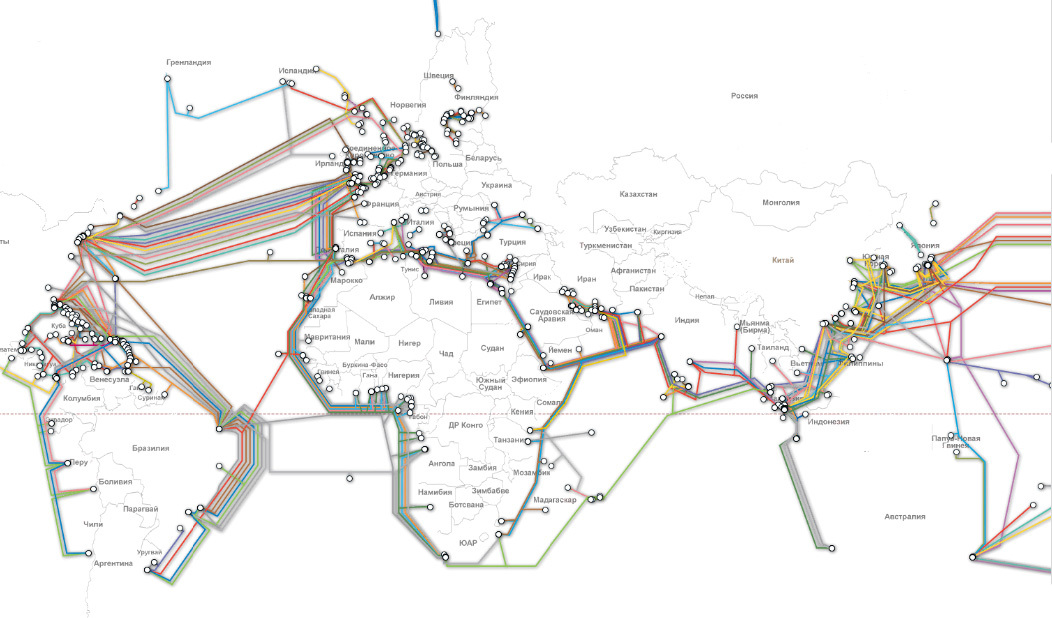

In early July, I prepared an interesting publication for the community about deep-sea communication cables , in which the main emphasis was placed on the design features of the deep-sea cable compared to the usual optics. Unfortunately, very little attention was paid to the process itself and how to lay the cable along the bottom of rivers, seas and oceans. Now I want to correct this situation and acquaint you with a brief information about how communication lines are laid, including in such difficult conditions as the aquatic environment.

In the comments to the previous material, a reasonable question arose, what kind of black device is schematically depicted in a gif showing the cable laying process?

Surprisingly, this device is called an underwater cable layer . Based on the design, cable layers are divided into several types:

The knife cable-laying machine is an analogue of the plow and has a very simple design: a working wedging knife and a front knife, drums on which a cable for laying is wound, cassettes, rollers that reduce cable friction inside the cassette. The cable cutter is towed during operation. On the example of the schematic image below, tractors or other traction machines on a wheeled or tracked track can be used.

The principle of operation of the knife cable layer is as follows: When moving, the working knife wedges the soil, forms a trench between the soil surface and its wedging part, the depth of which reaches 1.5 meters. An empty cassette is attached to the back of the knife on the hinges, through which a cable (or several cables at once) is passed and laid on its bottom.

There are also self-sufficient models on their own that do not require towing.

However, if you think it’s enough to stick a knife and start pulling, you are deeply mistaken. For different types of soils, there are rules and recommendations for conducting preparatory measures before using the cable layer. First of all, this is the so-called proportion or differently loosening the soil. The intensity and scale of the preparatory work depends on the type of soil. It is clear that digging soft soil is easier than rock, and the chance to run into obstacles in the process is an order of magnitude lower.

A separate subtype is the underwater cable-laying knife. It is necessary to dig cable into the ground in coastal zones in order to protect it from anchors, trawls and other human and animal activities. This method is used in coastal areas at shallow depths. The device itself moves along the bottom on special runners. A conventional underwater cable layer breaks through a not very wide, 0.1 - 0.2 m, and shallow, ~ 0.7 m, trench into which the cable is laid. The equipment itself is towed by the vessel at a speed of about 3 km / h and is connected with it by a separate cable to monitor the status of the device itself and the work it is doing.

Rotary cable layer- This is a self-propelled rotary excavator with a trailed trolley equipped with devices for loading, transportation and cable laying. Such a cable layer is used for laying cable in both thawed and frozen soils. The main working device of the rotary cable layer is a disk with cutting teeth. The productivity of the rotary cable layer is up to 1 km of trench per day.

The fundamental difference between the design and the cable-laying knife is the trench digging mechanism:

The well-established name for such a KVG device is the Vibrating Hydraulic Cable Stacker, although in reality it is a knife-type device.

ПГКУ or Underwater Hydraulic Cable Layers are used for laying cables through rivers and other water barriers using ships. In fact, a hydraulic drill, which is the main working part of the mechanism, is connected to a hose / pipe going to the pump located on the vessel. A stream of water under pressure is supplied to the drill, which loosens the rock and punches a trench in the ground for subsequent laying of a cable into it.

It is worth remembering that laying the cable in the ground under water is necessary only at shallow depths. When laying cables in the open ocean, it simply falls to the bottom (depth up to 8 km!), Where nothing but sea water and pressure threatens it (except for force majeure in the form of seismic activity).

If everything is clear with digging into the ground, then how to pull the cable through the water can raise a number of questions.

By small water barriers are meant streams, small lakes, narrow swamps and rivers, including mountain ones.

With a depth of less than 0.8m to special. they don’t resort to equipment and lay as well as along the entire length of the route. With river depths from 0.8 to 6.0m, an underwater cable layer is used.

Before laying the cable, a huge amount of preparatory work is performed. I will omit the point about the need to prepare the infrastructure and obtain permits, and go directly to the preparation before starting the work of the cable layer. From the ongoing activities, the following can be distinguished:

The cable layer is run through a narrow (less than 300 m) river with the help of a tractor column draft.

A significant role in the course of work is played by the terrain in which they are carried out. For example, the freezing of the water surface and the formation of a thick layer of ice that can withstand people and wheeled-tracked equipment, surprisingly enough, greatly simplifies the process if cable laying vessels (distance of 400 meters or more) were necessary for this segment. The workers make a lane (a slot in the ice), through which the cable drops to the prepared bottom.

If you can stretch the cable through narrow rivers using mechanized equipment located on the other side, then for carrying out cable laying activities on wide rivers, as well as in coastal areas and the open sea, you have to use specially equipped barges or ships.

As mentioned above, hydraulic cable layers are popular for work underwater. This is quite reasonable: the river or sea bottom is more malleable than frozen ground or rock, and the force of a stream of water supplied under pressure will be enough to “cut through” a gap in the ground for further cable laying.

It is worth noting that the cable is laid in trenches at depths of up to 1500-2000 m due to fishing activities and other factors. In such situations, you have to use the knife laying principle or simply lower the gigantic plow to the bottom of the sea, which will plow it and allow you to protect the cable from gear and other troubles. At great depths, for obvious reasons, powerful, reinforced cables are used that simply lay on the ground.

Photo of a plow with an estimated working depth of 2000 meters

If in the case of small distances a whole piece of cable is used, then when laying in the sea, the distances increase several times, and the linear length of the cable bay is limited. Plus, when transmitting a signal over long distances, its distortion and attenuation occur. To compensate for these losses, given the cable design described in the previous article, signal amplifiers and repeaters are used in splices or other necessary areas. There are no problems with power, the design of the fiber optic cable implies the possibility of transmitting current from which the equipment placed at a distance of up to 150 km from each other is powered.

This is what the signal amplifier looks like before installation, in partial analysis:

And so it looks ready to be laid on the ocean floor:

As mentioned above, relays, depending on cable properties and installation circumstances, can be mounted with a frequency of up to 150 km. Modern industry allows the manufacture and delivery of cables with an average length of 5, and sometimes 25 km, which is much less than the distance of the arrangement of repeaters. In these cases, the end of one bay is spliced with a new one, and the connection point is protected by the so-called docking box (see an example of such a design below):

Box in disassembly:

In turn, repairing, for example, a breakage of an already laid cable is not an easy task, although the procedure itself is schematically quite banal. With the help of a vessel, one ragged end is lifted to the surface and fixed onto the buoy, then they are also horned and the second end of the cable is lifted. The part into which the water has penetrated under pressure is cut off, and for connecting the ends use a repair "cut" of the cable, specially stored for this purpose. In general, everything looks simple and logical: cut, stripped, twisted, works. But the scale of such a “twist” is striking, and it has a weak relation to the styling itself. With any luck, I can tell you about this procedure separately.

I hope you enjoyed this material.

But first about the main thing. About equipment

In the comments to the previous material, a reasonable question arose, what kind of black device is schematically depicted in a gif showing the cable laying process?

Surprisingly, this device is called an underwater cable layer . Based on the design, cable layers are divided into several types:

- Knife

- Rotary

- Hydraulic

The knife cable-laying machine is an analogue of the plow and has a very simple design: a working wedging knife and a front knife, drums on which a cable for laying is wound, cassettes, rollers that reduce cable friction inside the cassette. The cable cutter is towed during operation. On the example of the schematic image below, tractors or other traction machines on a wheeled or tracked track can be used.

The principle of operation of the knife cable layer is as follows: When moving, the working knife wedges the soil, forms a trench between the soil surface and its wedging part, the depth of which reaches 1.5 meters. An empty cassette is attached to the back of the knife on the hinges, through which a cable (or several cables at once) is passed and laid on its bottom.

There are also self-sufficient models on their own that do not require towing.

However, if you think it’s enough to stick a knife and start pulling, you are deeply mistaken. For different types of soils, there are rules and recommendations for conducting preparatory measures before using the cable layer. First of all, this is the so-called proportion or differently loosening the soil. The intensity and scale of the preparatory work depends on the type of soil. It is clear that digging soft soil is easier than rock, and the chance to run into obstacles in the process is an order of magnitude lower.

A separate subtype is the underwater cable-laying knife. It is necessary to dig cable into the ground in coastal zones in order to protect it from anchors, trawls and other human and animal activities. This method is used in coastal areas at shallow depths. The device itself moves along the bottom on special runners. A conventional underwater cable layer breaks through a not very wide, 0.1 - 0.2 m, and shallow, ~ 0.7 m, trench into which the cable is laid. The equipment itself is towed by the vessel at a speed of about 3 km / h and is connected with it by a separate cable to monitor the status of the device itself and the work it is doing.

Rotary cable layer- This is a self-propelled rotary excavator with a trailed trolley equipped with devices for loading, transportation and cable laying. Such a cable layer is used for laying cable in both thawed and frozen soils. The main working device of the rotary cable layer is a disk with cutting teeth. The productivity of the rotary cable layer is up to 1 km of trench per day.

The fundamental difference between the design and the cable-laying knife is the trench digging mechanism:

The well-established name for such a KVG device is the Vibrating Hydraulic Cable Stacker, although in reality it is a knife-type device.

ПГКУ or Underwater Hydraulic Cable Layers are used for laying cables through rivers and other water barriers using ships. In fact, a hydraulic drill, which is the main working part of the mechanism, is connected to a hose / pipe going to the pump located on the vessel. A stream of water under pressure is supplied to the drill, which loosens the rock and punches a trench in the ground for subsequent laying of a cable into it.

It is worth remembering that laying the cable in the ground under water is necessary only at shallow depths. When laying cables in the open ocean, it simply falls to the bottom (depth up to 8 km!), Where nothing but sea water and pressure threatens it (except for force majeure in the form of seismic activity).

If everything is clear with digging into the ground, then how to pull the cable through the water can raise a number of questions.

Shallow water barriers

By small water barriers are meant streams, small lakes, narrow swamps and rivers, including mountain ones.

With a depth of less than 0.8m to special. they don’t resort to equipment and lay as well as along the entire length of the route. With river depths from 0.8 to 6.0m, an underwater cable layer is used.

Before laying the cable, a huge amount of preparatory work is performed. I will omit the point about the need to prepare the infrastructure and obtain permits, and go directly to the preparation before starting the work of the cable layer. From the ongoing activities, the following can be distinguished:

- Cutting coastal slopes with a bulldozer or excavator to ensure smooth descent of the cable layer from the coast and its exit from the water;

- Washing with water monitors the obstacles found during a diving survey and removing them from the track;

- Two to three times the proportion of soil along the intended route;

- Checking the tightness of the cable sheath with excess air pressure, direct current test, continuity of conductors;

- Loading the cable onto the cable layer and access to the main stage of work.

The cable layer is run through a narrow (less than 300 m) river with the help of a tractor column draft.

A significant role in the course of work is played by the terrain in which they are carried out. For example, the freezing of the water surface and the formation of a thick layer of ice that can withstand people and wheeled-tracked equipment, surprisingly enough, greatly simplifies the process if cable laying vessels (distance of 400 meters or more) were necessary for this segment. The workers make a lane (a slot in the ice), through which the cable drops to the prepared bottom.

Cable laying to the bottom when using the vessel

If you can stretch the cable through narrow rivers using mechanized equipment located on the other side, then for carrying out cable laying activities on wide rivers, as well as in coastal areas and the open sea, you have to use specially equipped barges or ships.

As mentioned above, hydraulic cable layers are popular for work underwater. This is quite reasonable: the river or sea bottom is more malleable than frozen ground or rock, and the force of a stream of water supplied under pressure will be enough to “cut through” a gap in the ground for further cable laying.

It is worth noting that the cable is laid in trenches at depths of up to 1500-2000 m due to fishing activities and other factors. In such situations, you have to use the knife laying principle or simply lower the gigantic plow to the bottom of the sea, which will plow it and allow you to protect the cable from gear and other troubles. At great depths, for obvious reasons, powerful, reinforced cables are used that simply lay on the ground.

Photo of a plow with an estimated working depth of 2000 meters

If in the case of small distances a whole piece of cable is used, then when laying in the sea, the distances increase several times, and the linear length of the cable bay is limited. Plus, when transmitting a signal over long distances, its distortion and attenuation occur. To compensate for these losses, given the cable design described in the previous article, signal amplifiers and repeaters are used in splices or other necessary areas. There are no problems with power, the design of the fiber optic cable implies the possibility of transmitting current from which the equipment placed at a distance of up to 150 km from each other is powered.

This is what the signal amplifier looks like before installation, in partial analysis:

And so it looks ready to be laid on the ocean floor:

But what if the repeater is set early and the cable bay is over?

As mentioned above, relays, depending on cable properties and installation circumstances, can be mounted with a frequency of up to 150 km. Modern industry allows the manufacture and delivery of cables with an average length of 5, and sometimes 25 km, which is much less than the distance of the arrangement of repeaters. In these cases, the end of one bay is spliced with a new one, and the connection point is protected by the so-called docking box (see an example of such a design below):

Box in disassembly:

In turn, repairing, for example, a breakage of an already laid cable is not an easy task, although the procedure itself is schematically quite banal. With the help of a vessel, one ragged end is lifted to the surface and fixed onto the buoy, then they are also horned and the second end of the cable is lifted. The part into which the water has penetrated under pressure is cut off, and for connecting the ends use a repair "cut" of the cable, specially stored for this purpose. In general, everything looks simple and logical: cut, stripped, twisted, works. But the scale of such a “twist” is striking, and it has a weak relation to the styling itself. With any luck, I can tell you about this procedure separately.

I hope you enjoyed this material.