Making a self-timer for almost any camera

If anyone does not know, I have a hobby - copters and recently set out to raise instead of a soap box something decent for taking pictures from the air. But in the air you don’t press the buttons, but sculpt the mechanics to simulate the fingers — this is overweight and hemorrhoids with the mechanics proper. Therefore, without hesitation, I looked at the hole with the inscription remote on the Panasonic G3 and climbed to google what can be done with it. And I got to a wonderful site with a pinout of a similar connector for almost all cameras.

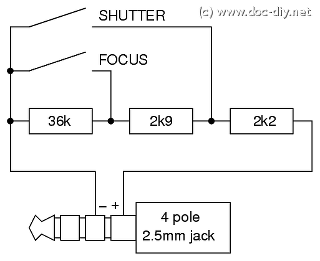

If anyone does not know, I have a hobby - copters and recently set out to raise instead of a soap box something decent for taking pictures from the air. But in the air you don’t press the buttons, but sculpt the mechanics to simulate the fingers — this is overweight and hemorrhoids with the mechanics proper. Therefore, without hesitation, I looked at the hole with the inscription remote on the Panasonic G3 and climbed to google what can be done with it. And I got to a wonderful site with a pinout of a similar connector for almost all cameras. As it turned out, it all boils down to just short-circuiting the contacts, but Panasonic threw up concern, apparently deciding that everyone is not cool. Therefore, in the photo on the right, you see scary assemblies of series-connected resistors, so that it slightly approaches the value indicated in the picture:

Of course, it was not possible to select the exact one, but in the end it worked and didn’t even need to think about the focus button, when you press the shutter button, both of them happen immediately.

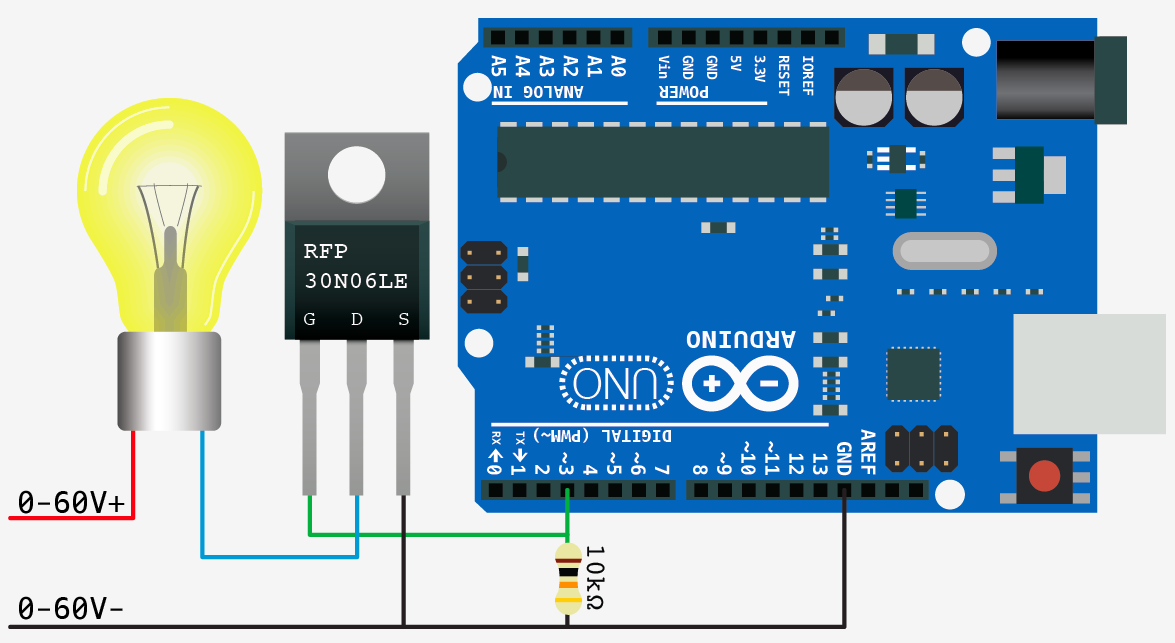

As you remember, I need this to control the camera in the air and, after indulging in the closure of the wires, I began to look for how to close these wires through the Arduino. Serving + 5v is at least dangerous, just short-circuit the contacts without getting into the circuit, the arduinka does not know how. The first thing that came to mind was the usual relay, but knowledgeable people said that there is such a thing - n-fet, which will do the same thing, only easier and less in weight. RC modelers know that in any speed controller (ESC) of these fets, they simply fell into pieces, so I finished off one of the regulators, dropping 3 n-fet from it immediately marked 4420, which led me to Si4420DY * SingleN-Channel Logic Level PowerTrench® MOSFET, which was exactly what I needed. Further (I’m not a radio amateur, excuse me) I began to look for how to connect this miracle to Arduino, everything turned out to be very simple, for example, connecting a light bulb:

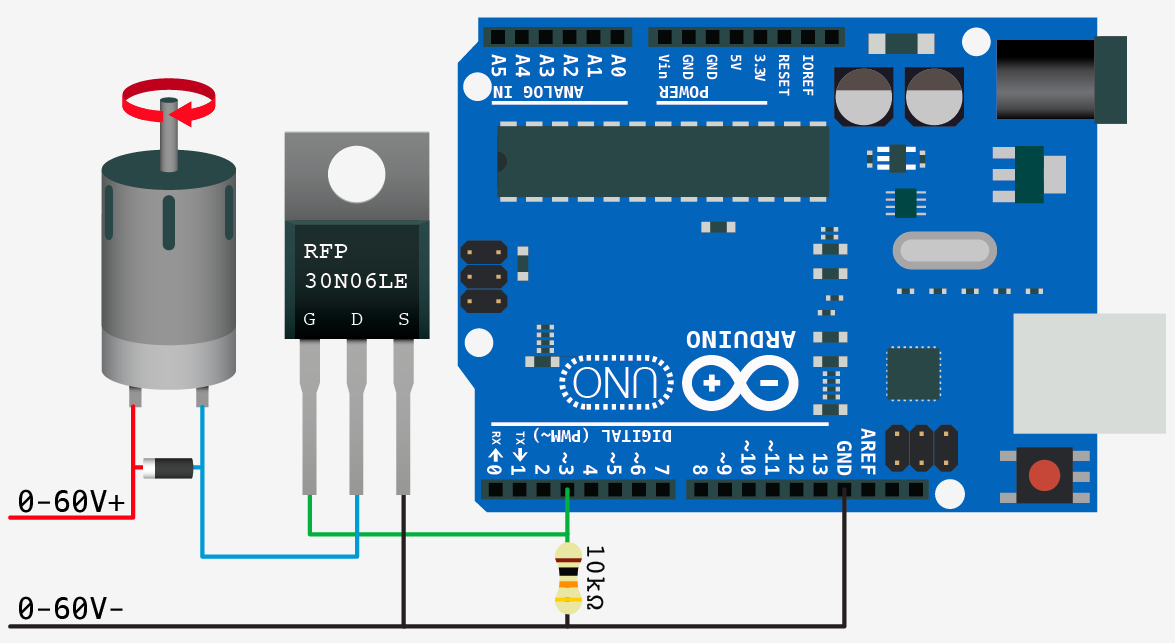

Or a motor:

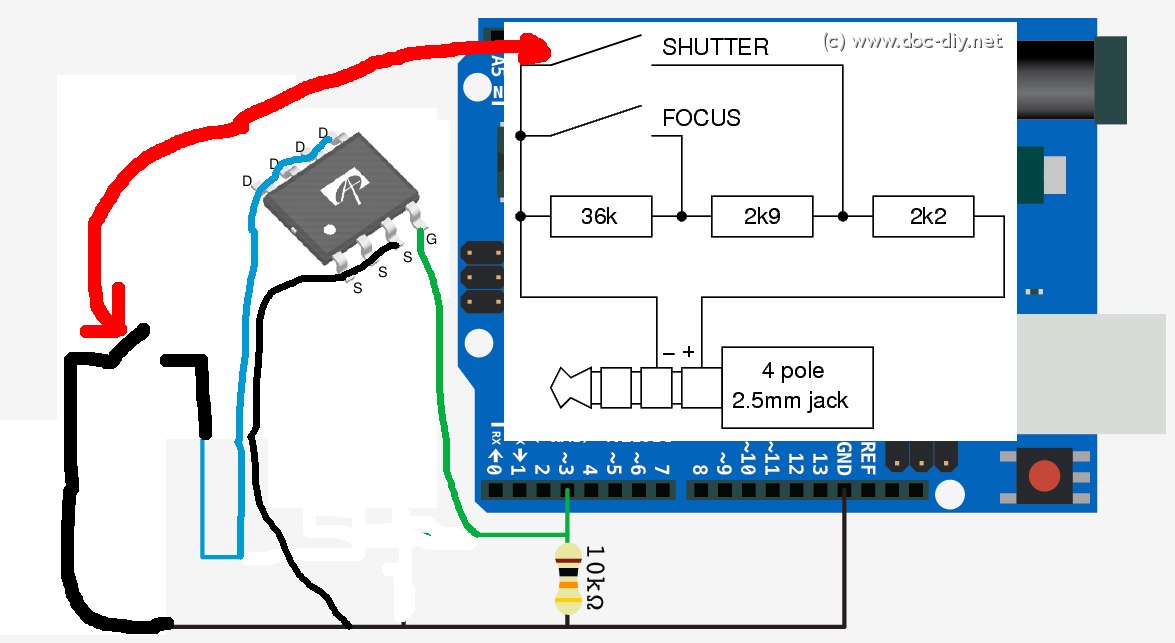

After thinking and looking at the markings, I concluded that such a connection would work (before soldering checked with a knowledgeable person who gave the go-ahead):

Soldered according to the scheme, uploaded a small sketch:

void setup() {

pinMode(13, OUTPUT);

pinMode(3, OUTPUT);

}

void loop() {

digitalWrite(13, HIGH); // зажечь статусный светодиод

digitalWrite(3, HIGH); // активировать спуск

delay(500); // ждем пол секунды, чтобы фотоаппарат сфокусировался

// и сделал кадр (надо варьировать в зависимости от вашей технике)

digitalWrite(3, LOW); // выключаем спуск

digitalWrite(13, LOW); // и светодиод

delay(5000); // ждем 5 секунд и делаем еще один кадр

}

We connect the Arduino to the camera and apply power to it:

As you can see, it works perfectly and you can do anything further, for example, add a variable resistor or a screen with buttons to change the delay before descent. Or catch insects and animals crossing the sensor. Or just take pictures and then upload thieves to the Internet . Or make a rotating object table with automatic photography and make pseudo-3D models for online stores. There are many applications and is limited only by imagination and needs.

But I was interested in working with a regular RC receiver. I will not bore the reader with the details, and I don’t need it (and I don’t know exactly how this magic works). Therefore, a simple copy-paste project was posted on github , so that anyone could complement and improve this thing for aircraft models and not only.

And what if there is no specialized solution

Here it’s more difficult, sometimes the manufacturer leaves such an input for controlling equipment in a tricky proprietary connector, but the easiest and most dangerous option is to solder to the contacts of the shutter button of your camera.

I prepared the Sony tx55 (I also use it on the copter, it shoots beautifully , it weighs only 100 grams).

An autopsy showed such beauty in very small sizes. The tester managed to find out which contacts are responsible for pressing the focus button (half-press) and the shutter button itself.

After that, he sharpened the soldering iron with a file and very neatly adjusted 3 wires: focus, shutter and gnd (ground / common).

After which he turned on the camera and tried to close the contacts, it turned out that everything should be closed right away, i.e. focus and shutter to the ground. For a future connection, Arduino brought contacts to the comb:

In terms of aesthetics, this is certainly terrible, but the soap box is used exclusively on copters, where such things do not bother anyone at all - the main thing is to make it easy and work.

One could bring out the zoom buttons (zoom) and connect them through the remaining n-fets. Unfortunately, the start button for video recording is made in the form of an icon on the screen, where there is no way to solder the wires.

Although the article is chaotic, I hope it will be pleasant and will benefit photographers and not only.

Opponents of Arduino controllers, I hasten to assure you that at the press of a button, things will not end. And forgive me for such a lamer description of the process.