3D Printer Classification

3D printing is steadily gaining momentum, and we are increasingly seeing posts that 3D printers have learned to print parts for the ISS, organs, homes, and more. Foreign technology publications are starting to say that 3D printing is able to revive industry in the states, and the shapeways service, before our eyes, shows interesting growth rates, albeit far from industrial ones. With such an abundance of laudatory texts about the impending revolution in production, the idea comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial proportions by reducing the cost of the printers themselves and the emergence of open source projects? You decide, and food for thought on the topic under the cut.

Immediately make a reservation that the standards in the industry are very arbitrary, for now. But a brief overview with the order of prices can be generated now. And so, let's get started.

Consumer

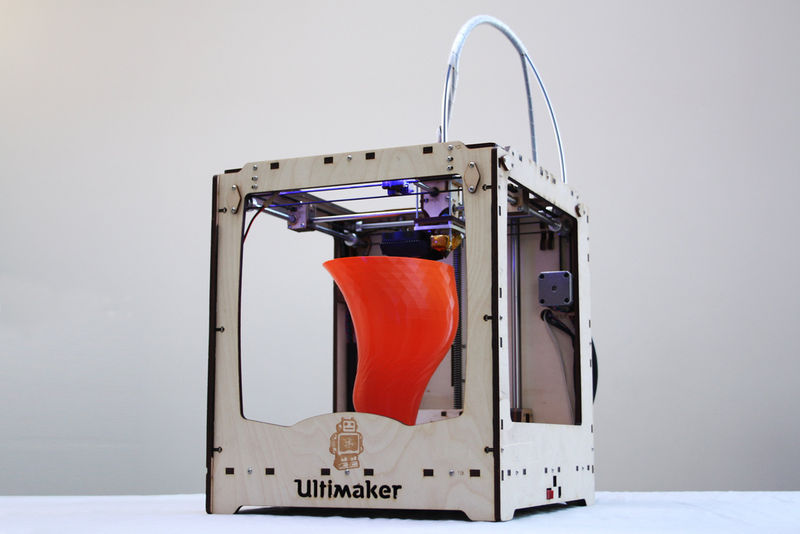

Type of printer, which is intended mainly for personal use. It is delivered in the form of the designer, or assembled. The vast majority of printer models of this type are derived from the open source RepRap project. Since their platform is basically the same, their characteristics are also very similar.

Designed with an eye for the average user and equipped with a fairly simple and intuitive interface. They print, as a rule, ABS and PLA plastic. Complex and high-precision objects to print will be quite problematic, but they print ordinary crafts with ease, albeit for a long time.

Price range: $ 500 - $ 3,500

Who it focuses on:

Designers / artists / inventors who work at home.

Personal

Border class printers, which is home, but at the same time refers to the lower level of industrial printers for business. These devices have much in common with brothers from the consumer class, but have higher quality and print accuracy that are inherent in professional 3D print systems. The appearance of such printers is more likely a reaction of large manufacturers to the growing market for home systems. Given the low accuracy of the consumer class, vendors have proposed smaller models of professional systems with close indicators.

Using printers of this class is just as simple and comes down to loading the image and pressing the start button. At the same time, this limits the possibilities in terms of various additional printing options.

Suitable for use in offices, however, the noise and high temperature conditions of some models suggests their placement at a certain distance from the working area. The ease of cleaning objects at the exit was not transferred to this class from industrial models, so it would be logical to place them in a separate workspace.

Price range: $ 7,000 - $ 40,000

For whom it is oriented:

For a small business with a small budget, but which has a need for periodic use of 3D printing. It can be engineering companies, design studios, marketing agencies.

Professional

Systems of this class no longer look compact, but rather look like large refrigerators. This is the basis of 3D printing technology, which includes all the achievements and opportunities available to the industry. The purpose of professional systems can be very different, from prototyping to full-scale production, which in turn makes them an excellent option for both large businesses and high-tech companies with a small staff. ShapeWays, by the way, uses printers of exactly this class.

Unlike their little brothers, these printers, due to the large number of modes and additional options, already require certain skills to work with them, so you can’t do without an operator here.

As for the workspace, here, too, is not so simple. They are very large and noisy, therefore they require a separate room with good ventilation. The requirements for the room vary, but the space should be something like a laboratory and with a high-voltage line.

At the output, we get a universal 3D print installation, which provides the highest print quality and larger product sizes compared to the lower grades. ShapeWays, for example, collects several objects per print cycle, placing them at some distance from each other, which ultimately has a positive effect on the speed of order processing.

Price range: $ 30,000 - $ 750,000

who directed:

For companies that have a constant need for prototyping, modeling, manufacturing of various kinds of objects with high quality and accuracy.

The production

name of the class speaks for itself. These machines are a combination of precision and quality of professional printers, a large printing area, a high level of automation and process control. On them, as in professional installations, you can print not only prototypes, but also the final consumer product.

Systems of this kind are not intended for ordinary users, and the amounts that will have to be invested in such production will make you have a logical desire to hire an experienced operator who will make the whole mechanism work 24 hours a day without downtime.

Small rooms can not do here. Here you need to clearly plan the future line and take care of the supply of a high-voltage line and a gas pipe.

The output will be high-tech production, which can quickly change the profile and use materials from ABS plastic to titanium.

Price range: $ 300,000 - $ 1,000,000

For whom it is oriented:

For companies with a need for the production of high-precision large-sized products, or for companies with a need for the production of a large number of less bulky items with high accuracy and a high level of quality.

Summarizing, I want to add that despite the fact that the threshold for entering this industry is still very high, such systems have a future. Within the event horizon, we can see a real revolution, at least in high-tech production. One of the first to realize this at General Electric and have already begun to produce complex parts from titanium for aircraft engines on 3D printers.

As Albert Einstein said:

Everything is very simple. All people believe that this is impossible. But there is one daredevil who disagrees with this ...