How we took second place at MATEC ROV 2014 in the USA

Hi, my name is Mikhail, I am a student of the Faculty of Informatics and Control Systems of MSTU. Bauman. Not so long ago, I was able to participate in the international competition of underwater vehicles MATEC ROVCompetition as part of the university team. I would like to talk about this, especially in view of the fact that few people know about such competitions. On Habré there was already a publication about these competitions from one of the participants, but for various reasons it was deleted. Here I will try to tell in more detail about my involvement in the project, about the preparation of the team for the competitions during the year and about the competitions themselves, held in June in the city of Alpena, Michigan, USA.

Under the cut a lot of photos.

Our lab on a typical day

My classmate is studying at the department of underwater robots of MSTU. N.E. Bauman. A little after the new year I receive a message from him with a proposal to participate in the project of an underwater robot for competitions as a microcontroller programmer, due to the fact that no one especially programmed in their team. Since I didn’t have any plans for independent work for the upcoming semester, I agreed with pleasure, in the end, I finally got the opportunity to do something real that could be touched and that goes beyond the scope of home crafts. It turned out that the Hydronavtika center has been operating in our institute for several years, whose activity is mainly focused on the preparation and participation in competitions from the organization Marine Advanced Technology Education Center (MATE) on the subject of underwater remote control vehicles (remotely operated underwater vehicle, which in English literature is traditionally abbreviated as ROV). It is worth noting that the center’s laboratory is equipped in principle with everything that is needed for productive work: an oscilloscope, soldering stations, various machines and tools, as well as its own small pool with a water filtration system. Without him, it would be very difficult, because every time I had to run into the pool of the university sports complex, if necessary. what you need for productive work: an oscilloscope, soldering stations, various machines and tools, as well as your own small pool with a water filtration system. Without him, it would be very difficult, because every time I had to run into the pool of the university sports complex, if necessary. what you need for productive work: an oscilloscope, soldering stations, various machines and tools, as well as your own small pool with a water filtration system. Without him, it would be very difficult, because every time I had to run into the pool of the university sports complex, if necessary.

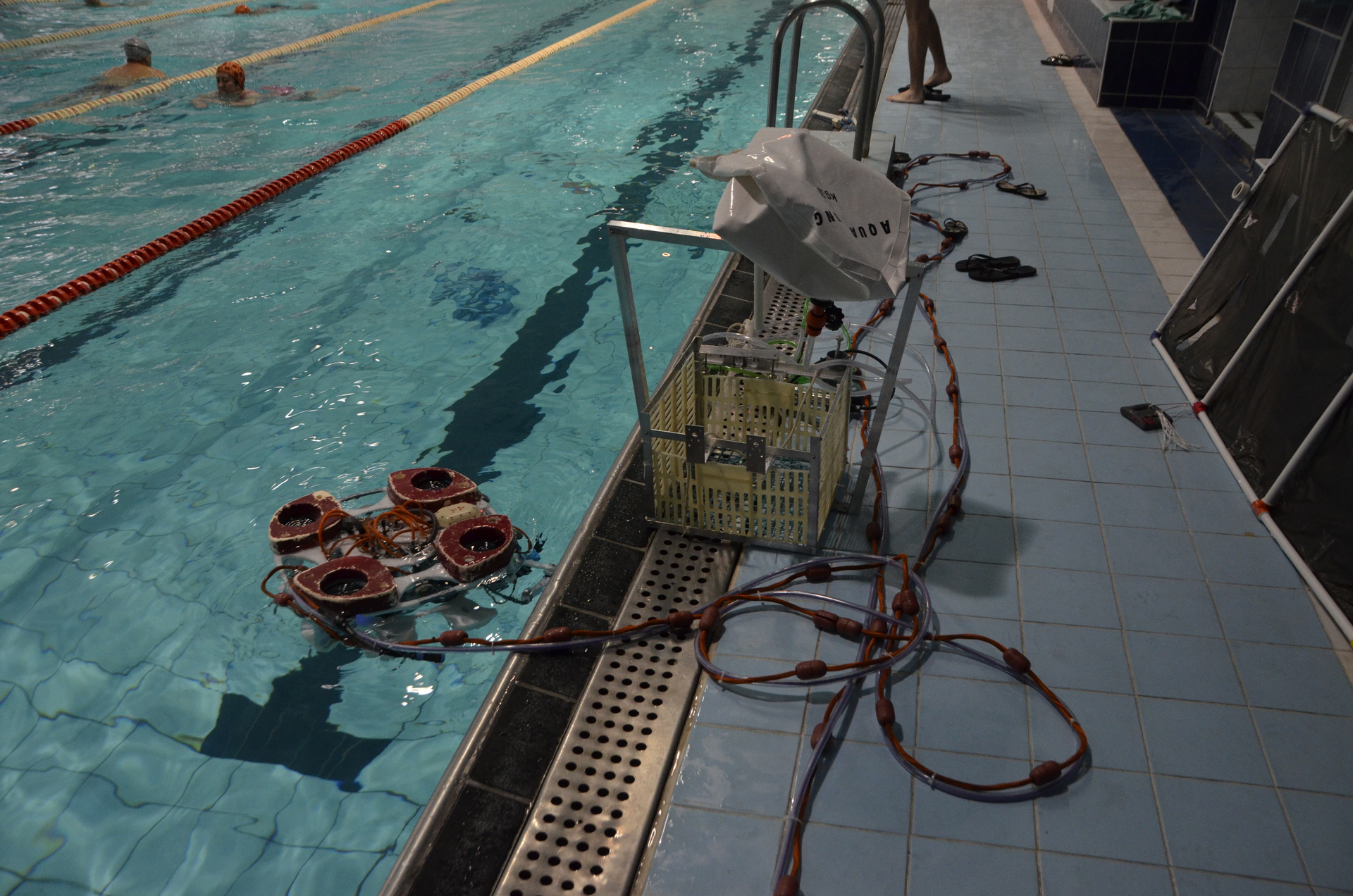

Testing the robot in our home pool

After a short chat with my friend, we agreed to meet with other guys in their lab. The guys were very nice and positive. After a short discussion of the current state of the project and the competitions themselves, a decision was made about my participation.

More information about the competitions can be found on the official website . In short, the competition is to go through several stages. Firstly, you need to get the approval of the organizers of the competition about your participation, for this you need to prepare a number of documents, for example, a technical report with a detailed description of the device. You also need to provide a video with a demonstration of the device’s work a month before the performance to show that it can even swim and perform at least some tasks underwater. After passing through the preparatory stages and obtaining the approval of the organizers, you can go to the competition. As with all similar events, the set of tasks changes annually.

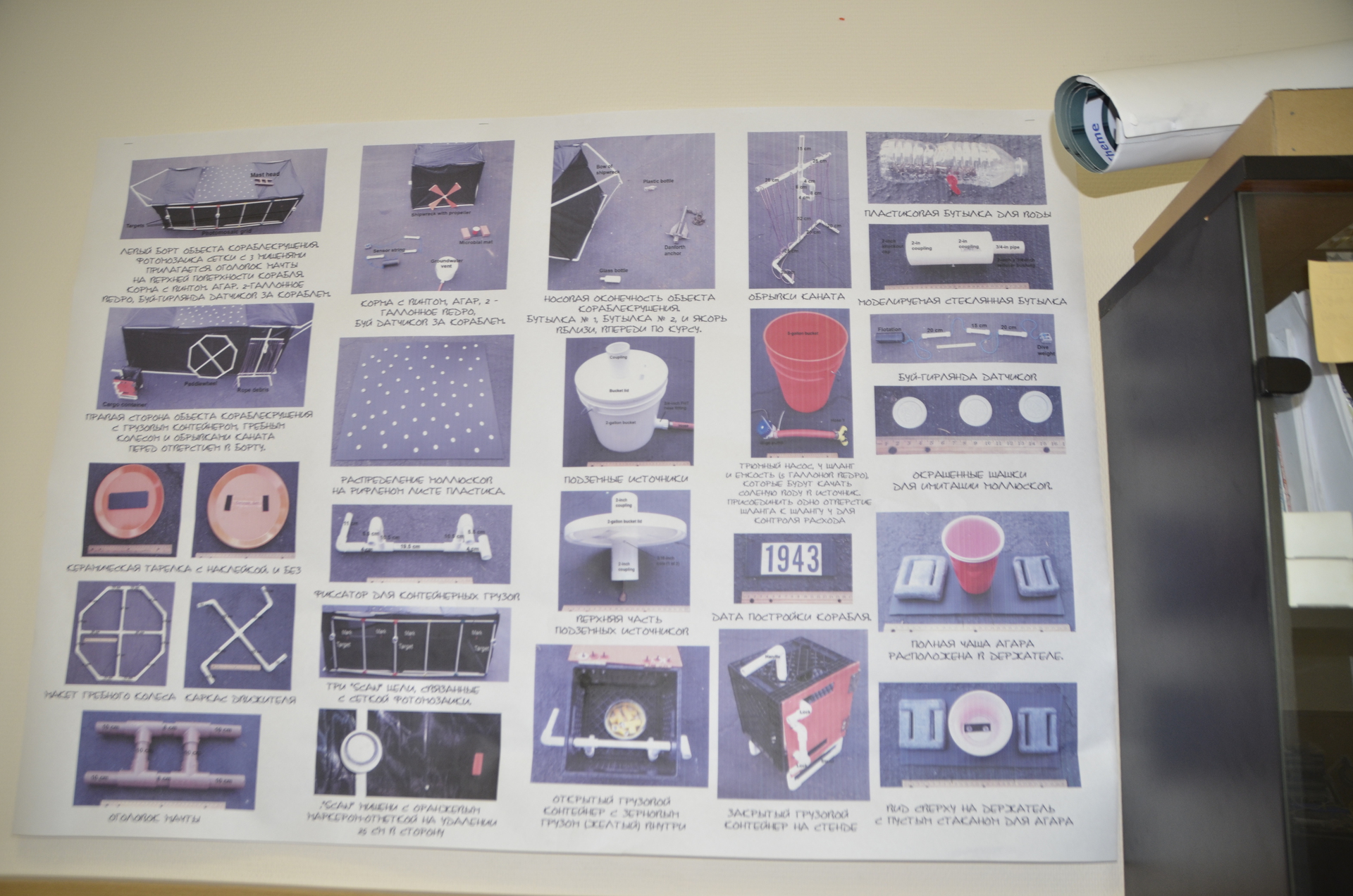

The list of all tasks on the laboratory wall

Every year, competitions have a certain theme related to real problems and tasks in the waters, which require underwater vehicles to solve. This year, the task was to study the bottom of one of the Great American Lakes, namely Lake Huron. At the bottom of the lake, many sunken ships remained intact. The mission of the apparatus consisted of three stages: the study of a shipwreck, scientific research at the bottom, cleaning the bottom of debris. Of course, the competitions themselves are only a simulation of the real situation, therefore the devices did not swim in the lake, but in a deep pool, at the bottom of which a shipwreck model and other bottom equipment were put up. In the first stage, it was necessary to investigate the shipwreck zone in order to determine the type of ship, year of its construction, port of registry, which will allow it to be uniquely identified.

Slightly stagnant and therefore moldy glasses with jelly for testing.

In the third stage, it was necessary to raise garbage (glass and plastic bottles) from the bottom of the lake, as well as the heavy steel anchor of the sunken ship.

It should be noted that successfully completing all tasks under water is not enough to win. Underwater missions “cost” only 320 points out of a total of 600. Competitions are designed in such a way that teams are required to present themselves in the place of private companies participating in the tender for underwater operations. That is, each team must successfully present itself to the judges and justify why their apparatus and their team will be able to most successfully carry out the work. This part of the competition is called Engineering and Communication and also consists of 3 items - a technical report, an engineering presentation and a poster.

A technical report is a 25-page document containing a detailed description of the device and the process of its development, its technical features (“features”), which will ensure that it successfully performs an underwater mission. This document should be prepared about a month before the competition and sent to the judges. For the technical report you can get up to 100 points.

On the poster, the team should concisely, but colorfully fit the information about the team and the device. The posters are also evaluated by the judges during the competition, for them the team can get up to 50 points.

An engineering presentation is an oral presentation by a team in front of a panel of expert judges with a story about the advantages of the apparatus over competitors. A presentation is worth 100 points.

The remaining 30 points are given to those teams that, on the first try, passed a test of their device for safety and compliance with the regulations.

Thus, only careful preparation of all points can bring the team victory.

At the time I was accepted into the project, but let me remind you, it was somewhere in the beginning of February or even later, things were not very good: the previous team graduated, and from it there were only 2 people who somehow understood how everything should be. The new team, unfortunately, had practically no work experience, for many it was the first real project. The old team left behind a working robot, and it worked perfectly. But, unfortunately, participating in the competition with one robot twice in a row is not welcome, so the task of the new team was to develop and assemble a new robot. Also, the first semester of this school year was spent almost empty, and there was only six months left before the competition, which, given the general academic load, is a rather short time.

My tasks in the project included writing on-board electronics software, the basis of which was the Arduino platform. This choice was justified by the fact that most of the participants only learned programming, and such a platform was the best choice. I, as a fan of pure MK programming, although at first I resisted, but in the end I agreed with this choice, since all the boards were already designed for arduins and there was no time to change anything.

Actually, this is how it all started, unfortunately, I went into the course of affairs for a long time and only after almost a month and a half did I understand how everything should look in the end. Again, the training load affected, which did not allow working at full strength.

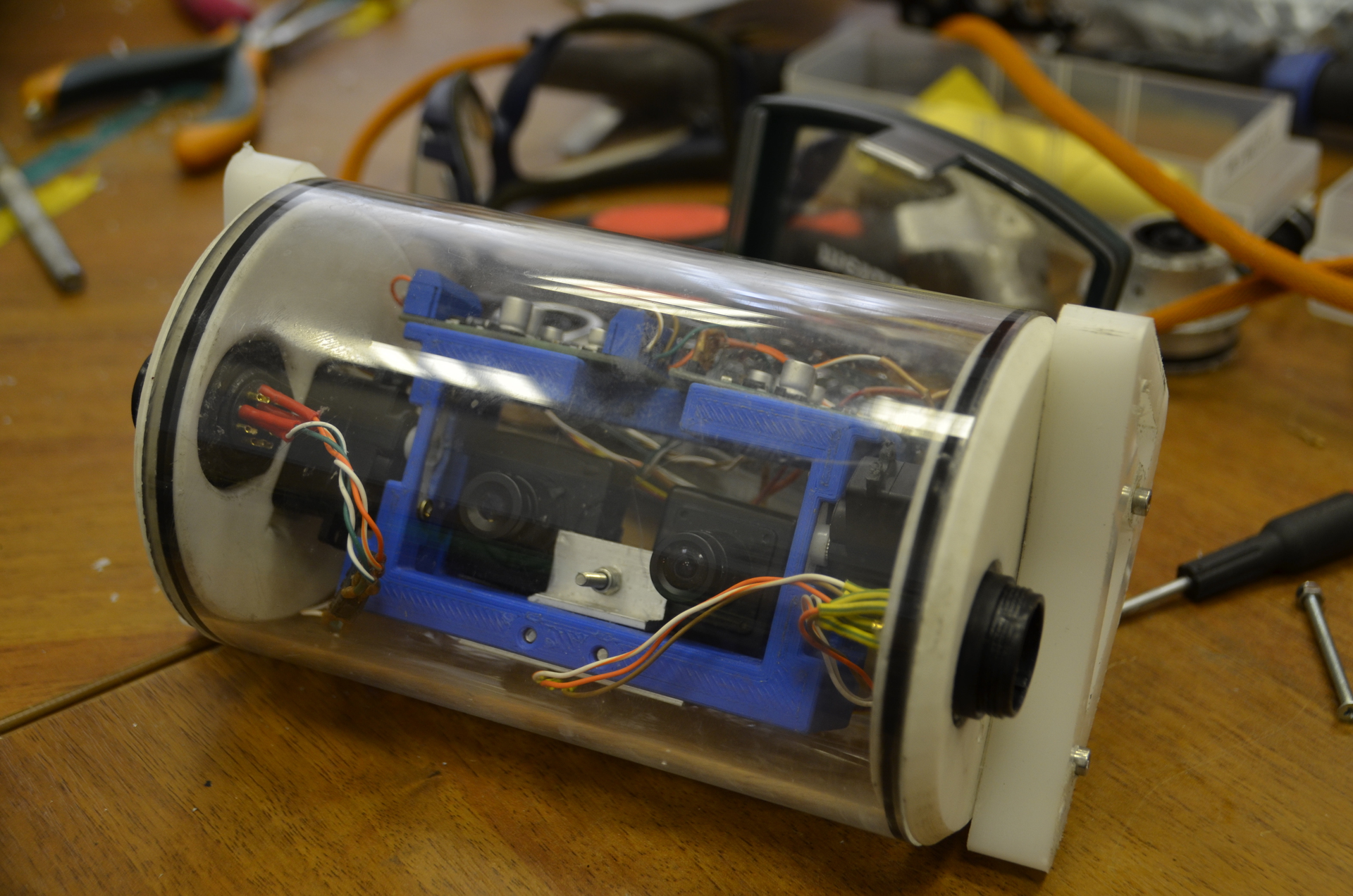

Now a little about the technical details. The electronics of our robot was a tower of several round printed double-sided boards, placed a cylindrical plexiglass case, closed on both sides with sealed covers.

Two parts of an electronics tower

Fastening the covers of the electronics housing takes place without screws, thus assembling / disassembling can be done quite quickly. All boards have the same connectors with the same pinout, so the possibility of incorrect assembly is eliminated. This concept was taken from a previous robot and, in my opinion, is very convenient in this situation. The tower consists of a main controller board - Arduino Mega, a rotor motor driver board, a secondary power supply board, a device control board (manipulators, a light, a pressure sensor, a camera drive), two interface boards with pressurized connectors, one on each side. The robot itself has 8 rotor motors located vector: 4 vertical, 4 horizontal.

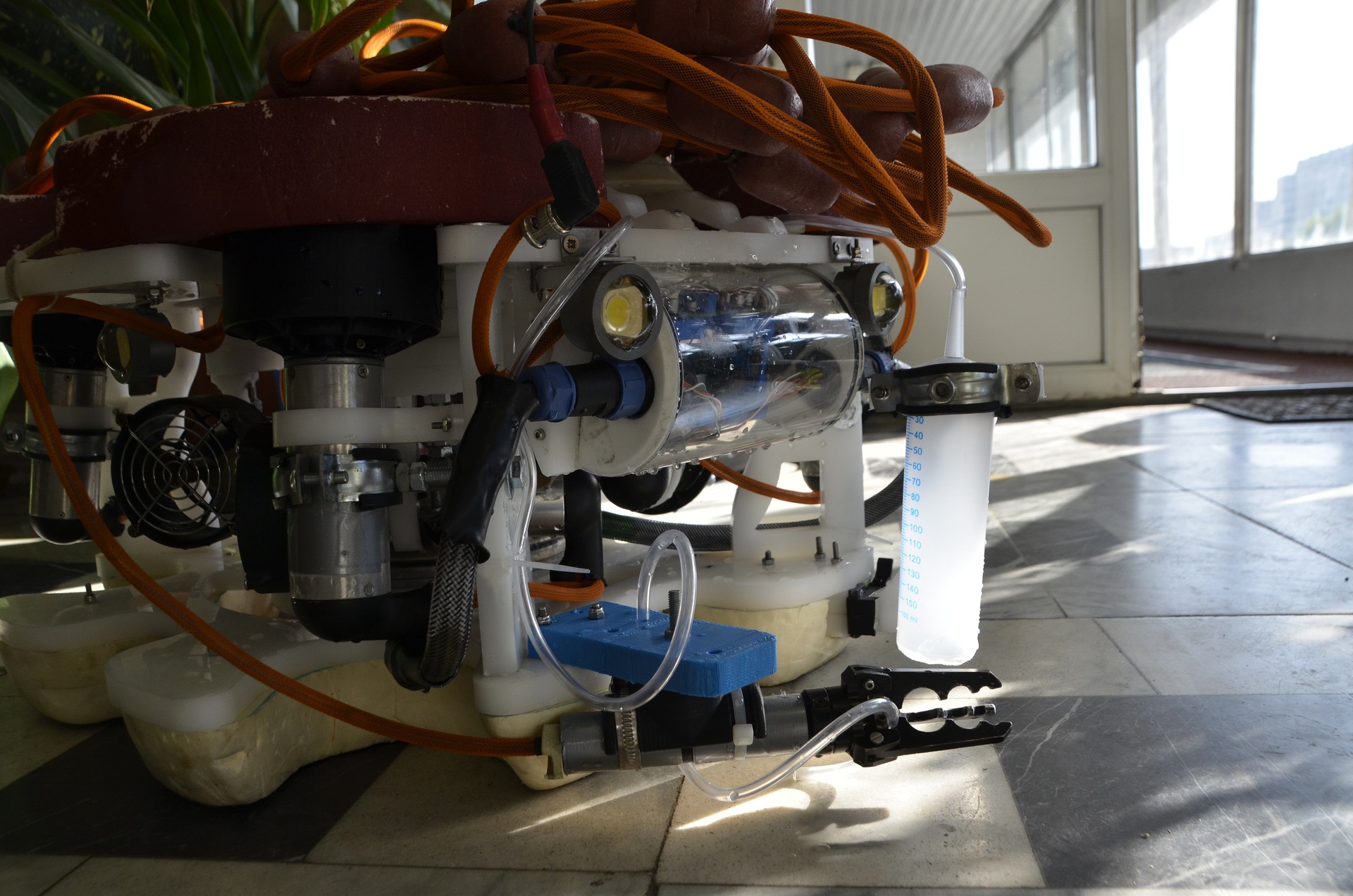

The upper part of the body of the robot. One vertical and two horizontal rotor motors are visible

There is also a camera box in which there are 2 cameras, one for the pilot, one for the image processing system. There are also 2 manipulators and a light.

Camera body, still crude version.

Orientation in space and stabilization is performed using the Vectornav VN-100 sensor. Communication with the robot takes place via the RS-485 interface, according to the simple protocol we developed. There is also a control panel left over from the previous command, with 2 kW power supplies, an integrated PC, a 3D monitor for video from cameras and a small touch screen for rendering the dashboard.

Remote Control

In parallel to the development, assembly and testing of various parts of the robot, registration for competitions, paperwork and so on was in progress. In early May, we had an interview at the US Embassy for a visa. This event was significant not only because most of us were sent for additional verification, but also because the next day I found out that due to the fact that we did not have time to finish and debug the current electronics, it was decided to use electronics from previous robot, as it is fully operational. In principle, the decision was quite logical, although it was a little annoying, since by that time the new electronics was 60-70 percent ready, that is, there was orientation, control of rotor motors, grips, light, and camera position.

The remaining in Moscow is the result of several months of work. The tulip inside was accidentally

But there was a situation to defend my results, so I quickly switched to another task - a conductivity sensor. At the beginning it was assumed that this would be a small block with a sensor sticking out of it, which the pilot would install in a simulation of a hydrothermal source. However, the design was subsequently slightly changed, leaving the data processing unit on the shore, and only the sensor cell sank to the bottom. For those who do not know, the water conductivity sensor consists of two graphite rods, between which an alternating current is introduced. Variable - to prevent "sticking" of ions on the rods. Then, from one rod, this alternating voltage is supplied through the diode to the ADC, where the voltage level is measured and further processed to obtain the conductivity value. The guys made the circuitry themselves - assembled on a breadboard, looked what kind of works. It was required of me to write software for the nano arduino standing in the block, that is, to organize the measurement of the voltage level through the ADC and the delivery of this data to the computer, for which I also had to write the software for display on the screen. It was also necessary to place a temperature sensor inside the conductivity sensor to adjust the conductivity value.

The just completed device for measuring conductivity.

The funniest thing is that almost before leaving and after a heap of time spent on getting the temperature sensor to work normally, it turned out that it was not needed, because by condition it was necessary to determine the conductivity in general, at the current time, and this value does not depend on temperature. In principle, this was one of the many schools that we committed while working on the project. Despite the simplicity of the sensor, I spent a lot of time on it. Since, in addition to a slightly clumsy analog circuit, apparently, who lived a life of its own, there were a bunch of other problems, such as, for example, with a temperature sensor and glitches of the USB-UART adapter. Software for processing data from the sensor was completed literally until the last moment, but more on that later.

After the robot was assembled (mid-end of May), we went to the pool several times, here we need to say thanks to the administration of our university for contributing to the allocation of tracks in the pool of the sports complex.

The final version of

Training shortly before departure. The main thing was not to forget the slippers.

There were a lot of problems during the tests: leaks, loss of communication and burned-out boards. So, once the video connection was lost. Having disassembled the camera unit, we saw a burned-out diode on the video camera signal conversion board. The solution is to replace the cable with a shielded twisted pair cable. It also eliminated the interference in the analog video signal.

Once the leak caused a complete burnout of the power tracks on the driver and, accordingly, the engine was turned off. We noticed this not immediately, because the robot remained operational, there was simply no traction along the lag (lag is a plane-parallel movement along the transverse axis). At first they thought that the screw had flown off the shaft mount, however, having come to the laboratory, they found that everything was much sadder.

Rotor feed paths burned out from the short circuit

Etc. As a result, it turned out that at the time of departure we were not able to conduct a single full-fledged training of the team and completing all the missions for the set time. It was also interesting that during training in our pool, the pilot constantly had to cope with undercurrents, which were often quite strong and very interfere with the tasks. But, as it turned out, it was hard to learn - easy in battle, and there were no currents in the pool where the competitions were held, so it was much easier for our pilot to complete tasks.

The week before departure, as expected, was quite eventful. In addition to the fact that many had exams, it was still necessary to prepare for departure. Various devices, robot parts, my sensor and a whole bunch of other things were quickly completed. On the day of departure, while the guys were sorting and packing the robot in their suitcases, I went shopping and bought various junk.

Packing suitcases. It is very important that everything arrives whole

It's funny that both times when I left the university, I was hit by a wild downpour that ended in 20 minutes. We had a plane at five in the morning, so we spent the entire previous day in the laboratory in training camps to go to the airport at night and fly off in the morning. In addition to the robot, we brought tools, an oscilloscope, a set of spare parts for the robot and a lot more. I was very worried about overload, because the dynamometer that day was one of the main tools. The guys urgently printed a poster and prepared documents that we will show to the judges. In the end, having reached Sheremetyevo in a university car and meeting the rest of the guys there, safely handing over our suitcases into our luggage, having paid a couple of overloads, we flew to Amsterdam.

5 hours before departure

In Amsterdam, we were waiting for a very short transfer, as a result, after a light run from one gate to another and a casual conversation with security officers, we were on a plane flying to Detroit.

Competitions are held every year in a new city, the last time they were in the town of Federal Way in a suburb of Seattle, this time we were less fortunate and we were waiting for the provincial town of Alpena in northern Michigan, right on the shore of Lake Huron. For me, this was my first visit to America, and, unlike most people visiting this country for the first time, my acquaintance with it began from a real heartland.

10 thousand people live in Alpena, which is almost ten times less than in my hometown. So international competitions of this level for the city were really a big event. I will not describe my impressions of what I saw, I think that few people will be interested. I will say one thing: I liked the city and its inhabitants incredibly. Maybe the Americans are smiling at everyone, but the people we met on the street, having learned that we are one of the teams, and even more so from Russia, smiled and sincerely wished us good luck.

So, having arrived in Detroit, we quickly picked up 2 rented cars and drove to Alpena. After almost 5 hours of travel, we finally reached our hotel. Since Alpena is a tiny town, there are only two hotels there, on which the participants of the competition are quite evenly accommodated. Teams from America, Indonesia, China, and Canada also lived with us at the hotel. The first day was completely busy assembling the robot. Each team did this in its own way: those who were lucky and whose numbers went inside were located right in the inner room, who were unlucky and the numbers were outside, assembled a robot in the rooms.

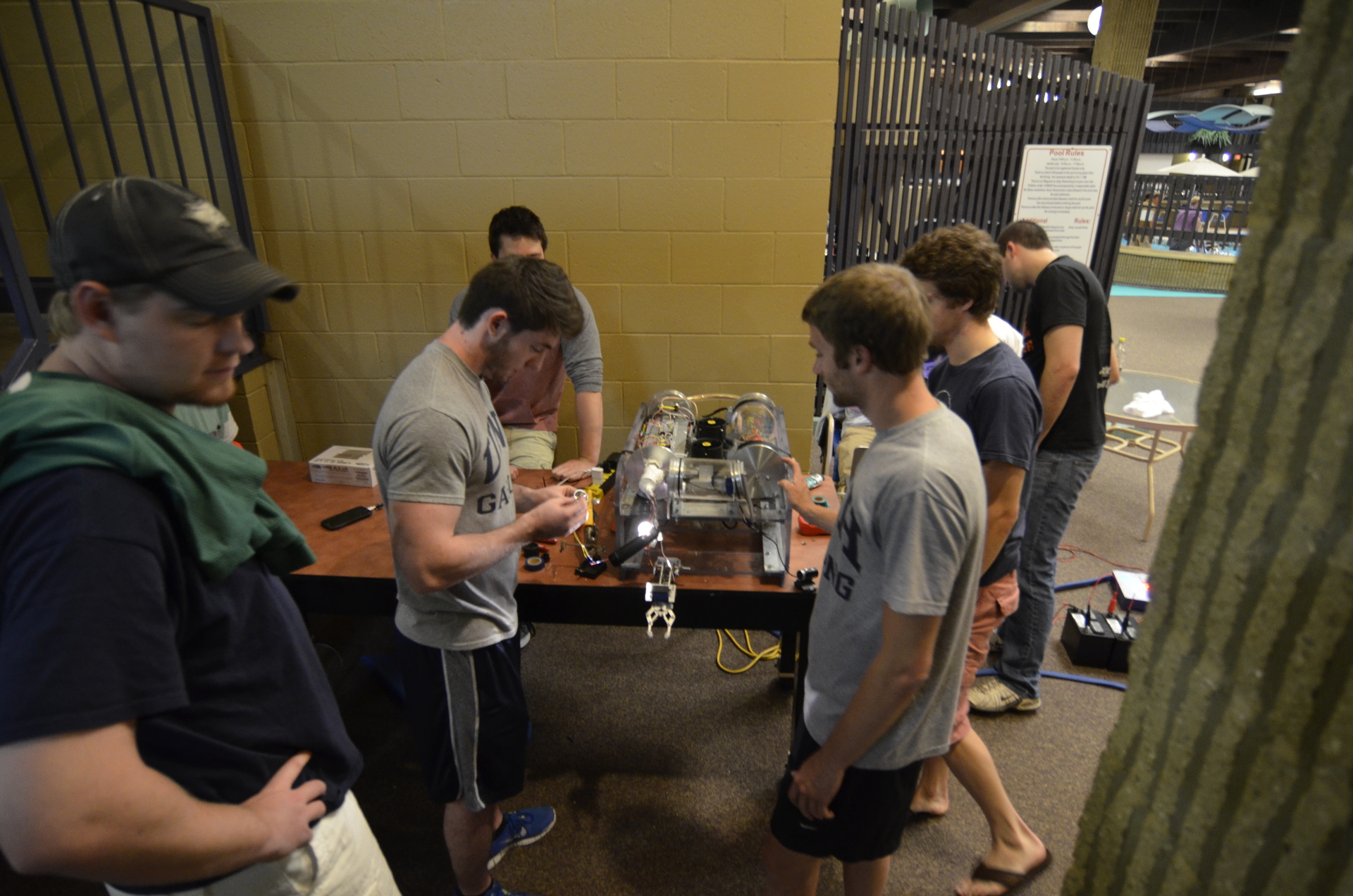

These guys were lucky, they have a big table and a lot of space.

We were less lucky. As expected, one room turned into a small workshop, where someone was constantly doing something.

Although we didn’t have a large table, it was more comfortable.

For lack of an accessible pool, the robot was sealed in the bathroom.

We spent the entire first and second days at the hotel, collecting robots and accessories for it, only having gone to eat a couple of times, to the store for details and for registration.

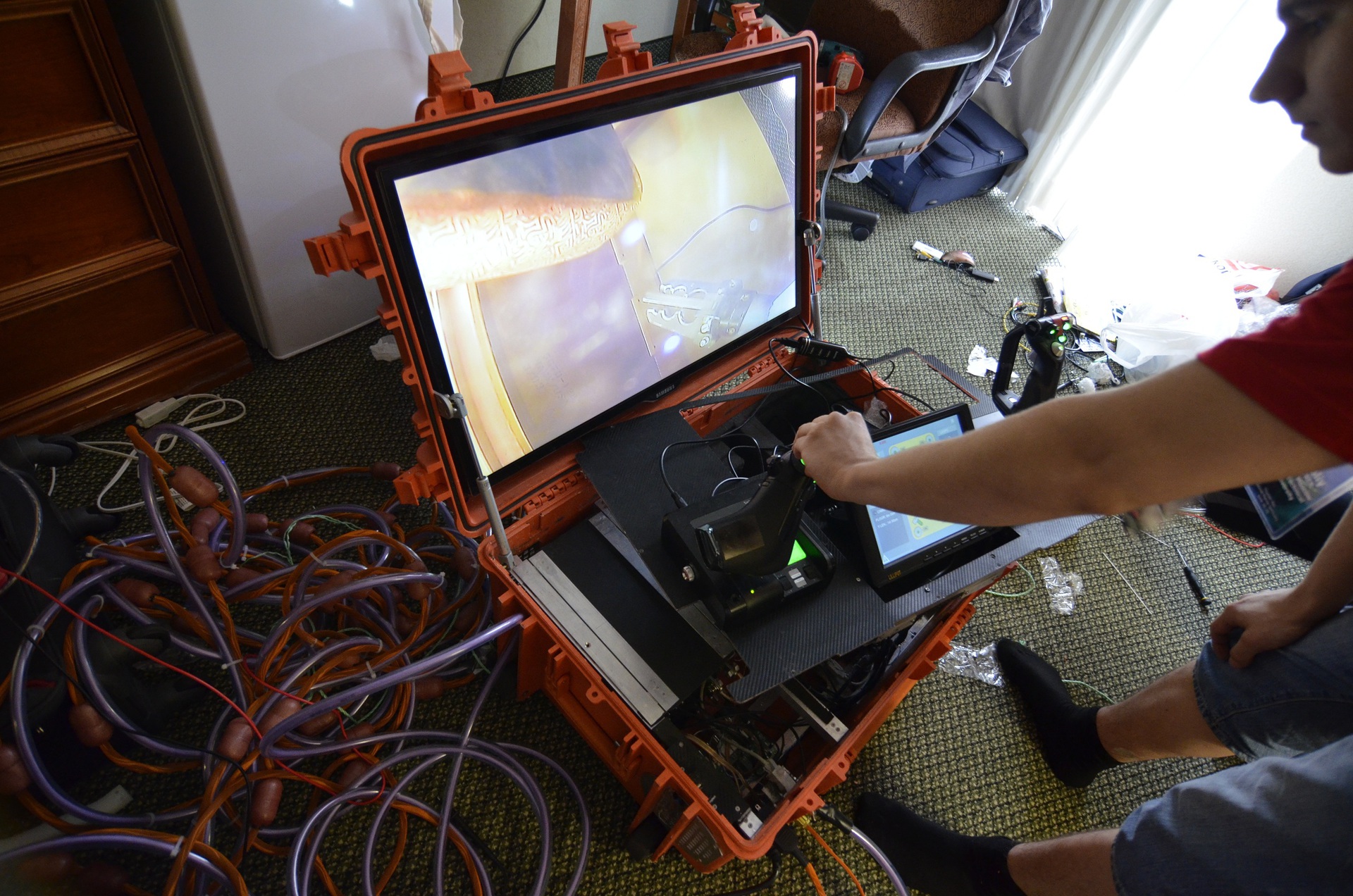

Checking the video on an already assembled robot

The third day was the first day of the competition. An opening ceremony, a safety check of the robots, and a trial 15-minute launch were scheduled for this day. We were a bit late for the opening and arrived just a couple of minutes before we called our team, to which the guys shouted something together in response. At that time, I was already running around with the camera between the teams' tables, photographing robots and their details. Unfortunately, at that time, far from all the devices were on the tables, so nothing special could be found, except for a couple of funny mechanisms.

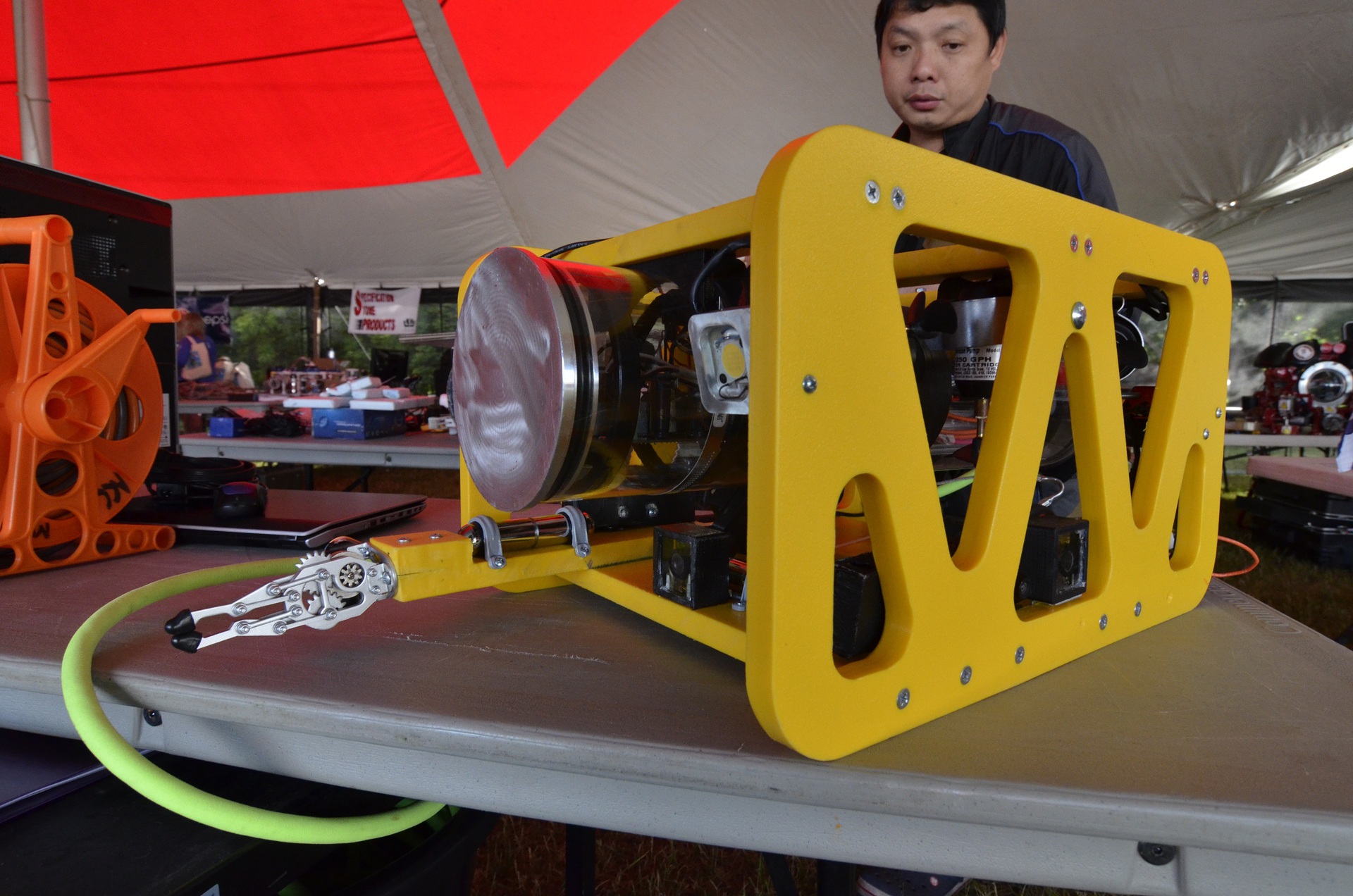

A very neat robot with an interesting grip

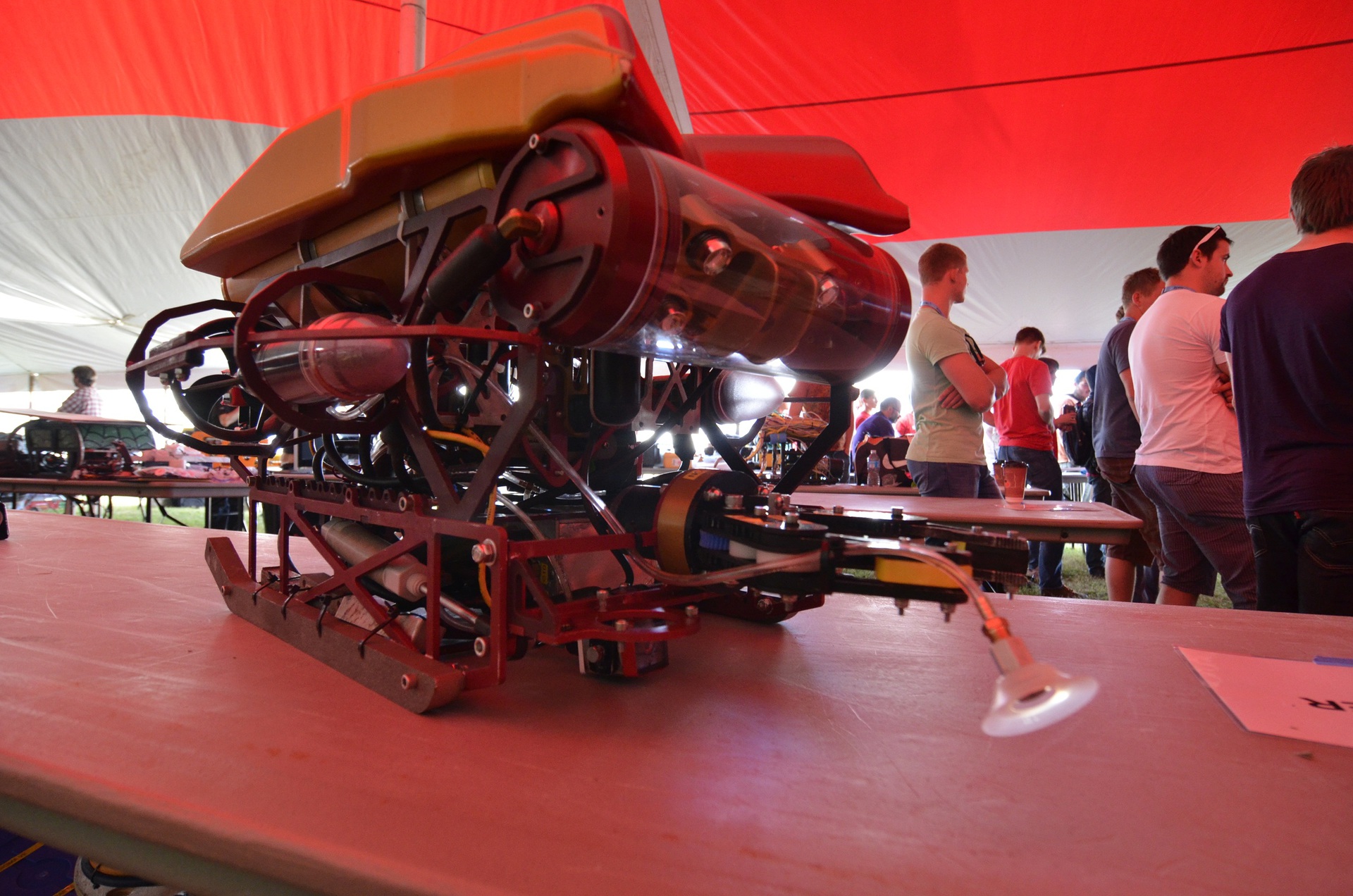

A unique robot with stylization as Iron Man A four- finger grip and huge engines set this robot apart from the

rest

After the opening ceremony, all teams continued to prepare their robots for security checks. We were no exception. Our robot was completely pasted with warnings about sharp corners, rotating parts and so on. Despite this, before checking, we cleaned sharp scraps of screeds, filed sharp corners with a file so that the judges had nothing to complain about. In principle, we did everything perfectly, so we went through both security checks without any problems.

The penultimate check passed perfectly

Satisfied with the first small success - the maximum score for a security check, we were pleased to go further. As I said, several more teams lived with us at the hotel. So, the guys from Oregon agreed with a local school, which has a pool, so that they allowed us to swim in it. But also, being very nice people, they posted a notice at the hotel that all those who also want to swim before the official test dives can come, having agreed in advance with them. Therefore, we decided not to miss the opportunity to swim longer. Thus, after a security check, we went to school, where we tried to imitate the quick layout of the remote control and the preparation of the robot. It didn’t work out very well, but at least they swam.

Extreme workouts worth its weight in gold

The lack of competition simulations is not a problem, even just swimming is good.

After some time, the rest of our team arrived and it became known that the organizers put calibration liquids to calibrate the conductivity sensors, so after a while I and a couple of people went to calibrate our conductivity meter. Arriving at the place and lowering our sensor into the provided liquids, we found an unpleasant fact, namely, our sensor was configured for a liquid with significantly lower conductivity, while the provided liquids had a very high conductivity. Understanding the new plan for the evening, we collected samples for calibration and drove to the hotel. At that time, the rest of the guys returned from school, swam for 15 minutes in the competitive pool and also arrived at the hotel.

We spent the evening of the first day, preparing for the presentation of the project, which was scheduled for the next day. In the intervals between translating texts for the rest of the guys and learning my passage, I calibrated the conductivity sensor and added its software. As a result, the sensor seemed to be calibrated, but there was a problem with overheating: after 1-2 minutes, the operational amplifier in the circuit was heating up too much, which led to its failure. In principle, this was not a big problem, but still it was unpleasant.

Cool photo from divers working in the pool

The second day was the first truly competitive day, since in addition to presenting projects on this day, other teams already had real attempts. We were extremely lucky and our two attempts were scattered on two different days, so if something happened, we had time to fix and fix something. It began with a funny incident: me and my roommate were simply forgotten at the hotel. They only remembered us when they began to check whether they had taken everything with them, and it turned out that there was no conductivity sensor. Just five for teamwork. In principle, this case slightly lowered the tension. There is nothing special to tell about the presentation itself. We went into the tent, put the robot, the remote control, told the prepared text, after that we talked with the judges in a more free form, and told us about various interesting details of our robot. I really liked the judges at the presentation. All three judges are specialists with extensive experience in certain areas. For example, one of them has 25 years of experience in the field of underwater robotics. So their assessment is rather objective and they obviously will not succeed in “dusting their brains”. But, in general, everyone was satisfied with the result and, although the assessment was not announced immediately, the feelings were extremely positive. After the presentation of the project, we had about 3 hours before the first attempt, so we went to the room, because we had to finish something. Then there was something. Entering literally 2.5 hours before the first attempt in the room, I saw a disassembled robot and the guys blow dry the electronics boards. It turned out that during yesterday’s dive, water leaked into the hull and it was discovered only today a couple of hours before the first attempt. So the atmosphere at that moment was, to say the least, tense. But at the last moment everything was dried and put in order. Unfortunately, these days, especially at the time of the competition, it was not possible to take many photos, so there is nothing special to show.

How is the attempt to complete missions. The team approaches the station, speaks with the judges, asks questions, listens to the rules again. Next, she is given 5 minutes to prepare for the tasks, that is, connect the power, configure everything, etc.

We listen to the rules again before starting the attempt

After 5 minutes, the judges immediately detect the main time. The team is divided into two parts. The first is at the console, the second at the side of the pool. You can’t communicate with each other, the only thing that can be said is to demand more cable. This is done in order to simulate the operation of the device at great depths and to prevent the tips of the pilots working at the side. After the end of the 15-minute mission period, the team is given 5 minutes to pack up and leave the station. If you do not have time to leave on time, you can get penal points. You can also get penalty points if, at the end of normal time, the robot is still in the water or something from its equipment is left at the bottom.

We started our attempt confidently and professionally. Having clearly distributed the roles in advance, we all knew who was doing what, so we didn’t even communicate much with each other. However, this did not last long, approximately in the second minute we found that the contact of the PS / 2 connector from the joystick bent. We found a screwdriver to fix this quickly, but it turned out that this was only the beginning. Further, for some reason, there was no connection with the robot and it was not there for quite some time, so we lost the first 2 minutes from the main time. Then everything was a little more successful, they managed to complete some missions, some not. My sensor fell out of the bottle safely due to the high center of gravity of the weighting agent. At the end of time, we quickly packed up and dumped from the station. The result of 135 points is not as bad as that of some teams, but they could reach 200,

By and large, all the mistakes were there, a few minutes later they started quite an active discussion, which continued all the way to the hotel and in the hotel itself. Our main mistake was that we did not check everything in advance, that is, we arrived from the hotel and immediately to the start, so there were all sorts of problems, such as bent connectors. Proceeding from this, it was decided the next day to arrive a little earlier, find a table, collect everything there and, in open form, carry it all to the station. Well, various small jambs, such as, for example, underestimating the center of gravity on a conductivity sensor. After all this, we went to the hotel, where someone was left to finish the robot, and the rest went to the store and walk along the lake.

The second attempt, as I said, was scheduled for the third, last day of the competition at 10-30 in the morning. Having got up a little earlier, we arrived at the place and, according to the plan, after having decomposed everything and tested the robot’s working capacity three times, we started. This time we already knew what and how it would be, so we managed to get ready in 3 minutes, the rest of the time we waited for the computer to restart on the control panel. But, nevertheless, calmly waiting for the end of the download and the beginning of the main time, we started to complete the tasks.

The updated conductivity sensor successfully failed in the “hydrothermal source” (salt water tank) and, to my deepest surprise, correctly measured the conductivity of water. Further, everything went quite successfully too: they lifted the anchor, sailed into the ship, lifted a plate with the home port - and so on. They tried to pick up the bottles, but quickly left this venture. The only negative was that it was not possible to correctly measure all the dimensions of the vessel, because of which they could not determine the number of mollusks that had grown on it and lost quite a lot of points. But everything else was done quite successfully and, having managed to pull the robot out of the water at the last moment, they successfully completed the missions. The result of the second attempt is 245 points, a very unexpected result, taking into account the fact that we expected to get at least two hundred points.

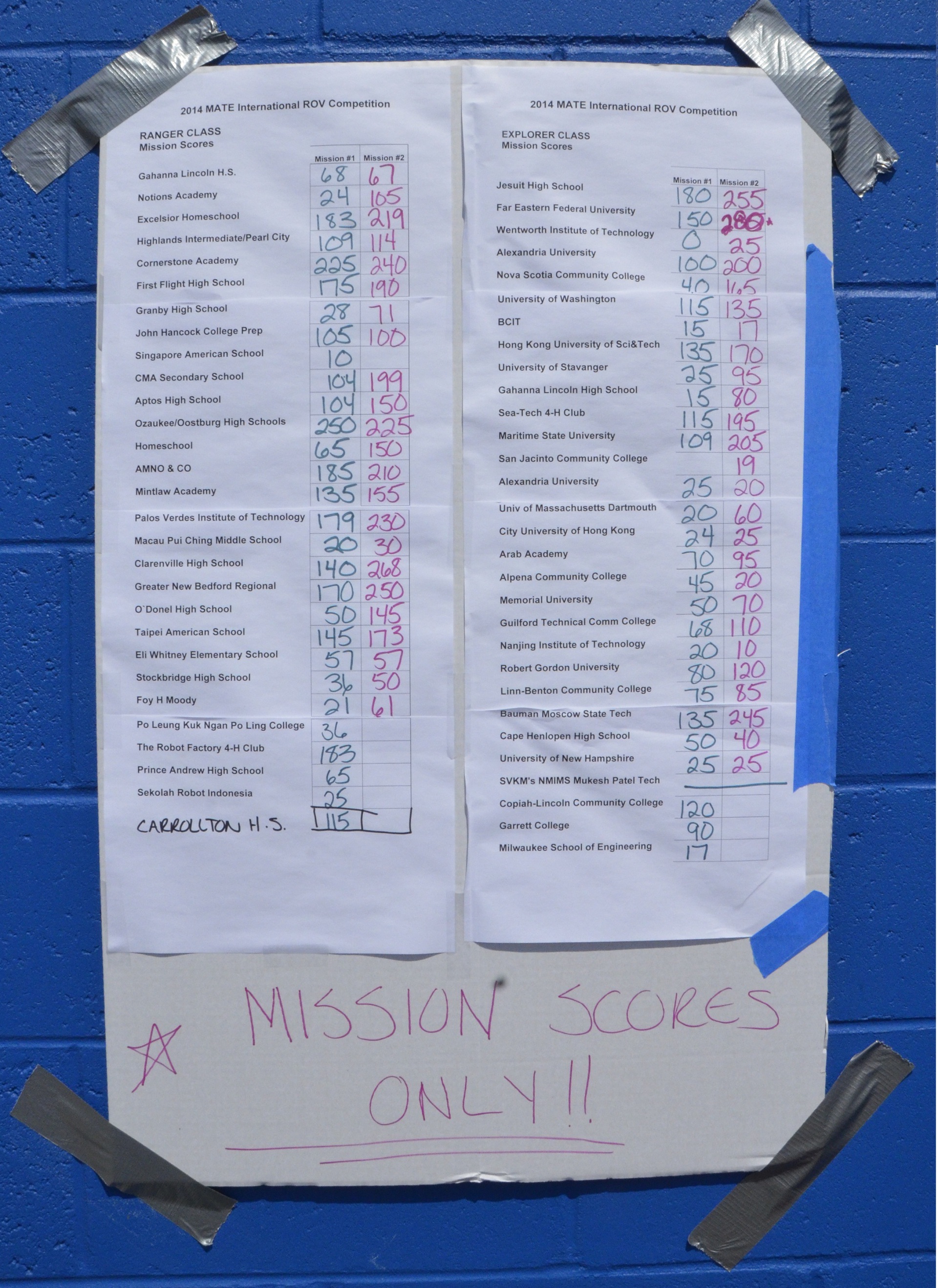

The results of two attempts. Someone never got to the second

Our team after the second attempt

In the evening of the same day, the winners of the competitions were awarded. An interesting feature of these competitions is a large number of nominations. Any judge can create his own nomination and choose the winners. It is also interesting that prizes are awarded not only in purely technical nominations, but also in such as the best leader, the team that has overcome the most difficulties, and so on. In general, it was not necessary to have a good robot to take any prize.

We part with the prize for innovation, received last year for 3D vision in the robot. This year, the prize went to the team that organized the device using the Oculus Rift

The results of all tests are not known in advance, so the intrigue persists until the last moment. Although, based on the results of the missions, you can make some assumptions. According to the results of the missions, we were the third, and therefore focused on this place, although the final result could be any. Our team eventually took 3 prizes: in the security nomination, a slightly unexpected, but quite logical result: no one had so many stickers on the robot. The second prize was for the best technical report, many thanks to those who eventually stayed in Moscow, because the technical report was their business. And the third prize - for second place in the overall standings. Also quite unexpectedly, but very nice, our training on all fronts yielded results.

Winning the Best Technical Report nomination

Second place in the overall standings

Victory in the nomination “For Security”

We overtook the team from the Far East: the guys had 280 points for the mission, but the results on the remaining points were slightly worse than ours. In the first place was the team from Jesuit High School. A huge team, people under 25 or more, last year’s winners, scored 255 points for the mission and won the prize for the best poster. The awards took place in a very family atmosphere, the host, one of the organizers of the competition, constantly joked and generally maintained a somewhat informal atmosphere, which really created the impression that we were one big family.

The winner’s numerical advantage

The awards were followed by photographing with various teams, followed by a celebration that was already taking place at the hotel.

Against the backdrop of the Alpena school, the

awards received look good with highlighting.

On the sixth day, we had to drive home. Again 5 hours by car to Detroit, then two flights to Moscow. And then someone went to rest, and someone went to military training.

We unload and rent cars.

The result of the competition was really unexpected for everyone, because the best result of previous years was only 7th place, and this year the number of participants also increased sharply. One way or another, we exceeded our expectations. Of course, something could be done better, and our lag behind the winners was not so big, but even so, for the team that is in such a roster for the first time, such a result is an incredible success. Perhaps the truth is newcomers lucky.

In the end, I would like to say that at the moment we have already begun to design a new apparatus for the next competition. It is planned to make a new robot with new electronics, new rotor motors and generally try to do everything at a higher level. So our center continues to work on preparing for the competition next year.

Obviously, such competitions, and especially preparation for them, provide invaluable experience. Perhaps this is just what is often so lacking in our educational process. Therefore, I am infinitely glad that on that day, six months ago, I gave a positive answer to the question about my participation in the project.

And here is a short video about the preparation and the trip itself:

Under the cut a lot of photos.

Background

Our lab on a typical day

My classmate is studying at the department of underwater robots of MSTU. N.E. Bauman. A little after the new year I receive a message from him with a proposal to participate in the project of an underwater robot for competitions as a microcontroller programmer, due to the fact that no one especially programmed in their team. Since I didn’t have any plans for independent work for the upcoming semester, I agreed with pleasure, in the end, I finally got the opportunity to do something real that could be touched and that goes beyond the scope of home crafts. It turned out that the Hydronavtika center has been operating in our institute for several years, whose activity is mainly focused on the preparation and participation in competitions from the organization Marine Advanced Technology Education Center (MATE) on the subject of underwater remote control vehicles (remotely operated underwater vehicle, which in English literature is traditionally abbreviated as ROV). It is worth noting that the center’s laboratory is equipped in principle with everything that is needed for productive work: an oscilloscope, soldering stations, various machines and tools, as well as its own small pool with a water filtration system. Without him, it would be very difficult, because every time I had to run into the pool of the university sports complex, if necessary. what you need for productive work: an oscilloscope, soldering stations, various machines and tools, as well as your own small pool with a water filtration system. Without him, it would be very difficult, because every time I had to run into the pool of the university sports complex, if necessary. what you need for productive work: an oscilloscope, soldering stations, various machines and tools, as well as your own small pool with a water filtration system. Without him, it would be very difficult, because every time I had to run into the pool of the university sports complex, if necessary.

Testing the robot in our home pool

After a short chat with my friend, we agreed to meet with other guys in their lab. The guys were very nice and positive. After a short discussion of the current state of the project and the competitions themselves, a decision was made about my participation.

The essence of the event

More information about the competitions can be found on the official website . In short, the competition is to go through several stages. Firstly, you need to get the approval of the organizers of the competition about your participation, for this you need to prepare a number of documents, for example, a technical report with a detailed description of the device. You also need to provide a video with a demonstration of the device’s work a month before the performance to show that it can even swim and perform at least some tasks underwater. After passing through the preparatory stages and obtaining the approval of the organizers, you can go to the competition. As with all similar events, the set of tasks changes annually.

The list of all tasks on the laboratory wall

Every year, competitions have a certain theme related to real problems and tasks in the waters, which require underwater vehicles to solve. This year, the task was to study the bottom of one of the Great American Lakes, namely Lake Huron. At the bottom of the lake, many sunken ships remained intact. The mission of the apparatus consisted of three stages: the study of a shipwreck, scientific research at the bottom, cleaning the bottom of debris. Of course, the competitions themselves are only a simulation of the real situation, therefore the devices did not swim in the lake, but in a deep pool, at the bottom of which a shipwreck model and other bottom equipment were put up. In the first stage, it was necessary to investigate the shipwreck zone in order to determine the type of ship, year of its construction, port of registry, which will allow it to be uniquely identified.

Slightly stagnant and therefore moldy glasses with jelly for testing.

In the third stage, it was necessary to raise garbage (glass and plastic bottles) from the bottom of the lake, as well as the heavy steel anchor of the sunken ship.

It should be noted that successfully completing all tasks under water is not enough to win. Underwater missions “cost” only 320 points out of a total of 600. Competitions are designed in such a way that teams are required to present themselves in the place of private companies participating in the tender for underwater operations. That is, each team must successfully present itself to the judges and justify why their apparatus and their team will be able to most successfully carry out the work. This part of the competition is called Engineering and Communication and also consists of 3 items - a technical report, an engineering presentation and a poster.

A technical report is a 25-page document containing a detailed description of the device and the process of its development, its technical features (“features”), which will ensure that it successfully performs an underwater mission. This document should be prepared about a month before the competition and sent to the judges. For the technical report you can get up to 100 points.

On the poster, the team should concisely, but colorfully fit the information about the team and the device. The posters are also evaluated by the judges during the competition, for them the team can get up to 50 points.

An engineering presentation is an oral presentation by a team in front of a panel of expert judges with a story about the advantages of the apparatus over competitors. A presentation is worth 100 points.

The remaining 30 points are given to those teams that, on the first try, passed a test of their device for safety and compliance with the regulations.

Thus, only careful preparation of all points can bring the team victory.

Development start

At the time I was accepted into the project, but let me remind you, it was somewhere in the beginning of February or even later, things were not very good: the previous team graduated, and from it there were only 2 people who somehow understood how everything should be. The new team, unfortunately, had practically no work experience, for many it was the first real project. The old team left behind a working robot, and it worked perfectly. But, unfortunately, participating in the competition with one robot twice in a row is not welcome, so the task of the new team was to develop and assemble a new robot. Also, the first semester of this school year was spent almost empty, and there was only six months left before the competition, which, given the general academic load, is a rather short time.

My tasks in the project included writing on-board electronics software, the basis of which was the Arduino platform. This choice was justified by the fact that most of the participants only learned programming, and such a platform was the best choice. I, as a fan of pure MK programming, although at first I resisted, but in the end I agreed with this choice, since all the boards were already designed for arduins and there was no time to change anything.

Actually, this is how it all started, unfortunately, I went into the course of affairs for a long time and only after almost a month and a half did I understand how everything should look in the end. Again, the training load affected, which did not allow working at full strength.

Now a little about the technical details. The electronics of our robot was a tower of several round printed double-sided boards, placed a cylindrical plexiglass case, closed on both sides with sealed covers.

Two parts of an electronics tower

Fastening the covers of the electronics housing takes place without screws, thus assembling / disassembling can be done quite quickly. All boards have the same connectors with the same pinout, so the possibility of incorrect assembly is eliminated. This concept was taken from a previous robot and, in my opinion, is very convenient in this situation. The tower consists of a main controller board - Arduino Mega, a rotor motor driver board, a secondary power supply board, a device control board (manipulators, a light, a pressure sensor, a camera drive), two interface boards with pressurized connectors, one on each side. The robot itself has 8 rotor motors located vector: 4 vertical, 4 horizontal.

The upper part of the body of the robot. One vertical and two horizontal rotor motors are visible

There is also a camera box in which there are 2 cameras, one for the pilot, one for the image processing system. There are also 2 manipulators and a light.

Camera body, still crude version.

Orientation in space and stabilization is performed using the Vectornav VN-100 sensor. Communication with the robot takes place via the RS-485 interface, according to the simple protocol we developed. There is also a control panel left over from the previous command, with 2 kW power supplies, an integrated PC, a 3D monitor for video from cameras and a small touch screen for rendering the dashboard.

Remote Control

In parallel to the development, assembly and testing of various parts of the robot, registration for competitions, paperwork and so on was in progress. In early May, we had an interview at the US Embassy for a visa. This event was significant not only because most of us were sent for additional verification, but also because the next day I found out that due to the fact that we did not have time to finish and debug the current electronics, it was decided to use electronics from previous robot, as it is fully operational. In principle, the decision was quite logical, although it was a little annoying, since by that time the new electronics was 60-70 percent ready, that is, there was orientation, control of rotor motors, grips, light, and camera position.

The remaining in Moscow is the result of several months of work. The tulip inside was accidentally

But there was a situation to defend my results, so I quickly switched to another task - a conductivity sensor. At the beginning it was assumed that this would be a small block with a sensor sticking out of it, which the pilot would install in a simulation of a hydrothermal source. However, the design was subsequently slightly changed, leaving the data processing unit on the shore, and only the sensor cell sank to the bottom. For those who do not know, the water conductivity sensor consists of two graphite rods, between which an alternating current is introduced. Variable - to prevent "sticking" of ions on the rods. Then, from one rod, this alternating voltage is supplied through the diode to the ADC, where the voltage level is measured and further processed to obtain the conductivity value. The guys made the circuitry themselves - assembled on a breadboard, looked what kind of works. It was required of me to write software for the nano arduino standing in the block, that is, to organize the measurement of the voltage level through the ADC and the delivery of this data to the computer, for which I also had to write the software for display on the screen. It was also necessary to place a temperature sensor inside the conductivity sensor to adjust the conductivity value.

The just completed device for measuring conductivity.

The funniest thing is that almost before leaving and after a heap of time spent on getting the temperature sensor to work normally, it turned out that it was not needed, because by condition it was necessary to determine the conductivity in general, at the current time, and this value does not depend on temperature. In principle, this was one of the many schools that we committed while working on the project. Despite the simplicity of the sensor, I spent a lot of time on it. Since, in addition to a slightly clumsy analog circuit, apparently, who lived a life of its own, there were a bunch of other problems, such as, for example, with a temperature sensor and glitches of the USB-UART adapter. Software for processing data from the sensor was completed literally until the last moment, but more on that later.

After the robot was assembled (mid-end of May), we went to the pool several times, here we need to say thanks to the administration of our university for contributing to the allocation of tracks in the pool of the sports complex.

The final version of

Training shortly before departure. The main thing was not to forget the slippers.

There were a lot of problems during the tests: leaks, loss of communication and burned-out boards. So, once the video connection was lost. Having disassembled the camera unit, we saw a burned-out diode on the video camera signal conversion board. The solution is to replace the cable with a shielded twisted pair cable. It also eliminated the interference in the analog video signal.

Once the leak caused a complete burnout of the power tracks on the driver and, accordingly, the engine was turned off. We noticed this not immediately, because the robot remained operational, there was simply no traction along the lag (lag is a plane-parallel movement along the transverse axis). At first they thought that the screw had flown off the shaft mount, however, having come to the laboratory, they found that everything was much sadder.

Rotor feed paths burned out from the short circuit

Etc. As a result, it turned out that at the time of departure we were not able to conduct a single full-fledged training of the team and completing all the missions for the set time. It was also interesting that during training in our pool, the pilot constantly had to cope with undercurrents, which were often quite strong and very interfere with the tasks. But, as it turned out, it was hard to learn - easy in battle, and there were no currents in the pool where the competitions were held, so it was much easier for our pilot to complete tasks.

Departure on a combat mission

The week before departure, as expected, was quite eventful. In addition to the fact that many had exams, it was still necessary to prepare for departure. Various devices, robot parts, my sensor and a whole bunch of other things were quickly completed. On the day of departure, while the guys were sorting and packing the robot in their suitcases, I went shopping and bought various junk.

Packing suitcases. It is very important that everything arrives whole

It's funny that both times when I left the university, I was hit by a wild downpour that ended in 20 minutes. We had a plane at five in the morning, so we spent the entire previous day in the laboratory in training camps to go to the airport at night and fly off in the morning. In addition to the robot, we brought tools, an oscilloscope, a set of spare parts for the robot and a lot more. I was very worried about overload, because the dynamometer that day was one of the main tools. The guys urgently printed a poster and prepared documents that we will show to the judges. In the end, having reached Sheremetyevo in a university car and meeting the rest of the guys there, safely handing over our suitcases into our luggage, having paid a couple of overloads, we flew to Amsterdam.

5 hours before departure

In Amsterdam, we were waiting for a very short transfer, as a result, after a light run from one gate to another and a casual conversation with security officers, we were on a plane flying to Detroit.

Competitions are held every year in a new city, the last time they were in the town of Federal Way in a suburb of Seattle, this time we were less fortunate and we were waiting for the provincial town of Alpena in northern Michigan, right on the shore of Lake Huron. For me, this was my first visit to America, and, unlike most people visiting this country for the first time, my acquaintance with it began from a real heartland.

10 thousand people live in Alpena, which is almost ten times less than in my hometown. So international competitions of this level for the city were really a big event. I will not describe my impressions of what I saw, I think that few people will be interested. I will say one thing: I liked the city and its inhabitants incredibly. Maybe the Americans are smiling at everyone, but the people we met on the street, having learned that we are one of the teams, and even more so from Russia, smiled and sincerely wished us good luck.

So, having arrived in Detroit, we quickly picked up 2 rented cars and drove to Alpena. After almost 5 hours of travel, we finally reached our hotel. Since Alpena is a tiny town, there are only two hotels there, on which the participants of the competition are quite evenly accommodated. Teams from America, Indonesia, China, and Canada also lived with us at the hotel. The first day was completely busy assembling the robot. Each team did this in its own way: those who were lucky and whose numbers went inside were located right in the inner room, who were unlucky and the numbers were outside, assembled a robot in the rooms.

These guys were lucky, they have a big table and a lot of space.

We were less lucky. As expected, one room turned into a small workshop, where someone was constantly doing something.

Although we didn’t have a large table, it was more comfortable.

For lack of an accessible pool, the robot was sealed in the bathroom.

We spent the entire first and second days at the hotel, collecting robots and accessories for it, only having gone to eat a couple of times, to the store for details and for registration.

Checking the video on an already assembled robot

The third day was the first day of the competition. An opening ceremony, a safety check of the robots, and a trial 15-minute launch were scheduled for this day. We were a bit late for the opening and arrived just a couple of minutes before we called our team, to which the guys shouted something together in response. At that time, I was already running around with the camera between the teams' tables, photographing robots and their details. Unfortunately, at that time, far from all the devices were on the tables, so nothing special could be found, except for a couple of funny mechanisms.

A very neat robot with an interesting grip

A unique robot with stylization as Iron Man A four- finger grip and huge engines set this robot apart from the

rest

After the opening ceremony, all teams continued to prepare their robots for security checks. We were no exception. Our robot was completely pasted with warnings about sharp corners, rotating parts and so on. Despite this, before checking, we cleaned sharp scraps of screeds, filed sharp corners with a file so that the judges had nothing to complain about. In principle, we did everything perfectly, so we went through both security checks without any problems.

The penultimate check passed perfectly

Satisfied with the first small success - the maximum score for a security check, we were pleased to go further. As I said, several more teams lived with us at the hotel. So, the guys from Oregon agreed with a local school, which has a pool, so that they allowed us to swim in it. But also, being very nice people, they posted a notice at the hotel that all those who also want to swim before the official test dives can come, having agreed in advance with them. Therefore, we decided not to miss the opportunity to swim longer. Thus, after a security check, we went to school, where we tried to imitate the quick layout of the remote control and the preparation of the robot. It didn’t work out very well, but at least they swam.

Extreme workouts worth its weight in gold

The lack of competition simulations is not a problem, even just swimming is good.

After some time, the rest of our team arrived and it became known that the organizers put calibration liquids to calibrate the conductivity sensors, so after a while I and a couple of people went to calibrate our conductivity meter. Arriving at the place and lowering our sensor into the provided liquids, we found an unpleasant fact, namely, our sensor was configured for a liquid with significantly lower conductivity, while the provided liquids had a very high conductivity. Understanding the new plan for the evening, we collected samples for calibration and drove to the hotel. At that time, the rest of the guys returned from school, swam for 15 minutes in the competitive pool and also arrived at the hotel.

We spent the evening of the first day, preparing for the presentation of the project, which was scheduled for the next day. In the intervals between translating texts for the rest of the guys and learning my passage, I calibrated the conductivity sensor and added its software. As a result, the sensor seemed to be calibrated, but there was a problem with overheating: after 1-2 minutes, the operational amplifier in the circuit was heating up too much, which led to its failure. In principle, this was not a big problem, but still it was unpleasant.

Cool photo from divers working in the pool

The second day was the first truly competitive day, since in addition to presenting projects on this day, other teams already had real attempts. We were extremely lucky and our two attempts were scattered on two different days, so if something happened, we had time to fix and fix something. It began with a funny incident: me and my roommate were simply forgotten at the hotel. They only remembered us when they began to check whether they had taken everything with them, and it turned out that there was no conductivity sensor. Just five for teamwork. In principle, this case slightly lowered the tension. There is nothing special to tell about the presentation itself. We went into the tent, put the robot, the remote control, told the prepared text, after that we talked with the judges in a more free form, and told us about various interesting details of our robot. I really liked the judges at the presentation. All three judges are specialists with extensive experience in certain areas. For example, one of them has 25 years of experience in the field of underwater robotics. So their assessment is rather objective and they obviously will not succeed in “dusting their brains”. But, in general, everyone was satisfied with the result and, although the assessment was not announced immediately, the feelings were extremely positive. After the presentation of the project, we had about 3 hours before the first attempt, so we went to the room, because we had to finish something. Then there was something. Entering literally 2.5 hours before the first attempt in the room, I saw a disassembled robot and the guys blow dry the electronics boards. It turned out that during yesterday’s dive, water leaked into the hull and it was discovered only today a couple of hours before the first attempt. So the atmosphere at that moment was, to say the least, tense. But at the last moment everything was dried and put in order. Unfortunately, these days, especially at the time of the competition, it was not possible to take many photos, so there is nothing special to show.

How is the attempt to complete missions. The team approaches the station, speaks with the judges, asks questions, listens to the rules again. Next, she is given 5 minutes to prepare for the tasks, that is, connect the power, configure everything, etc.

We listen to the rules again before starting the attempt

After 5 minutes, the judges immediately detect the main time. The team is divided into two parts. The first is at the console, the second at the side of the pool. You can’t communicate with each other, the only thing that can be said is to demand more cable. This is done in order to simulate the operation of the device at great depths and to prevent the tips of the pilots working at the side. After the end of the 15-minute mission period, the team is given 5 minutes to pack up and leave the station. If you do not have time to leave on time, you can get penal points. You can also get penalty points if, at the end of normal time, the robot is still in the water or something from its equipment is left at the bottom.

We started our attempt confidently and professionally. Having clearly distributed the roles in advance, we all knew who was doing what, so we didn’t even communicate much with each other. However, this did not last long, approximately in the second minute we found that the contact of the PS / 2 connector from the joystick bent. We found a screwdriver to fix this quickly, but it turned out that this was only the beginning. Further, for some reason, there was no connection with the robot and it was not there for quite some time, so we lost the first 2 minutes from the main time. Then everything was a little more successful, they managed to complete some missions, some not. My sensor fell out of the bottle safely due to the high center of gravity of the weighting agent. At the end of time, we quickly packed up and dumped from the station. The result of 135 points is not as bad as that of some teams, but they could reach 200,

By and large, all the mistakes were there, a few minutes later they started quite an active discussion, which continued all the way to the hotel and in the hotel itself. Our main mistake was that we did not check everything in advance, that is, we arrived from the hotel and immediately to the start, so there were all sorts of problems, such as bent connectors. Proceeding from this, it was decided the next day to arrive a little earlier, find a table, collect everything there and, in open form, carry it all to the station. Well, various small jambs, such as, for example, underestimating the center of gravity on a conductivity sensor. After all this, we went to the hotel, where someone was left to finish the robot, and the rest went to the store and walk along the lake.

The second attempt, as I said, was scheduled for the third, last day of the competition at 10-30 in the morning. Having got up a little earlier, we arrived at the place and, according to the plan, after having decomposed everything and tested the robot’s working capacity three times, we started. This time we already knew what and how it would be, so we managed to get ready in 3 minutes, the rest of the time we waited for the computer to restart on the control panel. But, nevertheless, calmly waiting for the end of the download and the beginning of the main time, we started to complete the tasks.

The updated conductivity sensor successfully failed in the “hydrothermal source” (salt water tank) and, to my deepest surprise, correctly measured the conductivity of water. Further, everything went quite successfully too: they lifted the anchor, sailed into the ship, lifted a plate with the home port - and so on. They tried to pick up the bottles, but quickly left this venture. The only negative was that it was not possible to correctly measure all the dimensions of the vessel, because of which they could not determine the number of mollusks that had grown on it and lost quite a lot of points. But everything else was done quite successfully and, having managed to pull the robot out of the water at the last moment, they successfully completed the missions. The result of the second attempt is 245 points, a very unexpected result, taking into account the fact that we expected to get at least two hundred points.

The results of two attempts. Someone never got to the second

Our team after the second attempt

In the evening of the same day, the winners of the competitions were awarded. An interesting feature of these competitions is a large number of nominations. Any judge can create his own nomination and choose the winners. It is also interesting that prizes are awarded not only in purely technical nominations, but also in such as the best leader, the team that has overcome the most difficulties, and so on. In general, it was not necessary to have a good robot to take any prize.

We part with the prize for innovation, received last year for 3D vision in the robot. This year, the prize went to the team that organized the device using the Oculus Rift

The results of all tests are not known in advance, so the intrigue persists until the last moment. Although, based on the results of the missions, you can make some assumptions. According to the results of the missions, we were the third, and therefore focused on this place, although the final result could be any. Our team eventually took 3 prizes: in the security nomination, a slightly unexpected, but quite logical result: no one had so many stickers on the robot. The second prize was for the best technical report, many thanks to those who eventually stayed in Moscow, because the technical report was their business. And the third prize - for second place in the overall standings. Also quite unexpectedly, but very nice, our training on all fronts yielded results.

Winning the Best Technical Report nomination

Second place in the overall standings

Victory in the nomination “For Security”

We overtook the team from the Far East: the guys had 280 points for the mission, but the results on the remaining points were slightly worse than ours. In the first place was the team from Jesuit High School. A huge team, people under 25 or more, last year’s winners, scored 255 points for the mission and won the prize for the best poster. The awards took place in a very family atmosphere, the host, one of the organizers of the competition, constantly joked and generally maintained a somewhat informal atmosphere, which really created the impression that we were one big family.

The winner’s numerical advantage

The awards were followed by photographing with various teams, followed by a celebration that was already taking place at the hotel.

Against the backdrop of the Alpena school, the

awards received look good with highlighting.

On the sixth day, we had to drive home. Again 5 hours by car to Detroit, then two flights to Moscow. And then someone went to rest, and someone went to military training.

We unload and rent cars.

The result of the competition was really unexpected for everyone, because the best result of previous years was only 7th place, and this year the number of participants also increased sharply. One way or another, we exceeded our expectations. Of course, something could be done better, and our lag behind the winners was not so big, but even so, for the team that is in such a roster for the first time, such a result is an incredible success. Perhaps the truth is newcomers lucky.

In the end, I would like to say that at the moment we have already begun to design a new apparatus for the next competition. It is planned to make a new robot with new electronics, new rotor motors and generally try to do everything at a higher level. So our center continues to work on preparing for the competition next year.

Obviously, such competitions, and especially preparation for them, provide invaluable experience. Perhaps this is just what is often so lacking in our educational process. Therefore, I am infinitely glad that on that day, six months ago, I gave a positive answer to the question about my participation in the project.

And here is a short video about the preparation and the trip itself: