SSD Form Factors

The term "form factor" is used in the computer industry to describe the shape and size of its various components, such as hard drives, motherboards, power supplies, and much more. When hard drives were just starting to be used in microcomputers (which were new at that time), they used magnetic plates up to 8 inches in diameter. These plates were the largest component of hard drives and determined the width of the metal case itself, which protected fragile entrails.

The height of the case was dictated by the number of “pancakes” used in a particular model. In the most capacious, the number reached 14. Since then, it was the diameter of the magnetic plates that was used to determine the form factor of hard drives. Large 8 "disks were replaced by 5.25", which for a long time were the main standard for desktop PCs, they were replaced by the usual 3.5 "disks, laptops mainly use 2.5", in some places 1.8 "micro-disks were used.

What determines the SSD form factor?

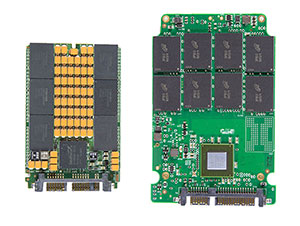

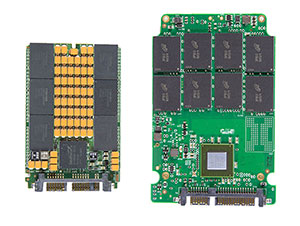

When SSDs began to replace the traditional HDD, their dimensions were dictated by compatibility, because they were installed in the same cases and the same connectors as mechanical drives. The discs shown in the image below are, in fact, twin in form factor, with the exception of dimensions. Both drives use almost the same SATA connectors, but the 1.8 "connector is narrower.

Inside the SSD board are 1.8" and 2.5 "

But in fact, the requirement for compatibility with the size of traditional hard drives is optional. Some SSDs are available in the form factor of the boards expansion for PCIe slots, which is reflected in their form factor.Despite the completely different appearance, the essence of the drive itself does not change much, the main difference is the changed interface (PCIe instead of SATA).

The biggest component of SSDs are memory chips. It is their quantity and size that determine the physical dimensions of the drive. With current trends towards miniaturization, the emergence of more compact form factors has not kept itself waiting long.

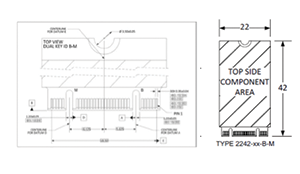

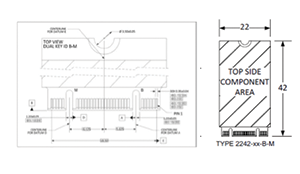

JEDEC (Joint Electronic Device Engineering Council) is usually involved in the development and standardization of the form factors of computer components, including SSDs. They developed the MO-297 standard, which describes the parameters, sizes, and layout of smaller format SSD connectors. The size of the drive by this standard is 54 mm x 39 mm, which allows you to use the same connectors as 2.5 "drives, taking up less space.

As the drives decreased, it became clear that the standard SATA connector interferes with further miniaturization. Besides the fact that he asked at least one of the sizes, he also increased the cost of the ready-made solution, since the SATA connector must also be soldered to the board. The logical step was the emergence of drives, the interface of which was the edge of the board, like expansion cards. In addition to the advantages described above, such a connector can simply be plugged directly into the corresponding slot on the motherboard, eliminating the need for extra wires / connectors.

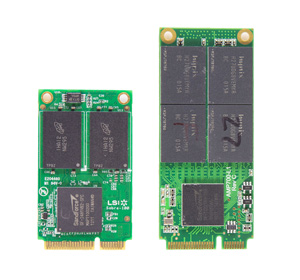

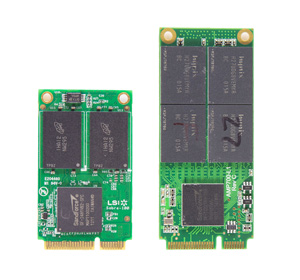

Realizing the need for further downsizing, JEDEC adopted the MO-300 standard (50.8 mm x 29.85 mm) with a mini-SATA (mSATA) connector. This connector is the same size as mini PCI Express, although it is not electrically compatible with it. SSD manufacturers have presented many solutions in this form factor. Some high-capacity drives were made longer to accommodate more memory chips.

MO-300 standard disc and disc of arbitrary length

In 2012, a new, even smaller, Next Generation Form Factor (NGFF) format was introduced, which was later renamed to M.2. This standard defines a large list of possible board sizes and introduces a connector that is electrically compatible simultaneously with mSATA and PCIe. The specific details of the interface are determined by its shape.

Apple, which often uses SSDs in its laptops, has traditionally gone its own way and used a proprietary interface similar to M.2, changing it almost every year. In 2013, they switched from SATA to PCIe to achieve even greater speed.

In some cases, not a single standard form factor is suitable, and SSD manufacturers produce highly specialized solutions designed for niche applications.

Finally, we came to the most familiar version of the interface - USB. Although the ubiquitous flash drives are no longer a novelty, they are also essentially SSDs and are worthy of mention. The first USB drives appeared as a more reliable and faster replacement for conventional 3.5 "floppy disks and the main speed limiter was USB. Now, with the advent of the USB 3 standard, high-speed SATA-USB 3 bridges and advanced controllers such as LSI® SandForce®, flash drives have reached speeds comparable to integrated drives, while still retaining their main advantage: portability and ease of connection.

As you can see, the main vector of development in SSD is miniaturization. But, like many rules, this has exceptions. For example, the SFF-8639 connector is currently under development and approval. Its main advantage is support for multiple interfaces on a single connector. Paying for such versatility just became the large size of the connector and, accordingly, the drives. The main application of SFF-8639 is complex data storage systems in data centers and mega data centers. The future SATA Express connector is similar to the SFF-8639, but it deserves a separate discussion.

In fact, the lack of mechanical elements in SSD solutions makes it possible to miniaturize them and expands the possibilities of use where traditional disks could not cope.

Posted by Kent Smith, LSI Flash Marketing Director

Original: bit.ly/1dHYJRN

The height of the case was dictated by the number of “pancakes” used in a particular model. In the most capacious, the number reached 14. Since then, it was the diameter of the magnetic plates that was used to determine the form factor of hard drives. Large 8 "disks were replaced by 5.25", which for a long time were the main standard for desktop PCs, they were replaced by the usual 3.5 "disks, laptops mainly use 2.5", in some places 1.8 "micro-disks were used.

What determines the SSD form factor?

When SSDs began to replace the traditional HDD, their dimensions were dictated by compatibility, because they were installed in the same cases and the same connectors as mechanical drives. The discs shown in the image below are, in fact, twin in form factor, with the exception of dimensions. Both drives use almost the same SATA connectors, but the 1.8 "connector is narrower.

Inside the SSD board are 1.8" and 2.5 "

But in fact, the requirement for compatibility with the size of traditional hard drives is optional. Some SSDs are available in the form factor of the boards expansion for PCIe slots, which is reflected in their form factor.Despite the completely different appearance, the essence of the drive itself does not change much, the main difference is the changed interface (PCIe instead of SATA).

The biggest component of SSDs are memory chips. It is their quantity and size that determine the physical dimensions of the drive. With current trends towards miniaturization, the emergence of more compact form factors has not kept itself waiting long.

JEDEC (Joint Electronic Device Engineering Council) is usually involved in the development and standardization of the form factors of computer components, including SSDs. They developed the MO-297 standard, which describes the parameters, sizes, and layout of smaller format SSD connectors. The size of the drive by this standard is 54 mm x 39 mm, which allows you to use the same connectors as 2.5 "drives, taking up less space.

As the drives decreased, it became clear that the standard SATA connector interferes with further miniaturization. Besides the fact that he asked at least one of the sizes, he also increased the cost of the ready-made solution, since the SATA connector must also be soldered to the board. The logical step was the emergence of drives, the interface of which was the edge of the board, like expansion cards. In addition to the advantages described above, such a connector can simply be plugged directly into the corresponding slot on the motherboard, eliminating the need for extra wires / connectors.

Realizing the need for further downsizing, JEDEC adopted the MO-300 standard (50.8 mm x 29.85 mm) with a mini-SATA (mSATA) connector. This connector is the same size as mini PCI Express, although it is not electrically compatible with it. SSD manufacturers have presented many solutions in this form factor. Some high-capacity drives were made longer to accommodate more memory chips.

MO-300 standard disc and disc of arbitrary length

In 2012, a new, even smaller, Next Generation Form Factor (NGFF) format was introduced, which was later renamed to M.2. This standard defines a large list of possible board sizes and introduces a connector that is electrically compatible simultaneously with mSATA and PCIe. The specific details of the interface are determined by its shape.

Apple, which often uses SSDs in its laptops, has traditionally gone its own way and used a proprietary interface similar to M.2, changing it almost every year. In 2013, they switched from SATA to PCIe to achieve even greater speed.

In some cases, not a single standard form factor is suitable, and SSD manufacturers produce highly specialized solutions designed for niche applications.

Finally, we came to the most familiar version of the interface - USB. Although the ubiquitous flash drives are no longer a novelty, they are also essentially SSDs and are worthy of mention. The first USB drives appeared as a more reliable and faster replacement for conventional 3.5 "floppy disks and the main speed limiter was USB. Now, with the advent of the USB 3 standard, high-speed SATA-USB 3 bridges and advanced controllers such as LSI® SandForce®, flash drives have reached speeds comparable to integrated drives, while still retaining their main advantage: portability and ease of connection.

As you can see, the main vector of development in SSD is miniaturization. But, like many rules, this has exceptions. For example, the SFF-8639 connector is currently under development and approval. Its main advantage is support for multiple interfaces on a single connector. Paying for such versatility just became the large size of the connector and, accordingly, the drives. The main application of SFF-8639 is complex data storage systems in data centers and mega data centers. The future SATA Express connector is similar to the SFF-8639, but it deserves a separate discussion.

In fact, the lack of mechanical elements in SSD solutions makes it possible to miniaturize them and expands the possibilities of use where traditional disks could not cope.

Posted by Kent Smith, LSI Flash Marketing Director

Original: bit.ly/1dHYJRN