3D Building Technology Survey

3D printing technology is conquering the world and this is a real scientific and technological revolution taking place before our very eyes. Looking at the speed of translating into everyday life ideas that were recently fantastic, such as fabricating by the method of volumetric printing of prostheses of human hands, not only futurologists, but also experts are confidently talking about the upcoming significant changes in the life of human society. And if in some sectors of the economy the practical applicability of 3D printing is no longer in doubt, it’s medicine, mechanical engineering, radio engineering and electronics, then in such a powerful industry as construction, volume printing robots look like expensive toys. Are 3D printers capable of real work in construction?

As you know, the main difference between a 3D printer and any other industrial robot is in the way of creating products. In particular, the construction 3D printer has a nozzle or extruder and squeezes out a quick-hardening working mixture from it. The surface on which the bulk product is created is called the working area and has dimensions determined by the magnitude of the nozzle stroke. Moreover, formwork is not required. That is, the construction machine for volume printing is declared as a self-sufficient mechanism capable of creating a finished building from scratch when connecting electricity.

Three methods of creating a three-dimensional structure are known:

1. Layer-by-layer extruding of a viscous working mixture.

In this case, a creamy mixture of concrete with additives is squeezed out of the working “nozzle”, like toothpaste from a tube.

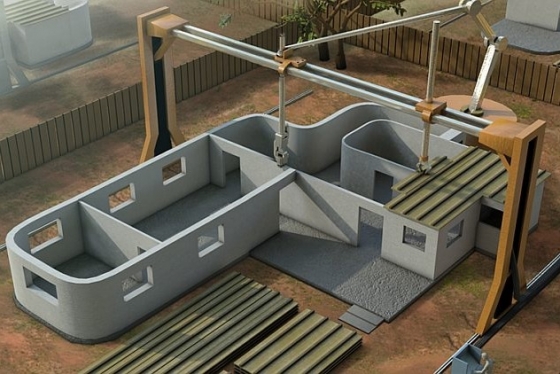

The first to justify the concept of using the robot in construction, in the form of a crane, laying viscous concrete mix according to a given program, industrial designer Sergey Dudin, together with the Moscow Art Theater named after D.I. Mendeleev in 1995. The first public presentation about this technology in construction was organized by Professor Baruch Koszniewitz from the University of Southern California in August 2012. His group put forward the concept of a giant, assembled at the construction site of the printer as a bridge crane.

A team of scientists led by Dr. Sungwu Lim of the British University of Loughborough (Loughborough University), printed the world's first hollow panel with double rounded contours.

3D printers of the Chinese company Shanghai WinSun Decoration Design Design Engineering Co, which was the first to print a series of real houses in early 2014, are built on the same principle.

2. Sintering method / selective sintering.

With this technology, in the working area of the 3D machine, the working mixture is melted, and melting is achieved, with respect to construction, by a concentrated laser or a sun beam, and ordinary sand acts as the working mixture. It is known, at the time of writing, about the only existing example of such a device inventor Marcus Kaiser, a student of the Royal College of Art (Royal College of Art).

3. Spraying / component bonding method.

Known, in particular, is a working example of a group of the Catalan Institute of Advanced Architecture (IAAC) (Petr Novikov's group) called Stone Spray Robot, as well as a D-Shape system developed by Enrico Dini (Monolite UK, (private company)) for building construction. At the same time, a sand stream leaves the working nozzle, which immediately mixes with the adhesive / catalyst, forming a volume at the programmed point.

Sintering and spraying methods, elegant in concept, as solar energy is used, are environmentally friendly (at least as long as there is a lot of sand on the planet), you can watch the movement of sand streams for hours and products come in very unusual shapes. Well, now it’s quite possible to build in this way small architectural forms, a flower girl, for example, or a doghouse. In the meantime, it’s hard to even imagine what the resulting operational effect will be when creating a real, albeit small, house from molten sand and turned into a glassy mass.

Of the above methods of volume formation, the attention of builders is primarily attracted to the method of layer-by-layer extrusion, largely because already quite large bearing surfaces and even real houses have been created.

And if European architects demonstrate primarily an aesthetic and environmental focus, then the Chinese in their designs are extremely pragmatic.

Many 3D romantics were frankly disappointed with a series of simple and rude looking houses of a Chinese company. Meanwhile, it is overlooked that these rectangular, simple structures are part of a clearly defined technological chain.

It is planned to mass-build factories for the processing of construction waste and garbage, the resulting material will be used in the preparation of the working mixture for a 3D printer. Considering China’s great achievements in bioenergy, namely the prevalence of wind, solar and bioelectric power plants, it can be assumed that giant construction waste shredders powered by electricity from the nearest bioelectric power station will be installed in the landfills of construction waste.

Built from a proprietary material (which is a mixture of construction waste, concrete and additives), the houses are segmented in the class of inexpensive prefabricated housing. This explains their plain appearance.

If we talk about 3D-construction technologies. then I would put in the first place is not the 3D device itself. A construction printer is a link in a new technology, and not the most, possibly technically difficult.

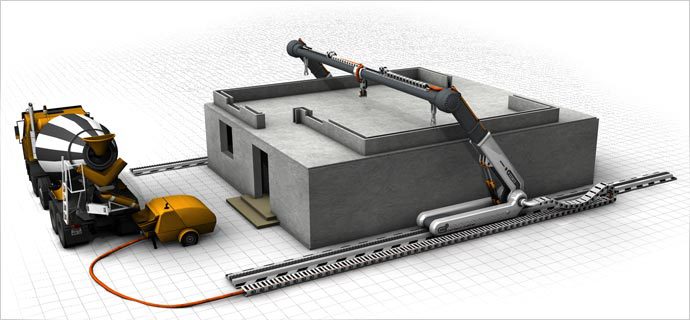

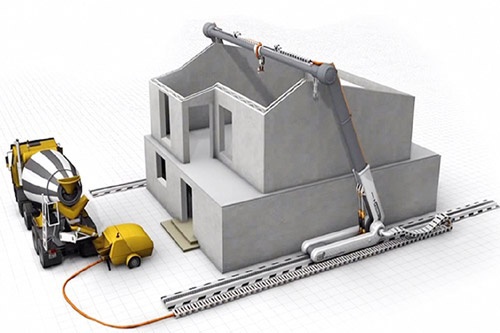

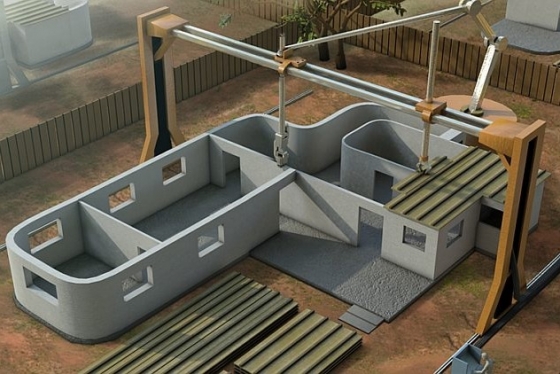

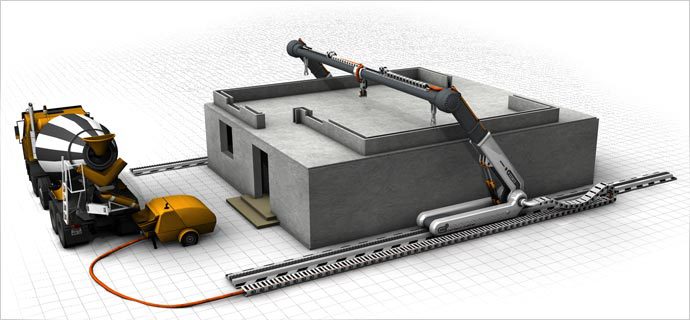

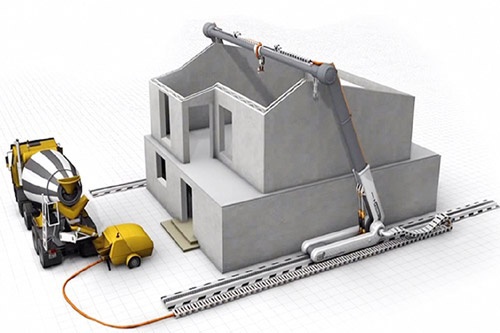

After all, the construction robot construction has been sufficiently developed. but for now, only the Chinese series. Two types of structures already exist in many instances - in the form of a gantry crane and in the form of a boom-manipulator.

Much more questions are caused by the composition of the working mixture and conceptual architectural forms. In general, when compiling a working questionnaire on the topic, more than 30 points were formed on the fly; the answer to some of them, according to the playful remark of engineer Sergei Zotov, requires a decent monograph. Zotov’s group has already developed the composition of the working mixture and a 3D printer in the form of a “bridge crane”.

Also, an interesting concept based on the idea of supplying a high-pressure mixture to a 3D printer with a rather elegant bridge design was proposed by industrial designer Sebastian Bernard.

The supply of thick concrete under high pressure translates volume printing technology into a fairly realistic framework. Further, materials are being developed specifically for the application of this technology. Research in Penza is known in Russia, and new types of concrete are being developed at the department of TBKiV of the Penza GUAS. New high-strength reaction powder concretes (BPM) are well suited for construction robots.

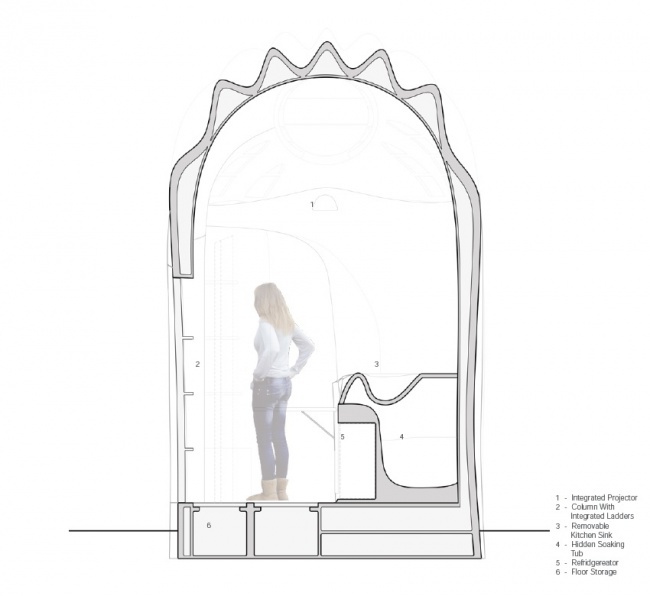

For building the technological process, in addition to the working mixture, an important point is the architecture of the building itself and the group of buildings as a single construction object. The most promising direction for Russia, apparently, is the construction of a village of two-story town houses of arched forms. About such as the domed house of the architect Grebnev.

The format of the arched house on two floors will allow the use of relatively small and inexpensive 3D printers, solve the problem of overlap and allow you to build, really, quickly, massively and inexpensively. And beautiful. At the scale of the village, it will be possible to use bridge printers, since the rail track (not necessarily from metal rails) will move as construction progresses.

Many questions are directly raised by construction technology. First, how the strength of the structure will be affected by the seams running every three to five centimeters. Secondly, the existing (from known) process of laying reinforcement is quite controversial. The Chinese are reinforced with fiberglass mesh. At least, it is visible in the video recording of the process.

There is an opinion about the applicability of fiber-reinforced concrete and perhaps such a dome in one or two floors will withstand the certification procedure. It is also proposed to connect the fittings to the pivots, to screw up, etc. Of course, while these are workarounds. Perhaps the problem of online reinforcement will be solved by using two robots at once: one mounts the reinforcement, the other puts the mixture. The automation situation is simplified by the fact that the formwork is absent as a “class”.

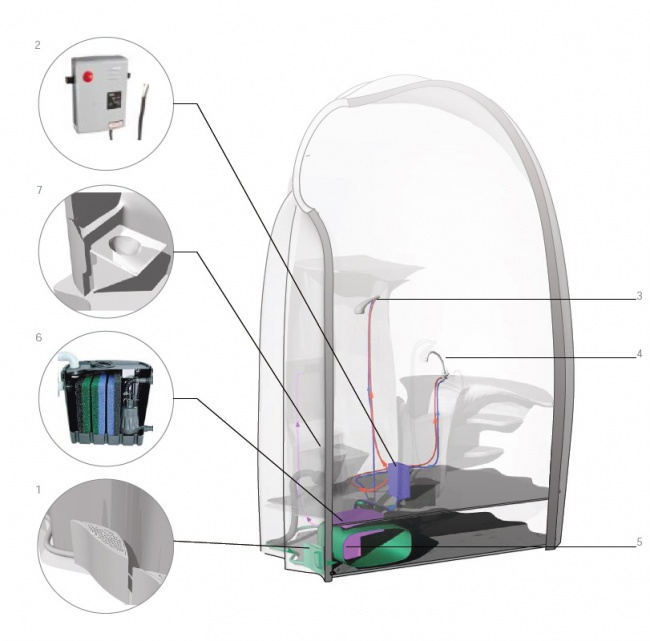

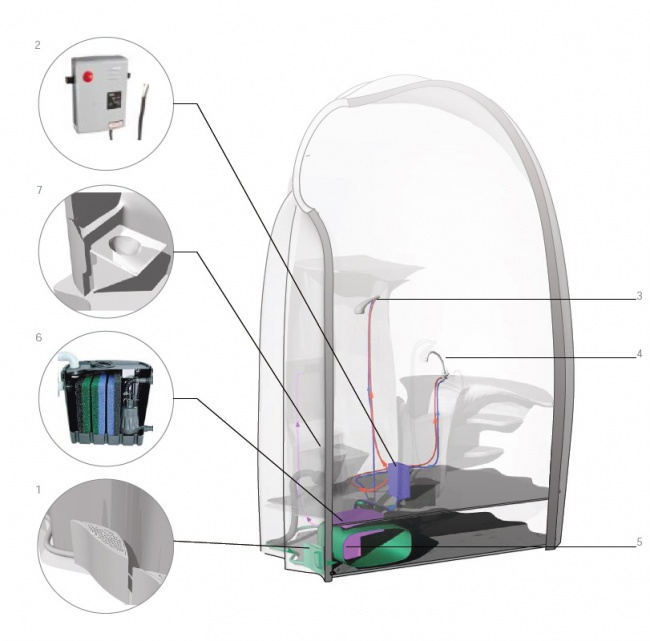

With the installation of engineering systems in terms of ventilation, sewage and heating, the solution is simpler. 3D printers are robots with a fairly accurate repeatability of operations and matching of pipe elements in a given sequence is quite feasible. Naturally, industrial designers will have to rack their brains over new designs of elements of engineering systems.

In general, most of these technical problems are characteristic of the transition period that 3D printers are entering. For some time old and new technologies will coexist, the time necessary, first of all, for psychological addiction. When some builders criticize the 3D process, they criticize evolution - “here, they say, the printer is big, expensive, noisy and consumes electricity, and your house will fall apart. And in general, a bunch - a panel plus "Tajikstroy" - does not happen cheaper. "

So, a construction 3D printer is not an evolution. For many, this moment still does not fit in my head, because this is a revolution, and it must be recognized.

Indeed, today it is difficult to imagine how much the structure of the construction company, or its unit specializing in cottage villages, will change. Apparently, the foremen will have no posts and “dopniks”, there will be no replaceable Moldavian, Belorussian and other brigades. The face of the company will be a small team of specialists and a couple of robots; operator-operator of a 3D robot (3 people with three shifts), a dispatcher-logistic officer (the current supplier) and further - subcontractors - bring the working mixture, assemble IT systems. In the process, several other specialists install fittings, mortgages and windows with doors. The staff of the construction division - 12 people, with a salary fund of one million rubles a month. During this month, such a team the village completely commissioned. Fantastically short construction time,

A 3D printer in construction is a production robot, a kind of conveyor. Naturally, all related industries in this chain meet the standards of the robot age. Where the working mixture will be produced, how transport logistics will be decided (if the solution is being prepared next to the facility being built, then delivery is not needed), the format of the component warehouse (a common for the entire village is created or an accessory brings the party to a particular house), these and many other questions a solution will undoubtedly be proposed. Specialists leading the development of bulk printing technologies are very active, 3D methods are being introduced into society with an unprecedented speed since the time of the first scientific and technological revolution. If during the presentation of Baruch Koszniewicz in 2012, the years 2017-2020 were carefully called as the threshold for the start of operation of construction robots, then in reality,

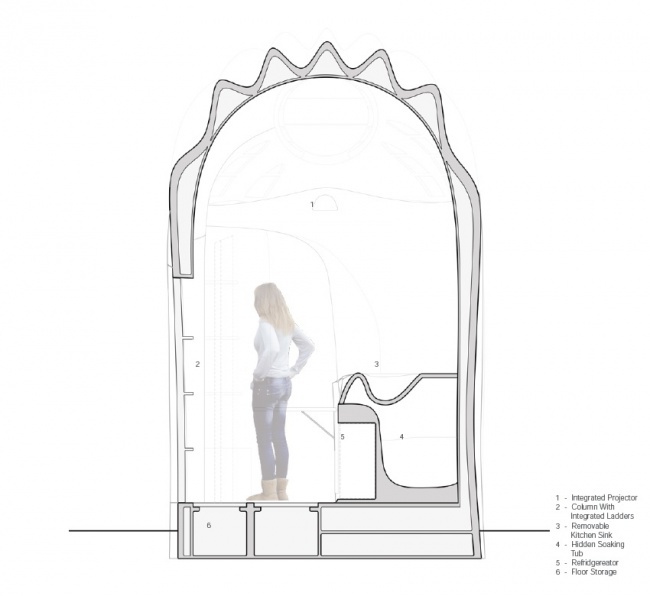

In addition to the opportunity to build truly inexpensive mass housing, let's say, of a standard class, original concepts appear that offer the opportunity to alleviate the severity of housing shortages in megacities. In Germany, Peter Ebner and his students printed a shell house.

The use of 3D technologies in this generally known conceptual direction makes it possible to massively and relatively inexpensively build and operate warm “shell houses” in northern Moscow. Too many residents of the immediate suburbs would buy such shells on the territory inside the Moscow Ring Road, for living in them from Monday evening to Friday morning.

We can say that now conditions and a certain framework have already been formed when an architect, an ASG engineer and a construction engineer are able to produce a feasible, socially oriented project in a profitable business format. Naturally, with the help of material specialists, logisticians, specialized design engineers. Only a comprehensive solution of issues: socially sought-after architectural forms and the format of the settlement, conveniently mounted engineering components and special building materials, plus automated transport and storage logistics, will allow us to talk about a revolution in construction. And manufacturers of 3D printers do not disappoint.

As you know, the main difference between a 3D printer and any other industrial robot is in the way of creating products. In particular, the construction 3D printer has a nozzle or extruder and squeezes out a quick-hardening working mixture from it. The surface on which the bulk product is created is called the working area and has dimensions determined by the magnitude of the nozzle stroke. Moreover, formwork is not required. That is, the construction machine for volume printing is declared as a self-sufficient mechanism capable of creating a finished building from scratch when connecting electricity.

Three methods of creating a three-dimensional structure are known:

1. Layer-by-layer extruding of a viscous working mixture.

In this case, a creamy mixture of concrete with additives is squeezed out of the working “nozzle”, like toothpaste from a tube.

The first to justify the concept of using the robot in construction, in the form of a crane, laying viscous concrete mix according to a given program, industrial designer Sergey Dudin, together with the Moscow Art Theater named after D.I. Mendeleev in 1995. The first public presentation about this technology in construction was organized by Professor Baruch Koszniewitz from the University of Southern California in August 2012. His group put forward the concept of a giant, assembled at the construction site of the printer as a bridge crane.

A team of scientists led by Dr. Sungwu Lim of the British University of Loughborough (Loughborough University), printed the world's first hollow panel with double rounded contours.

3D printers of the Chinese company Shanghai WinSun Decoration Design Design Engineering Co, which was the first to print a series of real houses in early 2014, are built on the same principle.

2. Sintering method / selective sintering.

With this technology, in the working area of the 3D machine, the working mixture is melted, and melting is achieved, with respect to construction, by a concentrated laser or a sun beam, and ordinary sand acts as the working mixture. It is known, at the time of writing, about the only existing example of such a device inventor Marcus Kaiser, a student of the Royal College of Art (Royal College of Art).

3. Spraying / component bonding method.

Known, in particular, is a working example of a group of the Catalan Institute of Advanced Architecture (IAAC) (Petr Novikov's group) called Stone Spray Robot, as well as a D-Shape system developed by Enrico Dini (Monolite UK, (private company)) for building construction. At the same time, a sand stream leaves the working nozzle, which immediately mixes with the adhesive / catalyst, forming a volume at the programmed point.

Sintering and spraying methods, elegant in concept, as solar energy is used, are environmentally friendly (at least as long as there is a lot of sand on the planet), you can watch the movement of sand streams for hours and products come in very unusual shapes. Well, now it’s quite possible to build in this way small architectural forms, a flower girl, for example, or a doghouse. In the meantime, it’s hard to even imagine what the resulting operational effect will be when creating a real, albeit small, house from molten sand and turned into a glassy mass.

Of the above methods of volume formation, the attention of builders is primarily attracted to the method of layer-by-layer extrusion, largely because already quite large bearing surfaces and even real houses have been created.

And if European architects demonstrate primarily an aesthetic and environmental focus, then the Chinese in their designs are extremely pragmatic.

Many 3D romantics were frankly disappointed with a series of simple and rude looking houses of a Chinese company. Meanwhile, it is overlooked that these rectangular, simple structures are part of a clearly defined technological chain.

It is planned to mass-build factories for the processing of construction waste and garbage, the resulting material will be used in the preparation of the working mixture for a 3D printer. Considering China’s great achievements in bioenergy, namely the prevalence of wind, solar and bioelectric power plants, it can be assumed that giant construction waste shredders powered by electricity from the nearest bioelectric power station will be installed in the landfills of construction waste.

Built from a proprietary material (which is a mixture of construction waste, concrete and additives), the houses are segmented in the class of inexpensive prefabricated housing. This explains their plain appearance.

If we talk about 3D-construction technologies. then I would put in the first place is not the 3D device itself. A construction printer is a link in a new technology, and not the most, possibly technically difficult.

After all, the construction robot construction has been sufficiently developed. but for now, only the Chinese series. Two types of structures already exist in many instances - in the form of a gantry crane and in the form of a boom-manipulator.

Much more questions are caused by the composition of the working mixture and conceptual architectural forms. In general, when compiling a working questionnaire on the topic, more than 30 points were formed on the fly; the answer to some of them, according to the playful remark of engineer Sergei Zotov, requires a decent monograph. Zotov’s group has already developed the composition of the working mixture and a 3D printer in the form of a “bridge crane”.

Also, an interesting concept based on the idea of supplying a high-pressure mixture to a 3D printer with a rather elegant bridge design was proposed by industrial designer Sebastian Bernard.

The supply of thick concrete under high pressure translates volume printing technology into a fairly realistic framework. Further, materials are being developed specifically for the application of this technology. Research in Penza is known in Russia, and new types of concrete are being developed at the department of TBKiV of the Penza GUAS. New high-strength reaction powder concretes (BPM) are well suited for construction robots.

For building the technological process, in addition to the working mixture, an important point is the architecture of the building itself and the group of buildings as a single construction object. The most promising direction for Russia, apparently, is the construction of a village of two-story town houses of arched forms. About such as the domed house of the architect Grebnev.

The format of the arched house on two floors will allow the use of relatively small and inexpensive 3D printers, solve the problem of overlap and allow you to build, really, quickly, massively and inexpensively. And beautiful. At the scale of the village, it will be possible to use bridge printers, since the rail track (not necessarily from metal rails) will move as construction progresses.

Many questions are directly raised by construction technology. First, how the strength of the structure will be affected by the seams running every three to five centimeters. Secondly, the existing (from known) process of laying reinforcement is quite controversial. The Chinese are reinforced with fiberglass mesh. At least, it is visible in the video recording of the process.

There is an opinion about the applicability of fiber-reinforced concrete and perhaps such a dome in one or two floors will withstand the certification procedure. It is also proposed to connect the fittings to the pivots, to screw up, etc. Of course, while these are workarounds. Perhaps the problem of online reinforcement will be solved by using two robots at once: one mounts the reinforcement, the other puts the mixture. The automation situation is simplified by the fact that the formwork is absent as a “class”.

With the installation of engineering systems in terms of ventilation, sewage and heating, the solution is simpler. 3D printers are robots with a fairly accurate repeatability of operations and matching of pipe elements in a given sequence is quite feasible. Naturally, industrial designers will have to rack their brains over new designs of elements of engineering systems.

In general, most of these technical problems are characteristic of the transition period that 3D printers are entering. For some time old and new technologies will coexist, the time necessary, first of all, for psychological addiction. When some builders criticize the 3D process, they criticize evolution - “here, they say, the printer is big, expensive, noisy and consumes electricity, and your house will fall apart. And in general, a bunch - a panel plus "Tajikstroy" - does not happen cheaper. "

So, a construction 3D printer is not an evolution. For many, this moment still does not fit in my head, because this is a revolution, and it must be recognized.

Indeed, today it is difficult to imagine how much the structure of the construction company, or its unit specializing in cottage villages, will change. Apparently, the foremen will have no posts and “dopniks”, there will be no replaceable Moldavian, Belorussian and other brigades. The face of the company will be a small team of specialists and a couple of robots; operator-operator of a 3D robot (3 people with three shifts), a dispatcher-logistic officer (the current supplier) and further - subcontractors - bring the working mixture, assemble IT systems. In the process, several other specialists install fittings, mortgages and windows with doors. The staff of the construction division - 12 people, with a salary fund of one million rubles a month. During this month, such a team the village completely commissioned. Fantastically short construction time,

A 3D printer in construction is a production robot, a kind of conveyor. Naturally, all related industries in this chain meet the standards of the robot age. Where the working mixture will be produced, how transport logistics will be decided (if the solution is being prepared next to the facility being built, then delivery is not needed), the format of the component warehouse (a common for the entire village is created or an accessory brings the party to a particular house), these and many other questions a solution will undoubtedly be proposed. Specialists leading the development of bulk printing technologies are very active, 3D methods are being introduced into society with an unprecedented speed since the time of the first scientific and technological revolution. If during the presentation of Baruch Koszniewicz in 2012, the years 2017-2020 were carefully called as the threshold for the start of operation of construction robots, then in reality,

In addition to the opportunity to build truly inexpensive mass housing, let's say, of a standard class, original concepts appear that offer the opportunity to alleviate the severity of housing shortages in megacities. In Germany, Peter Ebner and his students printed a shell house.

The use of 3D technologies in this generally known conceptual direction makes it possible to massively and relatively inexpensively build and operate warm “shell houses” in northern Moscow. Too many residents of the immediate suburbs would buy such shells on the territory inside the Moscow Ring Road, for living in them from Monday evening to Friday morning.

We can say that now conditions and a certain framework have already been formed when an architect, an ASG engineer and a construction engineer are able to produce a feasible, socially oriented project in a profitable business format. Naturally, with the help of material specialists, logisticians, specialized design engineers. Only a comprehensive solution of issues: socially sought-after architectural forms and the format of the settlement, conveniently mounted engineering components and special building materials, plus automated transport and storage logistics, will allow us to talk about a revolution in construction. And manufacturers of 3D printers do not disappoint.