How to make a dance platform for Dance Dance Revolution yourself

- Tutorial

Hello, dear Khabrovites. I thought about the name of the post for a long time, but in the end I decided, albeit longly, to write the essence in it. Under the cut, we will talk about how to create a good game controller for a rhythm game from scratch, while not spending much. And let the comments periodically slip lately, saying, “Habr is no longer a“ cake ”, I hope you will like my“ recipe ”.

But first, a small introduction, so that everyone understands what will be discussed below. An excellent article from Wikipedia will clarify.

Historically, the game in Russia, Ukraine and Belarus has gained popularity among anime lovers, gradually standing out in a separate sports direction. Gradually, instead of “scumbling” girls, guys appeared near the slot machines, scribbling something intensely in “To Do Lists” discussing the advantages of this or that dance technique and were desperately arguing about choosing the right footwear for the step. Soon the first championships loomed on the horizon.

And here there was a problem. Success in the game directly depended on the number of training sessions. Qualitatively, training was possible only on a slot machine. But since most of the players were of school and student age, only a few could afford full training. After all, everything costs money, and tokens are no exception.

The way out of the situation was obvious: find"Home" version of DDR . Alas, the hopes were not destined to come true. No, home versions existed, but were either of poor quality or could not afford . In addition, delivery sometimes increased the cost of the dance platform itself 2 or more times. And this is in Russia. About Belarus, there was not even a word.

So with this state of affairs I and jsirex , who lived in the glorious city of Minsk, turned out to be . Having not found an adequate option for reasonable money, we decided to build our own dance platformwith manchkin and geisha . The goals have been set ambitious. The dance platform \ rug \ pad should have been:

The design that will be discussed now is the result of two years of joint work. Having retained the original form factor, inside the mat radically changed several times. I would like to share the instructions for building the final version with the community.

For clarity, the assembly process was filmed on video. Therefore, everyone who wants to first see the final result, and only then read the sheet of the text with photos, I ask here:

In the meantime, let's proceed to the assembly.

The time spent on assembling the rug can be divided into two periods: theoretical and practical. The first means the time that you spend on the purchase of the necessary supplies and tools. Under the second is the assembly time itself. If you are not lazy, then alone the mat is assembled in 4 days.

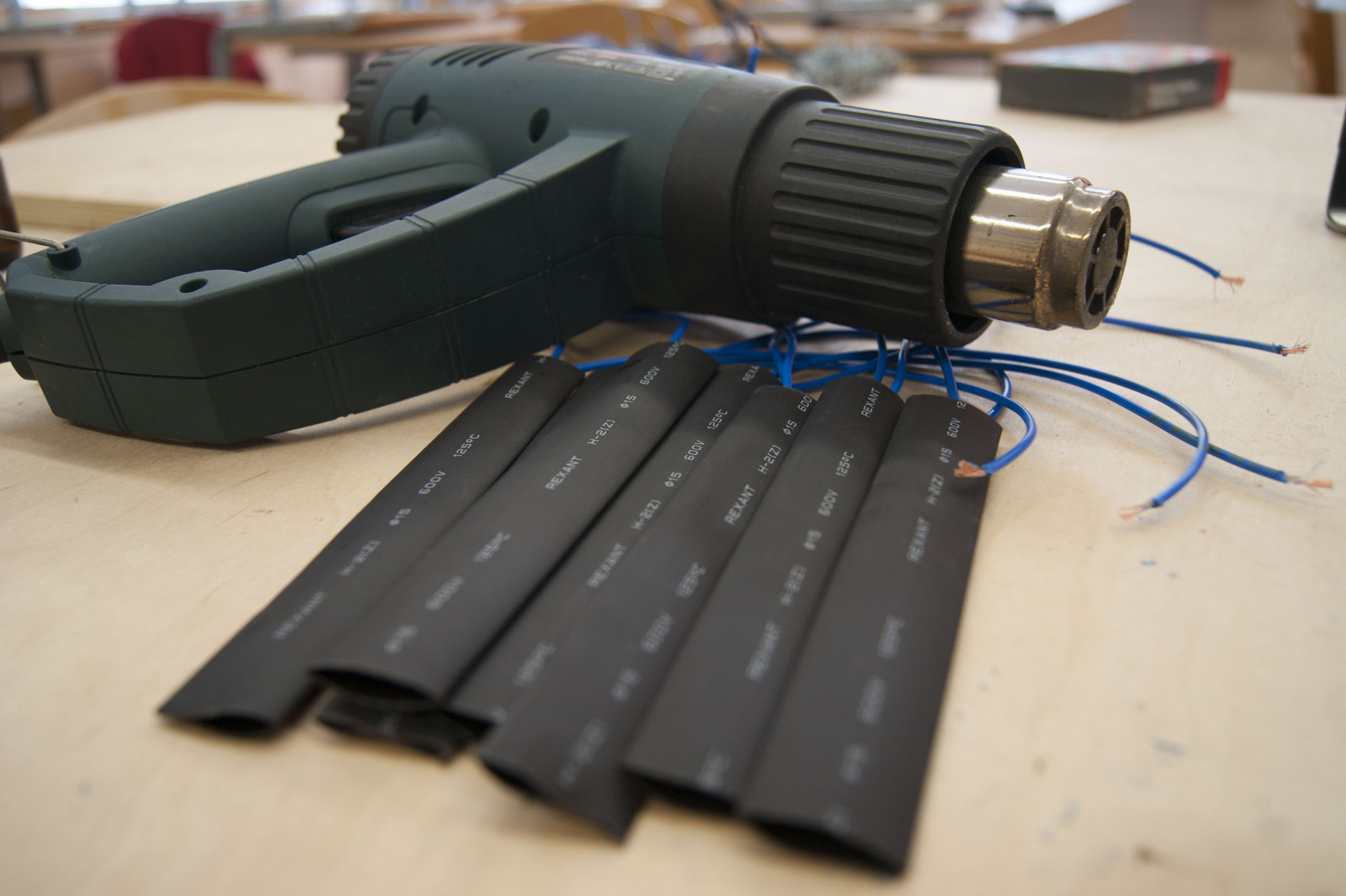

Back to shopping. You will need:

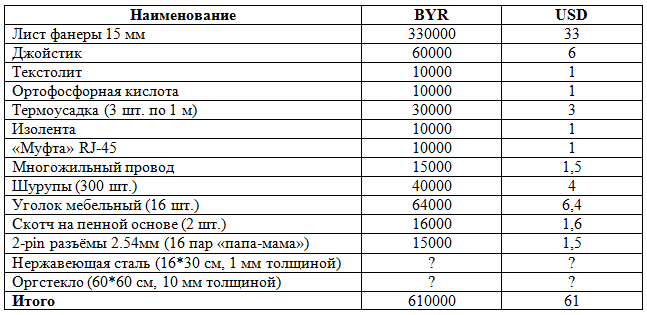

All of the above was in my possession. Therefore, I do not quote prices. The rest had to be purchased. Prices are relevant for Belarus in August 2014. I transferred in USD at the rate of 1 USD = 10 000 BYR.

As you can see, prices for stainless steel and plexiglass are not indicated. In my case, I did not have to buy them - jsirex helped . However, instead of stainless steel, you can take any conductive material (not necessarily metal) with shape memory. For example, textolite.

Plexiglass is more difficult. Sellers usually do not want to sell small pieces. But you can go for a trick. From plexiglass we will need to make 4 buttons 28 * 28 cm in size. Therefore, you can take both the "square" 60 * 60 cm and the "rectangle" 30 * 120 cm. Take the glass back to back or with a margin? Depends on how to cut it:

At this preparatory stage is completed.

You can start cutting plywood. The thickness of 15 mm was chosen by chance. One of the goals, as you remember, is weight. Too light a rug under heavy load will slip on the floor. Too heavy will be inconvenient to transport. For the first reason, do not consider plywood of 10 mm or less. On the second - 18 mm and thicker. In addition, the dependence of the cost of plywood on its thickness, it turns out, is non-linear. Thus, two “finalists” remain: 12 mm and 15 mm. I don’t know how in other cities, but in Minsk 12 mm turned out to be a rarity. Looking ahead, I’ll say that the mat made of 15 mm plywood weighs 18 kg.

Having decided on the thickness of plywood, you need to saw this sheet into "spare parts". From one standard sheet you should get:

You can cut plywood with a hacksaw or a circular saw. In the first case, it will not turn out very smoothly, and in the second it is important to take into account the fact that the circular “will eat” 2-3 millimeters. Therefore, all your sizes should "grow" by the appropriate amount.

Also, burrs will inevitably remain when cutting.

You can get rid of them with sandpaper or with a suitable tool.

Remember, when working with wood there will be a lot of shavings. Lots of. Therefore, make sure that relatives do not drive you out of the house. If everything ended successfully, feel free to proceed to the next step.

Over the years of DDR, jsirex and I have delved into arcade machines more than once.

On the one hand, there was a need (the automatic machine is always put in order before the championship), on the other hand, it was interesting, what did these Japanese invent. All ingenious, as you know, is simple.

The sensor is a simple construction: two conductive plates separated by a dielectric at the edges and locked in the center of the player’s weight. Each button has 4 sensors, one on each side. Thus, regardless of which part of the button the player steps on, pressing always works.

But enough words. Let's proceed to the assembly.

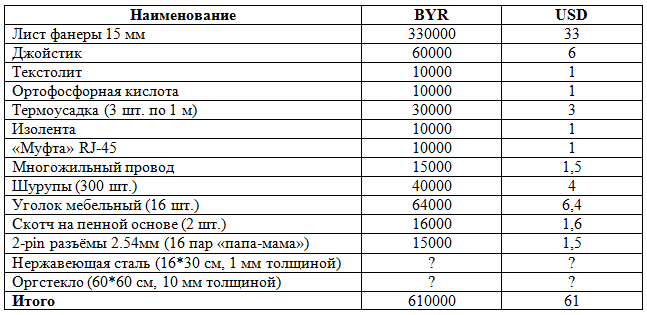

We draw textolite with 1 * 1 cm squares. Stainless steel - 1 * 15 cm stripes. The most difficult thing is to cut the stainless steel. There are no problems if there is a grinder on hand. The only caveat - you need to adjust the size. Instead of 1 * 15 cm there will be 1.1 * 15.1 cm. The Bulgarian will “eat” the excess.

But if you don’t have such a wonderful tool in your arsenal, “dancing with a tambourine” begins. At first I decided to use a dremel. In his arsenal there was just a cutting disc.

However, the stainless steel 1 mm thick wanted to spit on fashionable wheels and cut it off after 8 cm. Therefore, reluctantly, I had to climb over the “analog” instrument - metal scissors.

The stainless steel turned out to be quite tough for them. But still not a single barrel of honey in my memory could do without a fly in the ointment. And this case was no exception.

Scissors cut metal with cheerful curls with burrs. Therefore, at first it was necessary to level them with a hammer (blanks, not scissors) to a sane state.

And then “shave off” the burrs with a dremel. He coped with this task perfectly and without loss of consumables.

In the meantime, the soldering iron is warming up. No, nobody owed me money. The next stage of manufacturing the sensor has just come.

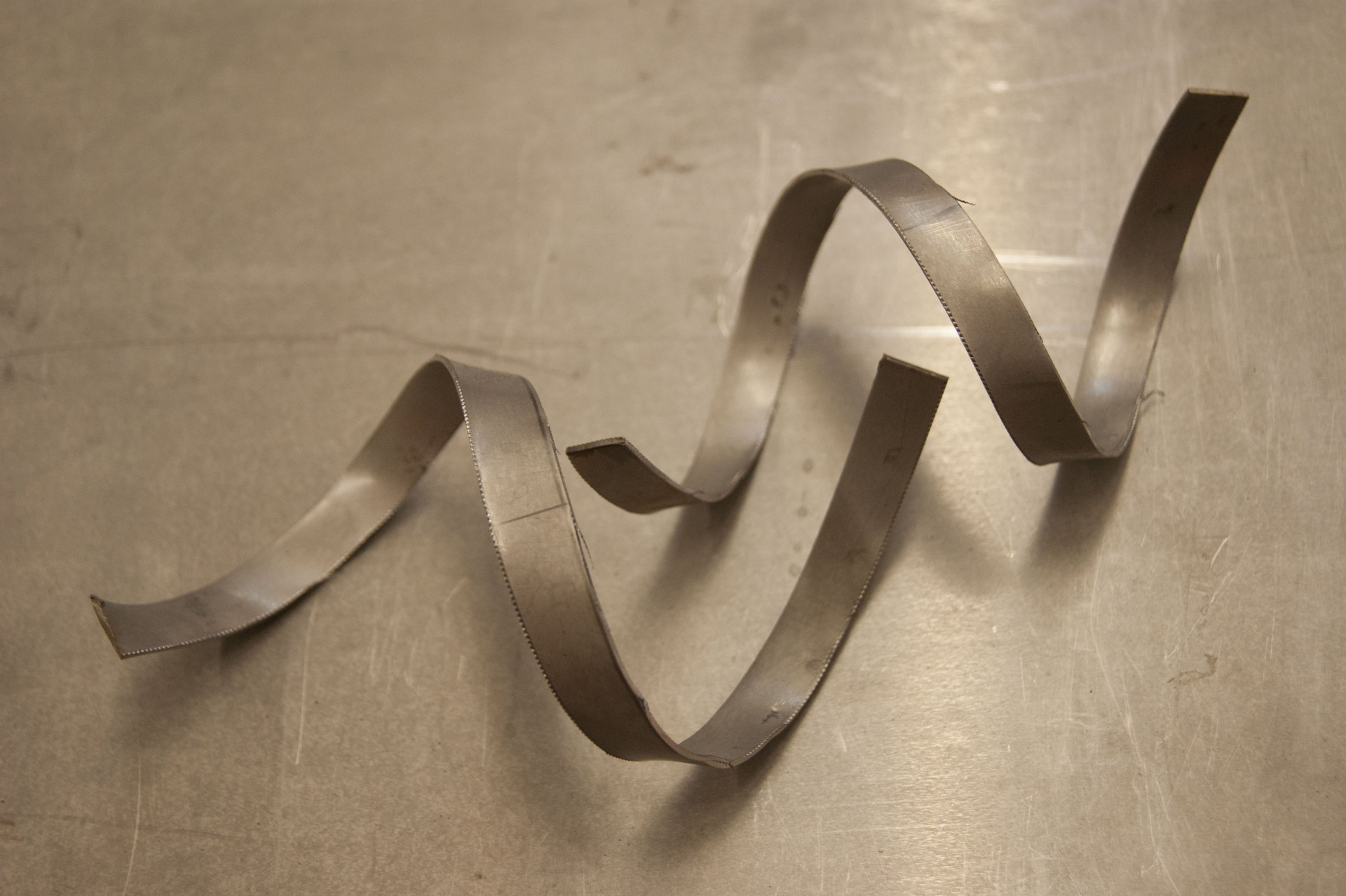

From the point of view of soldering, there are no subtleties. Tinning the wires, dripping orthophosphoric acid on the cleaned edge of the stainless steel strip and soldering.

It may not look very aesthetically pleasing, but you will tear off FIGs.

To the resulting blanks with the help of electrical tape, squares of the PCB are attached. He acts as a dielectric. It is wound on one workpiece from the soldering side, on the other from the “tail” side.

I confess, I used black electrical tape instead of blue, so I can not vouch for the durability of the sensors.

Then two blanks are fastened at the edges with tape. The final version is below.

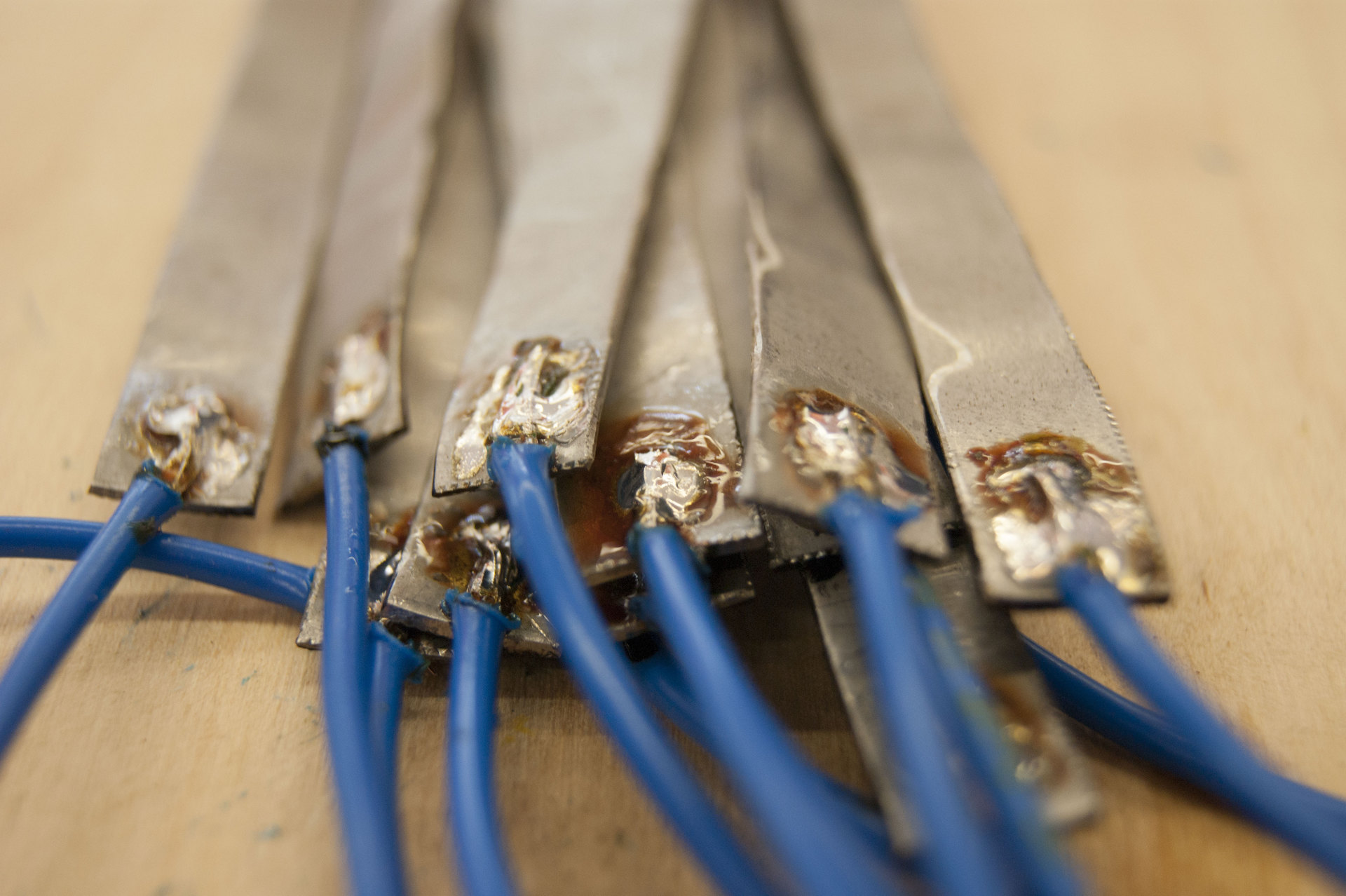

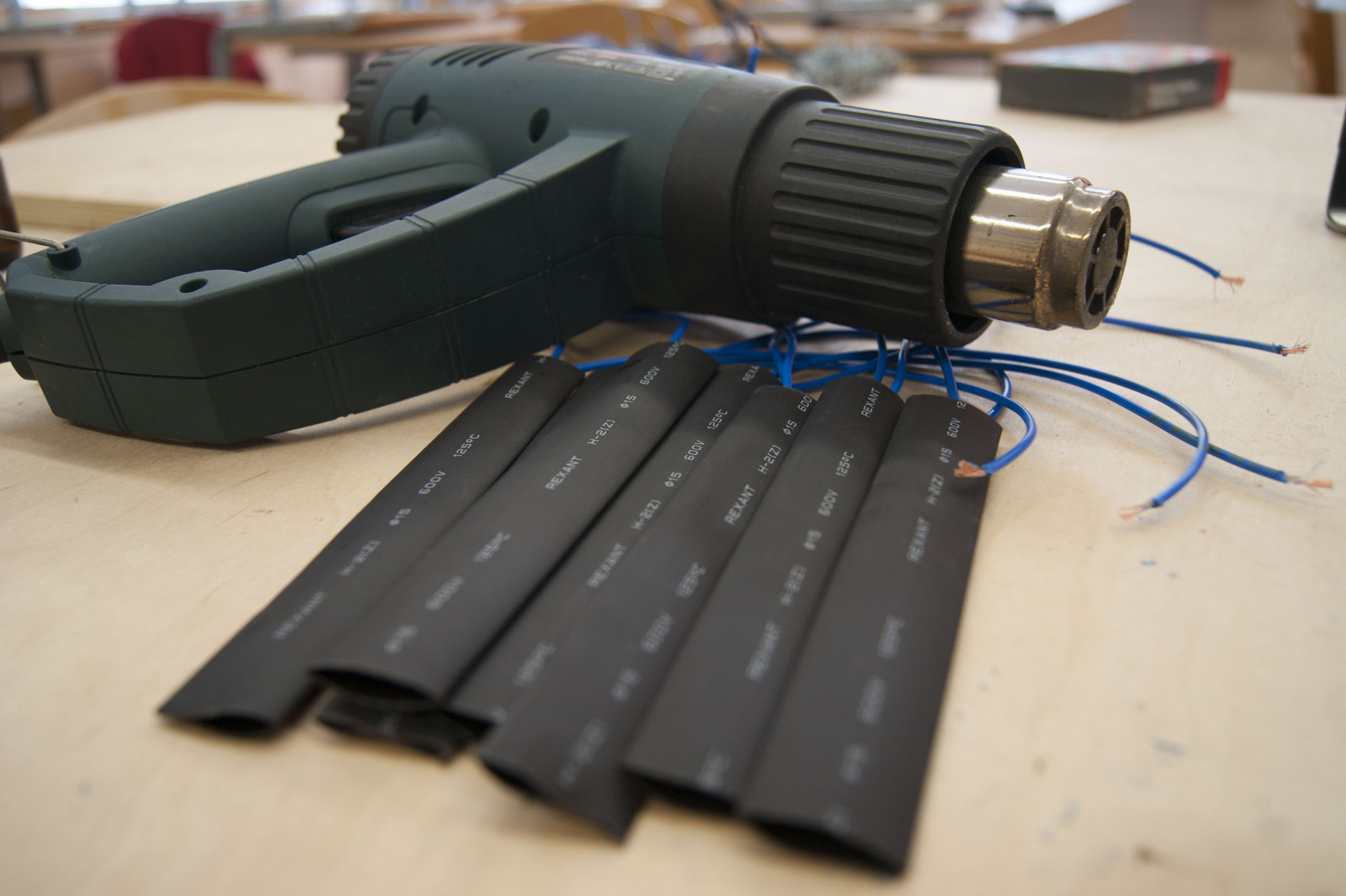

It's time to do it beautifully. To do this, you need heat shrink. With a sensor size of 1 * 15 cm, heat shrink with a diameter of 15 mm is perfect.

Shrink shrinks with an industrial hairdryer. If there is no hairdryer, a gas stove will do. The desired effect will be achieved. A bonus is the smell of burnt hair. By the way, if you slightly warm up the “tail” of the sensor, and then quickly clamp it with pliers or a screwdriver, you get a practically sealed case. This point is in the video.

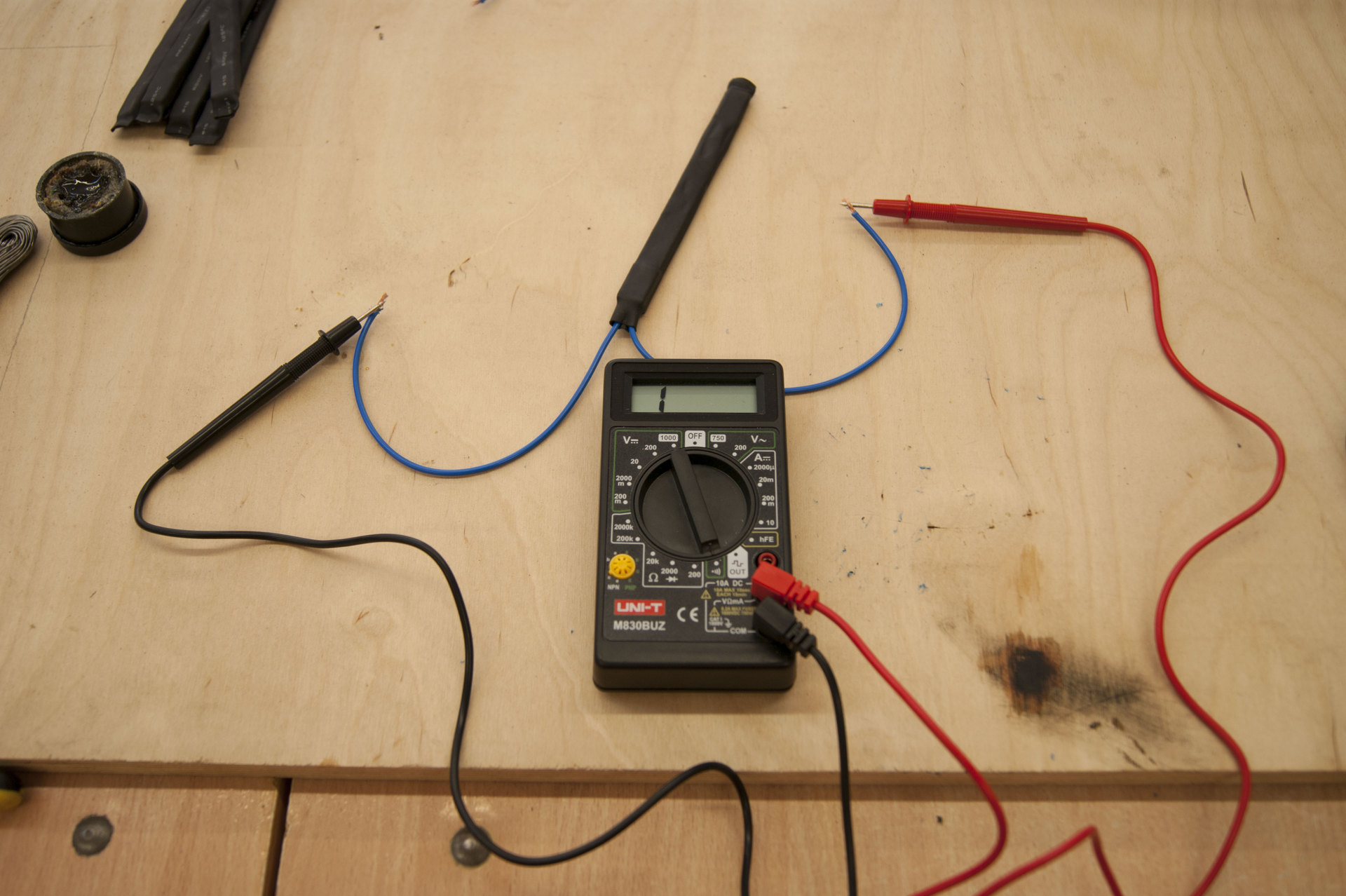

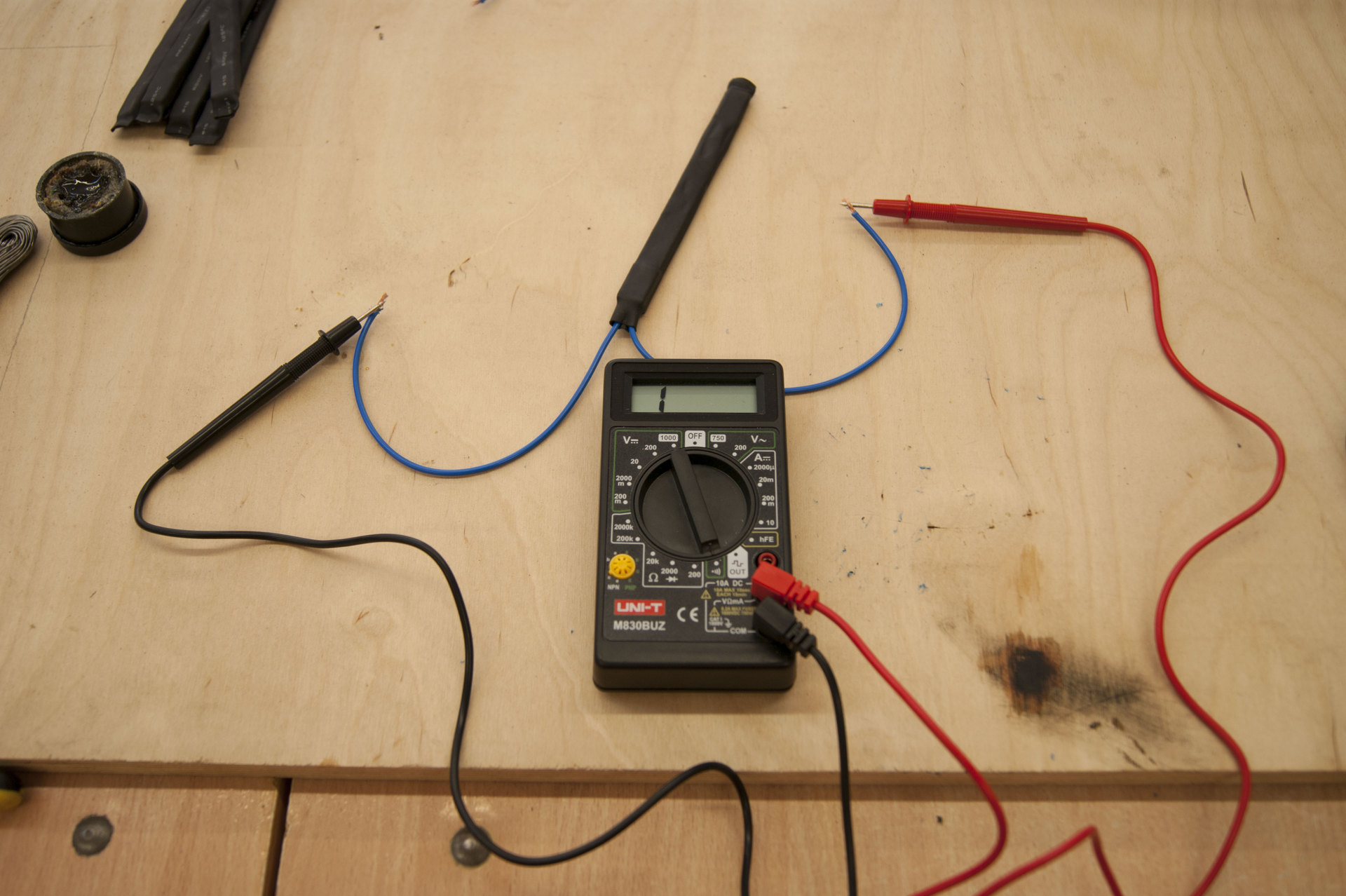

Just in case, the fruits of labor are checked by a tester. In a free state of contact, of course, should not be.

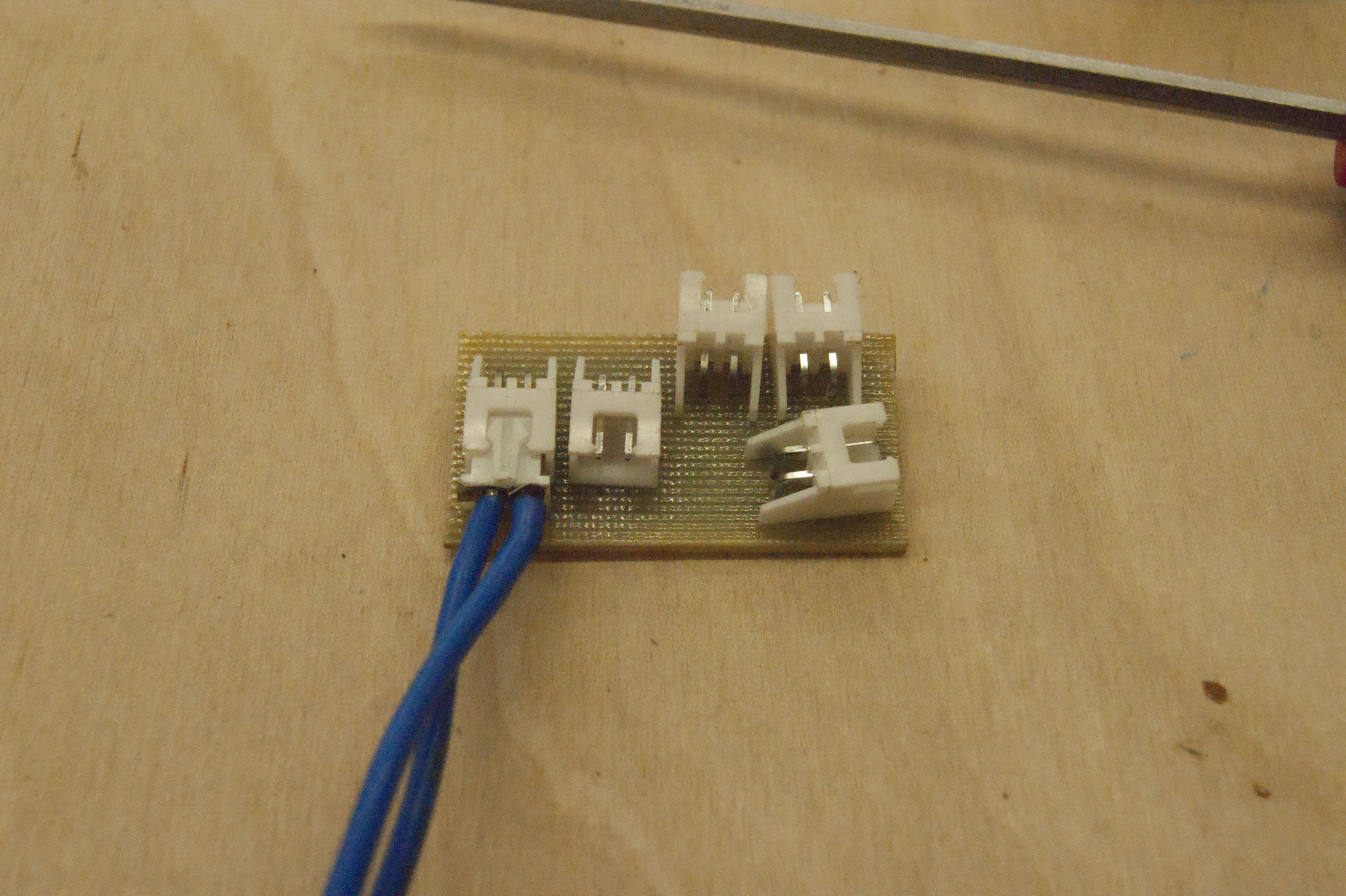

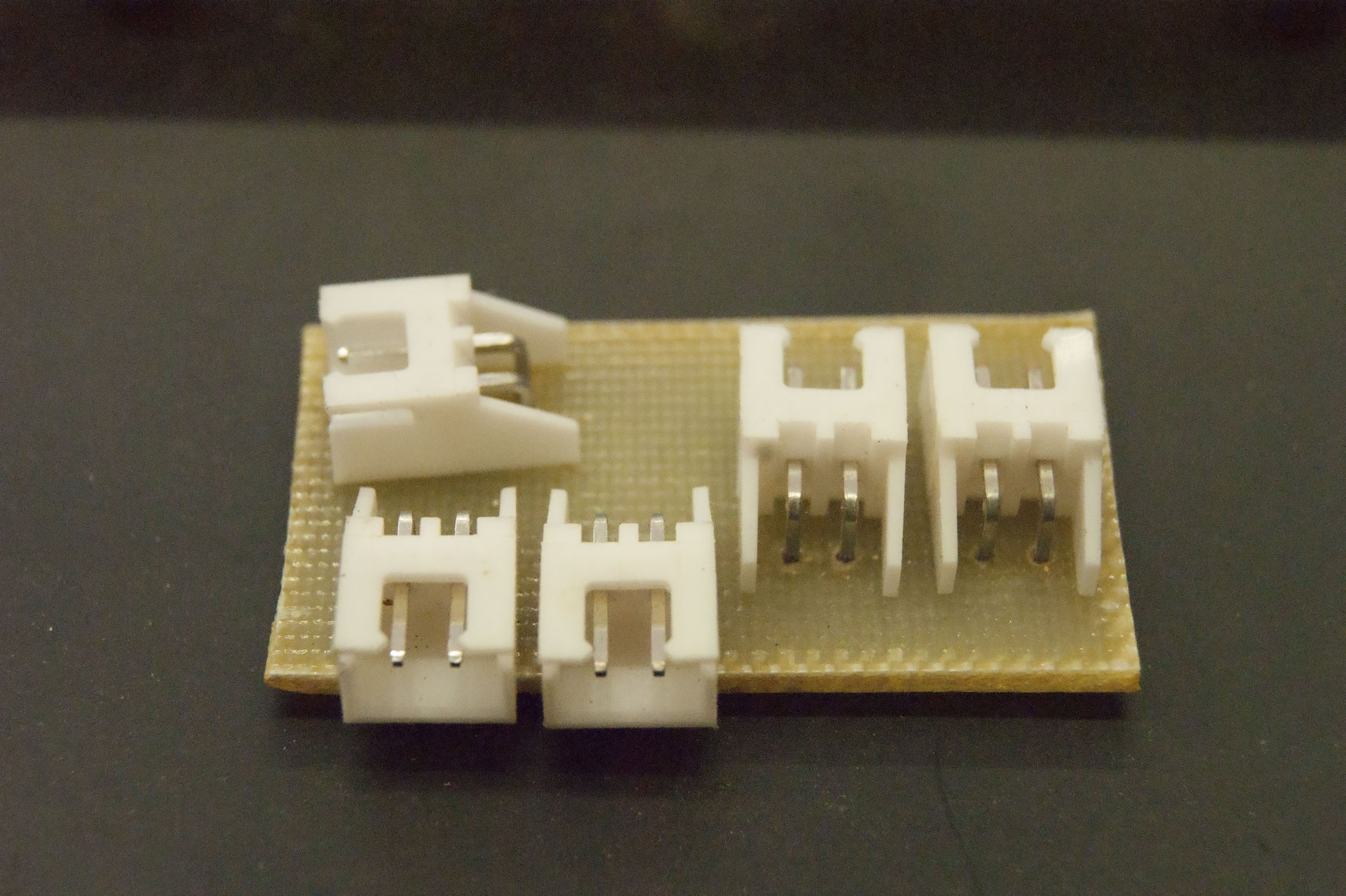

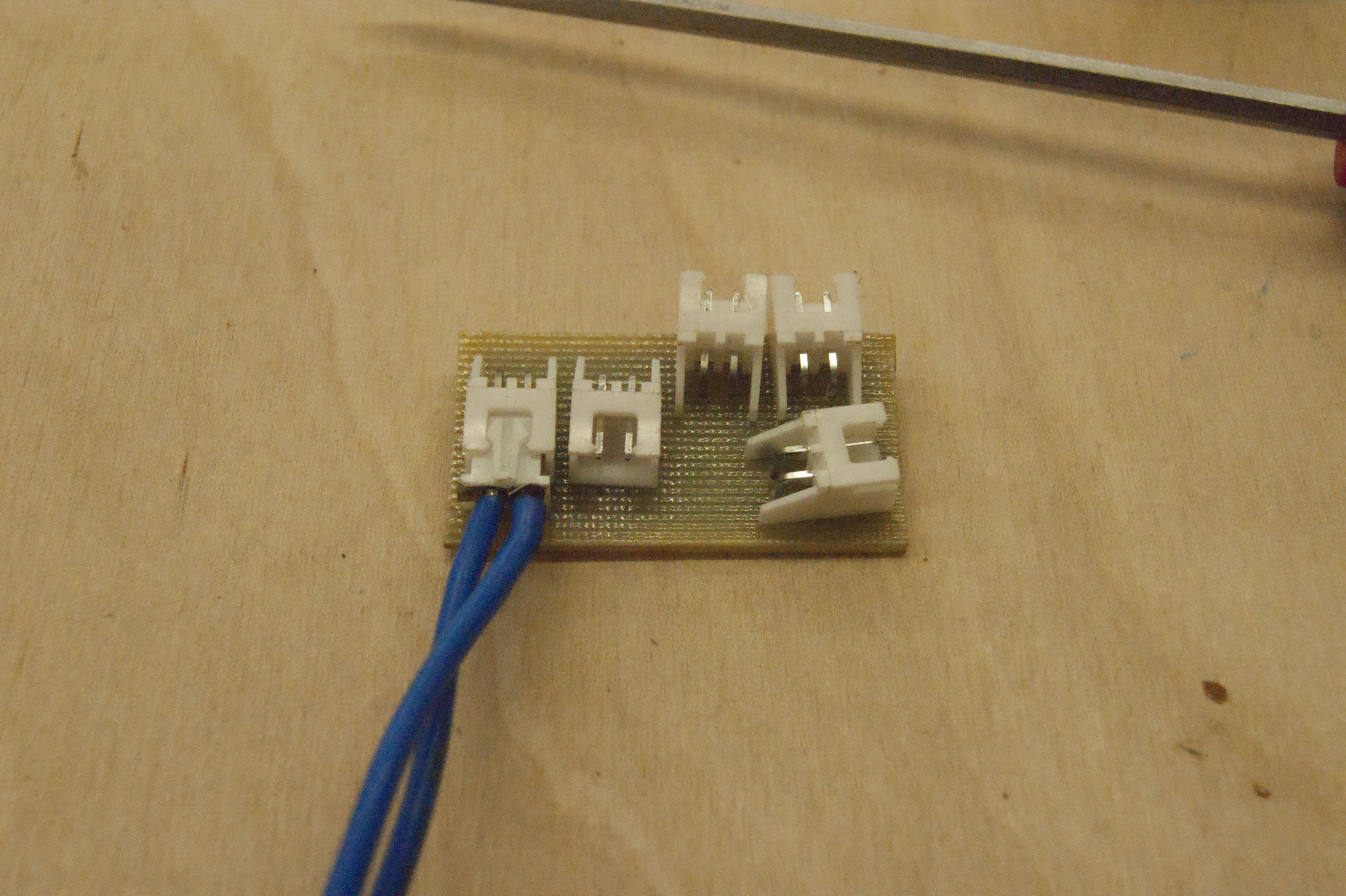

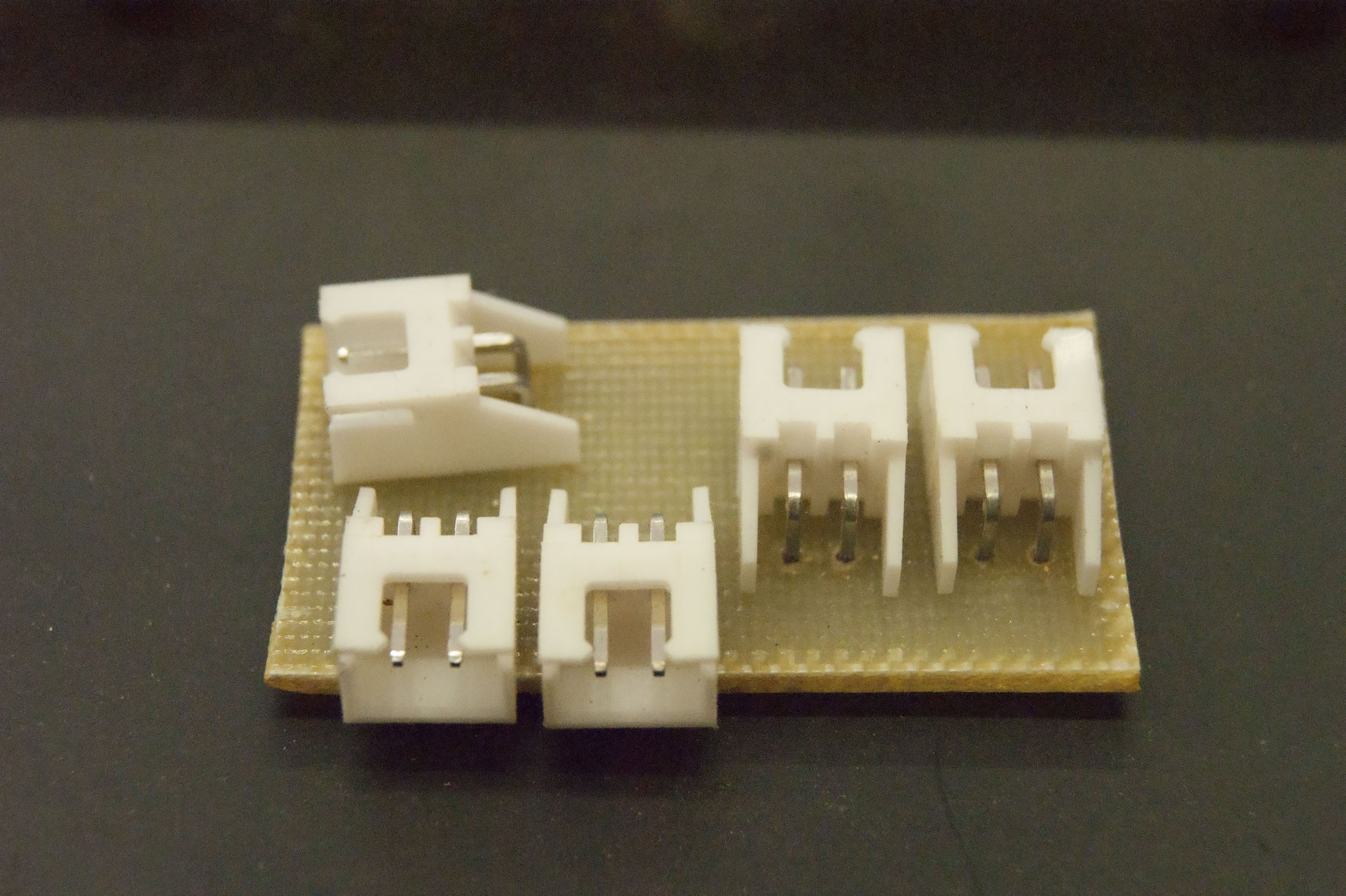

Now it’s the turn of the dad-mom connectors.

We solder something (to be honest, I do not know what it is called correctly) on the free ends of the wires. Here's an important note. If you have a thick stranded wire, it makes sense to bite part of the veins. In other words, do not do as shown in the photo below, do not leave all cores.

The message is simple: you can solder, but then you can’t insert the "father" in the "mother", because there will be no free space.

A correctly made sensor is moderately beautiful and beautiful.

In addition, it does not experience any problems when connecting to the board.

A few words about the board. To be honest, from personal experience I can say that it is not necessary to fence a garden with connectors and boards. You can take all the sensors in the button into a “twist”, fill it with solder, and then hot-melt adhesive. And such a design will work fine. At least the first samples of rugs still work, and it has been already about 6 years.

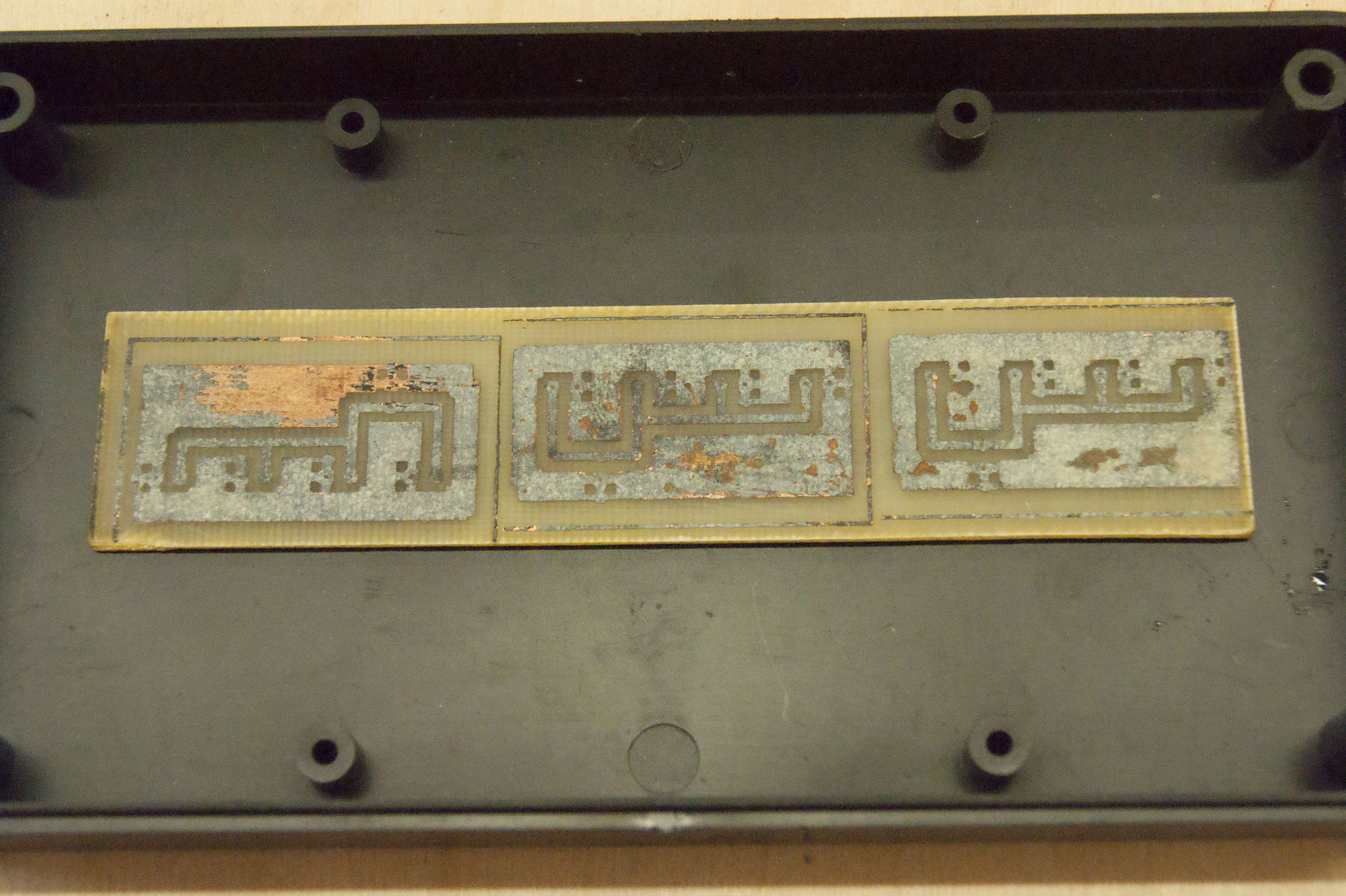

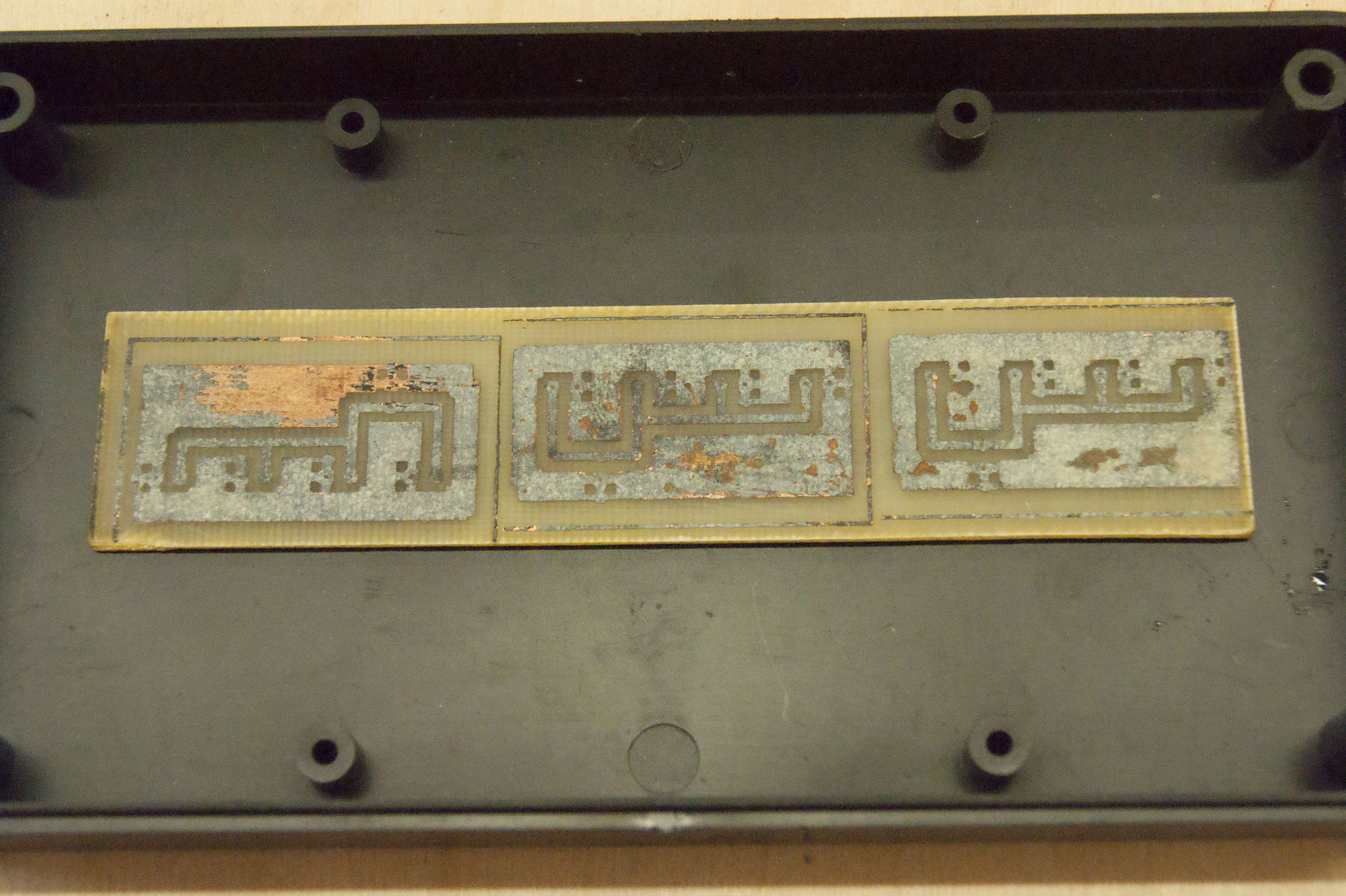

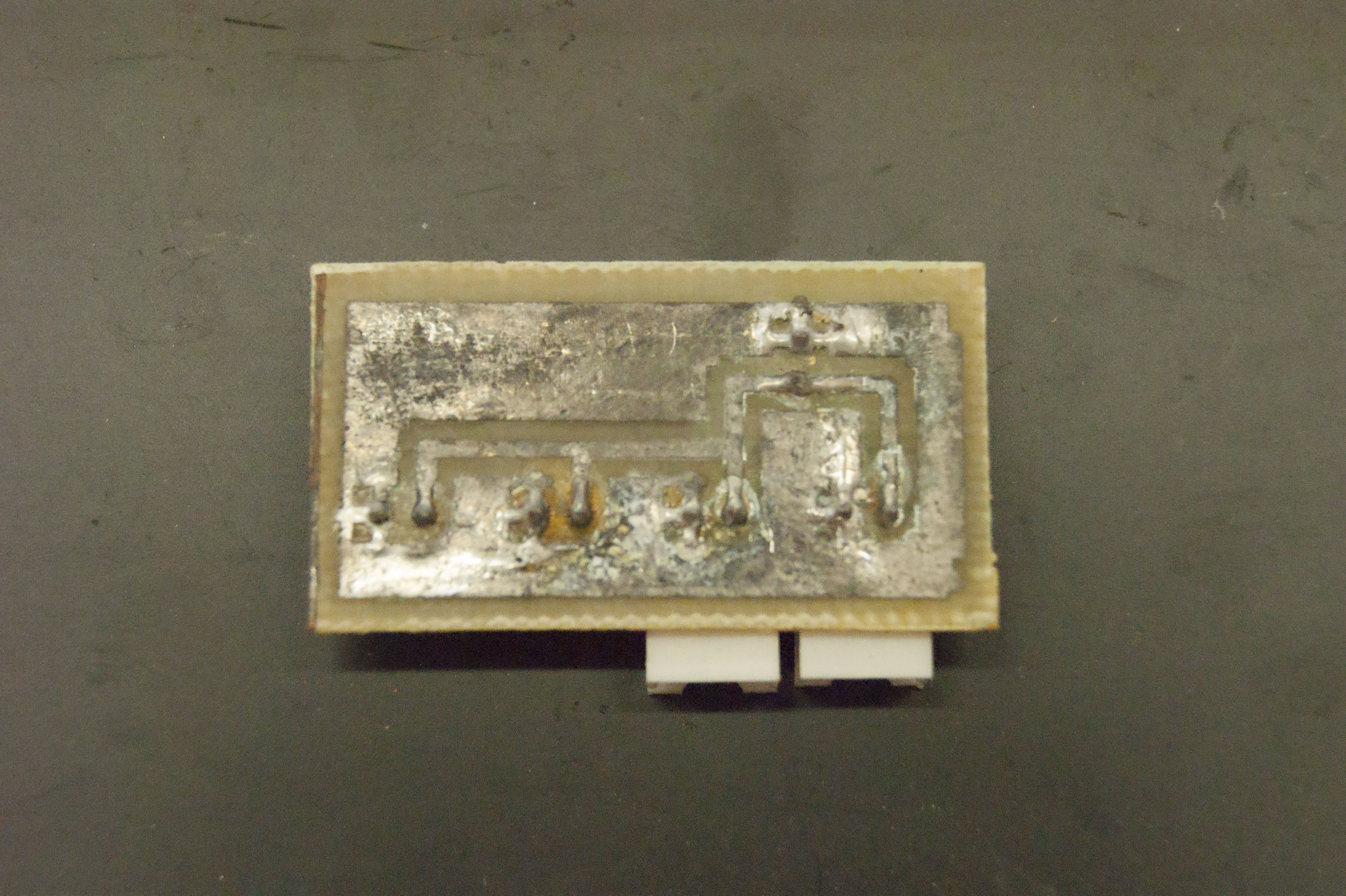

But back to the boards. They are etched according to the well-known method ofcarrots and sticks of the printer and iron. After etching, they have the following form:

After cutting, at least strategic holes are drilled in strategic places with a millimeter drill.

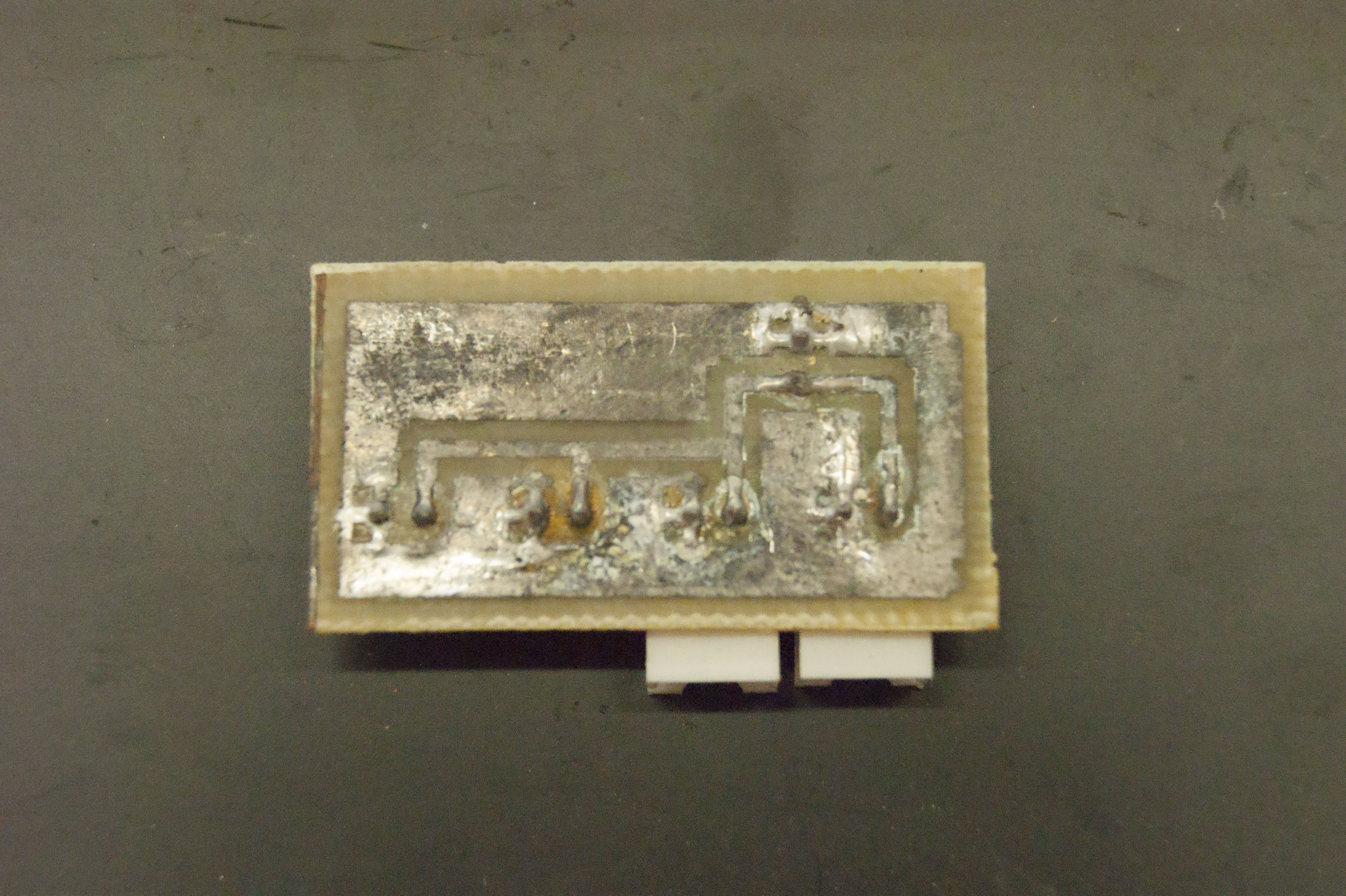

As a result, after soldering, it turns out even beautifully. Back view.

Front view:

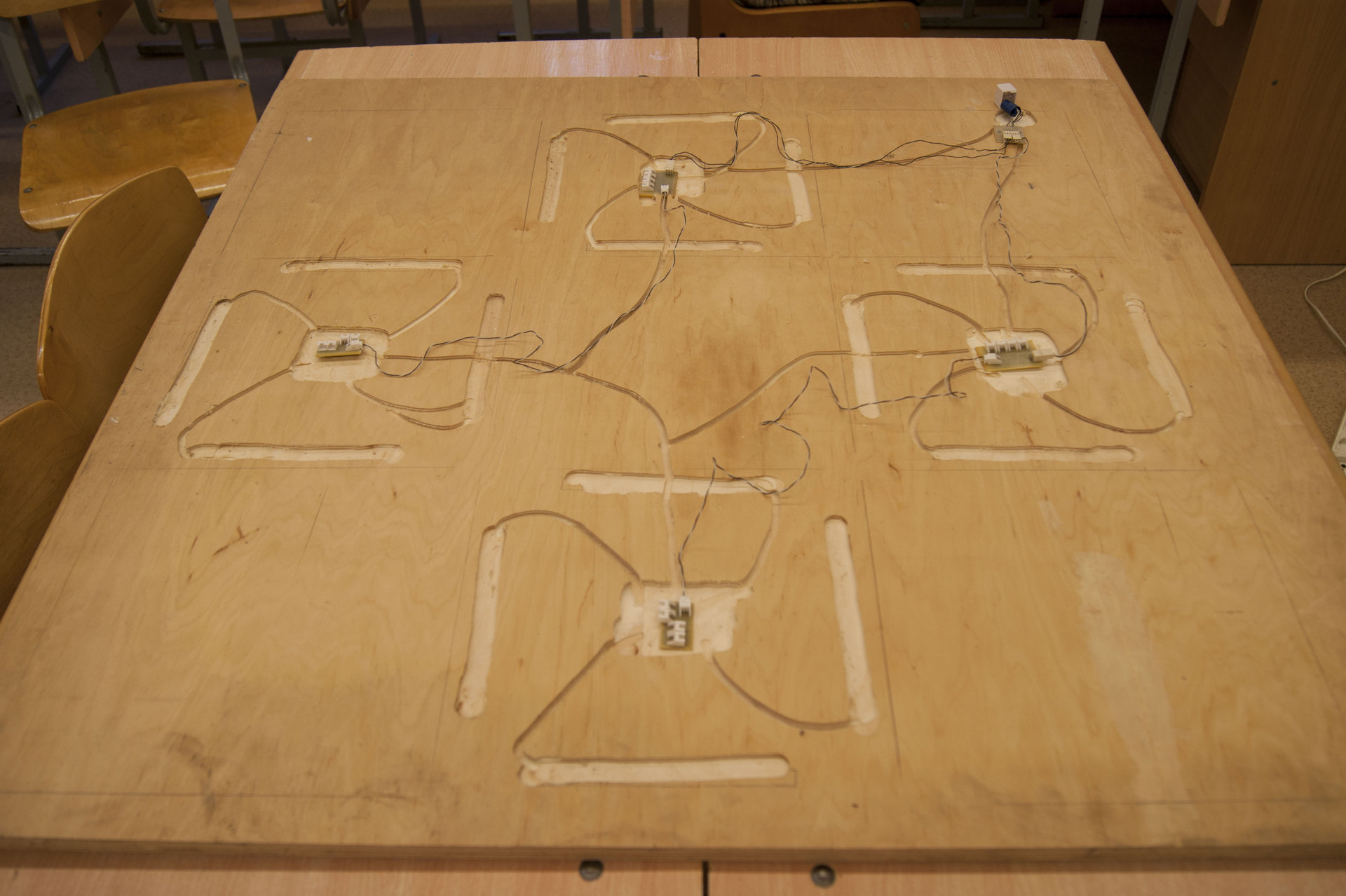

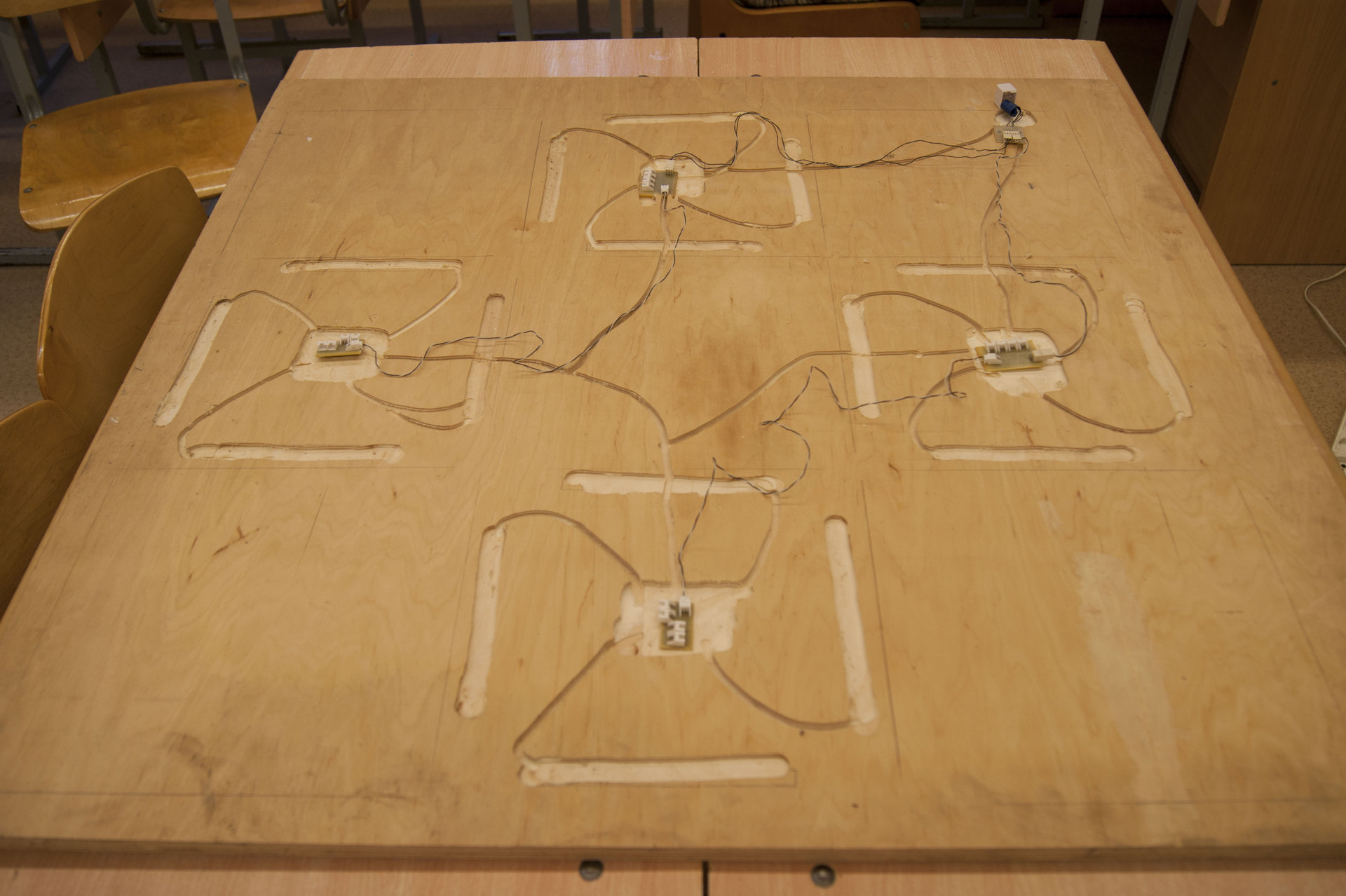

And so we came close to the wiring.

Meticulous readers will consider the complex option presented in the photo above. I’ll tell you about a simplified version, implemented through a twisted pair cable.

It all starts with a “sleeve” with an RJ-45 connector. It has 8 outputs, therefore there are 8 wires to it. Choose 4 “pluses” and 4 “minuses”. Since the "minus" is common - we twist 4 wires into one. Believe it or not, twisted pair cable also contains 8 wires. They are divided into "pros" and "cons" in exactly the same way. For example, I assign all colored ones to “minuses”, and all white-colored ones to “pluses”. Ultimately, 1 “+” and 1 “-” should come to each button in the mat.

To preserve the wiring, it should not be laid on the basis of ground, but according to the grooves made in it in advance. There are 2 ways:

I went in a modified second way. I didn’t have a milling machine, but I didn’t really want to buy 1 time. But there was a dremel with a set of sundries. Among other things, universal drills were found there. Their feature is sharpening. The drill can function as a milling cutter. The process was filmed in the video, so it makes no sense to describe in words. Better to see once.

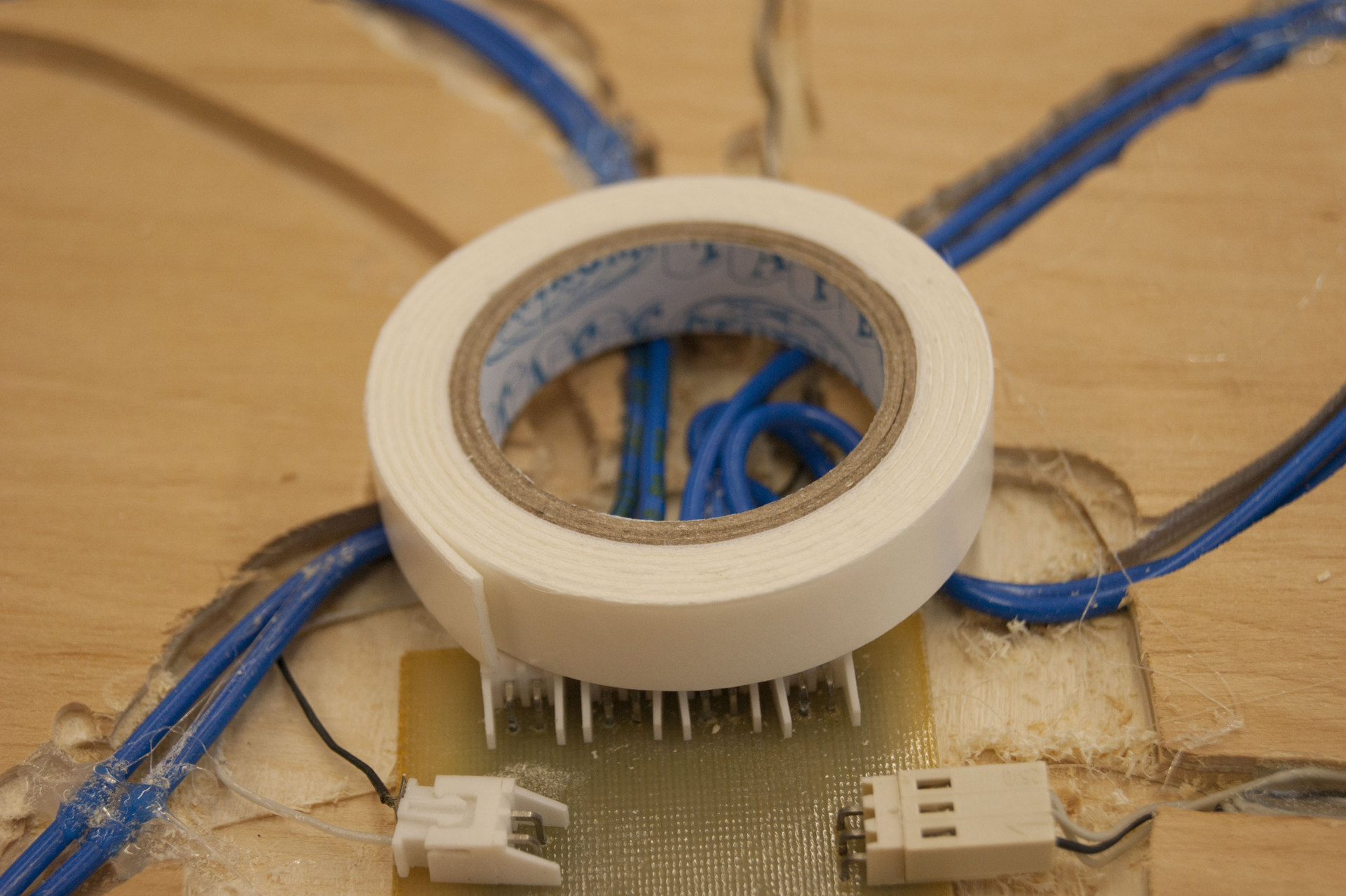

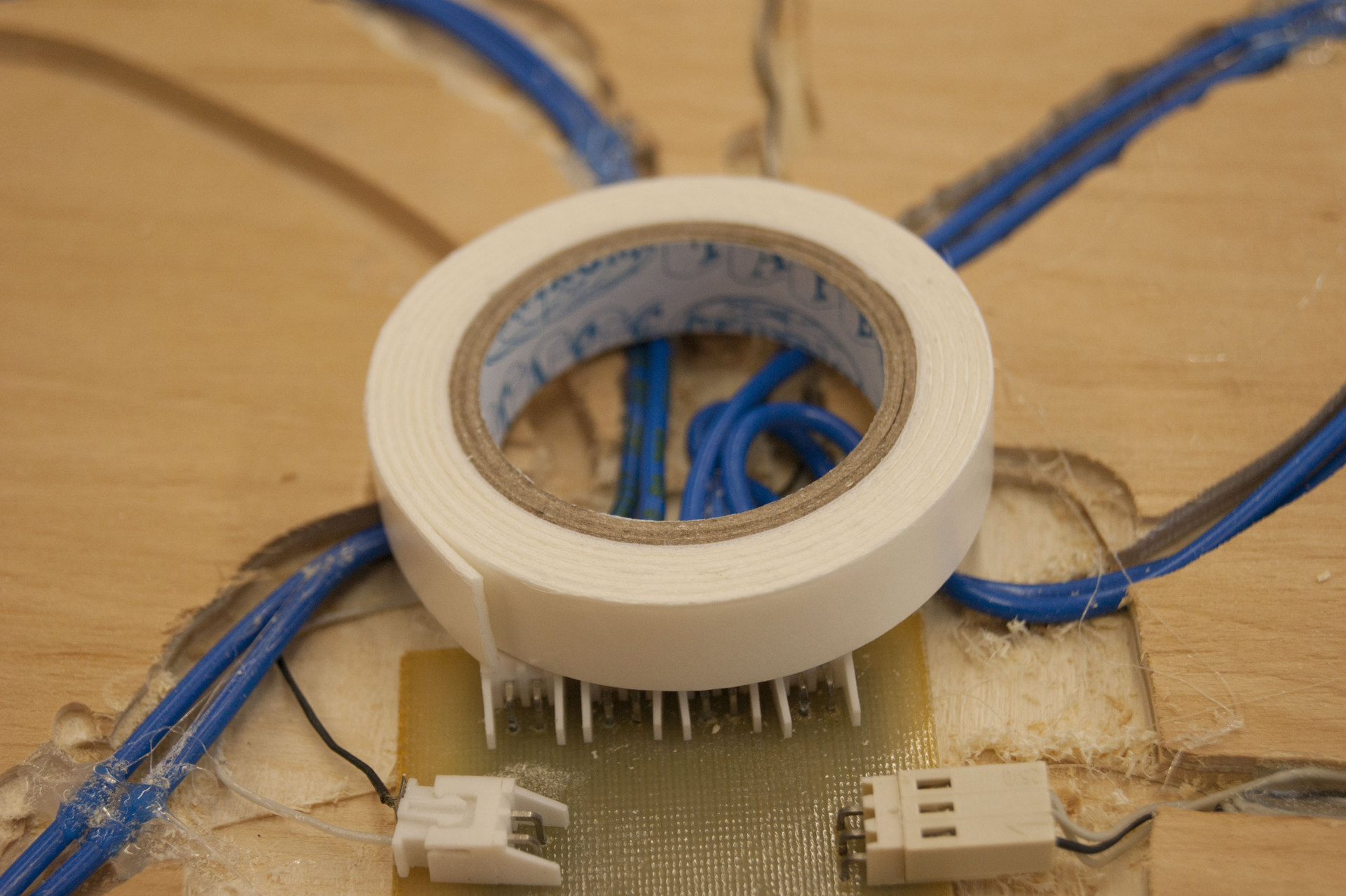

When all the grooves are sawn, it is time for hot melt. The piece is extremely useful for minor quick repairs. Using a thermal gun, we lay the wiring by gluing the sensors. Do not forget to periodically “ring” the structure, so that later you do not have to disassemble the finished mat to the base.

Well, the light is already visible at the end of the tunnel. The finish line is the assembly. Remember 5 wooden buttons, 4 plexiglass and 4 rails? It is their time.

It is curious that no matter how you try to cut everything evenly, no matter how straight and square the workpieces seem to you, at the assembly stage you will be haunted by a feeling of universal curvature and plainness. Do not worry, this is the paradox of the curvature of space-hands-time. It is still impossible to fix it without an additional 7 measurements, so reconcile.

Although no, there are still little tricks. If we assume that all the buttons and slats are a little crookedly sawn, then there is a chance to assemble them in such a combination when everything comes up straight. In general, take it and start trying. When the final arrangement is found, sign on the back of the button its place and direction. For example, LN is the lower left, C is central.

It’s better to start building this ikebana from any angle. As soon as it turns out - you make money on self-tapping screws. Plexiglass is not necessary to profit from self-tapping screws.

To prevent plexiglass from falling out, we fix it with furniture corners. Nuance: the corners in height are more than necessary. There are two options:

I chose the second option, having drilled a dremel.

During assembly, do not forget to ring the structure.

Finally, the most important component without which nothing will work is adhesive tape on a foam basis. You can laugh, but it is. Even in the original Japanese arcade machines, we found it.

It is glued in small strips of 3-4 centimeters in length in the center of each sensor. Since we did the sensors ourselves, and did not buy them at the factory, several layers may be needed. Usually 2-3. Ultimately, the button should be pressed with some effort. Not by touch, but by effort! It is important!

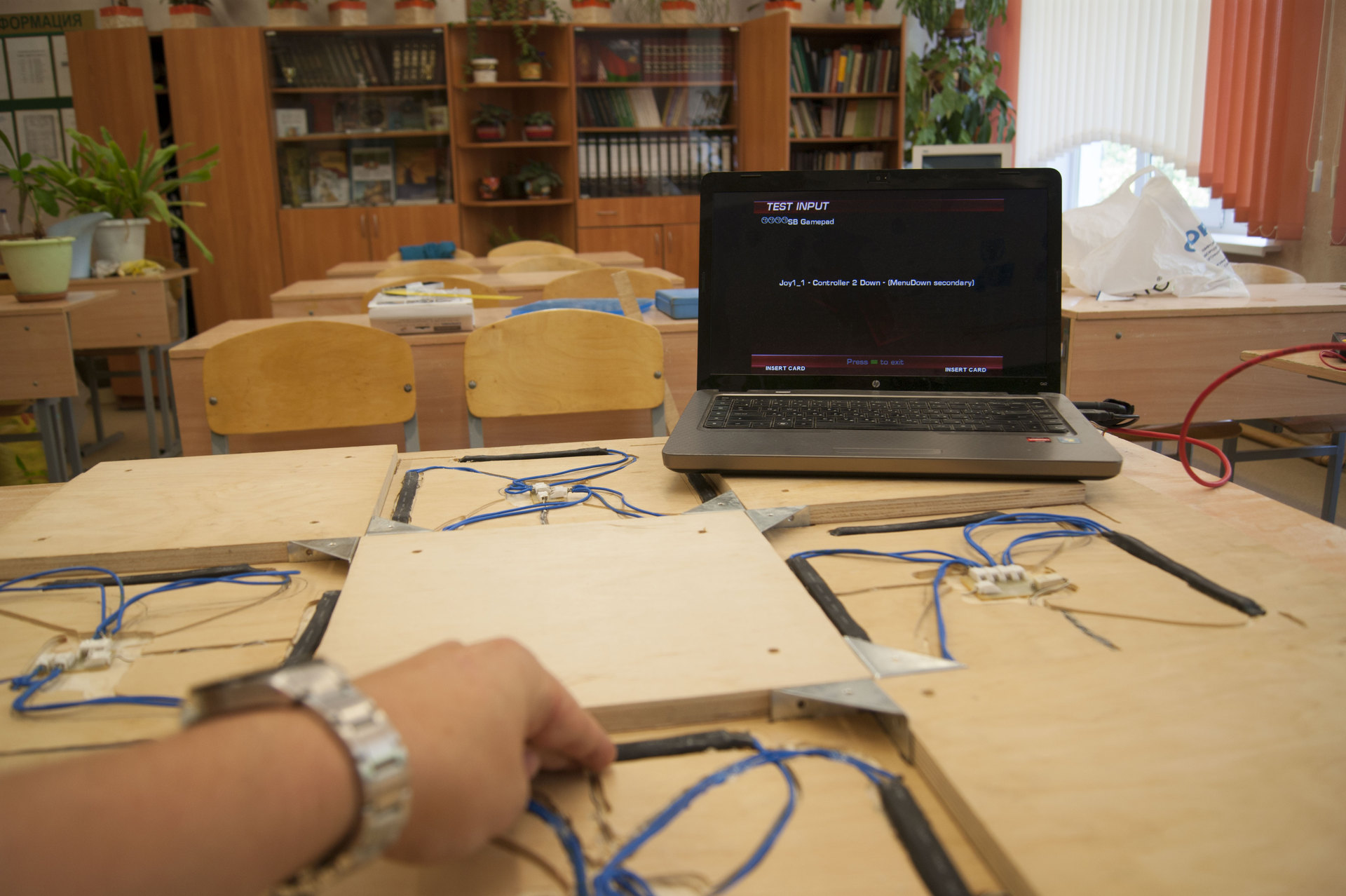

In parallel with the assembly of the rug, its connecting link with the computer is also assembled. Since Windows does not understand the ЕПРСТ \ ЕКЛМН protocol, you have to "make friends" with the computer in the traditional way, that is, via USB.

For these purposes, the cheapest gamepad is bought. On his board and to solder the end of the twisted pair. Just in case, I recall the order.

All this has already been done. Further.

So, we solder to the board as follows.

As you can see, the “pluses” are soldered to the action buttons. The "cons" are twisted-soldered together and soldered to the "ground".

In principle, everything is ready. But you can bring beauty. For example, push the board into the case. I bought it on the ruins of the radio market. True, then it turned out that these were just two covers that were not intended to be connected at least in the likeness of something whole. I had to grind a little.

In general, it turned out sane. With the help of sandpaper for dremel, he removed the excess, and with the help of a milling cutter he made a recess under the wire.

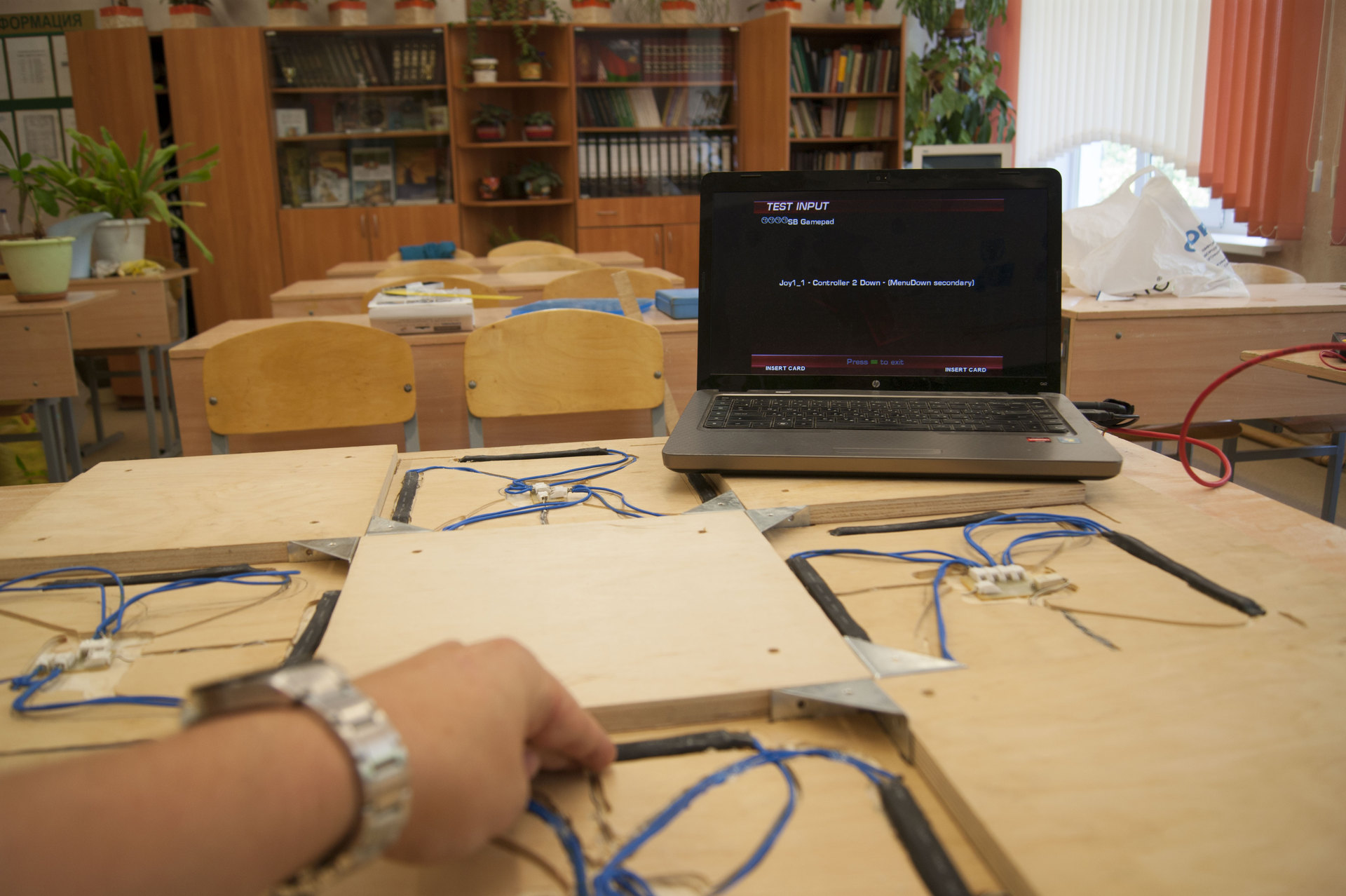

Finally, all parts of the mosaic are ready and you can connect the mat to the computer for testing in the game.

A few words about her. To play on a computer, good people wrote a DDR arcade machine simulator calledStepmania . Then no less kind people based on Stepmania created a modified version - In The Groove (ITG). It is with her, and more precisely with the OpenITG project, that I work. Download distributions here . You can compile it yourself from source . In general, setting up the game, downloading tracks and even creating your own is a topic for a separate post. If the community is for, then let me know in the comments. In the meantime, we return to the rug.

The final view of the patient.

You can do a lot on such a rug. Unfortunately, I’ve been out of shape for a long time and on the video I give out only languid fluttering. But once it was like this:

It is impossible not to notice that the appearance of the rug is not aesthetic. It doesn’t matter. Firstly, it can be painted.

Wooden parts are unscrewed and painted. Plexiglas is painted on the inside.

Secondly, if you do not want to work with paint, you can print stickers.

You come up with a drawing from the calculation of 9 squares 29 * 29 cm. I was not mistaken, the buttons are 28 * 28 cm, and the stickers are larger. But do you remember that the buttons are not quite square?

That's all. Questions, comments and suggestions are welcome.

Content

- What is the post about

- Preparatory stage

- Chronicles of the bark beetle (marking and milling)

- Solder me, solder me completely (make sensors)

- Holy couple (make wiring)

- Slap and production (assembly)

- USBsexual (friends dance platform with computer)

- What's next? Instead of totals.

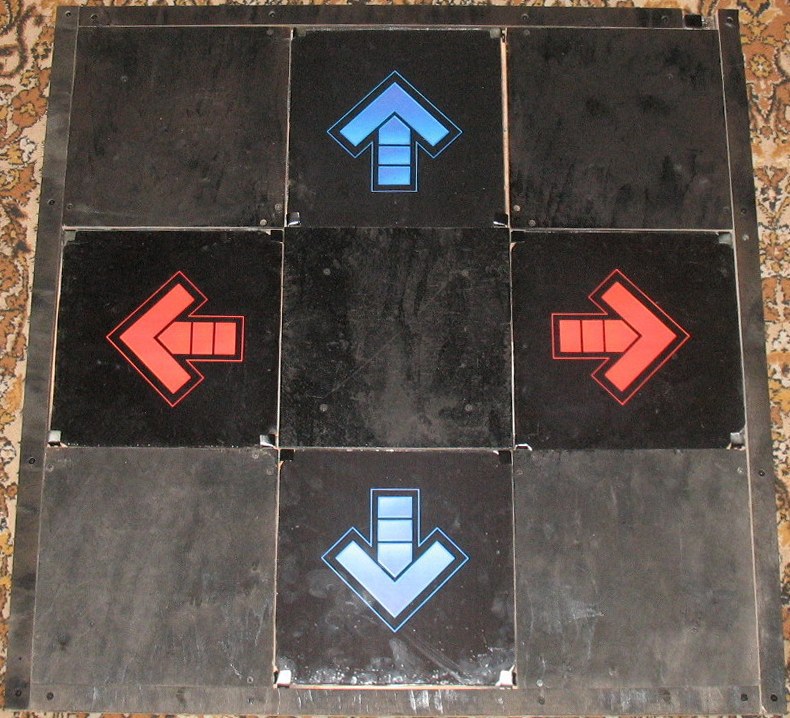

What is the post about

But first, a small introduction, so that everyone understands what will be discussed below. An excellent article from Wikipedia will clarify.

Dance Dance Revolution (DDR) is a music video game series from Konami Digital Entertainment, Inc, also known as the Dancing Stage. The game takes place on a dance platform with four panels: “up”, “down”, “left” and “right”. During the gameplay, a sequence of arrows moves around the screen that matches the musical rhythm of the song being played. The player must press the corresponding panels with his feet to the music at the moment when the arrows coincide with the translucent stencil, usually located at the top of the screen. Each time you press the player correctly, the level of the “life scale” is gradually replenished. For each miss, a certain amount of energy is taken from the scale. A round is considered to be lost if the player at least once during the passage of the song allowed the level of the “life scale” to drop to zero.Well, if you explain clearly, it is better to use the services of Jean Renault and the film "Wasabi".

Historically, the game in Russia, Ukraine and Belarus has gained popularity among anime lovers, gradually standing out in a separate sports direction. Gradually, instead of “scumbling” girls, guys appeared near the slot machines, scribbling something intensely in “To Do Lists” discussing the advantages of this or that dance technique and were desperately arguing about choosing the right footwear for the step. Soon the first championships loomed on the horizon.

And here there was a problem. Success in the game directly depended on the number of training sessions. Qualitatively, training was possible only on a slot machine. But since most of the players were of school and student age, only a few could afford full training. After all, everything costs money, and tokens are no exception.

The way out of the situation was obvious: find"Home" version of DDR . Alas, the hopes were not destined to come true. No, home versions existed, but were either of poor quality or could not afford . In addition, delivery sometimes increased the cost of the dance platform itself 2 or more times. And this is in Russia. About Belarus, there was not even a word.

So with this state of affairs I and jsirex , who lived in the glorious city of Minsk, turned out to be . Having not found an adequate option for reasonable money, we decided to build our own dance platform

- cheap;

- durable

- not too heavy (light) and not too bulky.

- The accuracy of clicks and sensations from the game should not differ from the arcade machine.

The design that will be discussed now is the result of two years of joint work. Having retained the original form factor, inside the mat radically changed several times. I would like to share the instructions for building the final version with the community.

For clarity, the assembly process was filmed on video. Therefore, everyone who wants to first see the final result, and only then read the sheet of the text with photos, I ask here:

In the meantime, let's proceed to the assembly.

Preparatory stage

The time spent on assembling the rug can be divided into two periods: theoretical and practical. The first means the time that you spend on the purchase of the necessary supplies and tools. Under the second is the assembly time itself. If you are not lazy, then alone the mat is assembled in 4 days.

Back to shopping. You will need:

- Clamps (2 pcs);

- Screwdriver;

- Wood drill;

- Saw;

- Dremel

- Scissors for metal;

- Tester;

- Square;

- Pencil;

- Screwdriver;

- Soldering iron;

- Solder;

- Rosin;

- Twisted pair;

- Hammer

- Industrial dryer;

- Glue gun.

All of the above was in my possession. Therefore, I do not quote prices. The rest had to be purchased. Prices are relevant for Belarus in August 2014. I transferred in USD at the rate of 1 USD = 10 000 BYR.

As you can see, prices for stainless steel and plexiglass are not indicated. In my case, I did not have to buy them - jsirex helped . However, instead of stainless steel, you can take any conductive material (not necessarily metal) with shape memory. For example, textolite.

Plexiglass is more difficult. Sellers usually do not want to sell small pieces. But you can go for a trick. From plexiglass we will need to make 4 buttons 28 * 28 cm in size. Therefore, you can take both the "square" 60 * 60 cm and the "rectangle" 30 * 120 cm. Take the glass back to back or with a margin? Depends on how to cut it:

- Manually using a special knife for cutting plexiglass (similar to a stationery knife). Glass is taken exactly in size. The cutting process resembles working with a glass cutter. This method is very budgetary, but due to inexperience, you can badly break off the workpiece and nullify all the savings.

- Laser cutting Cuts perfectly in size, but is expensive. The peculiarity of the laser operation requires a "minimum indentation" from the edge of the workpiece. That is, in order to cut the button 28 * 28 cm, you need a blank of at least 28.5 * 28.5 cm.

At this preparatory stage is completed.

Chronicles of the bark beetle (marking and milling)

You can start cutting plywood. The thickness of 15 mm was chosen by chance. One of the goals, as you remember, is weight. Too light a rug under heavy load will slip on the floor. Too heavy will be inconvenient to transport. For the first reason, do not consider plywood of 10 mm or less. On the second - 18 mm and thicker. In addition, the dependence of the cost of plywood on its thickness, it turns out, is non-linear. Thus, two “finalists” remain: 12 mm and 15 mm. I don’t know how in other cities, but in Minsk 12 mm turned out to be a rarity. Looking ahead, I’ll say that the mat made of 15 mm plywood weighs 18 kg.

Having decided on the thickness of plywood, you need to saw this sheet into "spare parts". From one standard sheet you should get:

- base dimensions 90 * 90 cm;

- 5 buttons 28 * 28 cm in size;

- 2 slats measuring 3 * 90 cm;

- 2 slats measuring 3 * 84 cm.

You can cut plywood with a hacksaw or a circular saw. In the first case, it will not turn out very smoothly, and in the second it is important to take into account the fact that the circular “will eat” 2-3 millimeters. Therefore, all your sizes should "grow" by the appropriate amount.

Also, burrs will inevitably remain when cutting.

You can get rid of them with sandpaper or with a suitable tool.

Remember, when working with wood there will be a lot of shavings. Lots of. Therefore, make sure that relatives do not drive you out of the house. If everything ended successfully, feel free to proceed to the next step.

Solder me, solder me completely (make sensors)

Over the years of DDR, jsirex and I have delved into arcade machines more than once.

On the one hand, there was a need (the automatic machine is always put in order before the championship), on the other hand, it was interesting, what did these Japanese invent. All ingenious, as you know, is simple.

The sensor is a simple construction: two conductive plates separated by a dielectric at the edges and locked in the center of the player’s weight. Each button has 4 sensors, one on each side. Thus, regardless of which part of the button the player steps on, pressing always works.

But enough words. Let's proceed to the assembly.

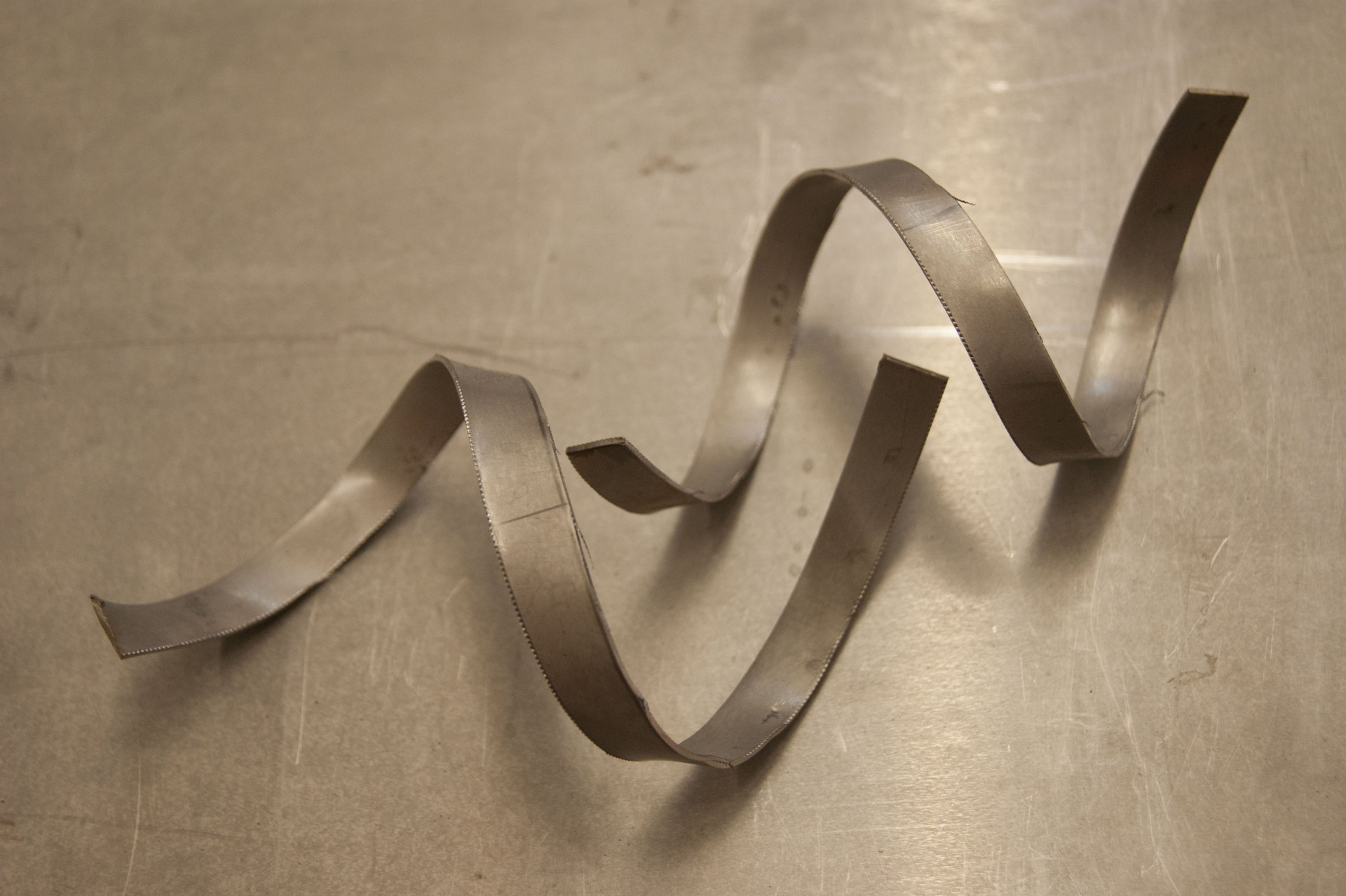

We draw textolite with 1 * 1 cm squares. Stainless steel - 1 * 15 cm stripes. The most difficult thing is to cut the stainless steel. There are no problems if there is a grinder on hand. The only caveat - you need to adjust the size. Instead of 1 * 15 cm there will be 1.1 * 15.1 cm. The Bulgarian will “eat” the excess.

But if you don’t have such a wonderful tool in your arsenal, “dancing with a tambourine” begins. At first I decided to use a dremel. In his arsenal there was just a cutting disc.

However, the stainless steel 1 mm thick wanted to spit on fashionable wheels and cut it off after 8 cm. Therefore, reluctantly, I had to climb over the “analog” instrument - metal scissors.

The stainless steel turned out to be quite tough for them. But still not a single barrel of honey in my memory could do without a fly in the ointment. And this case was no exception.

Scissors cut metal with cheerful curls with burrs. Therefore, at first it was necessary to level them with a hammer (blanks, not scissors) to a sane state.

And then “shave off” the burrs with a dremel. He coped with this task perfectly and without loss of consumables.

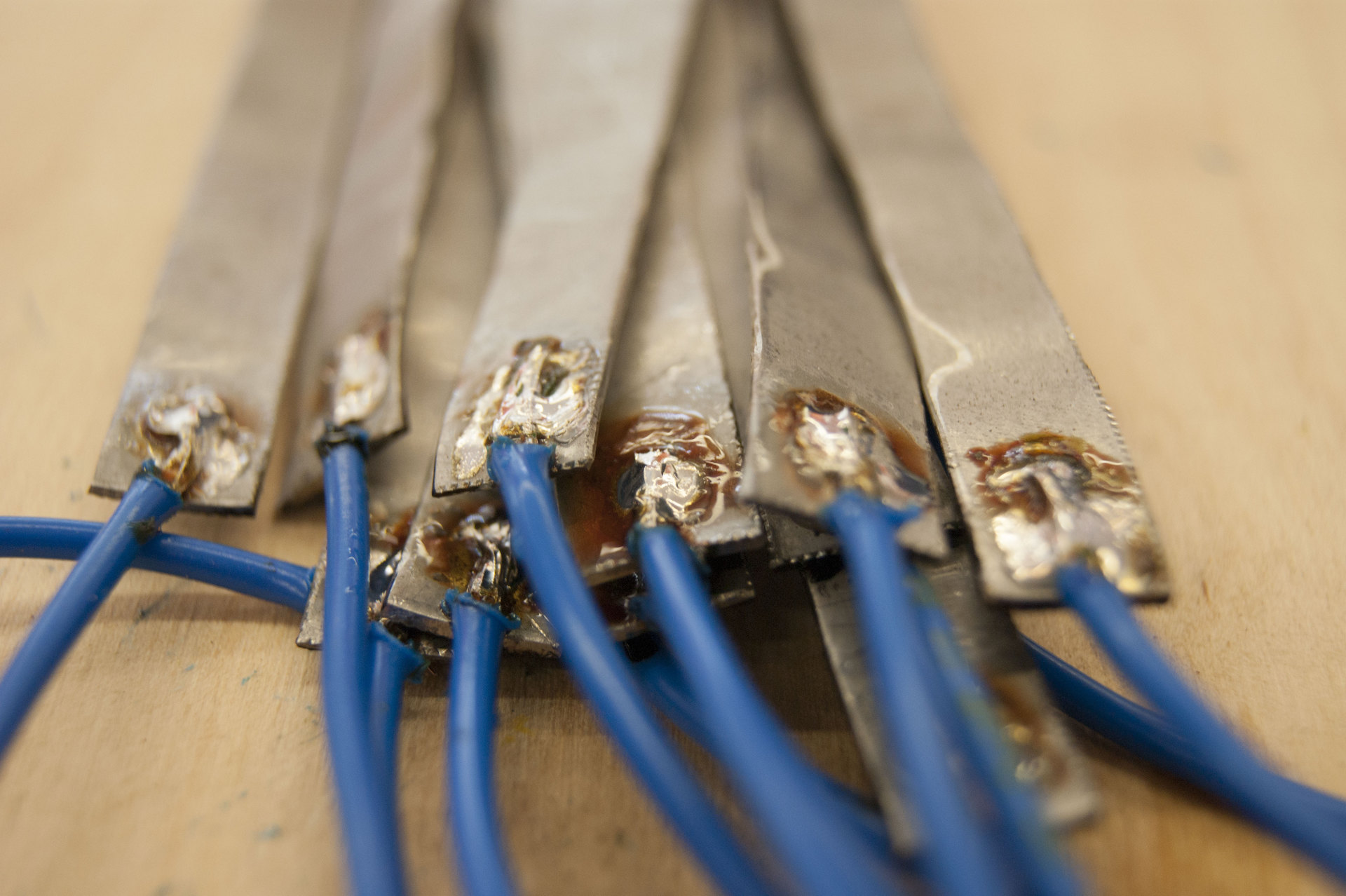

In the meantime, the soldering iron is warming up. No, nobody owed me money. The next stage of manufacturing the sensor has just come.

From the point of view of soldering, there are no subtleties. Tinning the wires, dripping orthophosphoric acid on the cleaned edge of the stainless steel strip and soldering.

It may not look very aesthetically pleasing, but you will tear off FIGs.

To the resulting blanks with the help of electrical tape, squares of the PCB are attached. He acts as a dielectric. It is wound on one workpiece from the soldering side, on the other from the “tail” side.

I confess, I used black electrical tape instead of blue, so I can not vouch for the durability of the sensors.

Then two blanks are fastened at the edges with tape. The final version is below.

It's time to do it beautifully. To do this, you need heat shrink. With a sensor size of 1 * 15 cm, heat shrink with a diameter of 15 mm is perfect.

Shrink shrinks with an industrial hairdryer. If there is no hairdryer, a gas stove will do. The desired effect will be achieved. A bonus is the smell of burnt hair. By the way, if you slightly warm up the “tail” of the sensor, and then quickly clamp it with pliers or a screwdriver, you get a practically sealed case. This point is in the video.

Just in case, the fruits of labor are checked by a tester. In a free state of contact, of course, should not be.

Now it’s the turn of the dad-mom connectors.

We solder something (to be honest, I do not know what it is called correctly) on the free ends of the wires. Here's an important note. If you have a thick stranded wire, it makes sense to bite part of the veins. In other words, do not do as shown in the photo below, do not leave all cores.

The message is simple: you can solder, but then you can’t insert the "father" in the "mother", because there will be no free space.

A correctly made sensor is moderately beautiful and beautiful.

In addition, it does not experience any problems when connecting to the board.

A few words about the board. To be honest, from personal experience I can say that it is not necessary to fence a garden with connectors and boards. You can take all the sensors in the button into a “twist”, fill it with solder, and then hot-melt adhesive. And such a design will work fine. At least the first samples of rugs still work, and it has been already about 6 years.

But back to the boards. They are etched according to the well-known method of

After cutting, at least strategic holes are drilled in strategic places with a millimeter drill.

As a result, after soldering, it turns out even beautifully. Back view.

Front view:

Holy couple (make wiring)

And so we came close to the wiring.

Meticulous readers will consider the complex option presented in the photo above. I’ll tell you about a simplified version, implemented through a twisted pair cable.

It all starts with a “sleeve” with an RJ-45 connector. It has 8 outputs, therefore there are 8 wires to it. Choose 4 “pluses” and 4 “minuses”. Since the "minus" is common - we twist 4 wires into one. Believe it or not, twisted pair cable also contains 8 wires. They are divided into "pros" and "cons" in exactly the same way. For example, I assign all colored ones to “minuses”, and all white-colored ones to “pluses”. Ultimately, 1 “+” and 1 “-” should come to each button in the mat.

To preserve the wiring, it should not be laid on the basis of ground, but according to the grooves made in it in advance. There are 2 ways:

- Cheap. Take a chisel and a hammer. Pound the grooves. It turns out effectively, but not very beautiful.

- We take a milling machine and cut out everything that is needed in 10 minutes.

I went in a modified second way. I didn’t have a milling machine, but I didn’t really want to buy 1 time. But there was a dremel with a set of sundries. Among other things, universal drills were found there. Their feature is sharpening. The drill can function as a milling cutter. The process was filmed in the video, so it makes no sense to describe in words. Better to see once.

When all the grooves are sawn, it is time for hot melt. The piece is extremely useful for minor quick repairs. Using a thermal gun, we lay the wiring by gluing the sensors. Do not forget to periodically “ring” the structure, so that later you do not have to disassemble the finished mat to the base.

Slap and production (assembly)

Well, the light is already visible at the end of the tunnel. The finish line is the assembly. Remember 5 wooden buttons, 4 plexiglass and 4 rails? It is their time.

It is curious that no matter how you try to cut everything evenly, no matter how straight and square the workpieces seem to you, at the assembly stage you will be haunted by a feeling of universal curvature and plainness. Do not worry, this is the paradox of the curvature of space-hands-time. It is still impossible to fix it without an additional 7 measurements, so reconcile.

Although no, there are still little tricks. If we assume that all the buttons and slats are a little crookedly sawn, then there is a chance to assemble them in such a combination when everything comes up straight. In general, take it and start trying. When the final arrangement is found, sign on the back of the button its place and direction. For example, LN is the lower left, C is central.

It’s better to start building this ikebana from any angle. As soon as it turns out - you make money on self-tapping screws. Plexiglass is not necessary to profit from self-tapping screws.

To prevent plexiglass from falling out, we fix it with furniture corners. Nuance: the corners in height are more than necessary. There are two options:

- Grind every corner.

- Make indentations in the base.

I chose the second option, having drilled a dremel.

During assembly, do not forget to ring the structure.

Finally, the most important component without which nothing will work is adhesive tape on a foam basis. You can laugh, but it is. Even in the original Japanese arcade machines, we found it.

It is glued in small strips of 3-4 centimeters in length in the center of each sensor. Since we did the sensors ourselves, and did not buy them at the factory, several layers may be needed. Usually 2-3. Ultimately, the button should be pressed with some effort. Not by touch, but by effort! It is important!

USBsexual (friends dance platform with computer)

In parallel with the assembly of the rug, its connecting link with the computer is also assembled. Since Windows does not understand the ЕПРСТ \ ЕКЛМН protocol, you have to "make friends" with the computer in the traditional way, that is, via USB.

For these purposes, the cheapest gamepad is bought. On his board and to solder the end of the twisted pair. Just in case, I recall the order.

- The signal begins with a short to the sensor;

- It is transferred to the board fixed in the center of the button;

- Then transferred to the "clutch";

- And it goes to the RJ-45 connector.

All this has already been done. Further.

- Insert the squeezed “dad” into the “mom” RJ-45;

- By twisted pair, the signal is transmitted to the gamepad;

- From the gamepad, the USB signal goes to the computer.

So, we solder to the board as follows.

As you can see, the “pluses” are soldered to the action buttons. The "cons" are twisted-soldered together and soldered to the "ground".

In principle, everything is ready. But you can bring beauty. For example, push the board into the case. I bought it on the ruins of the radio market. True, then it turned out that these were just two covers that were not intended to be connected at least in the likeness of something whole. I had to grind a little.

In general, it turned out sane. With the help of sandpaper for dremel, he removed the excess, and with the help of a milling cutter he made a recess under the wire.

Finally, all parts of the mosaic are ready and you can connect the mat to the computer for testing in the game.

A few words about her. To play on a computer, good people wrote a DDR arcade machine simulator calledStepmania . Then no less kind people based on Stepmania created a modified version - In The Groove (ITG). It is with her, and more precisely with the OpenITG project, that I work. Download distributions here . You can compile it yourself from source . In general, setting up the game, downloading tracks and even creating your own is a topic for a separate post. If the community is for, then let me know in the comments. In the meantime, we return to the rug.

The final view of the patient.

You can do a lot on such a rug. Unfortunately, I’ve been out of shape for a long time and on the video I give out only languid fluttering. But once it was like this:

What's next? Instead of totals

It is impossible not to notice that the appearance of the rug is not aesthetic. It doesn’t matter. Firstly, it can be painted.

Wooden parts are unscrewed and painted. Plexiglas is painted on the inside.

Secondly, if you do not want to work with paint, you can print stickers.

You come up with a drawing from the calculation of 9 squares 29 * 29 cm. I was not mistaken, the buttons are 28 * 28 cm, and the stickers are larger. But do you remember that the buttons are not quite square?

That's all. Questions, comments and suggestions are welcome.