How to do it yourself: open modular systems

- Transfer

The return of traditional crafts is one of the ways to sabotage the modern disposables industry. This article considers another option: the design of modular consumer products, parts and components of which are reused in other objects.

The return of traditional crafts is one of the ways to sabotage the modern disposables industry. This article considers another option: the design of modular consumer products, parts and components of which are reused in other objects. The OpenStructures, Grid Beam, and Contraptor initiatives combine the modularity of LEGO, Meccano, and Erector systems with the power of collective collaboration, as in Wikipedia and Linux.

An economy based on the concept of reuse will not only bring important benefits in terms of sustainability, but also save consumers money, accelerate innovation and take production out of the control of transnational corporations.

The modular system combines the advantages of standardization (since parts can be cheaply produced in large quantities) with the advantages of customization (a large variety of unique objects are made from a relatively small number of parts). Modularity is present in varying degrees in many products (for example, bicycles and computers) and systems (for example, trains and logistics), but the best examples of modular systems are toys: LEGO, Meccano and Erector (which has now become the Meccano brand in the USA).

LEGO, Meccano and Erector are made up of a relatively small number of simple blocks that make up various objects. After that, the parts are dismantled and reused for something completely different. In addition to elementary building blocks, there are many more specific building blocks that are less versatile but add diversity.

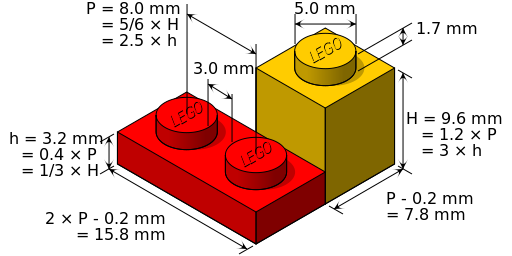

All the building blocks in the LEGO, Meccano and Erector sets match each other because they are designed according to a specific set of rules. The holes (Meccano and Erector) or spikes (LEGO) have the exact diameter and they are at a specific distance. In addition, the dimensions of the building blocks exactly match each other. The long-term success of the LEGO, Meccano and Erector (which appeared on the market in 1947, 1902 and 1911, respectively) is based on the fact that these rules never changed. All new building blocks for many years are compatible with the previous ones. Today, babies can expand their collection of toys with parts, with which parents and grandparents played, and on the market these items cost as much as new ones.

Grid Beam, Bit Beam, Open Beam, Maker Beam and Contraptor

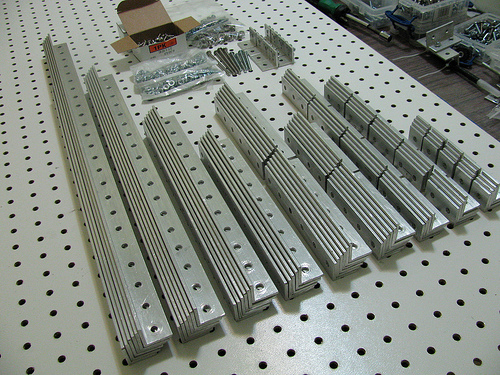

The same principle applies to everyday items: from coffee makers to furniture, gadgets, cars and renewable energy systems. Need only standardization at the design level. Design rules can be very simple, as is the case with the Grid Beam . This modular system, developed in 1976, is based on beams with simple geometry and a repetitive pattern of holes. Beams can be made of wood, aluminum, steel or any other material.

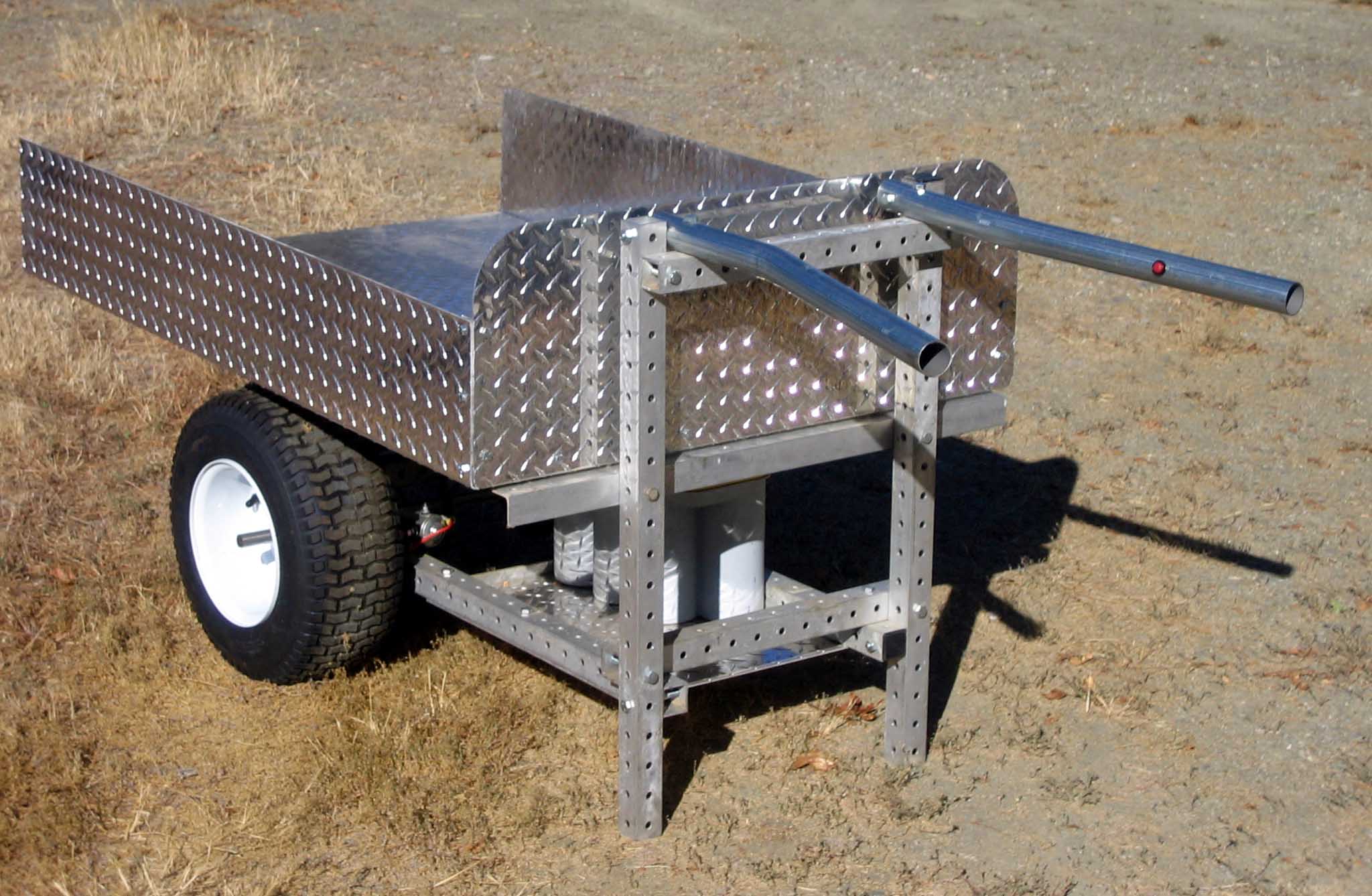

Despite its simplicity, a large variety of objects is available. On the basis of the Grid Beam they made all kinds of furniture, greenhouses, structures for workshops and production processes, windmills, cars, agricultural equipment, vehicles, sheds and buildings (a book about this modular system was published in 2009 and itscan be found online ). The Grid Beam was created based on the ideas of Ken Isaacs and the Living Structures system invented by him in the 1950s , where the same beams were used, but with fewer holes.

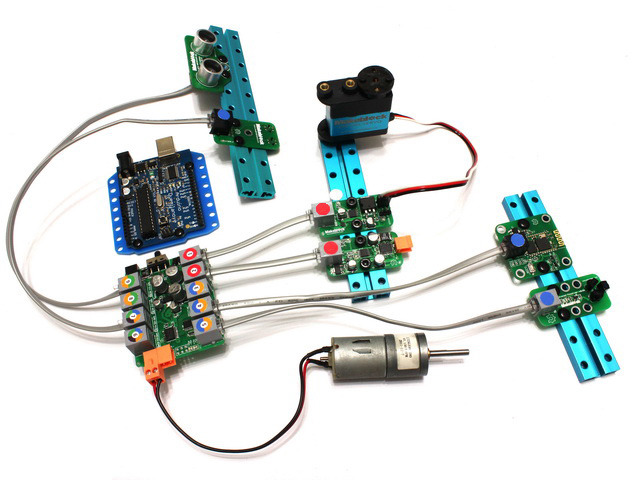

In recent years, several systems have emerged that use a very similar set of rules based on a repeating hole system. Bit Beam is essentially a scaled version of the Grid Beam, only for smaller structures made from cork, such as a laptop stand or prototype. Contraptor uses a similar approach, but specializes in structural metal frames for DIY 3D printers, milling machines, and robotics. OpenBeam and MakerBeam- also modular designs on very simple rules. There, the structure is not based on a pattern of holes, but on T-shaped aluminum grooves. Makeblock combines both approaches and includes electronic modules.

Most of these systems are limited to framework designs. But there is one system that offers much more possibilities, because it is based on a more complex set of rules: OpenStructures . The project started in Brussels in 2007. Unlike all of the above, the OpenStructures project is still in an experimental phase. However, it is interesting to look at it in more detail, because it best demonstrates the potential of modular building structures.

Openstructures

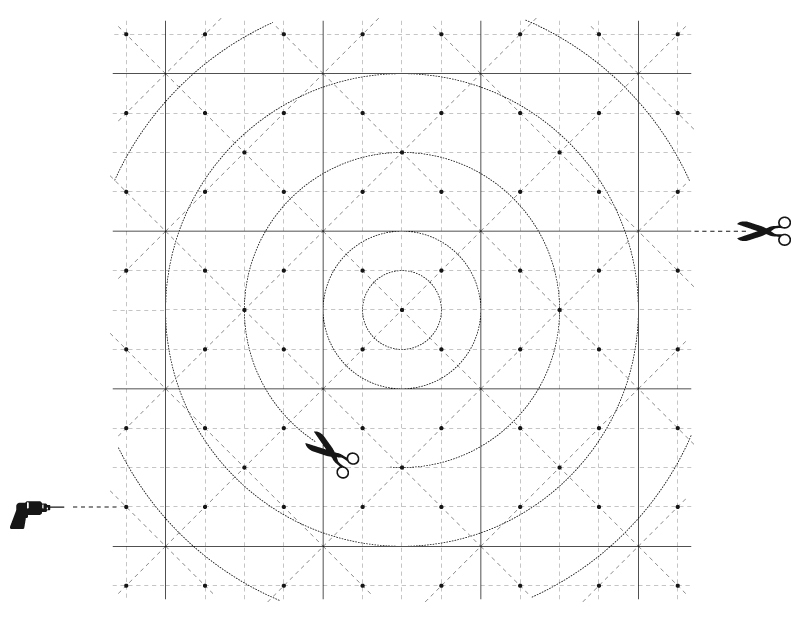

The first basic rule of OpenStructures coincides with the rule of the Grid Beam and similar systems: all parts are connected to each other so that they can be easily dismantled using bolts and screws, and not nails or glue. However, the OpenStructures design language is different: it is based on the OS Grid grid , which is based on 4 × 4 cm squares and scales. Squares are also divided into parts or combined and form even larger squares, without losing compatibility with each other. The figure shows nine full squares of 4 × 4 cm, combined together.

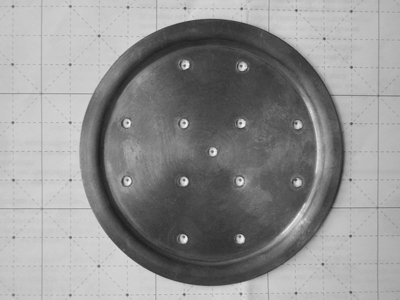

The boundaries of the squares indicate the cut lines (which establish the dimensions of the square details), the diagonal points define the assembly points, and the circles define the overall diameters. As in the case of LEGO, any modular part must meet at least one of these conditions in order to be compatible with other parts. Either the dimensions should correspond to the horizontal and vertical lines, or the assembly points should be marked according to the grid, or the diameters should be suitable. Below is a detail that satisfies two of the three conditions.

Although this set of rules is more complicated than the Grid Beam system, it is fairly simple. However, it allows you to create a much greater variety of objects, and not just square or rectangular frames. For five years, various objects were created on the basis of OpenStructures, ranging from home appliances to cargo bikes, luggage and furniture.

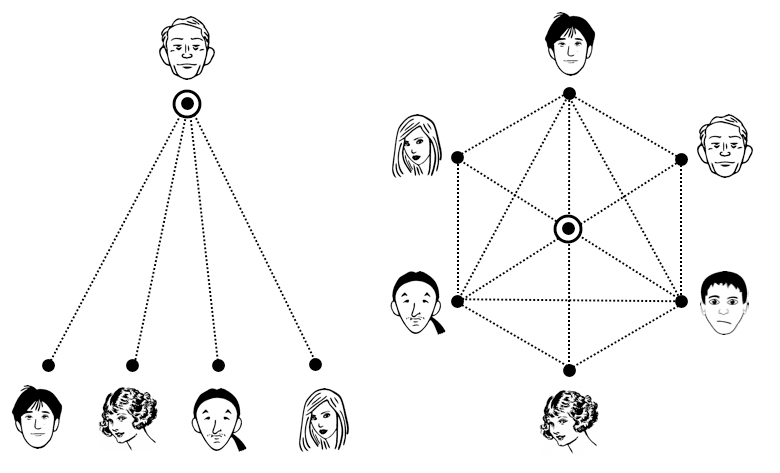

Open and closed modular systems

Despite the similarities, there is one fundamental difference between the modular systems OpenStructures, the Grid Beam, Contraptor and the modular toys LEGO, Meccano and Erector. The first group consists of “open” modular systems, where everyone can freely design and produce parts, while the second consists of “closed” modular systems, where all parts are designed and manufactured by one manufacturer. Closed modular systems produce uniform parts. For example, all LEGO blocks are made of plastic. LEGO does not manufacture wood, aluminum, glass or ceramic blocks. There is a limited range of colors. All because LEGO is a closed system. No one is allowed to make its cubes.

There are modular systems that operate on the same closed principles as T-profiles.from company 80/20 inc. But in the modular systems mentioned above, everyone is allowed to design and manufacture parts that are compatible with the basic set of rules. A similar approach operates in the field of open source software, such as Linux (operating system), OpenOffice (office software) or WordPress (blogging platform). The computer code for these systems is written by many people, each of whom builds a part of something bigger. Since all participants adhere to the basic set of rules, a large number of people independently add compatible details.

Consumer products on an open modular system can contribute to rapid innovation without loss of energy and materials.

An open modular system has many advantages over a closed one. Since everyone can design parts in an open system, it generates a much greater variety of parts: they are made in different colors and from different materials, and no manufacturer can set a fixed price. And since many designers constantly review and improve each other's work, the speed of innovation increases. All open software systems described above are probably better than their closed counterparts, and some have become more successful. A closed modular system has only one advantage: the one who owns the copyright, earns a lot of money.

Long-term consumer goods

Modular systems encourage the reuse of physical parts and thus form a sustainable alternative to the modern consumer goods production system. Most modern products go to landfills or incinerators a few years after purchase. This is due to the fact that most manufacturers are pushing consumers to replace their products as soon as possible. They either design objects for easy breakage, or introduce new generations of products that make the previous generation obsolete. This approach not only generates a massive pile of waste, but also consumes huge amounts of energy and raw materials.

Consumer products on an open modular system contribute to rapid innovation without loss of energy and materials. Details of the outdated generation of products can be used in the next generation or in a completely different product. In addition, modular objects are maintainable by definition.

Open modular systems will significantly accelerate the interpenetration of "low technologies", like pedal cars , solar thermal collectors , velomobiles and cargo bicycles. Building a windmill or a cargo bike goes much faster with modular parts than with carpentry or welding, and there is no need for expensive tools or special skills. Errors are easily corrected - just unscrew the bolts and start over. It would be interesting to look at the integration of modular parts with another open hardware project, such as the Global Village Construction Set , where many interesting designs are being created, but modularity is limited.

Circulation parts

“While eBay circulates goods and waste-free production systems circulate materials, modular systems circulate parts and components,” says Thomas Lommi, creator of OpenStructures. - Our goal is to create a mosaic instead of static objects. The system should generate objects from which it is not entirely clear who designed them. The object evolves as it passes through the hands of more designers. ”

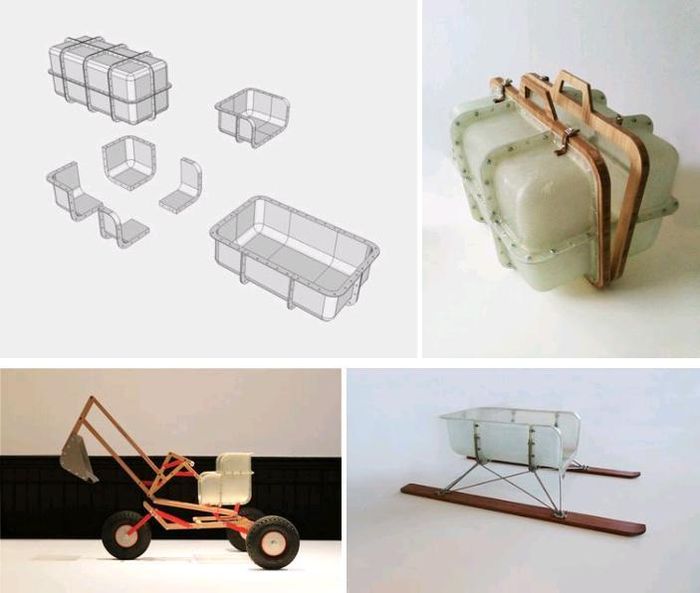

Kitchen appliances OpenStructures

A good example is kitchen appliances developed as part of the project. Some parts were originally made for the coffee grinder, then another designer used them along with new parts for the coffee maker. Then the third designer finalized the project and created a device for water purification. The plastic bottle, which served as a water tank, was replaced with a slotted glass bottle with a clay filter. Thomas Lomme says: "By adding or removing components or using them differently, you get a family of objects."

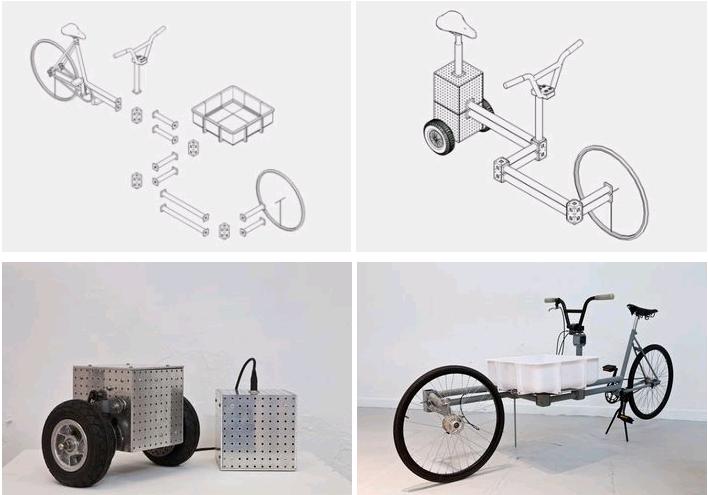

Cargo bike

Another prototype from this project is a cargo bike. The back part is sawed off from the frame of an ordinary bicycle, the other parts are compatible with the OS Grid. This means that the front can be made modular. Designer Joe Van Bostraten use this feature to design both a cargo bike and a cargo tricycle (the latter carries a 3D printer), and that’s not all. Together with Lommy, they designed a modular walk-behind tractor. It consists of an electric motor and wheels, on top of which a module with a battery is also placed. Since the blocks are compatible with the OS Grid grille, they can be mounted in front of a cargo bike, getting a fully modular motorized vehicle.

The last “family” of this project is intended for children. It is noteworthy that it grew from a single component of a cargo bike - from a container. It consists of modular parts bolted together and these parts can be fastened in different ways. Several designers played around with these details, resulting in (among other things) a sleigh, a seat, a toy excavator, and a swing. When a child grows up, you can make a suitcase or a tool box, or use it in the same cargo bike - and earn pocket money .

Open Source Objects

The user support system is more interesting than the objects themselves. Grid Beam is obviously a product of the pre-Internet era. To copy the design, it is recommended to look at his photo and “calculate the holes”. On the other hand, OpenStructures relies on online user support. To reuse parts, an online database has been created that can be used in three ways.

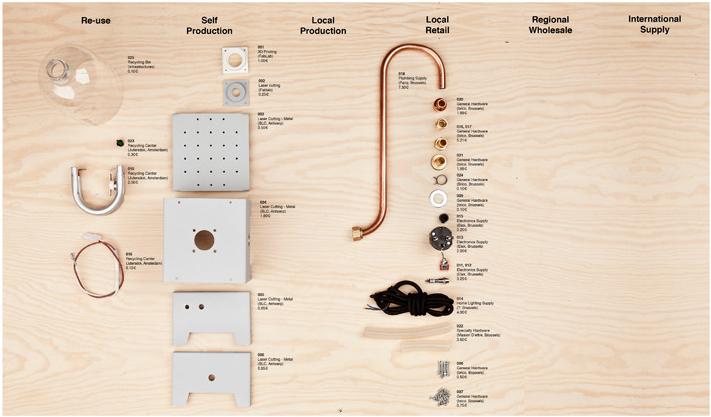

Modular database

First, you can display all objects developed on the basis of OS Grid. A page of each object shows its details and components. Secondly, you output all the details created based on the OS Grid. Each detail page shows in which components and objects it can be applied. Finally, you can see all the components with a list of their parts and objects for which the components can be used.

An open modular design does not mean that everyone should produce their own consumer goods.

The page for each part, component, and object also contains additional information: dimensions, materials, designer's name, license, and order information. In addition, parts and components have serial numbers. So, after disassembling a modular object, the serial number of each part and component can be entered into the database and see what else to do with it. The missing parts are also extracted from the database: you either find the address of the store where they are sold, and place an order, or download a digital model and make the part yourself.

Not everyone can be a designer.

An open modular design does not mean that everyone should produce goods for themselves. Things like a coffee maker or workbench can be obtained in at least three ways. First, load a digital design and assemble an object with parts that are bought, reused, or made using a 3D printer or laser cutter, whether at home, in a small lab (workshop), or shop. This can be a low-tech option, as with the Grid Beam: a person buys wooden / metal slats and drills holes himself .

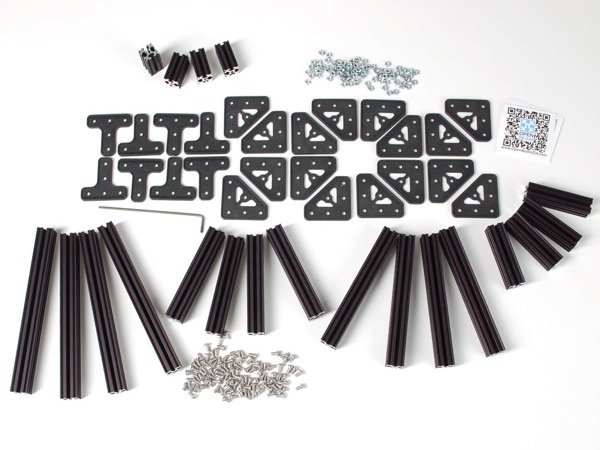

Modular parts of the boiler The

second option: the company buys a license for the design (if it is not free) and creates a kit for assembly as LEGO, Meccano or Erector. In this case, consumers do not need to independently search for spare parts, but the person still assembles the product himself, like IKEA furniture. In the same way, the company can offer a more versatile kit for assembling a variety of things, like a set of basic designer cubes. Bit Beam, Contraptor, Open Beam, Maker Beam and more recently the Grid Beam offer one or both of these options.

The third option: the manufacturer puts the object on the market in the form of finished, assembled product. A coffee maker or workbench will be sold and bought in the same way as any modern product, but after use they can be disassembled and parts can be reused in other objects.

Economic model: who produces parts?

Although designing OpenStructures and other open modular systems is identical to the process of designing digital products, such as Wikipedia, Linux or WordPress, there is a fundamental difference. Machine code and digital text accumulate without material costs. In the material world this is not the case. Therefore, the creation of modular systems is not so easy, but it opens up economic opportunities. It’s hard to make money from open source software or online articles. But in the case of an open modular system for objects, someone must provide the materials.

It is important that parts are manufactured by as many manufacturers as possible and are available worldwide. Otherwise, due to the cost of delivery, a modular item will be too expensive.

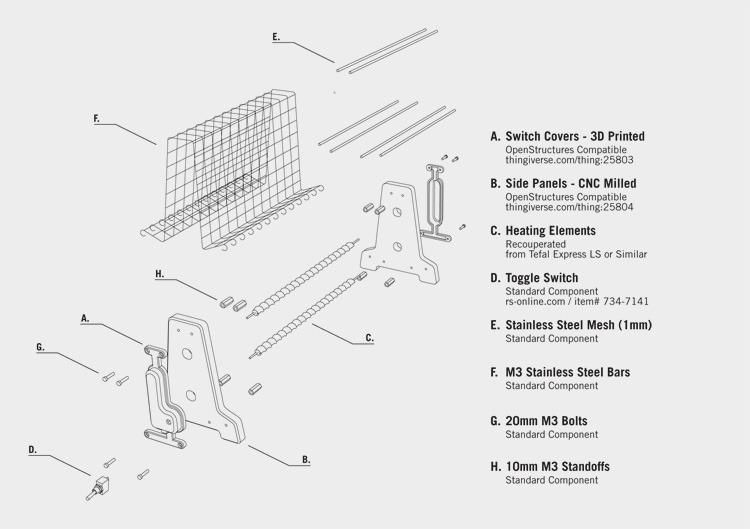

Modular Toaster

There are many opportunities to make money on an open modular model. The manufacturer can choose to produce one part, which sees the economic potential. Another manufacturer may choose to produce a whole set or a finished product for sale. A designer can make money on models that are free for personal but not commercial use. If the manufacturer wants to sell such a design, then he must buy a license from the designer.

Masters can focus on the design of exclusive handmade parts from special materials that are compatible with popular mass products. Others can run a fab lab or tech store where people make their own modular items for a monthly fee. To summarize, an open modular system offers economic opportunities for everyone.

Collective economy

“We are not going to build a giant plant that produces all the possible details,” writes Lommi. - OpenStructures should not be a modular version of IKEA. Our goal is to create a collective economic system in which one manufacturer benefits from the products of another manufacturer. Because the details of one can use others. We would like to see a lot of small shops, where everyone adds a little to the collective economy, and not just one giant producing everything. The social dimension is very important. ”

Parts of Contraptor

“If IKEA wants to sell a product that is compatible with our system, then that's fine. But the system can work only if it remains open. The larger the system, the easier it is for a small company or artisan to become part of it. The goal is to launch a universal, collective designer, so that the widest range of people - from craftsmen to transnational corporations - design, build and exchange the widest range of modular parts and components. ”

Reuse management

In addition to the design language (OS Grid) and the online database, the company OpenStructures has created a prototype warehouse in Brussels. This place should be the center for organizing the reuse of parts and components. Imagine a fab lab or a store, but with storage of modular parts. If a modular product is no longer needed and the owner is not going to use its details in new objects, then he brings it to one of these places. Here the subject is disassembled, and the details are stored.

An open modular system offers economic opportunities for everyone.

People can come in, buy spare parts, or collect something new right on the spot. As Lomme says: “Not everyone should assemble their own products, but after the end of their service life, a modular product will always fall into the hands of people who like to make”.

Compatibility between open modular systems

OpenStructures is still in the experimental phase, but this is the most ambitious and most seamless open modular system today. Being a European project, it follows the international metric system, while the much older Grid Beam project uses the imperial system. These systems are incompatible with each other. With the advent of increasingly open modular systems, is it not important to ensure compatibility between them?

Lommy's

Makeblock doesn't think so: “Most of these systems are designed for various applications. For example, Contraptor is focused on accuracy, because parts are used to create robots and other complex machines. Aesthetics is not important at all. I am a designer, therefore I am especially interested in whether it is possible to make beautiful objects on the basis of the modular system - things that you would like to put at home. There are also Wikispeed , for example, where a modular car is created. The Arduino project focuses on electronics. I do not think that all these modular systems should be compatible with each other, because the applications are very different. ”

Open Beam

Next, he explains why he chose the metric system. “I doubted a lot. But in the end I decided that it was easier to work with the metric system. And I think that there is a place in the world for both systems: just look at the diversity of energy standards. Someone has already developed a European version of Contraptor , based on the metric system and compatible with OS Grid. And there is always a way to connect these systems and use them together. On the other hand, we live in a networked world with complete links and copies. Often this means that only one survives in a competition of standards. And not necessarily the best. So cross your fingers. ”

Article written in December 2012