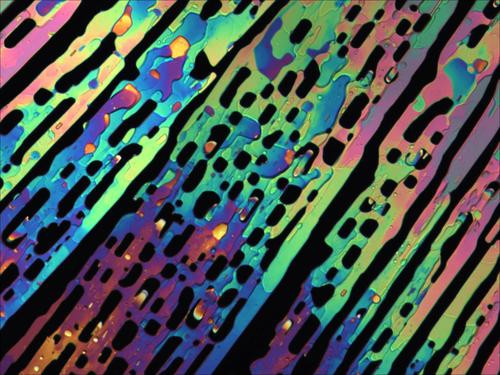

Biotechnology in the manufacture of printed circuit boards: mycelium instead of etching

What scientists are trying to get rid of at any plant - germs, dust, mold and moisture - have decided to adopt Canadian scientists .

A pattern from a nutrient solution is applied to the board, irrigated with fungal spores.

The matrix grows along the solution, forming 90-nanometer paths.

Then the mushrooms are irrigated with a solution of water mixed with the metals dissolved in it.

Then the matrix is drained, and the fibrous structure of the board is obtained according to a given current-conducting circuit.

with smooth bends - which significantly reduces noise from interference between tracks.

The technology does not allow making too tiny boards, but the manufacturing cost is 30% less than similar etching technologies.

The source .

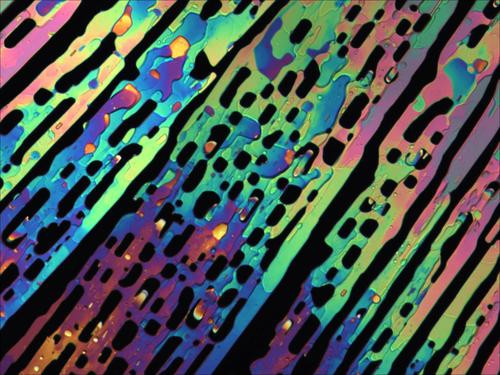

A pattern from a nutrient solution is applied to the board, irrigated with fungal spores.

The matrix grows along the solution, forming 90-nanometer paths.

Then the mushrooms are irrigated with a solution of water mixed with the metals dissolved in it.

Then the matrix is drained, and the fibrous structure of the board is obtained according to a given current-conducting circuit.

with smooth bends - which significantly reduces noise from interference between tracks.

The technology does not allow making too tiny boards, but the manufacturing cost is 30% less than similar etching technologies.

The source .