Raise 3D Pro 2 Plus 3D Printer Review

Hello! With you Top 3D Shop and today we look at the latest printer of the company Raise 3D Pro 2 Plus . Many were waiting for him, the previous version of the printer proved to be very good.

Raise 3D Pro 2 Plus

Specifications

- Printing technology: FDM

- Sizes, mm: 620 × 590 × 1105

- Displacement for one material, mm: 305 × 305 × 605

- Working volume for two materials, mm: 280х305х605

- Supported file formats: STL, OBJ, GCODE

- Heated platform: up to 110 ºC, aluminum, silicone coating, magnetic mounts

- Extruder temperature, ºC: 300

- Speed, mm / s: 30 - 150

- Accuracy of positioning XY, mm: 0,0125

- Step size XY, mkm: 0.78125

- Layer thickness, mm: 0.01

- The size of the step Z, μm: 0,078125

- Supported materials: PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG, ASA, PP, carbon-filled, wood-filled, metal-filled, glass-filled

- Thread diameter, mm: 1.75

- The diameter of the nozzle, mm: 0.2 / 0.4 / 0.6 / 0.8

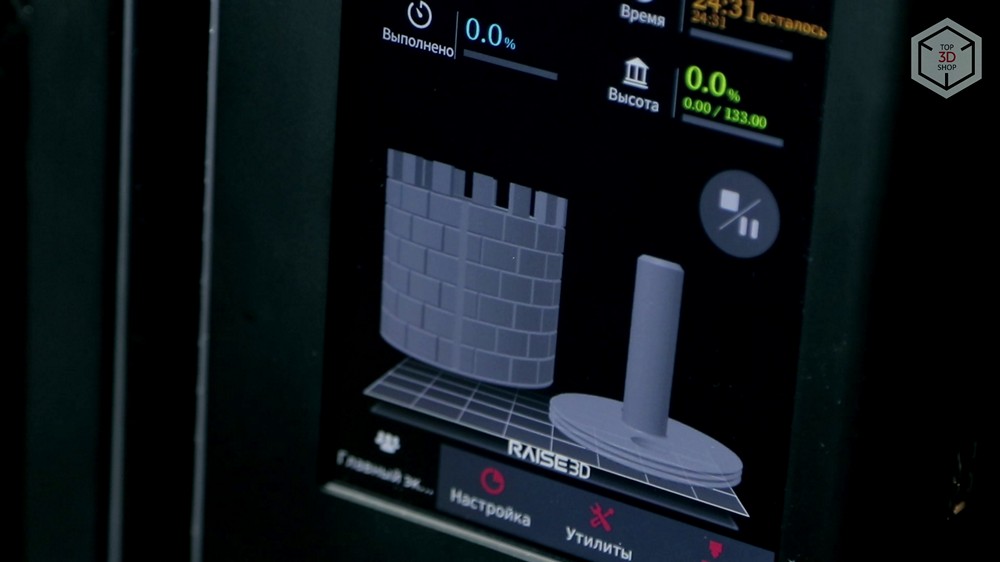

- Display: 7 ", touch, 1024x600

- Interfaces: Wi-Fi, LAN, USB

- Number of print heads: 2

- Price, rubles: 460 000

Description

For a short time, Raise managed to earn a good reputation among 3D printers.

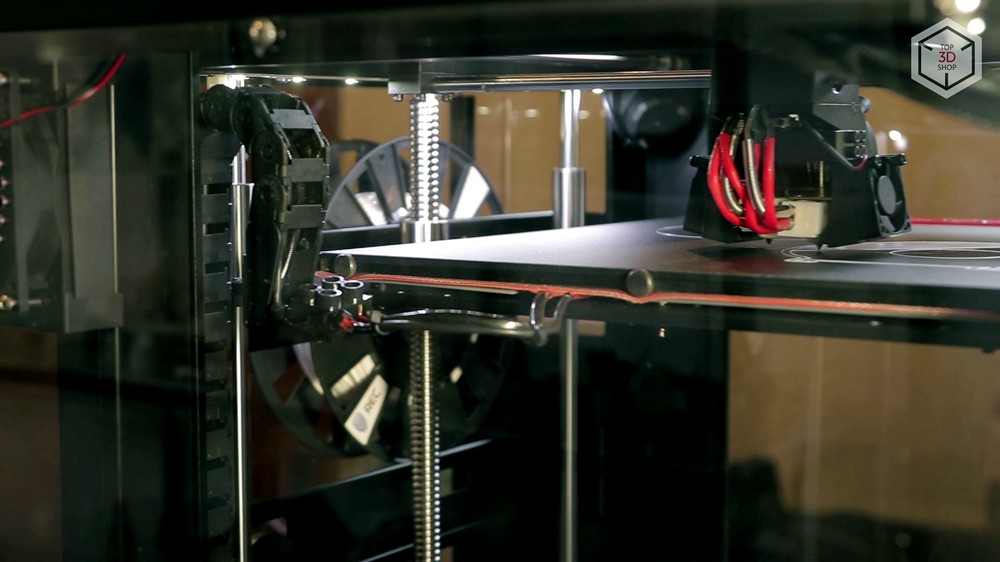

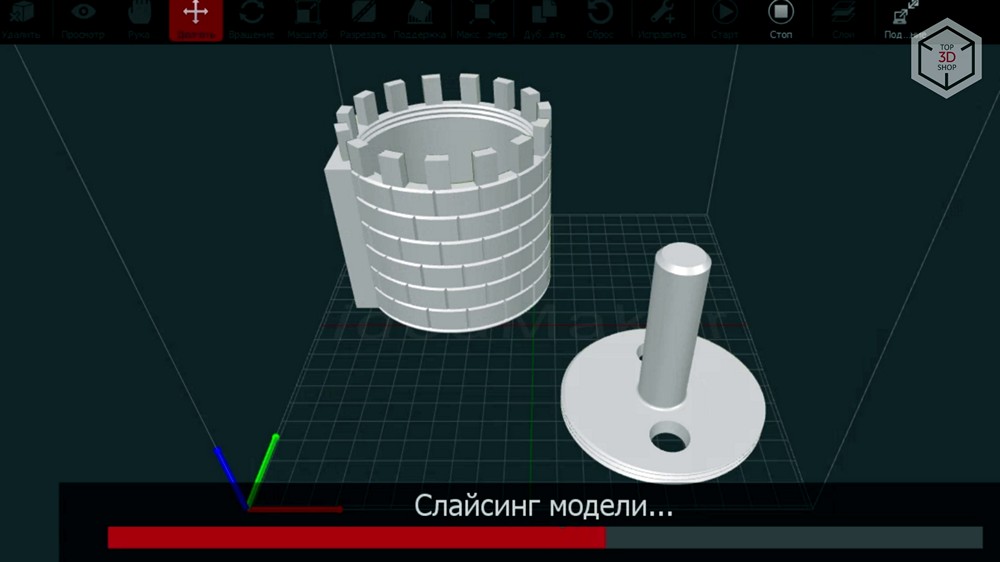

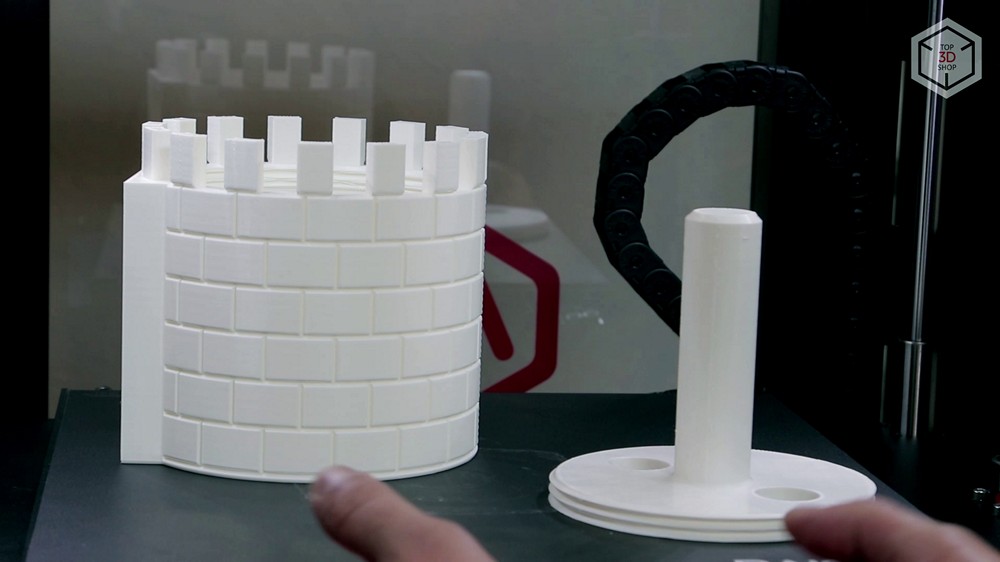

Of the important features of the novelty: the printer supports printing simultaneously with two materials, which allows, for example, to print support for water-soluble plastic or to print in two colors. The main thing, of course, is the print area: 305x305x600 mm, which is 30 cm higher than that of the Pro. When printing with two materials at once, the working area is slightly reduced, up to 280x305x600 mm, which is connected with the extruder device. The height of the printer more than a meter, it can not be called compact.

How prints

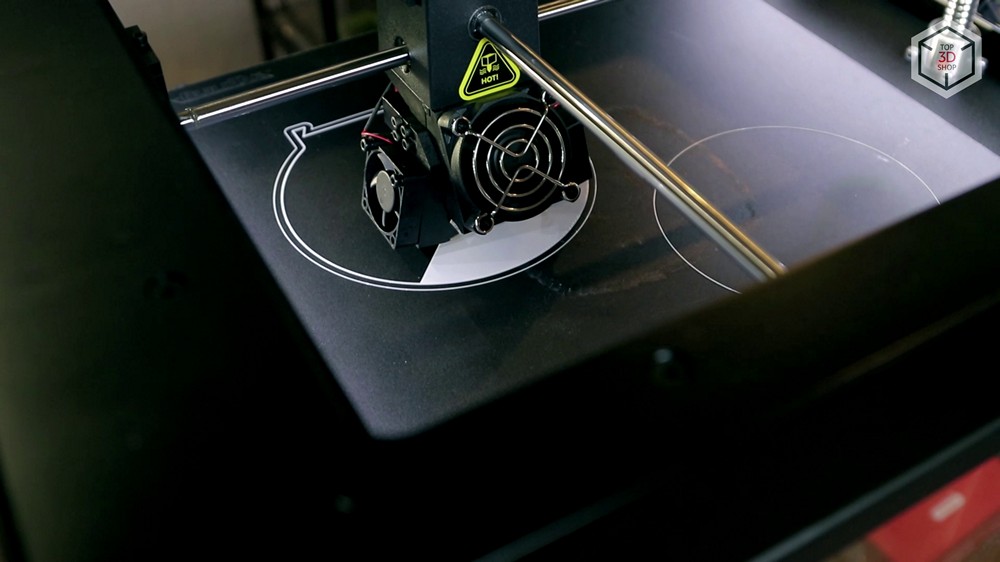

Like any FDM printer, Raise 3D Pro 2 Plus prints by applying molten plastic onto a work platform in layers. Different types of plastics are used as materials.

Some manufacturers chip coils of their own production and the printer can work only with these coils. There is nothing like this here, you can use the flag of any manufacturer. However, Raise also releases its plastic, and all the tests from the company the printer passed, of course, with it.

The layer thickness is adjusted in the slicer and is declared from 10 microns, which seems rather optimistic, because photopolymer printers print with a layer thickness of 10-20 microns. Also note that if you print a 60 cm model on a 10 micron layer, it will take you a long time to print. For example, if it is a pipe with a diameter of 10 cm, without a lid and bottom and with a wall thickness of one layer, at a maximum speed of 150 mm per second it will take you a little more than 33 hours to print, and at normal speed, at 30 mm per second, about 166 hours. You can imagine how long it will take for something more complex.

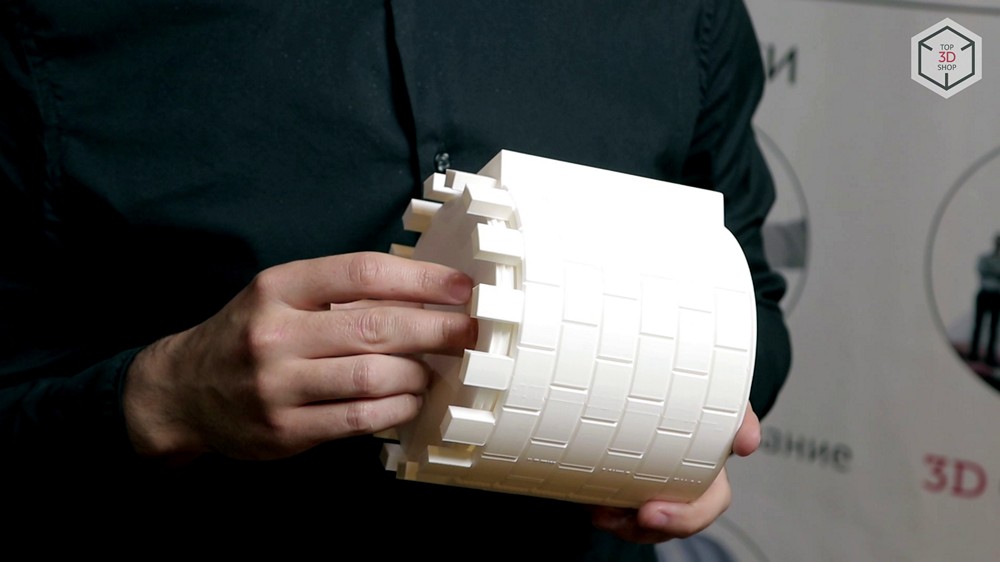

Compare products printed with a layer of 10 microns and 200 microns.

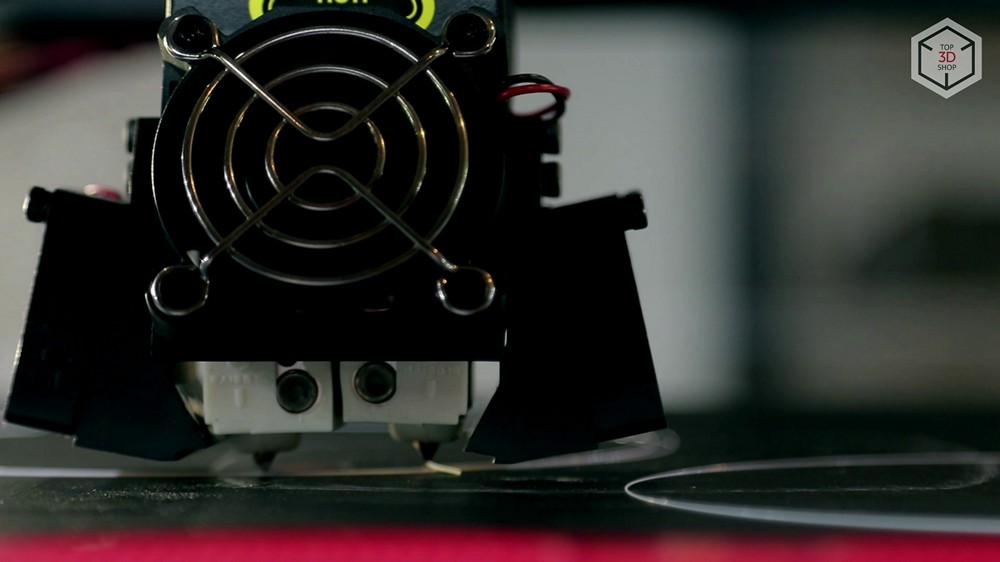

Nozzles are used with a diameter of from 0.2 to 0.8 mm, complete with nozzles of 0.4 mm.

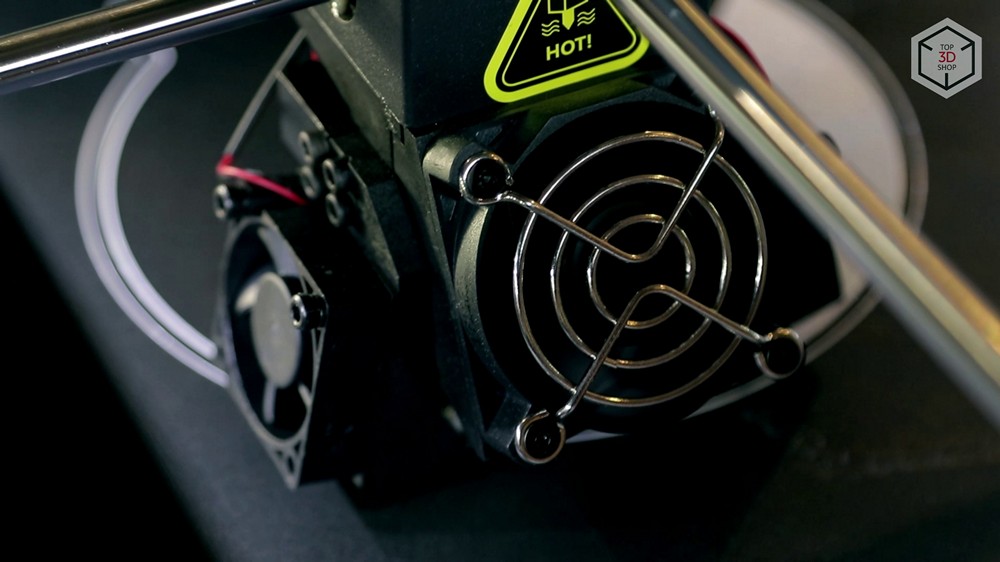

The platform is heated to 110 degrees, which is very good, helps when printing with thermoplastics with strong shrinkage. The extruder itself warms up to 300 degrees. This is not a record, but more than enough for most modern plastics to print.

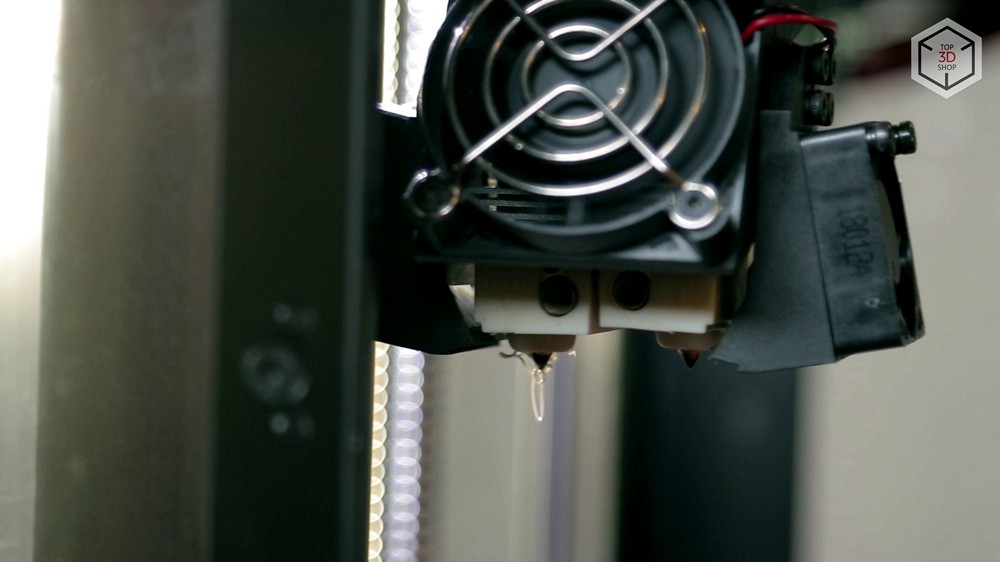

Extruder double. When switching, the nozzle rises by 1.5 mm, this is enough so that it does not interfere with printing with the second material, and this does not prevent printing with flexible materials that can clog the extruder nozzle. Switching lasts only a second.

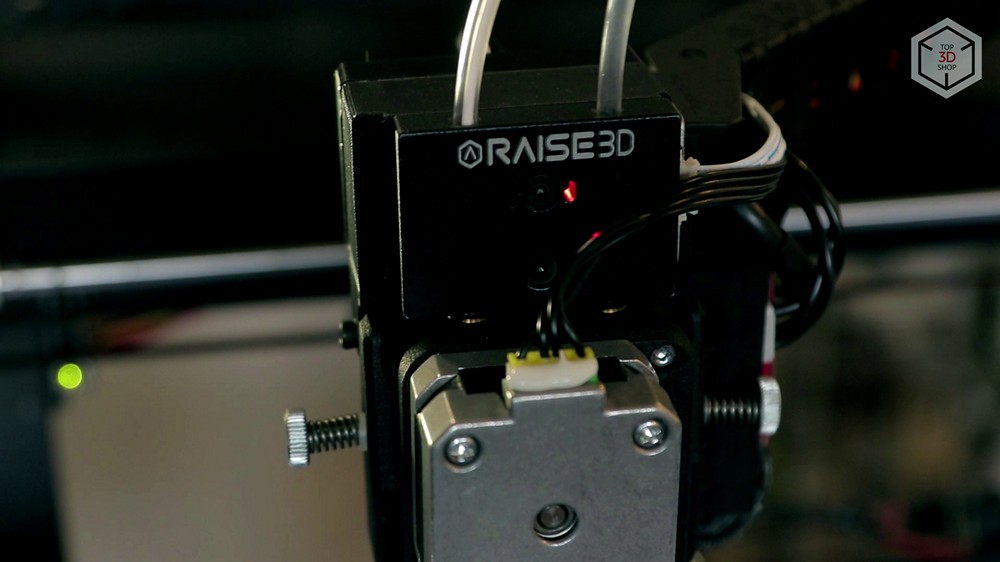

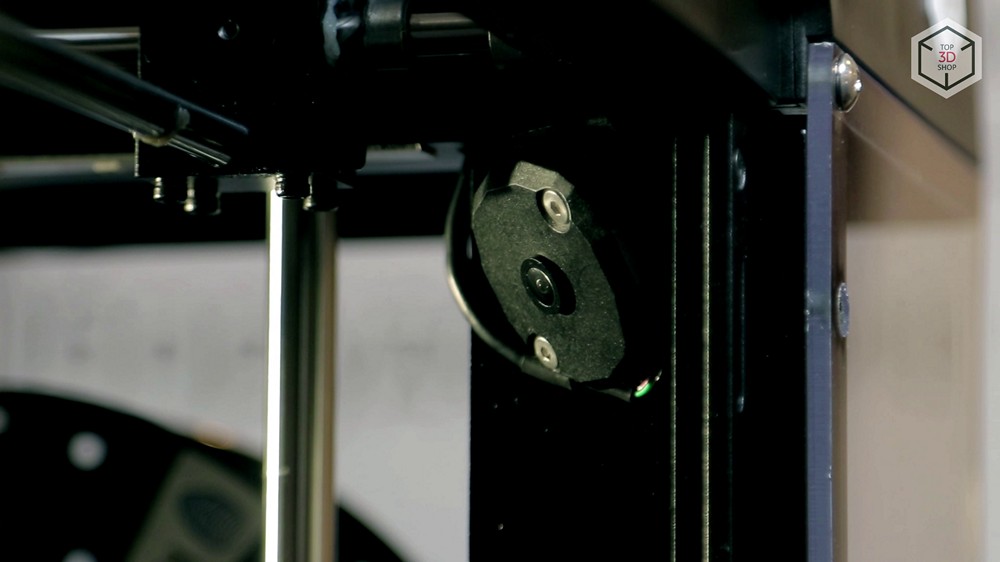

Another interesting feature of the extruder is the thread break sensor. Judging by the specification, it is optical and is located right here at the top of the extruder.

If the thread breaks, the printer pauses until the user fixes the problem.

Unlike the previous version, all calibrations are now automatic.

Well and, of course, the main feature: the size of the work area, this is actually a cube 30x30 cm, or a bit narrower, if we print with two nozzles. This is more than many personal printers. Actually, it is precisely such advantages as a large camera and a twin extruder that make this printer very interesting.

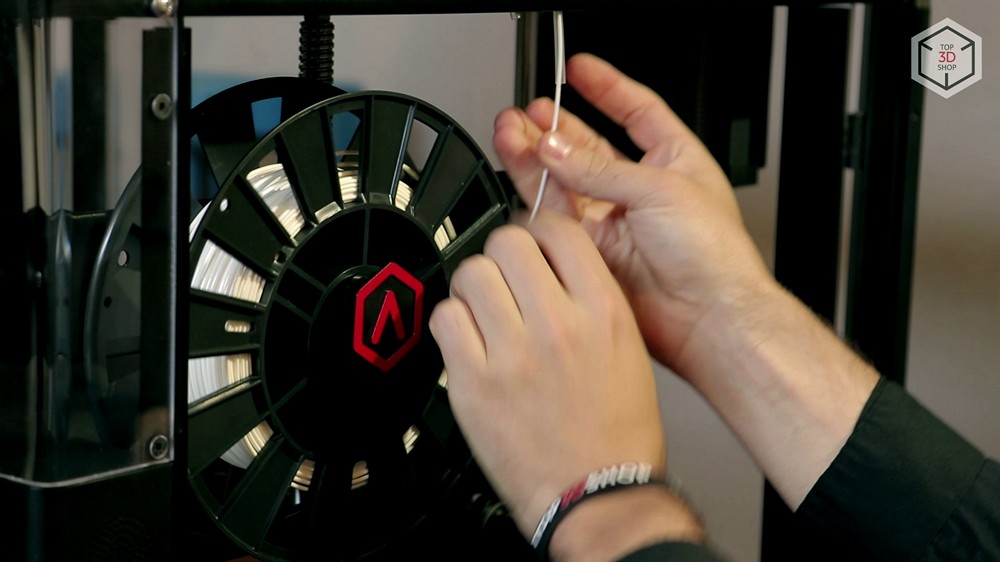

Coils are installed in a special side compartment, one above the other.

A little bit about coils: a multimaterial printer, freely prints with standard plastics such as ABS and PLA, as well as exotic, ranging from composites with wood filling to flexible materials like FLEX.

Extruder heats up to 300 degrees, very rarely you may need more, except in rare high-temperature plastics. It is better to print exotic with nozzles of at least 0.4 mm in diameter so that the nozzle does not clog.

The platform is aluminum, with magnetic holders, easily removed in one motion.

An interesting arrangement of magnets: four large magnets are used in the corners, which prevents the platform from slipping and bending during printing.

Equipment

The printer is delivered in a large cardboard box, inside everything is laid with foam plastic, all moving parts are secured with plastic fasteners and ties. Included: a set of hex keys, spatula, protective gloves and plastic for printing.

Design

The design of the printer has not changed much compared to previous Raise products, it is dark with lots of transparent parts. Printer material - aluminum and plastic, steel, cylindrical guides. The kinematics of the printer is the same as that of the Ultimaker.

The platform is rather unusual, it is not traditional glass, but a thin aluminum sheet with a special coating, similar to the “Makerboat” table. The basis of the platform is steel. The removable part of the platform is held by magnetic holders.

In general, such table material is very interesting and usually does not require the use of adhesives, such as glue or spray.

The printer is equipped with a camera so that you can monitor the print from your phone or computer, and you can connect to it remotely via Wi-Fi.

Files for printing can also be added via WiFi, either from an SD card or via USB.

Large seven-inch touch-screen printer with a resolution of 1024x600.

The printer is equipped with a HEPA filter for fine air filtration. Few people need this in practice, but it will be a good argument for buying this device in a school office of Labor or Technology.

Software Overview

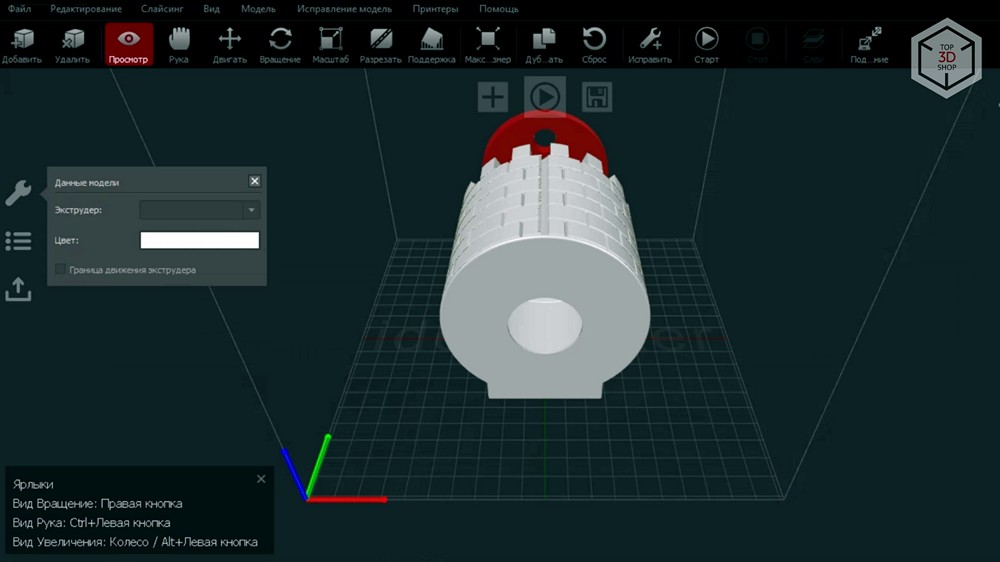

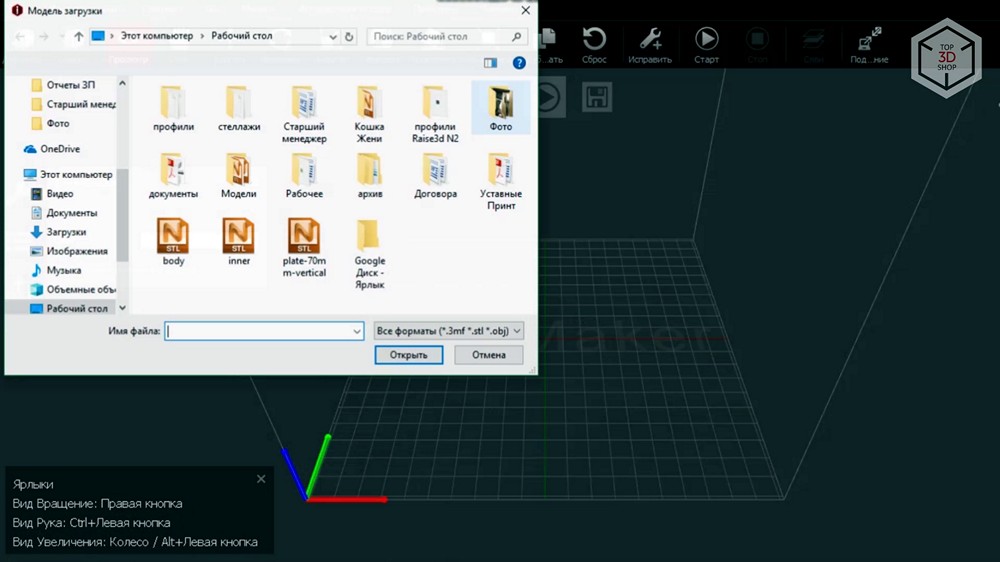

The printer works with its IdeaMaker slicer. It looks like a standard closed slicer, made for a certain line of printers.

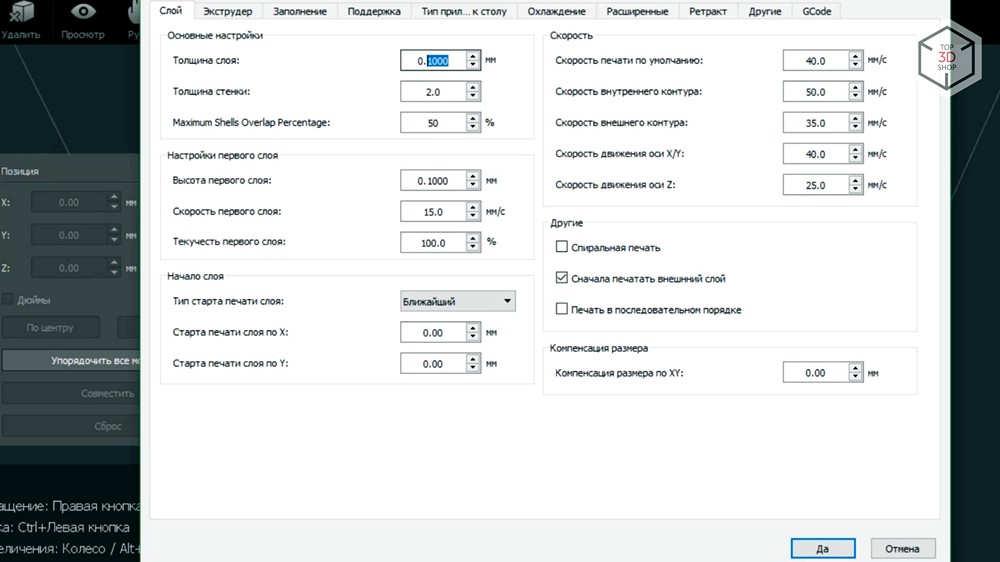

Upon closer inspection, we see that this slicer supports the profile system, and the number of print options available is quite large.

In principle, it is possible to prepare control programs for other printers. Of the interesting features: built-in system for checking and “curing” polygonal models.

When downloading a damaged model, the printer will display a message that it needs to be repaired, and this can be done directly in the slicer without using unauthorized software. Of course, the slicer has an embedded set of profiles for Raise 3D printers, basic plastics and print mode settings, such as “maximum quality” or “maximum speed”.

Before you begin, you need to take the coil of the plastic you chose in the slicer and place it in the printer. Refill plastic.

Then calibration, it serves to ensure that the printer stacks the first printing layer at the correct height, and here it is automated.

You can upload a file via Wi-Fi or via a USB flash drive.

You can also start printing a file directly from the software, via cable, but this can cause problems if the operating system suddenly starts updating.

It doesn't matter how you delivered your g-code to the printer. When it is in place, just start printing.

Printing is standard for FDM-printers, the printer displays information on the progress of printing.

Product removal

Printing is complete and it's time to remove the model from the platform. Since the surface is not glass, problems with the removal of the model should not be, and in extreme cases, you can use the complete spatula.

Total

The new printer Raise 3D does not depart from the concept of its predecessors, it just improves what has already happened. There were, for example, automated calibration and convenient platform mounting. This is all the same quality printer for printing models of impressive size.

High print quality and print support with two materials allow you to create large objects with completely soluble supports, which simplifies subsequent processing.

Recommended Raise 3D Pro 2 Plusfor prototyping, creating functional household and decorative art objects, details of cosplay costumes and much more. A large printing area and a transparent case make the printing process very visual, which makes it possible to use the printer as a teaching aid - it will be highly appreciated in educational institutions and engineering circles and clubs for children and youth.

You can buy Raise 3D Pro 2 Plus, pick up consumables and learn how to use the printer in Top 3D Shop: every printer customer gets the right to attend a master class for free, for the rest it will cost 2,000 rubles.

And on September 21, the master class is free for everyone at the exhibition and conference “Top 3D Expo. Digital Education 2018 ”, which itself is also free of charge, but requires prior registration on the event website.

Register and come, it will be interesting.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: