Triumph and weekdays. How to install the spire on the skyscraper Lakhta Center. Part 1

January 29, 2018 a new Russian satellite was launched into the near-ground orbit. The launch took place in St. Petersburg, in the area of the Lakhta Center construction site.

Start was successful. From Monday, St. Petersburgers can observe a new celestial phenomenon: - the lights of the object's light marking almost a half-kilometer mark above the city. Also, a good overview of the object is from the aircraft approaching the landing at Pulkovo airport.

Of course, this is a joke. In the photo - ground preparation for the installation of a constructive completion of the spire on the tower of Lakhta Center. The installation took place on the same day, January 29, 2018. The main European skyscraper reached the architectural height of 462 meters. The last leg of the way up - the spire of the tower, 117.5 meters high - was done in five months. How was the installation operation in conditions uniquely harsh for the global high-rise construction - read our review.

Lights of light marking on the spire of Lakhta Center. January 29, 2018

January 29, 2018, construction site of Lakhta Center, an hour earlier:

A little earlier:

Early in the morning of the same day:

This lightning-fast and bright finale is only the final part of the operation to install the construction of the spire of a skyscraper. Go down a hundred meters below to find out the whole history of the tower spire - from its very foundation.

Assemblers-spidermen on the tower Lakhta Center. January, 2018 (clickable) Installers and a group of building control engineers at the acceptance of work. Spire tower. December, 2017 (clickable) The installer at the edge of the future facade of the tower. December, 2017 (clickable) Is it scary to build at that height? “The feeling of danger is normal. I used to not accept those who say that they are not afraid of heights , ”says Igor Romanenko, an engineer of the construction team of the Lakhta Center, one of those engineers who go out with checks on the tower’s spire, “ The main thing is that there’s no panic " . "Not. I got used to it, ” Alexander Pimakin, construction engineering engineer of AECOM, shares a universal recipe for acrophobes and explains:

“The tower grew gradually, and I with it - from zero. The most important thing is to keep the situation under control, to strictly follow the rules of safety and labor protection "...

*** ***

The tower grew gradually - from September 2015. Exactly two years later - in September 2017, a unique operation to install the Supertoll spire began. Climbing has accelerated twice. The reason is in particular the construction of the final part of the skyscraper.

The Lahta Center Spire is a pyramidal frame composed of several types of elements.

The main supporting structures are columns-columns of meter-section pipes.

Spire frame: column columns, Ø 1020 mm. December, 2017

Every 8.4 m of the rack are fastened by horizontal and diagonal connections - also tubular, but of smaller diameter. Horizontal elements are annular beams. Diagonal - beam braces.

Spire frame: ring beams and beam-braces. December, 2017

Another type of elements of the spire is responsible for its architectural scope.

The tower in the plan has a pentagonal shape, and in height there are “ribs” spiraling around the central axis.

Spinning tower shape. The outer corners of the building are shaped by the “ribs” of the skyscraper. January, 2018

In order for the spire to be an organic continuation of this complex volume, half-timbered beams were introduced into the framework, forming triangles in plan. Such structures are placed on five sides and create the outer corners of the spire.

Half-timbered beams to form a spire. December, 2017 At the expense of the half-timbered beams the spire is an organic continuation of the tower. December, 2017 (clickable) The main elements of the pyramidal frame of the spire. December, 2017 Above 420 meters, when the spire is narrowed as much as possible, instead of five perimeter columns, a central pillar appears - also a tubular section with a diameter of 1420 mm. The final 13 meters - the cone-shaped final design of the spire. General scheme of the spire construct

On the half-timbered frame formed by force elements, the facing of the spire is fastened.

It has an important feature: instead of glass, a stainless steel mesh is installed in the frames.

Mesh samples for facing the spire facade. Layout area. June, 2016

Grid in the front profile. Spire Lakhta Center. December, 2017

Replacing glass with a grid is a necessity in St. Petersburg microclimate conditions.

Humidity and cold contribute to the formation of ice, and most of the spire passes through unheated space.

Unheated metal at height: icing of cranes. January, 2018

The cellular structure of the surface prevents the snow from splicing into layers, and the ice into large icicles. When gathering, for example, under gusts of wind, the snow breaks up into small fractions. In other cases, the wire mesh becomes a kind of rebar, which is growing ice - reinforced by a metallic rod, it is more resistant to spontaneous chipping.

For example, a photo of a crane on which you can compare the formation of a snow layer on a solid and mesh surface: The

formation of snow cover on an unheated metal surface:

1 - a solid frozen surface with snow cover

2 - a surface with a cellular structure, a snow layer is not formed

The decision on the facing of the facade was done, of course, not while observing cranes - this is just an illustration. Lakhta Center is the northernmost skyscraper in the world. The matter is aggravated by the transition to the sea climate, with humidity of 94% and active circulation of air masses with fast and frequent changes in the weather. For the PIC system , different options were considered, for example, coatings preventing metal adhesion with ice. According to the results of calculations and a series of field tests in Russia and Canada, they settled on the most effective variant - mesh facing. And for special weather cases in part of the structures of the spire laid profile with a heating cable. When certain indicators for ice formation are achieved, the BMSS includes a small heating, to prevent the formation of ice.

POS tests for Lakhta Center

Heating elements will be launched after the completion of the skyscraper’s engineering systems.

Will there be a difference between the glass and the grid in the facade of a skyscraper? To pick up two different materials so that they look like the same - a challenge for designers. The thickness, color, texture of steel wire for making the mesh was long and carefully selected.

Front elements of the spire. December, 2017

On hand designers - the height. If at a distance of a meter the glass is distinguished from the grid by anyone, then for half a kilometer, given the careful selection of the texture of materials, this is unlikely.

Will there be precipitation inside the spire due to its mesh lining? Insects? Birds?

The height of the mesh is small - just over 25 mm. Further did not become smaller - it would increase the windage of the spire. Enlarge - also, otherwise the question of birds would become relevant. Ubiquitous mosquitoes remain. But above the 20th floor of the tower, their flights have not yet been observed.

Spike facade mesh

But the snow and rain in the sub-spill space will be able to fall. But this is not a big problem. Everything that will be located inside the spire is made of anti-corrosion materials, resistant to different weather conditions. A small accumulation of precipitation on the upper overlap is a permissible thing. After all, no one seriously worried about the snow or puddles on the roof of the house? The Petersburg TV tower does not suffer from precipitation, does not close the pipes of plants in the snow or rain.

***

The installation of the spire was divided into four stages - in accordance with the features of its four constructive zones.

September-October 2017

The first zone is a transitional, conditionally “pre-sawd” space. This is the habitable and heated part, from the 83rd floor to level 88 (elevation 378 meters).

Level 88. Above - only the spire The

five transitional floors of the tower differ from the others only in that the supporting perimeter composite columns give way to steel columns-racks. Otherwise, there are no differences: all the constructive elements of other habitable zones of the skyscraper are present: core, interfloor overlappings, glass facade ...

At level 83, end of August 2017. The first section with steel pillars

Rack columns have a smaller diameter compared to composite. In addition to the constructive possibility to reduce the cross-section, this has a plus of operational properties: improved visibility in the panoramic restaurant and on the Lakhta Center observation platform.

Panoramic restaurant on the 76th floor of the tower of Lakhta Center. Visualization The

transitional space ends with an overlap at level 88. Conventionally, the overlap on the 88th can be called the "roof" of the building. At the stage of passing this level, Lakhta Center became the tallest skyscraper in Europe, having overtaken the Federation Tower - even before the installation of the half-timbered spire.

October-December 2017 The

second stage - from level 89 to level 100 (elevation 428 m). Here we already see the half-timbered spire in its purest form. From level 89, the number of columns is reduced from ten to five: this is enough to carry a lightweight frame and steel mesh cladding. The spire weighs about 2,000 tons - an almost imperceptible amount of 670,000 tons of the total mass of the tower.

In order for the columns to maintain the correct spatial position from the moment they were installed until they were fixed by ring beams and diagonals, the builders used temporary structures-struts. The assembly of a framework is an algorithm of several sequential operations: installation of columns - fixing with spacers - installation of diagonal and ring beams - dismantling of temporary structures.

The facade is not fixed yet: below, at level 88, concrete in-floor hardens. But then the stairs and the system of suspended platforms along the perimeter of the future spire facade are mounted immediately. In the life of the spire after construction, those who serve the structure and equipment located inside will move along these paths. English-speaking contractors call such overhead “roads” “feline” - cat wau.

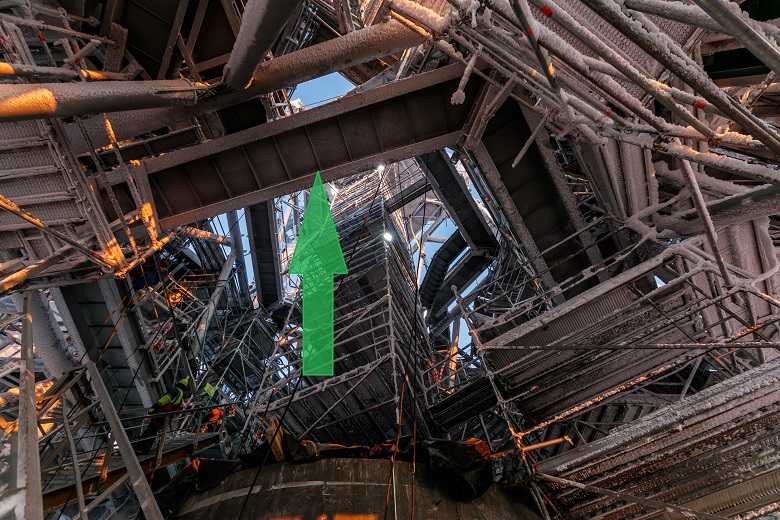

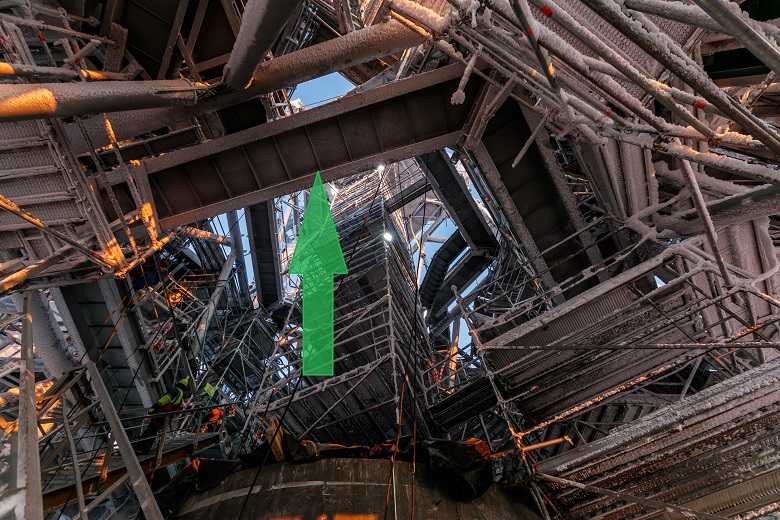

Suspended platform in the spire of the tower. January, 2018

December 2017- January 2018 A

mark of 420 meters is the last level of steel perimeter columns. In this section, they pass the baton to the central pillar column.

Lowering to the mounting level of the first segment of the central column. December 2017

The transition from the perimeter columns to the central rack. January, 2018

The constructs of the highest levels of the tower are collected on the ground. These are spire blocks that start at the hundredth level. On the ground, they are mounted on two annular beams with a front element between them.

Assembling the element of the spire on the ground. January, 2018

Then the crane lifts the assembled element to a height, and the installers install it on the central tube, like on the core of a pyramid.

Lifting precast unit

General view of the spire on the eve of the final. January, 2018

January 2018 January

28-29, 2018 - mark 449 m. Installation of the final design of the spire. This is the most difficult part of the whole operation. The maximum height, wind, features of constructive completion of the spire and extension of crane equipment - these are the factors that make this part of the process exceptional.

How it happened - read in the second part of the review. There you will find answers to the questions: what did the builders wait for a few days before the start of the operation? Why did the crane specialists think that it was impossible to install the final part of the spire by a crane? Why not call the helicopters? How did the builders' days go by at exorbitant levels? And what is the most frequent answer to the question - what is most remembered at a construction site in Lahta?

***

Continue the material on the spire read here

***

Thank you for helping to prepare the material for the construction engineer of the customer service IFC Lakhta Center Igor Romanenko, AECOM building control engineer Alexander Pimakin, Renaissance Construction engineer Rustam Doschanov, Liebherr service engineer Sergey Prochuhan.

Photos of Vyacheslav Korolev (operation on installation of a spire, inside a spire), Alexey Svotin (photo from cranes), Ruslan Genk (photo from cranes), Nikolai Gontarya (summer), Ivan Smelov (summer), Igor Romanenko (clouds), Rustam Doschanov ( cranes, spire mounting operation), Alexander Pimakin (clouds over the city, sunset).

Start was successful. From Monday, St. Petersburgers can observe a new celestial phenomenon: - the lights of the object's light marking almost a half-kilometer mark above the city. Also, a good overview of the object is from the aircraft approaching the landing at Pulkovo airport.

Of course, this is a joke. In the photo - ground preparation for the installation of a constructive completion of the spire on the tower of Lakhta Center. The installation took place on the same day, January 29, 2018. The main European skyscraper reached the architectural height of 462 meters. The last leg of the way up - the spire of the tower, 117.5 meters high - was done in five months. How was the installation operation in conditions uniquely harsh for the global high-rise construction - read our review.

Lights of light marking on the spire of Lakhta Center. January 29, 2018

January 29, 2018, construction site of Lakhta Center, an hour earlier:

A little earlier:

Early in the morning of the same day:

This lightning-fast and bright finale is only the final part of the operation to install the construction of the spire of a skyscraper. Go down a hundred meters below to find out the whole history of the tower spire - from its very foundation.

A couple months earlier

Assemblers-spidermen on the tower Lakhta Center. January, 2018 (clickable) Installers and a group of building control engineers at the acceptance of work. Spire tower. December, 2017 (clickable) The installer at the edge of the future facade of the tower. December, 2017 (clickable) Is it scary to build at that height? “The feeling of danger is normal. I used to not accept those who say that they are not afraid of heights , ”says Igor Romanenko, an engineer of the construction team of the Lakhta Center, one of those engineers who go out with checks on the tower’s spire, “ The main thing is that there’s no panic " . "Not. I got used to it, ” Alexander Pimakin, construction engineering engineer of AECOM, shares a universal recipe for acrophobes and explains:

“The tower grew gradually, and I with it - from zero. The most important thing is to keep the situation under control, to strictly follow the rules of safety and labor protection "...

*** ***

SPEAK THEORY

The tower grew gradually - from September 2015. Exactly two years later - in September 2017, a unique operation to install the Supertoll spire began. Climbing has accelerated twice. The reason is in particular the construction of the final part of the skyscraper.

Metal carcass

The Lahta Center Spire is a pyramidal frame composed of several types of elements.

The main supporting structures are columns-columns of meter-section pipes.

Spire frame: column columns, Ø 1020 mm. December, 2017

Every 8.4 m of the rack are fastened by horizontal and diagonal connections - also tubular, but of smaller diameter. Horizontal elements are annular beams. Diagonal - beam braces.

Spire frame: ring beams and beam-braces. December, 2017

Another type of elements of the spire is responsible for its architectural scope.

The tower in the plan has a pentagonal shape, and in height there are “ribs” spiraling around the central axis.

Spinning tower shape. The outer corners of the building are shaped by the “ribs” of the skyscraper. January, 2018

In order for the spire to be an organic continuation of this complex volume, half-timbered beams were introduced into the framework, forming triangles in plan. Such structures are placed on five sides and create the outer corners of the spire.

Half-timbered beams to form a spire. December, 2017 At the expense of the half-timbered beams the spire is an organic continuation of the tower. December, 2017 (clickable) The main elements of the pyramidal frame of the spire. December, 2017 Above 420 meters, when the spire is narrowed as much as possible, instead of five perimeter columns, a central pillar appears - also a tubular section with a diameter of 1420 mm. The final 13 meters - the cone-shaped final design of the spire. General scheme of the spire construct

Non-freezing

On the half-timbered frame formed by force elements, the facing of the spire is fastened.

It has an important feature: instead of glass, a stainless steel mesh is installed in the frames.

Mesh samples for facing the spire facade. Layout area. June, 2016

Grid in the front profile. Spire Lakhta Center. December, 2017

Replacing glass with a grid is a necessity in St. Petersburg microclimate conditions.

Humidity and cold contribute to the formation of ice, and most of the spire passes through unheated space.

Unheated metal at height: icing of cranes. January, 2018

The cellular structure of the surface prevents the snow from splicing into layers, and the ice into large icicles. When gathering, for example, under gusts of wind, the snow breaks up into small fractions. In other cases, the wire mesh becomes a kind of rebar, which is growing ice - reinforced by a metallic rod, it is more resistant to spontaneous chipping.

For example, a photo of a crane on which you can compare the formation of a snow layer on a solid and mesh surface: The

formation of snow cover on an unheated metal surface:

1 - a solid frozen surface with snow cover

2 - a surface with a cellular structure, a snow layer is not formed

The decision on the facing of the facade was done, of course, not while observing cranes - this is just an illustration. Lakhta Center is the northernmost skyscraper in the world. The matter is aggravated by the transition to the sea climate, with humidity of 94% and active circulation of air masses with fast and frequent changes in the weather. For the PIC system , different options were considered, for example, coatings preventing metal adhesion with ice. According to the results of calculations and a series of field tests in Russia and Canada, they settled on the most effective variant - mesh facing. And for special weather cases in part of the structures of the spire laid profile with a heating cable. When certain indicators for ice formation are achieved, the BMSS includes a small heating, to prevent the formation of ice.

POS tests for Lakhta Center

Heating elements will be launched after the completion of the skyscraper’s engineering systems.

How to combine types of facades

Will there be a difference between the glass and the grid in the facade of a skyscraper? To pick up two different materials so that they look like the same - a challenge for designers. The thickness, color, texture of steel wire for making the mesh was long and carefully selected.

Front elements of the spire. December, 2017

On hand designers - the height. If at a distance of a meter the glass is distinguished from the grid by anyone, then for half a kilometer, given the careful selection of the texture of materials, this is unlikely.

Walk through the facade

Will there be precipitation inside the spire due to its mesh lining? Insects? Birds?

The height of the mesh is small - just over 25 mm. Further did not become smaller - it would increase the windage of the spire. Enlarge - also, otherwise the question of birds would become relevant. Ubiquitous mosquitoes remain. But above the 20th floor of the tower, their flights have not yet been observed.

Spike facade mesh

But the snow and rain in the sub-spill space will be able to fall. But this is not a big problem. Everything that will be located inside the spire is made of anti-corrosion materials, resistant to different weather conditions. A small accumulation of precipitation on the upper overlap is a permissible thing. After all, no one seriously worried about the snow or puddles on the roof of the house? The Petersburg TV tower does not suffer from precipitation, does not close the pipes of plants in the snow or rain.

***

FOUR STEPS TO THE TOP

The installation of the spire was divided into four stages - in accordance with the features of its four constructive zones.

Step 1: Record Zone

September-October 2017

The first zone is a transitional, conditionally “pre-sawd” space. This is the habitable and heated part, from the 83rd floor to level 88 (elevation 378 meters).

Level 88. Above - only the spire The

five transitional floors of the tower differ from the others only in that the supporting perimeter composite columns give way to steel columns-racks. Otherwise, there are no differences: all the constructive elements of other habitable zones of the skyscraper are present: core, interfloor overlappings, glass facade ...

At level 83, end of August 2017. The first section with steel pillars

Rack columns have a smaller diameter compared to composite. In addition to the constructive possibility to reduce the cross-section, this has a plus of operational properties: improved visibility in the panoramic restaurant and on the Lakhta Center observation platform.

Panoramic restaurant on the 76th floor of the tower of Lakhta Center. Visualization The

transitional space ends with an overlap at level 88. Conventionally, the overlap on the 88th can be called the "roof" of the building. At the stage of passing this level, Lakhta Center became the tallest skyscraper in Europe, having overtaken the Federation Tower - even before the installation of the half-timbered spire.

Step 2: Five Columns

October-December 2017 The

second stage - from level 89 to level 100 (elevation 428 m). Here we already see the half-timbered spire in its purest form. From level 89, the number of columns is reduced from ten to five: this is enough to carry a lightweight frame and steel mesh cladding. The spire weighs about 2,000 tons - an almost imperceptible amount of 670,000 tons of the total mass of the tower.

In order for the columns to maintain the correct spatial position from the moment they were installed until they were fixed by ring beams and diagonals, the builders used temporary structures-struts. The assembly of a framework is an algorithm of several sequential operations: installation of columns - fixing with spacers - installation of diagonal and ring beams - dismantling of temporary structures.

The facade is not fixed yet: below, at level 88, concrete in-floor hardens. But then the stairs and the system of suspended platforms along the perimeter of the future spire facade are mounted immediately. In the life of the spire after construction, those who serve the structure and equipment located inside will move along these paths. English-speaking contractors call such overhead “roads” “feline” - cat wau.

Suspended platform in the spire of the tower. January, 2018

Step 3: The central axis, the earth - the sky

December 2017- January 2018 A

mark of 420 meters is the last level of steel perimeter columns. In this section, they pass the baton to the central pillar column.

Lowering to the mounting level of the first segment of the central column. December 2017

The transition from the perimeter columns to the central rack. January, 2018

The constructs of the highest levels of the tower are collected on the ground. These are spire blocks that start at the hundredth level. On the ground, they are mounted on two annular beams with a front element between them.

Assembling the element of the spire on the ground. January, 2018

Then the crane lifts the assembled element to a height, and the installers install it on the central tube, like on the core of a pyramid.

Lifting precast unit

General view of the spire on the eve of the final. January, 2018

Step 4: Final!

January 2018 January

28-29, 2018 - mark 449 m. Installation of the final design of the spire. This is the most difficult part of the whole operation. The maximum height, wind, features of constructive completion of the spire and extension of crane equipment - these are the factors that make this part of the process exceptional.

How it happened - read in the second part of the review. There you will find answers to the questions: what did the builders wait for a few days before the start of the operation? Why did the crane specialists think that it was impossible to install the final part of the spire by a crane? Why not call the helicopters? How did the builders' days go by at exorbitant levels? And what is the most frequent answer to the question - what is most remembered at a construction site in Lahta?

***

Continue the material on the spire read here

***

Thank you for helping to prepare the material for the construction engineer of the customer service IFC Lakhta Center Igor Romanenko, AECOM building control engineer Alexander Pimakin, Renaissance Construction engineer Rustam Doschanov, Liebherr service engineer Sergey Prochuhan.

Photos of Vyacheslav Korolev (operation on installation of a spire, inside a spire), Alexey Svotin (photo from cranes), Ruslan Genk (photo from cranes), Nikolai Gontarya (summer), Ivan Smelov (summer), Igor Romanenko (clouds), Rustam Doschanov ( cranes, spire mounting operation), Alexander Pimakin (clouds over the city, sunset).