FedEx: Part 2. We Drop Parcels for Money: FedEx Packaging Lab

- Transfer

FedEx - the largest shipping company in the world - can deliver almost anything to 22 countries. Anything, including ... satellites ?!

(Caution, a lot of photos!)

Yesterday we got acquainted with how the FedEx world center for sorting parcels works. Today we consider the other side of the issue - the reliability of packaging.

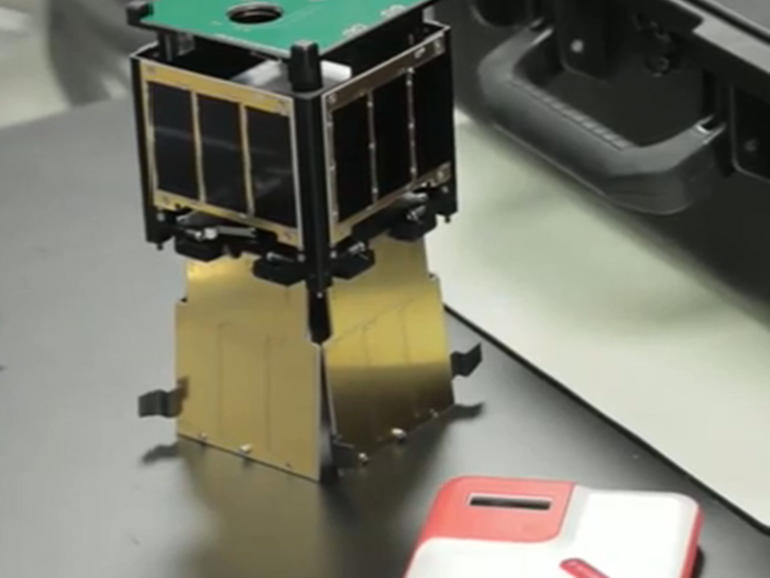

Of course, the company does not deliver huge communication satellites, but in recent months it has appeared many customers (specific organizations are not called) who need to send CubeSats micro satellites , small devices that NASA periodically sends into space as part of its countless experiments:

FedEx's problem was how to pack them for delivery around the planet. The case involved connecting the FedEx packaging lab. Over the years, FedEx has tried countless packaging options to ensure it is resistant to all the trials that a package may encounter while traveling from point A to point B by truck or plane, or possibly both. This spring, the company opened a large packaging testing laboratory in Memphis, providing room for all the necessary experiments.

Today we will visit this laboratory, where test engineer David Nelson will explain how the logistics giant exposes parcels to various bullying (naturally, in a controlled environment). Here the parcels drop again and again, compress, subject to vibration, as well as low and high temperatures.

Micro satellites, however, were too different in nature from anything FedEx had dealt with before. “It was something completely new,” Nelson explains. “We started scratching the back of the head. The satellites were too fragile and too expensive. ”When Nelson and his team realized that in this case the satellites were something relatively small, they gained confidence that they could find a solution. And maybe that's why the researchers who needed to deliver these satellites turned to FedEx. They said, “We know how to build a rocket, but we don’t understand a damn thing in the package.” To which Nelson answered them, “We don’t understand a damn thing in the rockets, but the packaging is our thing!”

For free

The FedEx packaging lab has two main goals. The first is material testing in order to make sure that any type of packaging used by FedEx performs well during transportation and protects any contents inside it. The second goal is to test the cargo itself to verify how it behaves under the influence of severe vibrations, extreme temperatures and high altitude. “Our goal is to simulate any part of the real delivery process,” says Mickey Rainey, laboratory manager.

The secret of the packaging laboratory is that it provides its services to any FedEx customer without any charge. Do you have a package to check? The company will do this for free, although at some point the company may still begin to charge for it.

In addition, laboratory engineers can help any client develop a special packaging design for their products - also for free. For example, says Nelson, a well-known company that produces electric guitars, recently asked the laboratory to develop a package that can be used to transport all models of electric guitars produced by the company, each of which has a slightly different shape. With the same packaging, companies will be easier to scale without having to deal with many different boxes. Using fewer packages allows companies to significantly reduce costs:

For a guitar company, as well as for other companies, FedEx engineers developed a prototype and then implemented it in the form of drawings so that someone could be hired to make the packaging itself. Only a few FedEx customers understand that in this situation, FedEx does all this at a loss to maintain and consolidate reliable partnerships with its customers. “They can't believe we don't bill for payment at the end of the process,” says Rainey.

Drop them over and over

Many FedEx customers send their packages to the packaging testing lab without any warning. Every day, new packages arrive in the laboratory, where one of the four engineers will soon be able to deal with them. According to Rainey, 4,500 parcels go through the lab every year, which means that an engineer needs to test at least 25 a day to get his work done.

As soon as the parcel arrives, it is time to check its durability and it all starts with the fact that the parcel is dropped again and again to see how the package behaves. One of the questions here is whether the parcel is intended for shipment domestically or abroad. This is important because the international package is subjected to much more shocks during delivery. We drop domestic shipments 10 times, and international shipments - 20:

The drop test is designed to assess the strength of each side of the package, despite the fact that during the delivery the package is unlikely to actually be dropped 10 times, and even more so 20. Drops are carried out by a special device that raises the packages to a certain height, and then sharply dropping it down, which allows you to check every corner of the parcel, every face and every plane. When I watched two technicians perform a drop test, it was immediately clear that the package would not pass it, because after a couple of strokes, the packaging began to open at the edges.

The purpose of the test is to check whether its packaging passes or not. If the parcel passes the test, the company reports this to the customer. If not, the responsible engineer gives recommendations on how packaging can be improved to pass the test in the future.

Compression and vibration

The next big test is checking how the packages withstand pressure. To do this, the company uses a press that simulates the loads that the package will experience when another load is placed on top of it. If the package does not pass, the engineers again give their advice:

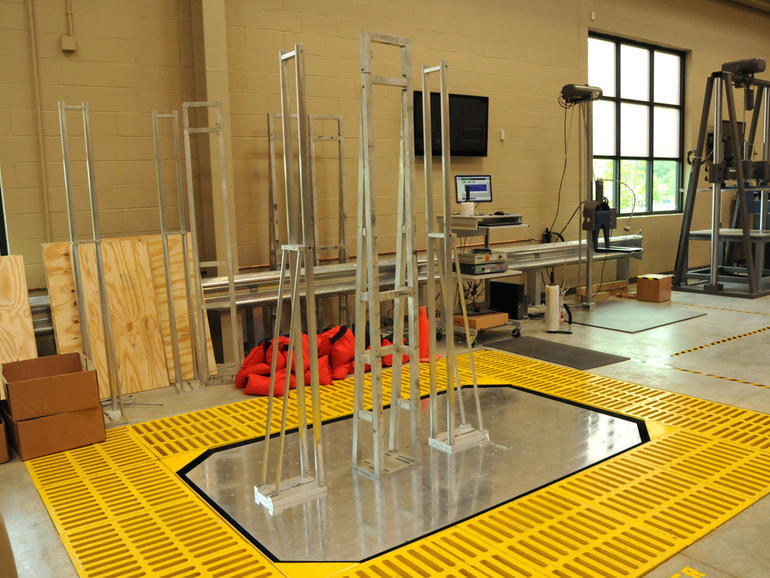

Then the packages are subjected to vibrations. To do this, they are placed on a vibration table and the engineer selects the test profile - simulating movement in a truck or on an airplane: The

loads that the package is subjected to during different transportation methods are very different. For domestic shipments, the test takes 45 minutes: 15 minutes simulating delivery by truck, then 15 minutes by plane, then again 15 minutes by truck. For international parcels, the test time is doubled.

For large packages, another test is also used: the package is placed on an inclined plane and rolled along it. Large loads, such as shelving with cans of paint, are subjected to similar loads during transportation. If you drop such a rack, the banks may break or something worse may happen to them. “No one will buy paint in broken cans,” Nelson explains.

Temperature and height

The last types of tests that laboratory packaging is subjected to are tests for aggressive media - too hot, too cold, too wet, and also height tests.

Temperature tests are extremely important. In winter, plastic can become brittle and liquids can freeze. High humidity is also a big problem because the box may get wet. Tests test all of these situations.

Cabinet for temperature tests:

Similarly, a height test checks how boxes behave when transported by truck at an altitude of up to 3 km - this is not uncommon in the Rockies. For example, there have been cases where packaging with chips exploded at such heights. Covers on paint cans may open slightly. In the best case, only the transported cargo will be a loss. At worst, FedEx hardware can be damaged, making shipping difficult for everyone.

Altitude simulation camera:

Check speed

Considering how many packages are being checked, FedEx engineers cannot afford to spend too much time on each, because FedEx is committed to returning packages to customers as quickly as possible. FedEx's goal is to check your package in 4 days.

Real time verification is much less. A typical small package requires about an hour to conduct tests, including examining it, photographing it, and including the results in the FedEx database. However, large packages may require 4 to 8 hours for testing. Work on the development of the original packaging design requires more time, from 2 to 3 weeks of engineer work.

Nelson likes his work. While FedEx package delivery drivers are often accused of spoiling and mistreating packages, for Nelson, on the contrary, it's part of the job. There are only 10 people in the company who are allowed to drop packages, and we are even paid for it!

PS The first part of the article: FedEx: part 1. Excursion to the world FedEx parcel sorting center .