Reinstalling SSD in a laptop

Good time of day, Habr!

Through this post, I would like to share mycollective farm experience with those who will soon upgrade the laptop with a solid-state drive. Caution, a lot of photos!

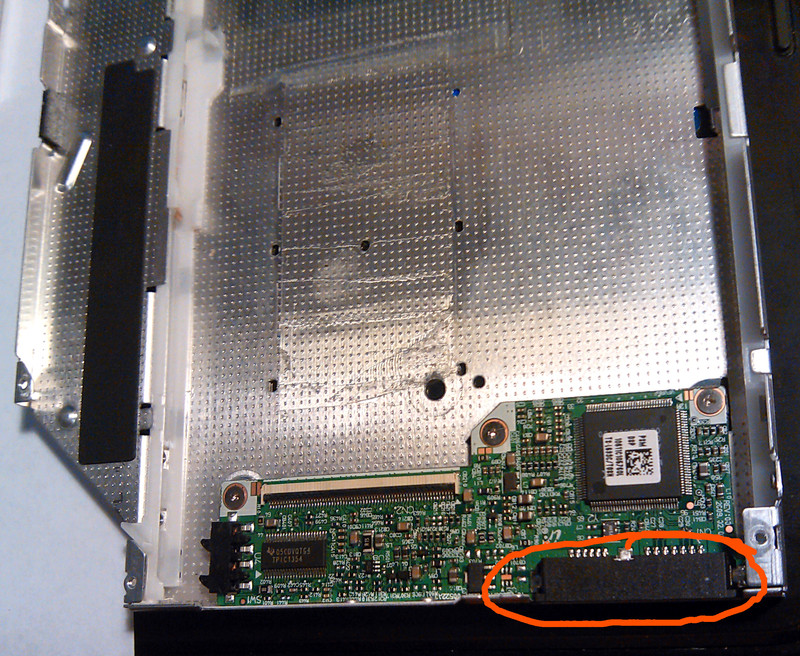

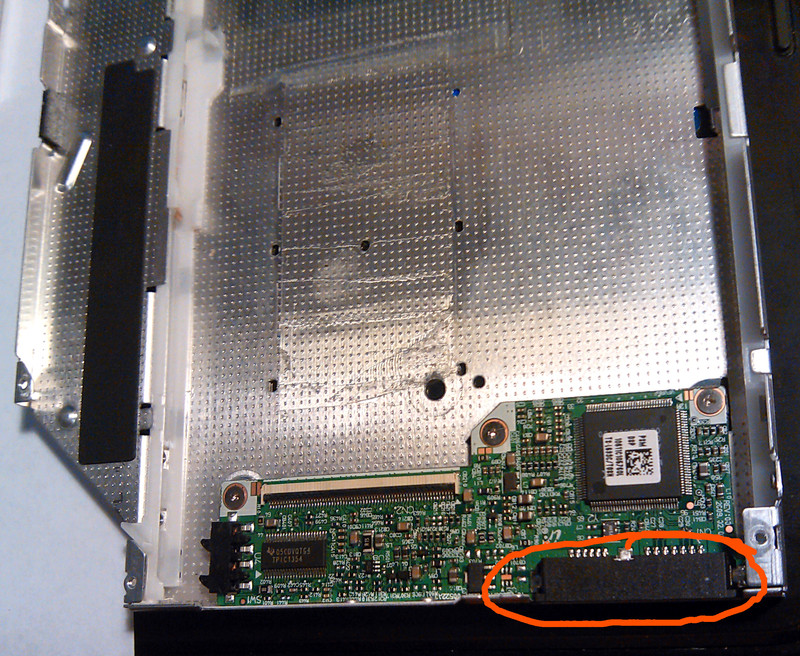

I changed my working laptop about six months ago and so far I am not complaining about its performance, but everything is sad with the download: the laptop began to require 3-5 minutes for this. Initially, the model is equipped with a 750 GB HDD and a logical transition to SSD is not at all pleasing with the lack of free space (60 GB disk) - it is much more convenient to keep all material offline at hand, you often have to go without a network and the Internet. The obvious way out is to replace an underutilized DVD-RW with an SSD. If you also think about buying an SSD, do not use cd / dvd and want to leave a hard drive, my experience may come in handy. We remove the drive, look: if the same as in the photo, then read on.

The optical drive has a Slimline SATA connector. You could connect it with a “Slimline 13 Pin SATA Male to 22 Pin SATA Female Cable” cable, which you would have to wait from the wise Chinese, but we are not looking for easy ways.

For wealthy Pinocchio there is an elegant solution: an adapter basket for 2.5 '' HDD (Espada SS12, similar to DX). With an SSD price of 1.5 kilo rubles, buying a basket for 1 kilo ruble looks unjustified, it was decided to collective farm of its own.

I want to make a reservation that disassembling a laptop to a screw for changing a disk (as I had to do it) is not necessary at all, and it is even advisable to install an SSD in place of an optical drive, since it is not so hot with cooling, and the SSD's energy consumption is an order of magnitude lower than it mechanical predecessor. The above is true provided that the revision of the sata drive is not less than the revision of the sata port of the purchased SSD, otherwise all the advantages of the SSD will be eaten by the low-speed port of the laptop.

Tools and materials:

We need solder, flux, soldering iron, tester, if they are not available, then there is no reason to fence something, it will not work on twists. The tools are inexpensive, then many more where useful. The flux is necessarily acid-free passive for soldering radioelements (usually rosin). Active is not recommended. Everything is acquired in the household.

It’s a pity to disassemble the native drive, so we go to the nearest service and beg for the dead masters. In St. Petersburg, you can go to Juno and walk around the ruins, I got a drive for a symbolic 200 rubles. Of the entire unit, we only need a housing and a connector, with which we will collective farm our adapter.

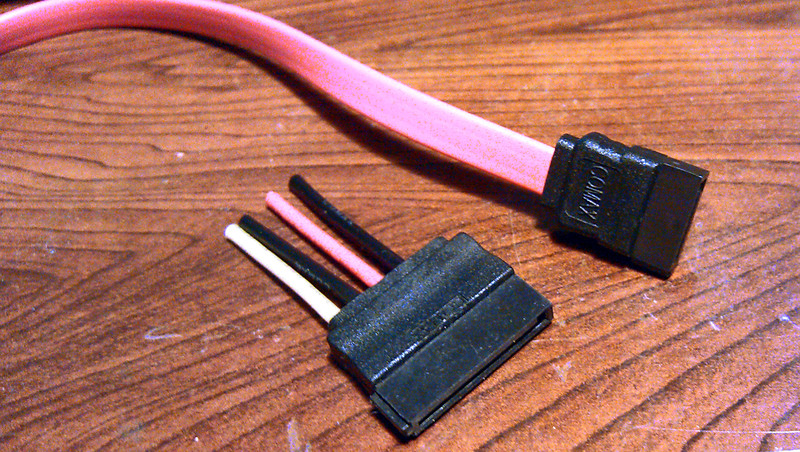

We need a sata cable to connect our implantable disk to the adapter:

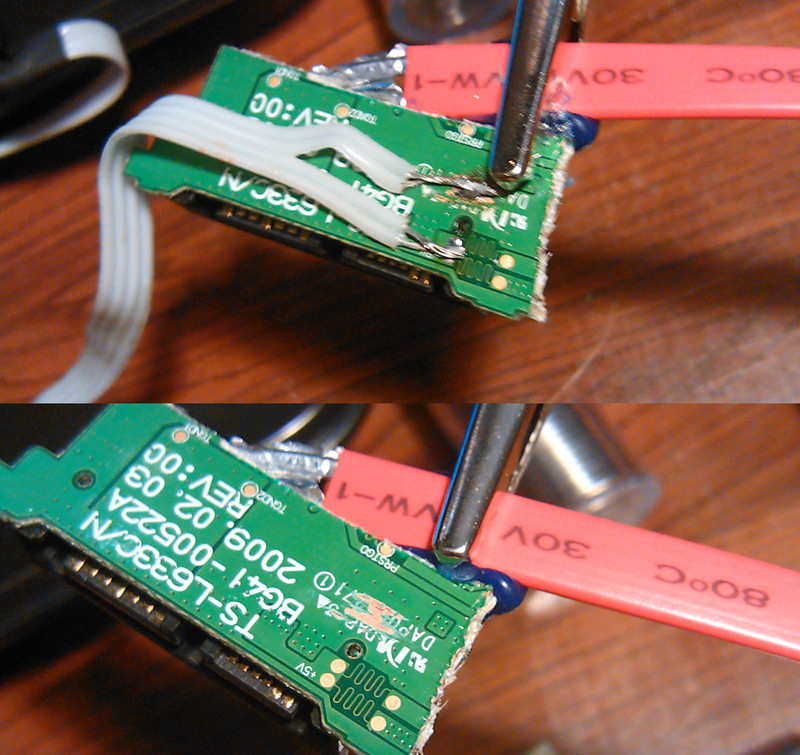

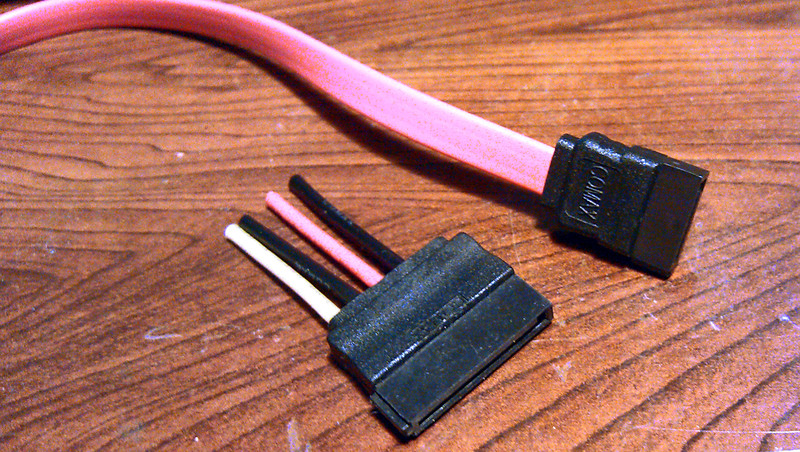

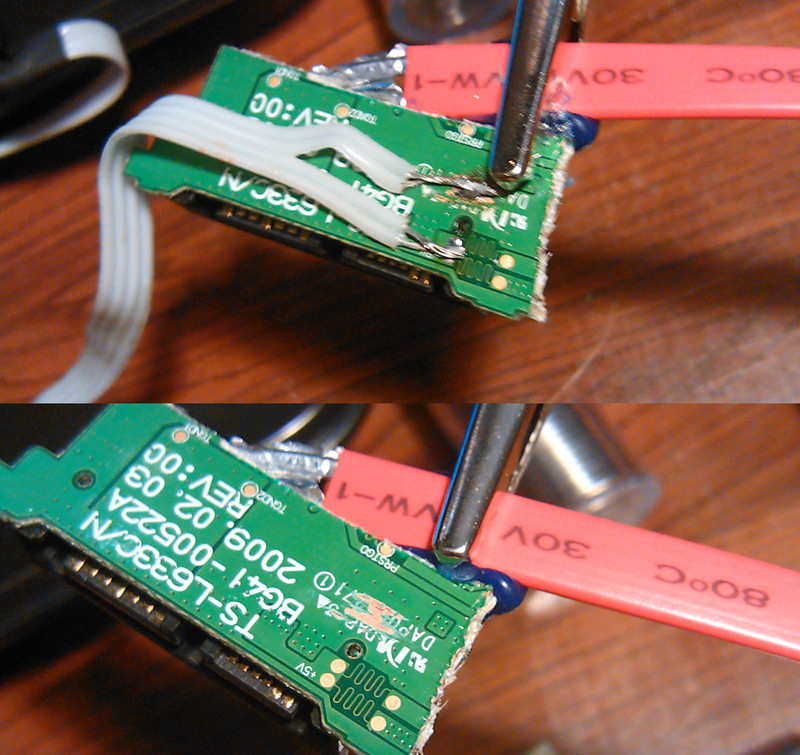

we cut it to a convenient length, we clean it, we tin the veins and solder it to the DVD controller board, from which all the offal was previously pulled out. The wiring lived on the cable and on the connector one to one.

for example, in the photo below from left to right: the 1st contact of the cable is connected to the 1st contact of the drive, the 2nd to the 2nd, and so on.

For convenience and to increase free space, I heartlessly broke off the controller board along with the mounting holes. Since then, it has been securely attached to the bold layer of hot melt adhesive. When "processing" our board, you need to ensure that the edges of ragged tracks do not touch each other and with surrounding objects. Another reason I broke the board is the controller binding, which introduces its interference into the work of our adapter. Therefore, we break it so that the power and signal lines also break off and we still have a board with a connector soldered on it. The broken-off board can be seen later.

In the photo below you can see the sata cable with removed plastic insulation, under it you can see two pairs of wires wrapped in copper foil. The foil needs to be unwound by 8-10 mm and cut, under the foil of 2 cores, using a red-hot soldering iron tip we make a scar on insulation 3-5 mm from the edge and quickly tear off the insulation, we bare the ends and solder the connector itself. Whether to solder the screen is a purely personal matter, in my case it was not necessary to solder, it works like that. Hot-melt adhesive is indispensable here: we use it to fasten the sata cable and power wires after unsoldering on our broken board. If you do not fix it, then everything will come off, we will not have time to collect it.

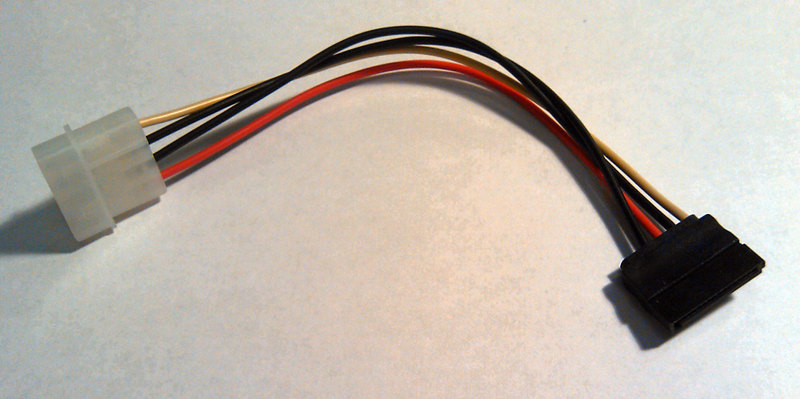

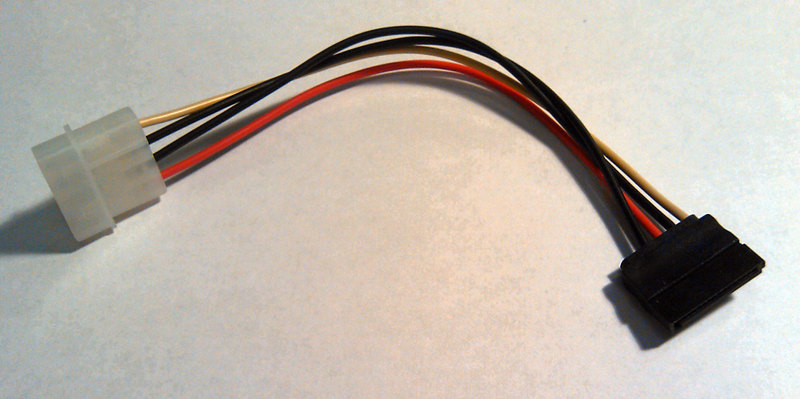

The molex-SATA adapter is needed, you know, to power our drive.

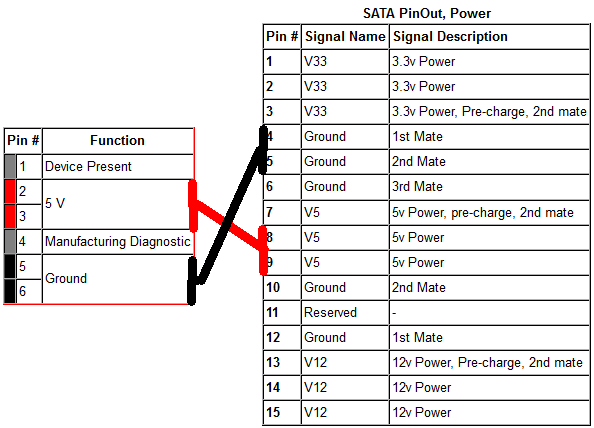

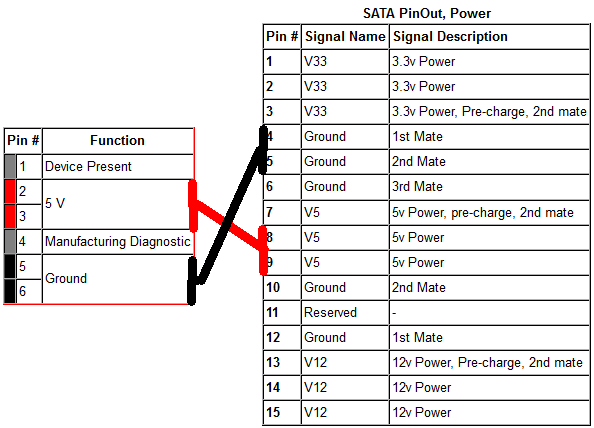

It is precisely because the power connector of the optical drive is non-standard that we are engaged in this collective farm. To make it work, you need to make connections according to the following scheme:

We cut Molex. If the standard conductors are long enough and soft, you can leave them, otherwise we cut almost at the root and build up.

Cut off the yellow conductors, this is +12 power, our drive will do without it. Also, if you are sure that the land on the disk is common to all (and, most likely, it is), then one of the black wires can also be cut.

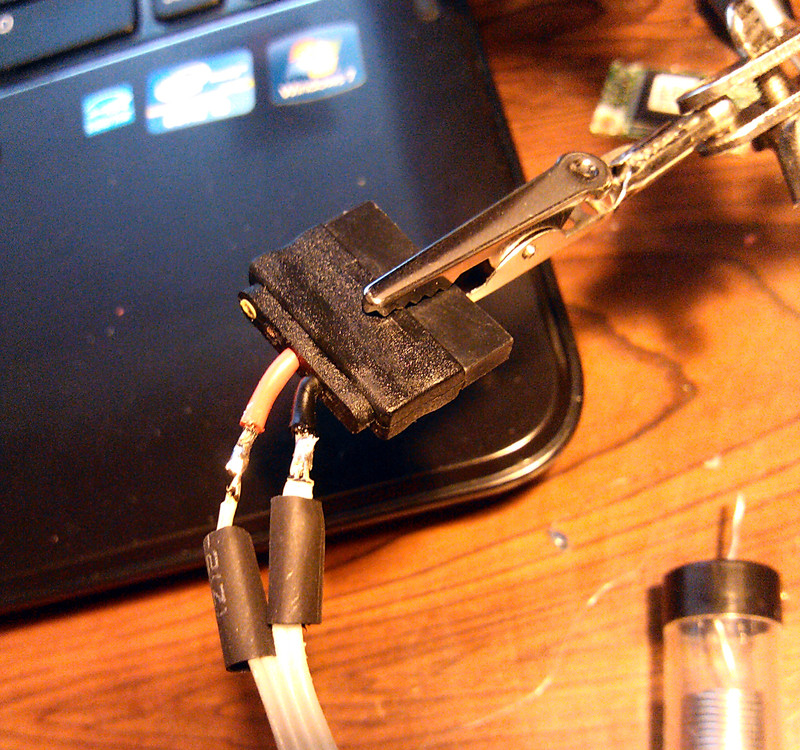

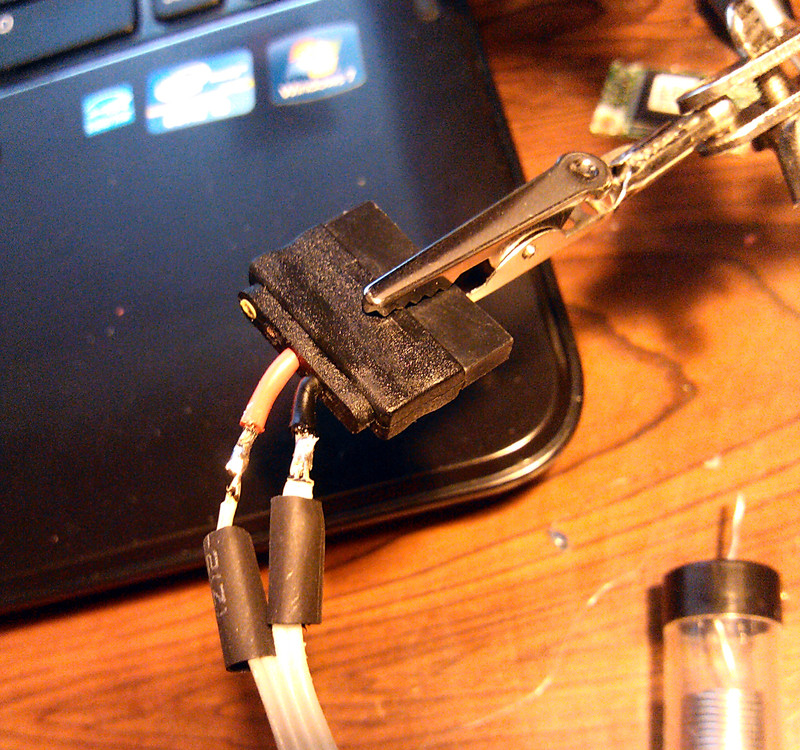

We clean, tin, solder a suitable cable of the required length, isolate with heat pipes. Red - + 5V, black - ground.

We solder the other end to our connector in the drive, do not confuse the polarity. You can find the sites on the board and solder there. A distinctive feature of the "Earth" are longer contacts.

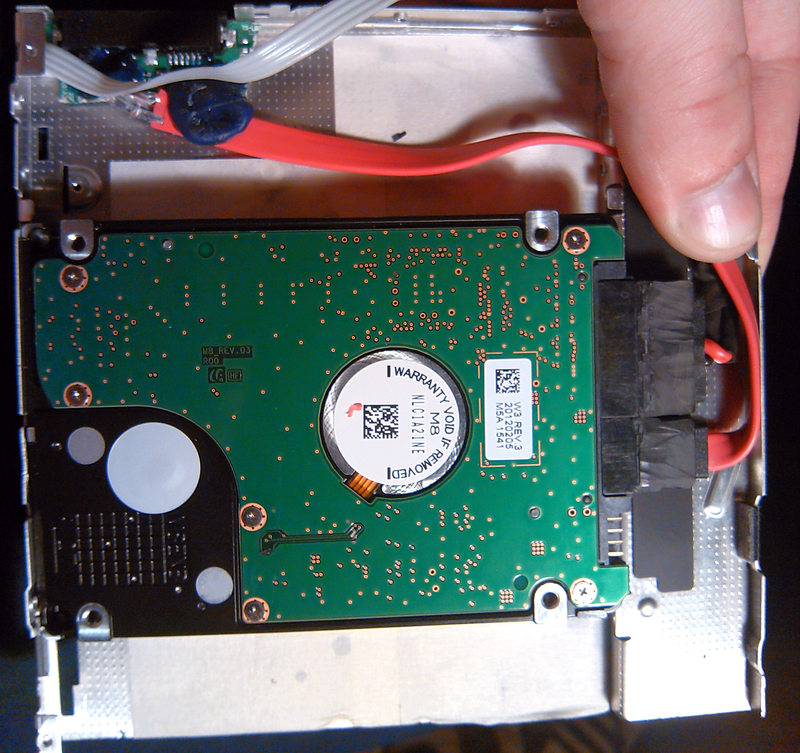

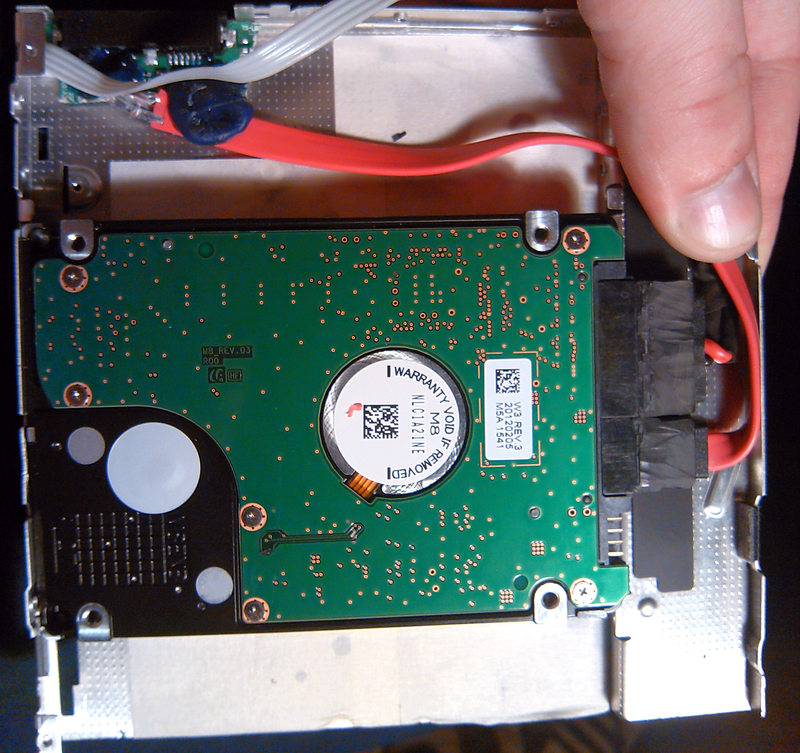

We soldered, fixed with hot-melt adhesive, tried on:

It would be nice to glue the inner surface with electrically insulating material (scotch tape?), It will prevent the implanted disk from closing on the controller, but it will worsen the unimportant heat transfer.

We tried it, everything is fine, before the final installation we call all the connections with the tester for the presence of contact where it should be, and the absence of where it should not be. We finally fix the board (with hot glue). You can try on a disk. In order to be able to close the upper half of the case, you can cut the plastic compound of the connectors and bend / remove the slide on which the drive tray came out.

Once again, we all call. We close the upper half of the case, fix the drive. In my case, no additional fixation was needed - the disk was firmly pressed. Caution! When you press the lid of a working disk, you can hold the lid on the spindle and spoil the HDD; restoring data will be problematic and expensive. Do not forget that we are for the sake of the collective farm. When installing in a laptop, you can rearrange the mounting bracket into which the fixing screw is screwed from the native drive to the implantable one. Almost everything, it remains to insert the drive into the slot and secure.

For aesthetics (so that no one would guess that we are collective farmers), the holes in the side of our laptop can be covered with a panel from their own DVD. The panel is removable, snaps. We fasten it (no, not to hot glue) on a double-sided tape!

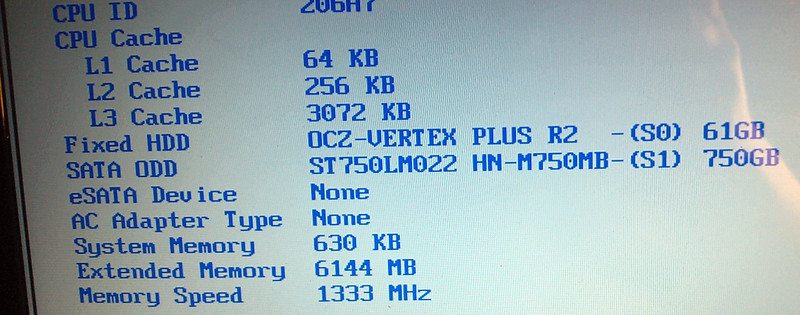

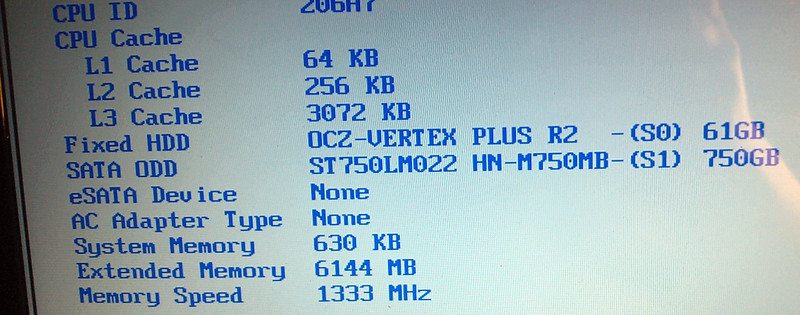

Before you boot, you should look in the BIOS and make sure that the device is determined. My drive was identified as ODD, for booting from SSD I had to put the optical drive last in the queue of boot devices.

In the operating system, as expected, everything is OK: SSDs and HDDs are defined as disk devices.

List of links:

http://ru.wikipedia.org/wiki/SATA

http://www.allpinouts.org/index.php/Serial_ATA_%28SATA,_Serial_Advanced_Technology_Attachment%29

http://spvd.ru/page/slim-sata -power

Through this post, I would like to share my

I changed my working laptop about six months ago and so far I am not complaining about its performance, but everything is sad with the download: the laptop began to require 3-5 minutes for this. Initially, the model is equipped with a 750 GB HDD and a logical transition to SSD is not at all pleasing with the lack of free space (60 GB disk) - it is much more convenient to keep all material offline at hand, you often have to go without a network and the Internet. The obvious way out is to replace an underutilized DVD-RW with an SSD. If you also think about buying an SSD, do not use cd / dvd and want to leave a hard drive, my experience may come in handy. We remove the drive, look: if the same as in the photo, then read on.

The optical drive has a Slimline SATA connector. You could connect it with a “Slimline 13 Pin SATA Male to 22 Pin SATA Female Cable” cable, which you would have to wait from the wise Chinese, but we are not looking for easy ways.

For wealthy Pinocchio there is an elegant solution: an adapter basket for 2.5 '' HDD (Espada SS12, similar to DX). With an SSD price of 1.5 kilo rubles, buying a basket for 1 kilo ruble looks unjustified, it was decided to collective farm of its own.

I want to make a reservation that disassembling a laptop to a screw for changing a disk (as I had to do it) is not necessary at all, and it is even advisable to install an SSD in place of an optical drive, since it is not so hot with cooling, and the SSD's energy consumption is an order of magnitude lower than it mechanical predecessor. The above is true provided that the revision of the sata drive is not less than the revision of the sata port of the purchased SSD, otherwise all the advantages of the SSD will be eaten by the low-speed port of the laptop.

Tools and materials:

- DVD-drive for a laptop (you can own, but better dead from a service nearby);

- Interface cable "sata";

- Power adapter "molex-SATA";

- Soldering iron, tin-lead solder, flux;

- Tester;

- Screwdrivers

- Knife / cutter

- Hot glue;

- Thermotubes / adhesive tape / electrical tape;

- Transplantable HDD.

We need solder, flux, soldering iron, tester, if they are not available, then there is no reason to fence something, it will not work on twists. The tools are inexpensive, then many more where useful. The flux is necessarily acid-free passive for soldering radioelements (usually rosin). Active is not recommended. Everything is acquired in the household.

It’s a pity to disassemble the native drive, so we go to the nearest service and beg for the dead masters. In St. Petersburg, you can go to Juno and walk around the ruins, I got a drive for a symbolic 200 rubles. Of the entire unit, we only need a housing and a connector, with which we will collective farm our adapter.

We need a sata cable to connect our implantable disk to the adapter:

we cut it to a convenient length, we clean it, we tin the veins and solder it to the DVD controller board, from which all the offal was previously pulled out. The wiring lived on the cable and on the connector one to one.

for example, in the photo below from left to right: the 1st contact of the cable is connected to the 1st contact of the drive, the 2nd to the 2nd, and so on.

For convenience and to increase free space, I heartlessly broke off the controller board along with the mounting holes. Since then, it has been securely attached to the bold layer of hot melt adhesive. When "processing" our board, you need to ensure that the edges of ragged tracks do not touch each other and with surrounding objects. Another reason I broke the board is the controller binding, which introduces its interference into the work of our adapter. Therefore, we break it so that the power and signal lines also break off and we still have a board with a connector soldered on it. The broken-off board can be seen later.

In the photo below you can see the sata cable with removed plastic insulation, under it you can see two pairs of wires wrapped in copper foil. The foil needs to be unwound by 8-10 mm and cut, under the foil of 2 cores, using a red-hot soldering iron tip we make a scar on insulation 3-5 mm from the edge and quickly tear off the insulation, we bare the ends and solder the connector itself. Whether to solder the screen is a purely personal matter, in my case it was not necessary to solder, it works like that. Hot-melt adhesive is indispensable here: we use it to fasten the sata cable and power wires after unsoldering on our broken board. If you do not fix it, then everything will come off, we will not have time to collect it.

The molex-SATA adapter is needed, you know, to power our drive.

It is precisely because the power connector of the optical drive is non-standard that we are engaged in this collective farm. To make it work, you need to make connections according to the following scheme:

We cut Molex. If the standard conductors are long enough and soft, you can leave them, otherwise we cut almost at the root and build up.

Cut off the yellow conductors, this is +12 power, our drive will do without it. Also, if you are sure that the land on the disk is common to all (and, most likely, it is), then one of the black wires can also be cut.

We clean, tin, solder a suitable cable of the required length, isolate with heat pipes. Red - + 5V, black - ground.

We solder the other end to our connector in the drive, do not confuse the polarity. You can find the sites on the board and solder there. A distinctive feature of the "Earth" are longer contacts.

We soldered, fixed with hot-melt adhesive, tried on:

It would be nice to glue the inner surface with electrically insulating material (scotch tape?), It will prevent the implanted disk from closing on the controller, but it will worsen the unimportant heat transfer.

We tried it, everything is fine, before the final installation we call all the connections with the tester for the presence of contact where it should be, and the absence of where it should not be. We finally fix the board (with hot glue). You can try on a disk. In order to be able to close the upper half of the case, you can cut the plastic compound of the connectors and bend / remove the slide on which the drive tray came out.

Once again, we all call. We close the upper half of the case, fix the drive. In my case, no additional fixation was needed - the disk was firmly pressed. Caution! When you press the lid of a working disk, you can hold the lid on the spindle and spoil the HDD; restoring data will be problematic and expensive. Do not forget that we are for the sake of the collective farm. When installing in a laptop, you can rearrange the mounting bracket into which the fixing screw is screwed from the native drive to the implantable one. Almost everything, it remains to insert the drive into the slot and secure.

For aesthetics (so that no one would guess that we are collective farmers), the holes in the side of our laptop can be covered with a panel from their own DVD. The panel is removable, snaps. We fasten it (no, not to hot glue) on a double-sided tape!

Before you boot, you should look in the BIOS and make sure that the device is determined. My drive was identified as ODD, for booting from SSD I had to put the optical drive last in the queue of boot devices.

In the operating system, as expected, everything is OK: SSDs and HDDs are defined as disk devices.

List of links:

http://ru.wikipedia.org/wiki/SATA

http://www.allpinouts.org/index.php/Serial_ATA_%28SATA,_Serial_Advanced_Technology_Attachment%29

http://spvd.ru/page/slim-sata -power