How we invent smart home again

Hi Habr! In the last article, I mentioned that it is quite difficult to find kits for children to study all sorts of disciplines in an environment of children's circles of technical creativity. Today I will tell you about how we invented children's robotics kits.

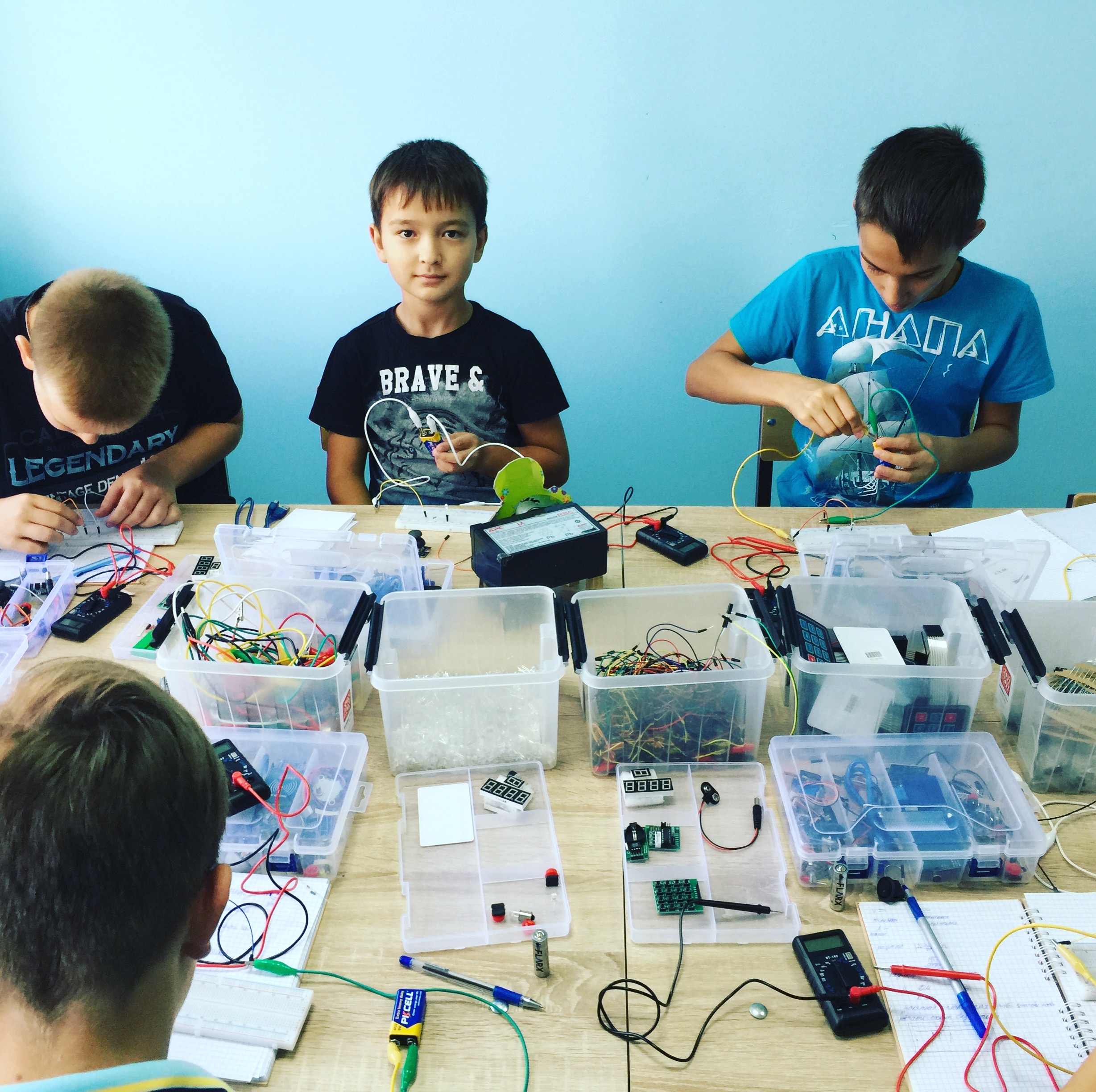

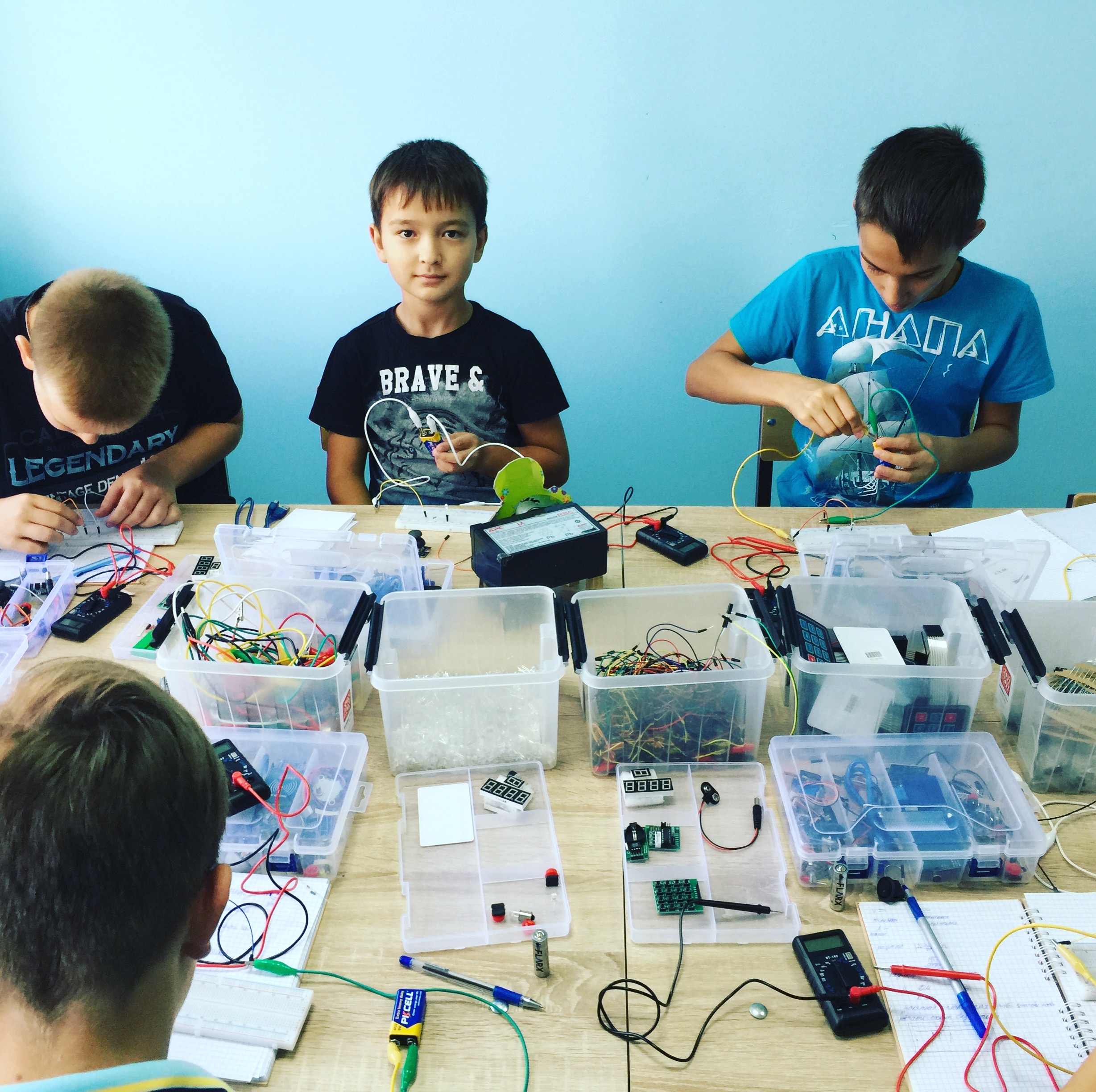

In the first month of the robotics center, in addition to speed writing various tutorials, we had to invent various devices for these programs. If the child says: “Look, this is a resistor, and this is a LED,” then there will be little confusion. It was always more interesting for children to do full-fledged projects that they had previously met in real life or could have applied them there.

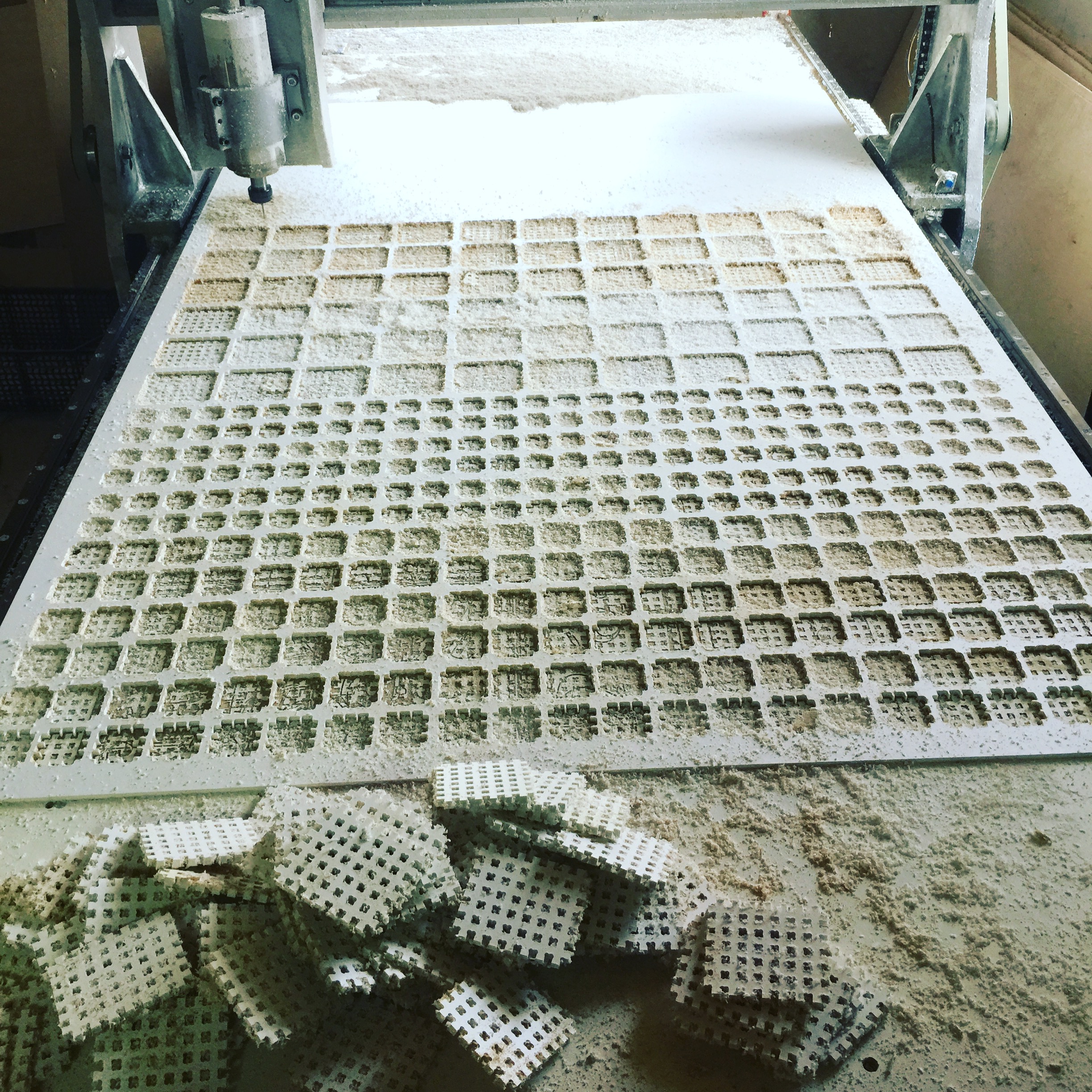

The first tool we decided to use was the structor. The Amperkivka price tags did not please us, to put it mildly, and we decided to produce the structure ourselves, since there was a production base with several CNC machines. For those who do not know, a structor is a completely open development. That is, everyone can download drawings from the Internet, cut a bag of a structurer and do whatever he wants with it.

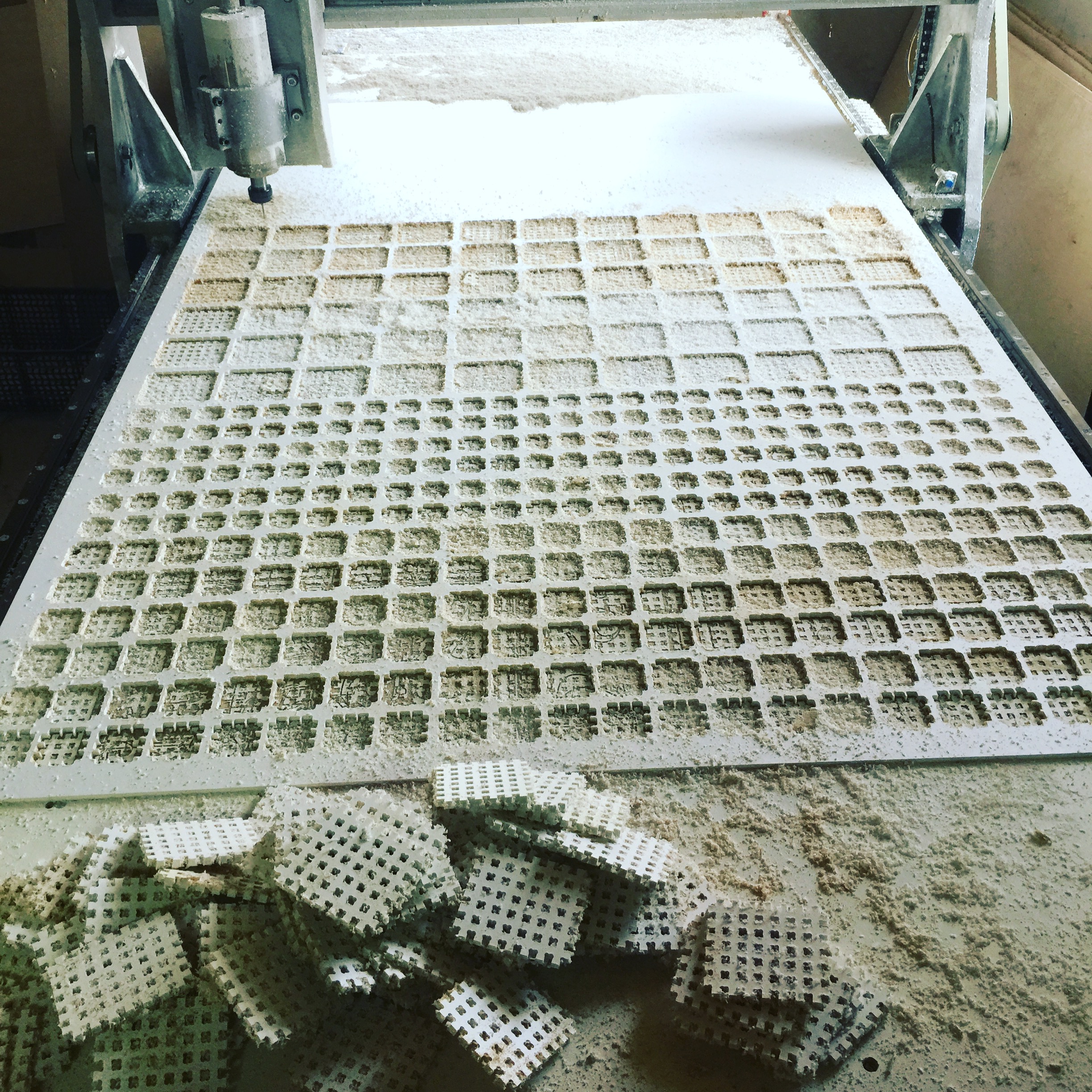

Looking at the pictures of finished parts, it seemed to us that it was simpler to produce a structor than to cut a wooden bar with a hand saw. But it turned out to be a bit more complicated.

The biggest difficulty was to choose the cutting mode, that is, the feed and rotation speed, as well as the optimal type of cutter. After a dozen broken cutters and more than a dozen defective parts, we still managed to cut the perfect piece of the structure. We immediately made a couple of crates of boxes and carried them to the center of robotics.

Structures like 90 percent of children. The rest did not understand him. It seemed too simple to them. The peculiarity of the structure is the offset of the part by 5 mm after insertion into another part. Therefore, the struct is actually more complicated than it seems. When the children, to whom the structor seemed incredibly simple, took him in hand, started to build something, and they did not succeed, the first reaction was the phrase: "Your structurer is complete garbage, and I do not want to collect it." But there were quite a few such children, so we considered testing the structurer successful. However, it is good to make various cases and boxes out of the structure, and that’s where his merits ended. A full-fledged robot from a structru would lose to a robot from the same Lego or Soviet designer. To build a robot in it is too monotonous parts. But we found a way out of this problem.

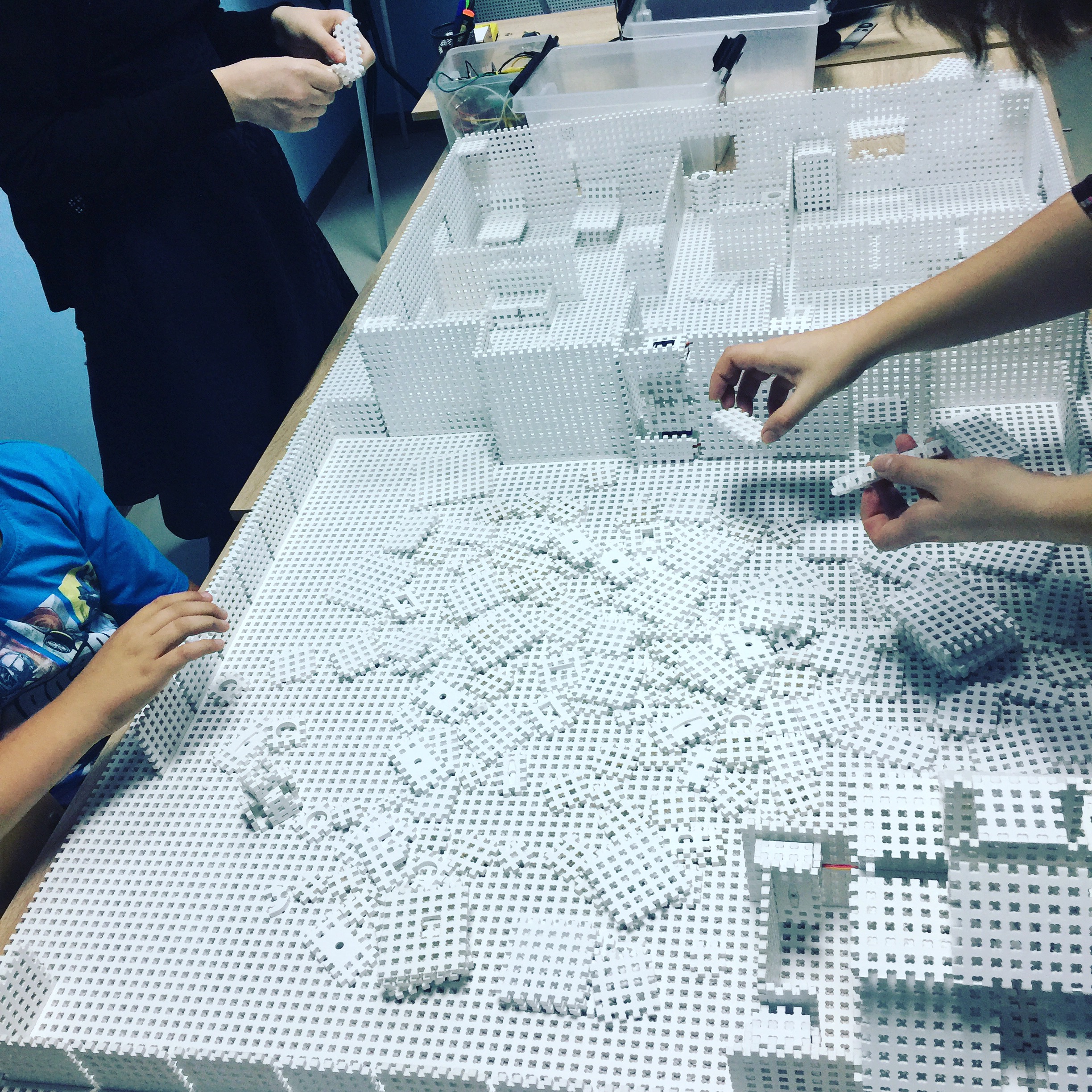

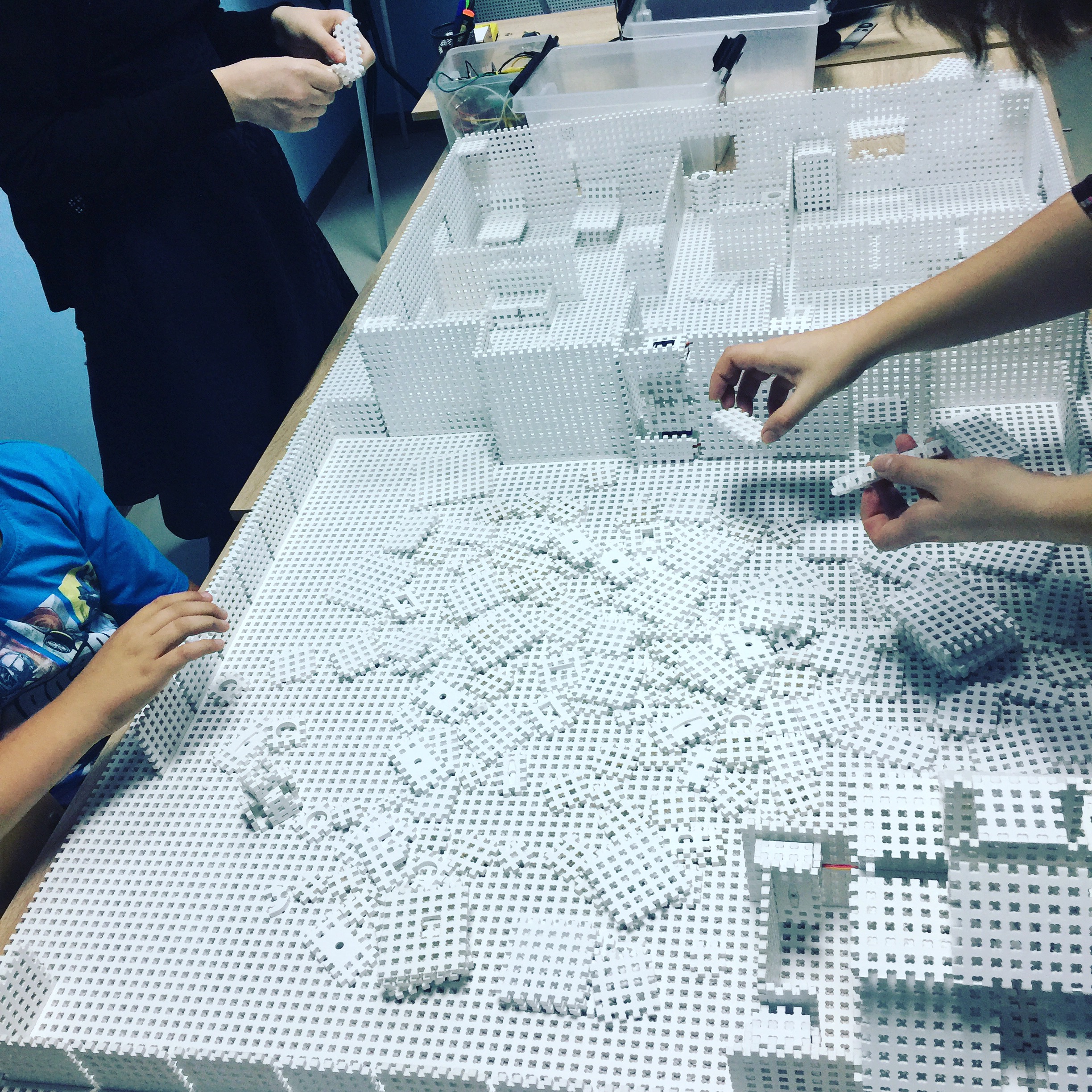

It was obvious that it was convenient to assemble rectangular elements from the struct, the other designers could not boast of it. Therefore, we decided to make a huge part of the structure for modeling a city of 2x1 meters. This sheet can be put on the desks, and the children right on it are collected at home, which can then be merged into the city. Children liked this approach tremendously. Those who did not understand the constructor at the very beginning, now gladly collected various structures from it.

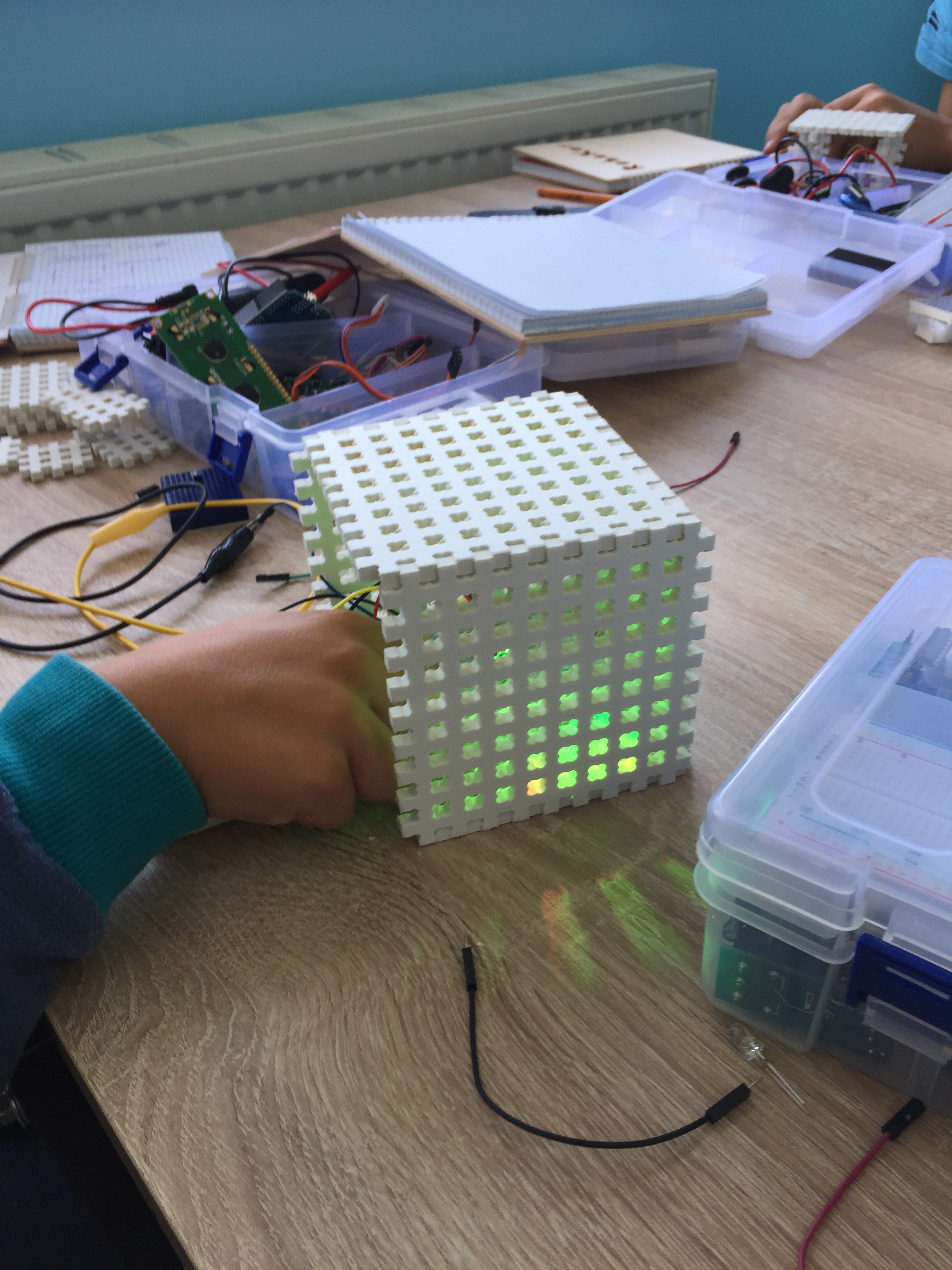

Children from him was just not to delay. The lesson plan with the construction of the city was as follows: half of the class children collect the city from the structure, while all the buildings should be thematic: school, hospital, zoo, military base, etc. The rest of the lesson the children have in the city all kinds of electronics: they pull wires from the power station (a block with batteries) into each house, carry out street lighting, make calls and so on. Everyone wanted to use as complex a scheme as possible in their home, so the children listened more attentively to the theory and better assimilated the material.

After a couple of months, we finally wrote a training program a few months in advance, and we had free time. We decided to spend it on the development of robotics kits for children's centers of technical creativity.

A small digression:

At the very beginning of the development of our robotics centers, we seriously considered the purchase of a franchise of a famous networker. Once again, the prices surprised us. Network mugs for the franchise asked from 0.5 to 1.5 million rubles. In this case, all that they offered for the money: help with choosing a place, opening a jur. persons access to the curriculum and a small landing. Robotics kits need to be bought separately. The lion's share of the cost of the franchise was in the brand of the circle itself. However, in small towns almost no one had heard of the famous Moscow robotics networks or regional centers. Yes, and without exception, all the circles worked on the lego, which did not make us happy. Lego-robotics at that time (in principle, as now), we disliked.

The analysis of the existing franchises was the first beacon to do everything in a normal way. Ideal - you buy a franchise for approximately 500 thousand rubles. This price includes: robotics and electronics kits, computers, a designer’s ton for design, curriculum, furniture and small household appliances (TV, water cooler, etc), assistance with site selection and legal entity registration, advertising assistance and start-up support . When we were looking for a franchise (mid-2017), there wasn’t that close in the market.

Continuation

We gathered a team of developers in one of the centers of robotics, closed tightly, typing in advance a meal for a couple of days, and began to invent sets. The first set of robotics was planned to be assembled on the basis of a structure. In dreams, it was a huge beautiful box in which there was a mountain of structure and electronics, and a huge book in which a hundred different devices and experiments were painted. After the initial evaluation of the planned work and competitors in our team, there was a split. Half thought that the set we will develop and get quite interesting. The other half said that the structor is not suitable for such a set. After a day of work, we still had models of various devices ready. It is worth saying that there were very interesting projects. For example, an automated chandelier, which was included by the movement itself or by the degree of illumination, a safe with a combination lock, a robot that can drive along the line, a cell phone model and much more. However, when the lion's part of the work was already done, the main programmer had an interesting idea.

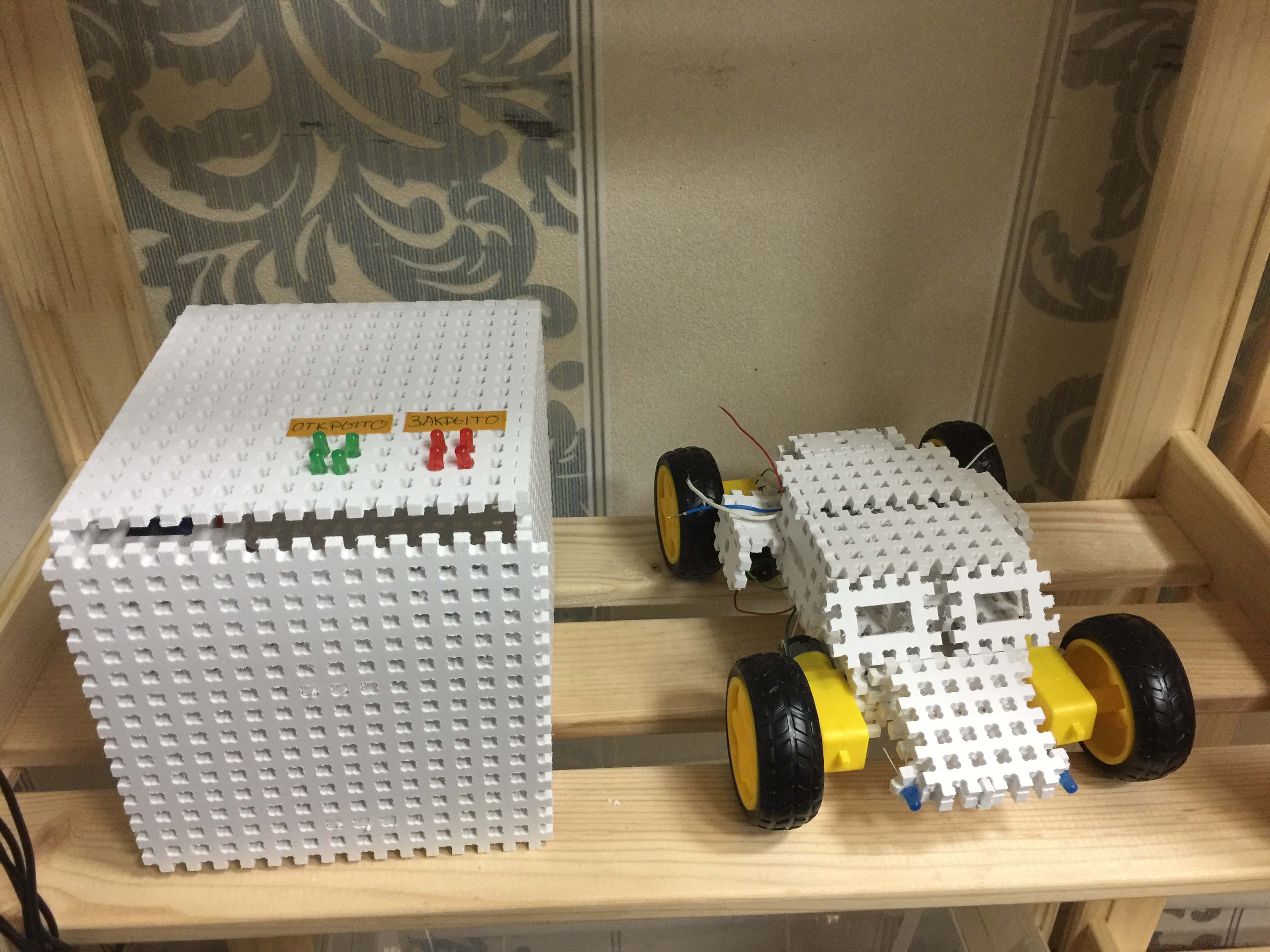

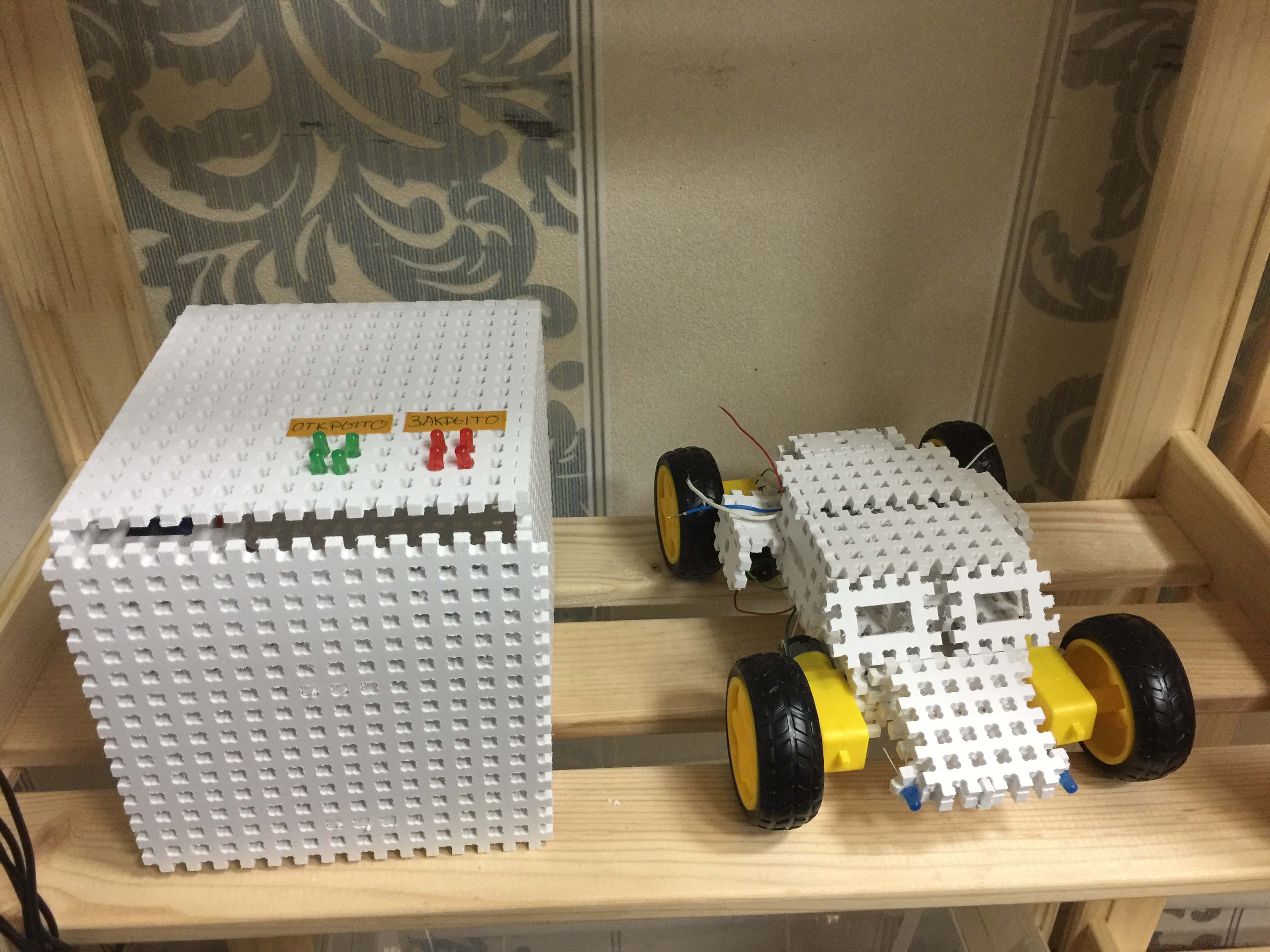

A few months after the opening of the first robotics center, we drove several children to regional competitions with a huge model of a smart house, made on the same sheet for designing 2x1 m. Teach children to the presentation. They addressed each other by name and patronymic. In general, we won the competition at that moment, as soon as we entered the room in which it was held. A smart house on the basis of a structure is quite interesting, because it has all the necessary details for this! Electronics for a smart home model was always full, but for some reason no one produced any designer.

We decided to look for sets of smart home. The idea of combining electronics with a structure seemed so simple that we didn’t believe that nobody had done that yet. Yes, at least the same Ampere. You'd be surprised, but this really was not. We immediately outlined a rough project plan, the model of the house was assembled from the available structure, all the electronics were unsoldered. After creating the first, rough model of a smart home from a structure, we realized that making a set based on it is a really cool idea!

The countdown began, and we began to design our first set of child robotics. A lot of processes were developed in parallel and worked day and night.

From interesting:

We were going to order boxes for our set from the guys who make the packaging almost for the whole Krasnodar region. However, the minimum order amount for boxes of interest to us was 300 thousand rubles. This sum itself is not so big on the scale of the whole development, but if we count how many sets we need to complete in these boxes, it turns out a bit too much. Very few people are engaged in small lots of boxes in Russia, and if they do, then it costs unreasonably expensive. The decision was under our noses. PVC foamed plastic, from which we made the structure, is also excellent for making boxes. As a result, we modeled the boxes for the recruitment of a smart home from the structure in the form factor of the structure. It turned out very well.

A little more than a month later the first prototype of the set was ready. The curriculum for the recruitment at that time was written in half, but it is the most difficult part of the development of the recruitment. The first tests of recruitment in the field showed that we did something very cool.

In the middle of development, it dawned on us that we can also make a younger version of a smart home - a smart room. Most of the set of the smart room was taken from the smart home, so we got two sets for children's technical creativity in the shortest time possible!

The set of a smart home is assembled in several stages: first of all you design a model of your own home from a whole mountain of a constructor, then place all the necessary electronics in the model, according to the book, then transfer the electronics to your real home.

At the robotics centers, all the children liked our kits. Absolutely everything was included in the assembly, even the teachers. When new children come to register with us and see the whole process of developing a smart home, they almost always ask to stay right to class and at least watch what is happening.

Unfortunately, after the execution of work on 60% of the development of a set of smart home a bit faded. Now we have a fully prepared package. With the instructions things are worse.

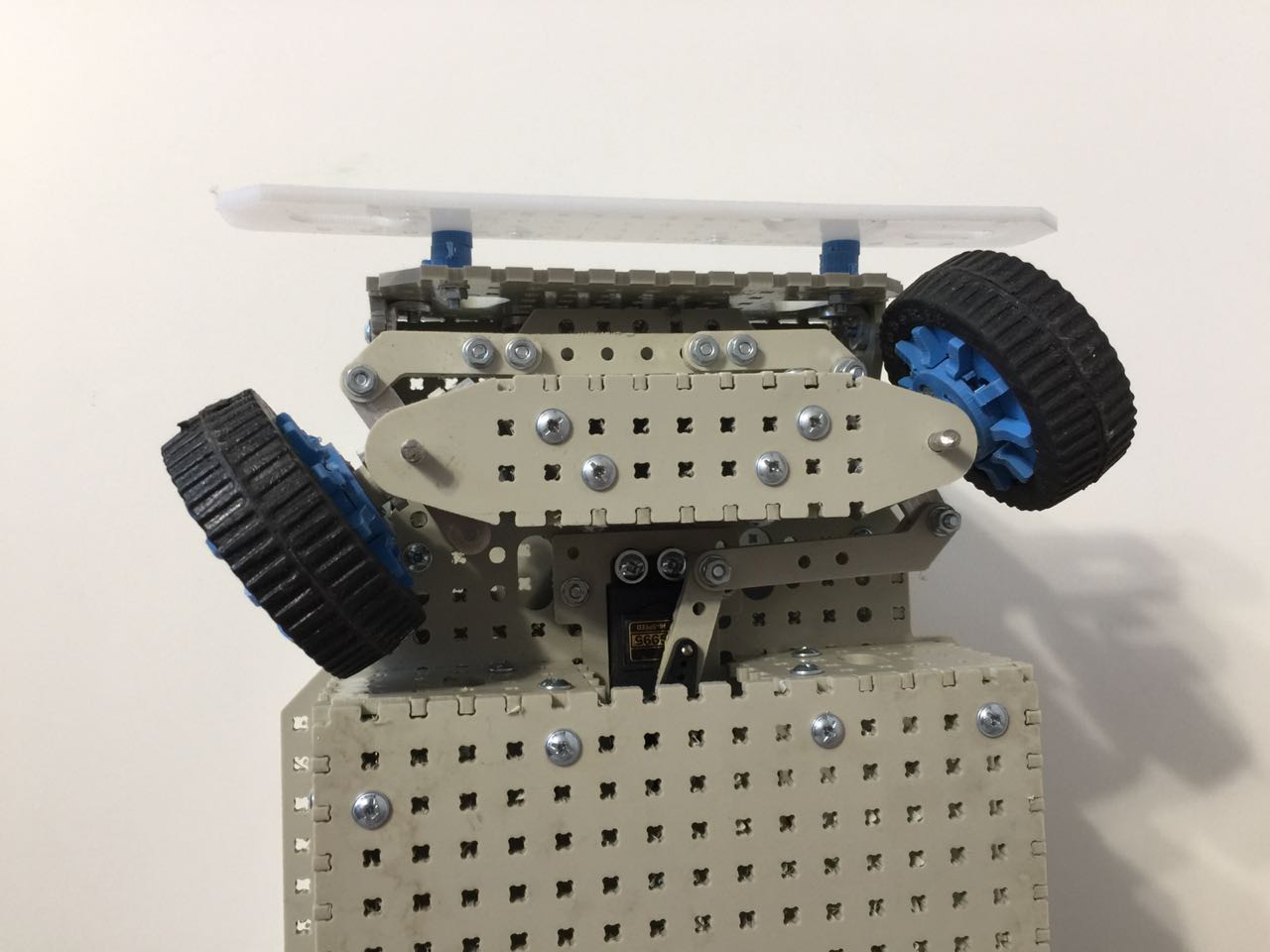

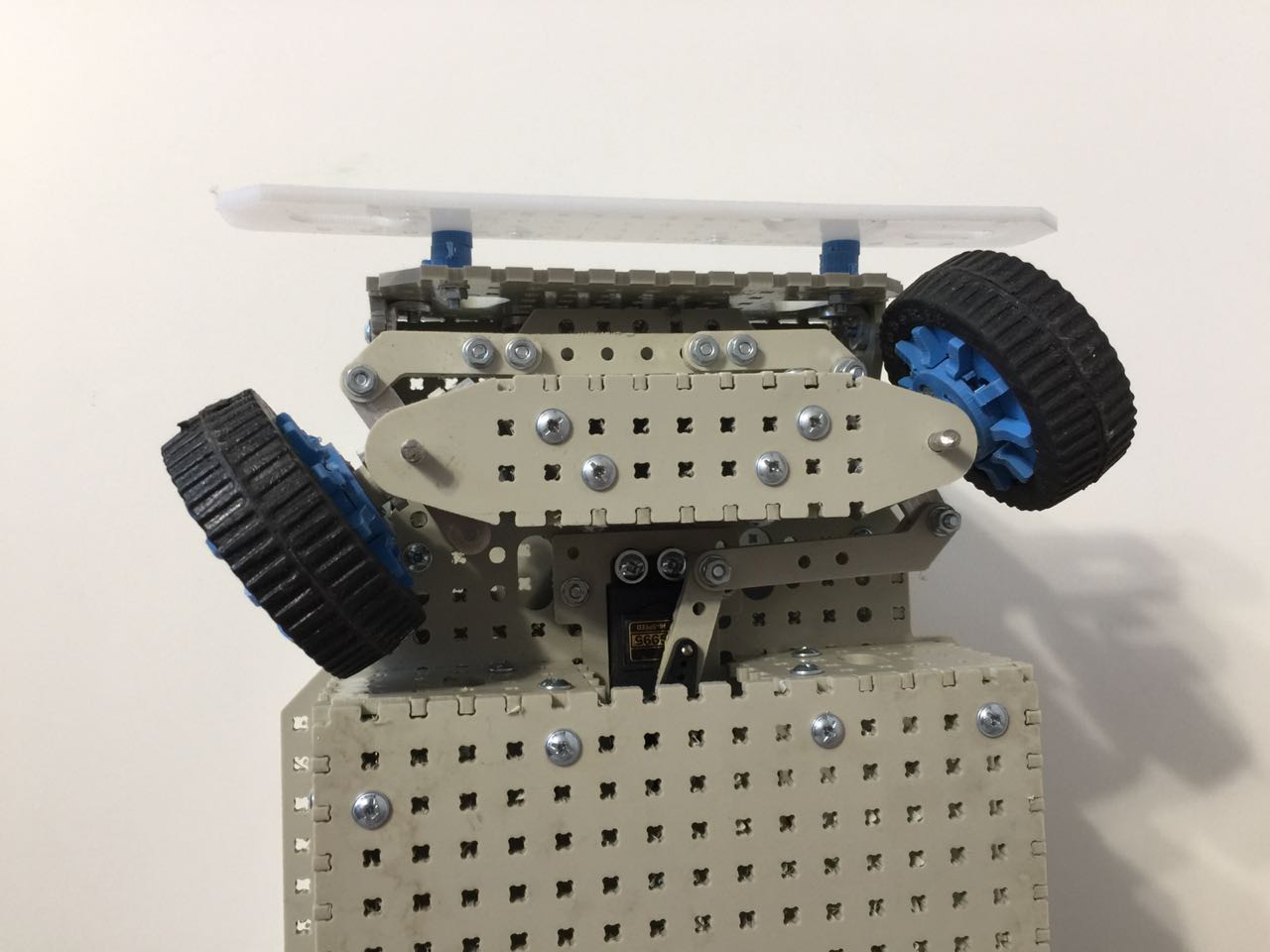

In parallel with the structure, we worked out a technical process for creating a multiplayer constructor, which is also an open source design. It was an order of magnitude more difficult to produce than a structurer, but in the end we learned how to cut quality parts.

The result of the development of a set on the basis of a multiplex was a very interesting truck.

Its dimensions slightly exceeded the standard car models. Load capacity was impressive.

Also, the rotation of the front wheels was made in a very interesting way. Body driving separate servo.

By the way, we also made all the aluminum parts and tires ourselves.

When developing the truck, we again suffered a disease of 60 percent. The truck itself is completely ready, but the packaging and instructions for it are not written. In general, as you already understood, everything is bad with our instructions. At the moment, the projects were put on the back burner, or put on the shelf as an exhibition sample with the hope that someday they will be able to return to the development.

In the first month of the robotics center, in addition to speed writing various tutorials, we had to invent various devices for these programs. If the child says: “Look, this is a resistor, and this is a LED,” then there will be little confusion. It was always more interesting for children to do full-fledged projects that they had previously met in real life or could have applied them there.

The first tool we decided to use was the structor. The Amperkivka price tags did not please us, to put it mildly, and we decided to produce the structure ourselves, since there was a production base with several CNC machines. For those who do not know, a structor is a completely open development. That is, everyone can download drawings from the Internet, cut a bag of a structurer and do whatever he wants with it.

Looking at the pictures of finished parts, it seemed to us that it was simpler to produce a structor than to cut a wooden bar with a hand saw. But it turned out to be a bit more complicated.

The biggest difficulty was to choose the cutting mode, that is, the feed and rotation speed, as well as the optimal type of cutter. After a dozen broken cutters and more than a dozen defective parts, we still managed to cut the perfect piece of the structure. We immediately made a couple of crates of boxes and carried them to the center of robotics.

Structures like 90 percent of children. The rest did not understand him. It seemed too simple to them. The peculiarity of the structure is the offset of the part by 5 mm after insertion into another part. Therefore, the struct is actually more complicated than it seems. When the children, to whom the structor seemed incredibly simple, took him in hand, started to build something, and they did not succeed, the first reaction was the phrase: "Your structurer is complete garbage, and I do not want to collect it." But there were quite a few such children, so we considered testing the structurer successful. However, it is good to make various cases and boxes out of the structure, and that’s where his merits ended. A full-fledged robot from a structru would lose to a robot from the same Lego or Soviet designer. To build a robot in it is too monotonous parts. But we found a way out of this problem.

It was obvious that it was convenient to assemble rectangular elements from the struct, the other designers could not boast of it. Therefore, we decided to make a huge part of the structure for modeling a city of 2x1 meters. This sheet can be put on the desks, and the children right on it are collected at home, which can then be merged into the city. Children liked this approach tremendously. Those who did not understand the constructor at the very beginning, now gladly collected various structures from it.

Children from him was just not to delay. The lesson plan with the construction of the city was as follows: half of the class children collect the city from the structure, while all the buildings should be thematic: school, hospital, zoo, military base, etc. The rest of the lesson the children have in the city all kinds of electronics: they pull wires from the power station (a block with batteries) into each house, carry out street lighting, make calls and so on. Everyone wanted to use as complex a scheme as possible in their home, so the children listened more attentively to the theory and better assimilated the material.

After a couple of months, we finally wrote a training program a few months in advance, and we had free time. We decided to spend it on the development of robotics kits for children's centers of technical creativity.

A small digression:

At the very beginning of the development of our robotics centers, we seriously considered the purchase of a franchise of a famous networker. Once again, the prices surprised us. Network mugs for the franchise asked from 0.5 to 1.5 million rubles. In this case, all that they offered for the money: help with choosing a place, opening a jur. persons access to the curriculum and a small landing. Robotics kits need to be bought separately. The lion's share of the cost of the franchise was in the brand of the circle itself. However, in small towns almost no one had heard of the famous Moscow robotics networks or regional centers. Yes, and without exception, all the circles worked on the lego, which did not make us happy. Lego-robotics at that time (in principle, as now), we disliked.

spoiler

A year has passed since the launch of our first circle, we gained experience and opened another 4 circles of robotics. Each subsequent Center to launch was even more exciting than the previous one, while the more recent ones showed the best result. We recently started packing the franchise and faced a lot of pitfalls and interesting solutions. In the near future, we will publish on Habré our experience in the packaging of a franchise, because there was no detailed guide on this topic on the Internet.

The analysis of the existing franchises was the first beacon to do everything in a normal way. Ideal - you buy a franchise for approximately 500 thousand rubles. This price includes: robotics and electronics kits, computers, a designer’s ton for design, curriculum, furniture and small household appliances (TV, water cooler, etc), assistance with site selection and legal entity registration, advertising assistance and start-up support . When we were looking for a franchise (mid-2017), there wasn’t that close in the market.

Continuation

We gathered a team of developers in one of the centers of robotics, closed tightly, typing in advance a meal for a couple of days, and began to invent sets. The first set of robotics was planned to be assembled on the basis of a structure. In dreams, it was a huge beautiful box in which there was a mountain of structure and electronics, and a huge book in which a hundred different devices and experiments were painted. After the initial evaluation of the planned work and competitors in our team, there was a split. Half thought that the set we will develop and get quite interesting. The other half said that the structor is not suitable for such a set. After a day of work, we still had models of various devices ready. It is worth saying that there were very interesting projects. For example, an automated chandelier, which was included by the movement itself or by the degree of illumination, a safe with a combination lock, a robot that can drive along the line, a cell phone model and much more. However, when the lion's part of the work was already done, the main programmer had an interesting idea.

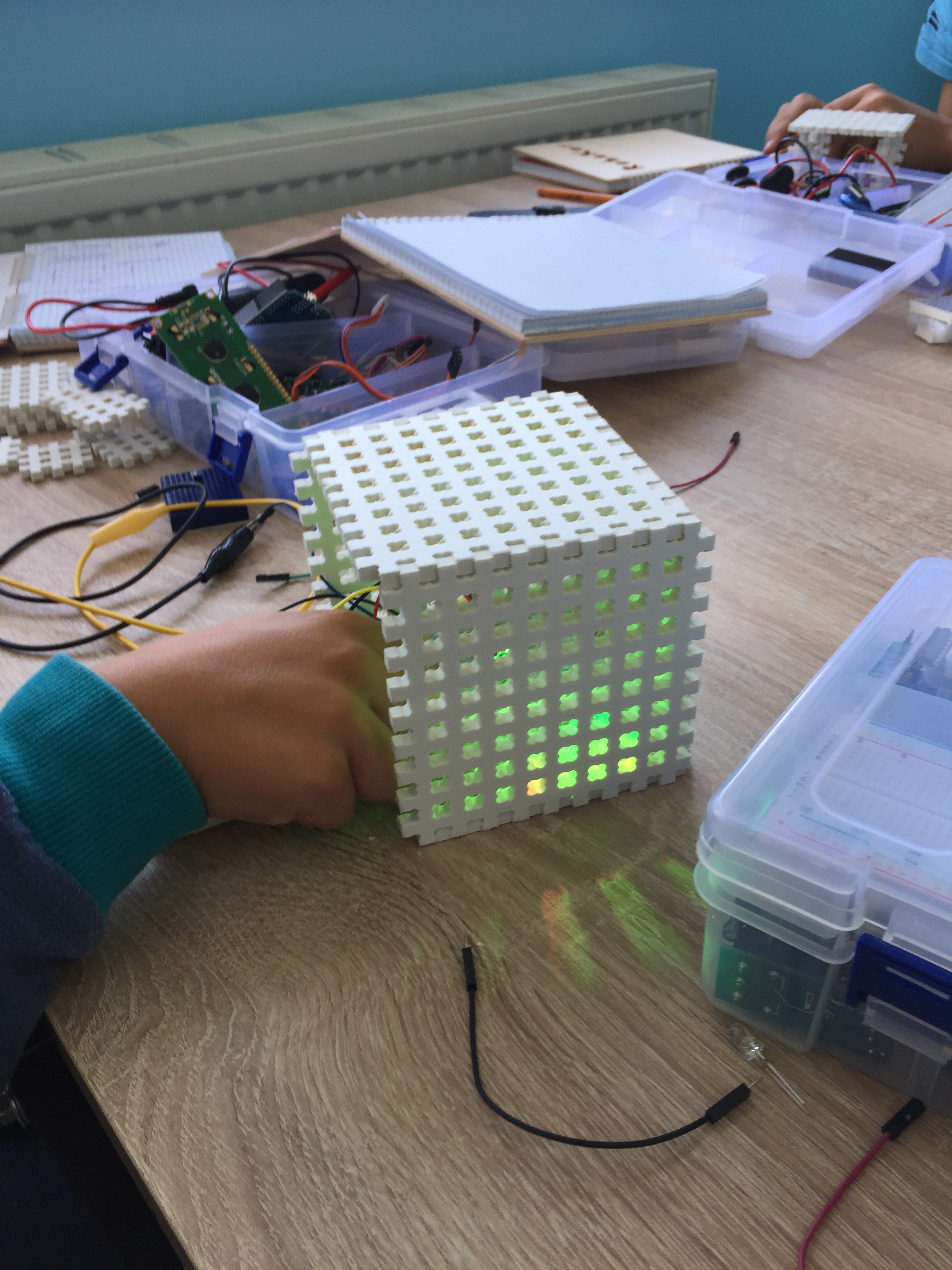

A few months after the opening of the first robotics center, we drove several children to regional competitions with a huge model of a smart house, made on the same sheet for designing 2x1 m. Teach children to the presentation. They addressed each other by name and patronymic. In general, we won the competition at that moment, as soon as we entered the room in which it was held. A smart house on the basis of a structure is quite interesting, because it has all the necessary details for this! Electronics for a smart home model was always full, but for some reason no one produced any designer.

We decided to look for sets of smart home. The idea of combining electronics with a structure seemed so simple that we didn’t believe that nobody had done that yet. Yes, at least the same Ampere. You'd be surprised, but this really was not. We immediately outlined a rough project plan, the model of the house was assembled from the available structure, all the electronics were unsoldered. After creating the first, rough model of a smart home from a structure, we realized that making a set based on it is a really cool idea!

The countdown began, and we began to design our first set of child robotics. A lot of processes were developed in parallel and worked day and night.

From interesting:

We were going to order boxes for our set from the guys who make the packaging almost for the whole Krasnodar region. However, the minimum order amount for boxes of interest to us was 300 thousand rubles. This sum itself is not so big on the scale of the whole development, but if we count how many sets we need to complete in these boxes, it turns out a bit too much. Very few people are engaged in small lots of boxes in Russia, and if they do, then it costs unreasonably expensive. The decision was under our noses. PVC foamed plastic, from which we made the structure, is also excellent for making boxes. As a result, we modeled the boxes for the recruitment of a smart home from the structure in the form factor of the structure. It turned out very well.

A little more than a month later the first prototype of the set was ready. The curriculum for the recruitment at that time was written in half, but it is the most difficult part of the development of the recruitment. The first tests of recruitment in the field showed that we did something very cool.

In the middle of development, it dawned on us that we can also make a younger version of a smart home - a smart room. Most of the set of the smart room was taken from the smart home, so we got two sets for children's technical creativity in the shortest time possible!

The set of a smart home is assembled in several stages: first of all you design a model of your own home from a whole mountain of a constructor, then place all the necessary electronics in the model, according to the book, then transfer the electronics to your real home.

At the robotics centers, all the children liked our kits. Absolutely everything was included in the assembly, even the teachers. When new children come to register with us and see the whole process of developing a smart home, they almost always ask to stay right to class and at least watch what is happening.

Unfortunately, after the execution of work on 60% of the development of a set of smart home a bit faded. Now we have a fully prepared package. With the instructions things are worse.

In parallel with the structure, we worked out a technical process for creating a multiplayer constructor, which is also an open source design. It was an order of magnitude more difficult to produce than a structurer, but in the end we learned how to cut quality parts.

The result of the development of a set on the basis of a multiplex was a very interesting truck.

Its dimensions slightly exceeded the standard car models. Load capacity was impressive.

Also, the rotation of the front wheels was made in a very interesting way. Body driving separate servo.

By the way, we also made all the aluminum parts and tires ourselves.

When developing the truck, we again suffered a disease of 60 percent. The truck itself is completely ready, but the packaging and instructions for it are not written. In general, as you already understood, everything is bad with our instructions. At the moment, the projects were put on the back burner, or put on the shelf as an exhibition sample with the hope that someday they will be able to return to the development.