Peltier elements or my path to cryogenic temperatures

Many have heard about the "magic" Peltier elements - with the passage of current through them, one side cools and the other heats up. This works in the opposite direction - if one side is heated and the other side is cooled, electricity is generated. The Peltier effect has been known since 1834, but to this day we are not ceased to be pleased with innovative products based on it (you just need to remember that when generating electricity, like solar panels, there is a point of maximum power, and if you work far from it - efficiency generation is greatly reduced).

Many have heard about the "magic" Peltier elements - with the passage of current through them, one side cools and the other heats up. This works in the opposite direction - if one side is heated and the other side is cooled, electricity is generated. The Peltier effect has been known since 1834, but to this day we are not ceased to be pleased with innovative products based on it (you just need to remember that when generating electricity, like solar panels, there is a point of maximum power, and if you work far from it - efficiency generation is greatly reduced). Recently, the Chinese have pushed, and flooded the Internet with their relatively cheap modulesso experimenting with them no longer takes too much money. The Chinese promise a maximum temperature difference between hot and cold side of 60-67 degrees. Hmmm ... And what if we take 5 elements, connect in series, then we should get 20C-67 * 5 = -315 degrees! But something tells me that everything is not so simple ...

Brief theory

The classic "Chinese" Peltier elements are 127 elements connected in series and soldered to a ceramic "printed circuit board" made of Al2O3. Accordingly, if the operating voltage is 12V, then each element accounts for only 94mV. There are elements with a different number of consecutive elements, and accordingly with a different voltage (for example 5V).It must be remembered that the Peltier element is not a resistor, its resistance is non-linear, so if we apply 12V, we may not be able to get 6 amperes (for a 6 ampere element) - the current may change depending on the temperature (but not too much ) Also at 5V (i.e. less than the nominal value), the current will not be 2.5A, but less.

The amount of heat transferred is proportional to the current. But besides this, there is parasitic heating from current flow, and parasitic thermal conductivity - all this makes the Peltier element at least somewhat effective in very narrow conditions.

In addition, the amount of heat transferred is highly dependent on the temperature difference between the surfaces. With a difference of 60-67С - heat transfer tends to 0, and with a zero difference - 51 watts for a 12 * 6 = 72-watt cell. Obviously, this already does not allow connecting the elements in a series so simply - it is necessary that each next one is smaller than the previous one, otherwise the coldest element will try to give more heat (72W) than the element of the next stage can pass through itself at the desired temperature difference (1 -51W).

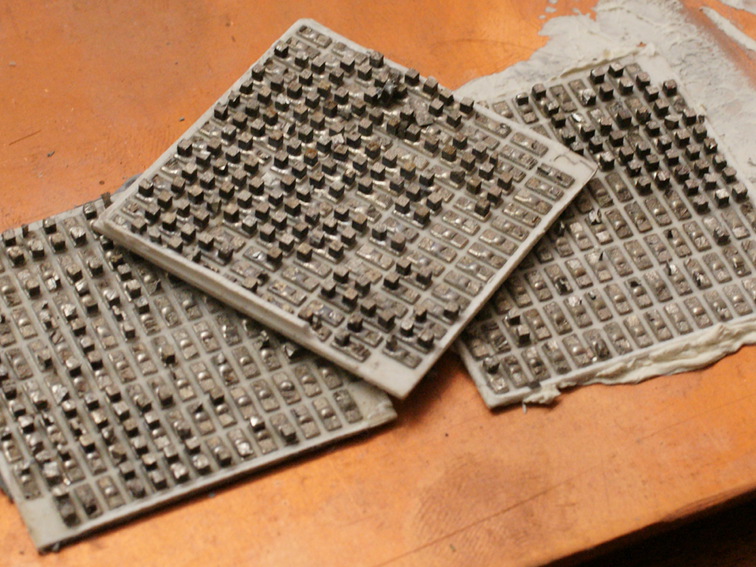

Peltier elements are assembled with fusible solder with a melting point of 138C - so if an element accidentally remains without cooling and overheats, it will be enough to solder one of 127 * 2 contacts to throw the element into a landfill. Well, the elements are very fragile - both the ceramics and the cooling elements themselves - I accidentally tore up 2 elements “along” due to the thermopaste that had dried up tightly:

Try

So, the small element is 5V * 2A, the large is 12 * 9A. Heatpipe cooler, room temperature. Result: -19 degrees. It’s strange ... 20-67-67 = -114, but it turned out to be miserable -19 ...

The idea is to take everything out to frosty air, but there is a problem - the cooler on the heat pipes cools well only if the temperatures of the “hot” and “cold” sides of the cooler are different side of the gas-liquid phase transition of the filler tube. In our case, this means that the cooler, in principle, is not able to cool anything below + 20C (since only thin walls of heat pipes work below). We'll have to return to the roots - to the all-copper cooling system. And so that the limited performance of the cooler does not affect the measurements, we add a kilogram copper plate - a thermal accumulator.

The result is shocking - the same -19 with both one and two stages. Ambient temperature - -10. Those. with zero load, we barely squeezed a miserable 9 degrees of difference.

Roll out heavy artillery

It turned out that refrigeration plant # 7 was not far from me, and I decided to drop in with a cardboard box. He returned with 5 kilograms of dry ice (sublimation temperature -78C). We lower the copper structure there - we connect the current - at 12V the temperature instantly starts to rise, at 5V it drops by 1 degree per second, and then it grows rapidly. All hopes are broken ...

Conclusions and video for sweets

The effectiveness of conventional Chinese Peltier elements quickly drops at temperatures below zero. And if it is still possible to cool a can of cola with apparent efficiency, then temperatures below -20 cannot be achieved. And the problem is not in specific elements - I tried elements of different models from 3 different sellers - the behavior is the same. It looks like cryogenic stages need elements from other materials (and perhaps each stage needs its own element material).

Well, with the remaining dry ice, you can do the following:

PS. And if you mix dry ice with isopropyl alcohol - you get liquid nitrogen for the "poor" - it just as fun freezes and breaks flowers and so on. That's just due to the fact that alcohol does not boil upon contact with the skin - it is much easier to get frostbite.