FiberForce Wood Wood

Hello! We have a lot of interesting plastics for decorative 3D printing. Today we will tell you about the new product - Wood from the company FiberForce.

Hello! We have a lot of interesting plastics for decorative 3D printing. Today we will tell you about the new product - Wood from the company FiberForce. Coil price 0.5 kg. - 3500 rubles.

FiberForce was founded in 2013 in Italy. In addition to ABS and PLA, FiberForce produces several types of special plastics, in particular FiberForce Carbon , which we have been supplying to Russia for quite a long time and which has proven itself to be excellent.

From the name FiberWood it becomes clear that plastic imitates woodwork. Today we will try to figure out what is its difference from other similar plastics?

Decorative plastics can be divided into 2 types:

1. Imitating only the color of the product due to the added pigments. For example, ESUN Wood or ESUN Bronze .

The undeniable advantage of these plastics - they do not cause problems when printing, and you immediately get a finished product that simulates the color of the metal or wood.

2. They contain in their composition "filling" in the form of a material that is imitated.

For example, ESUN eAfill or eCopper .With these plastics, you should be more attentive to setting up printed parameters. Incorrect parameters can lead to clogging of the nozzle. To “open” the filler, it may sometimes require additional processing of the product after printing.

Wood from FiberForce belongs to the second type of decorative plastics. The basis of the plastic is plain PLA filled with wood dust.

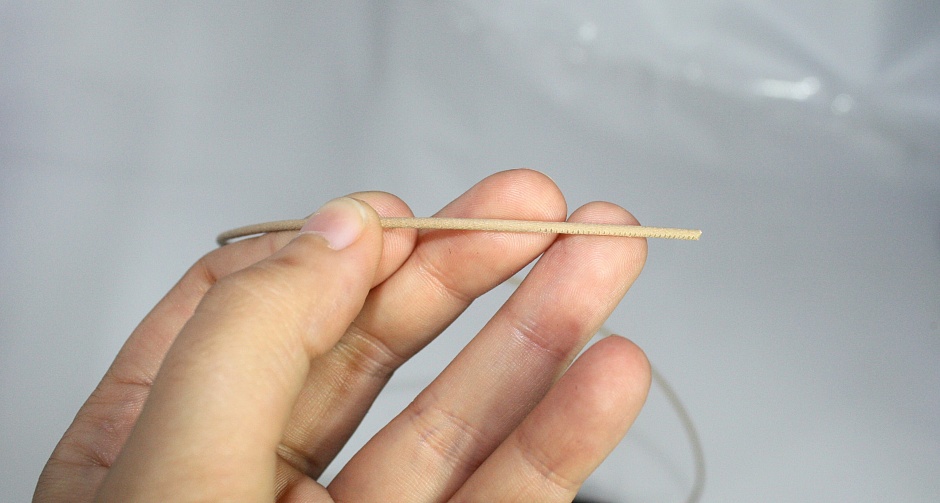

The bar is rough to the touch, with an interesting matte color of light wood.

The recommended nozzle temperature for printing is about 200 degrees, the table is 50-60 degrees. Although plastic sticks perfectly to printed platforms that are not heated. The main thing do not forget to turn on the fan for blowing the model =)

When printing plastic smells very nice fresh sawdust. Unlike similar plastic LAYWOO-D3, Fiber Wood does not change color when printing temperature changes, does not clog the nozzle and is very stable when printing. LAYWOO-D3 - managed to stably print only using nozzles of large diameter (from 0.8).

After 40 minutes of printing we get just such a pretty typewriter)

The surface of the products looks very beautiful. Due to the haze of the material, almost no layers are visible.

Surprisingly, our jar inside still smells of wood =)

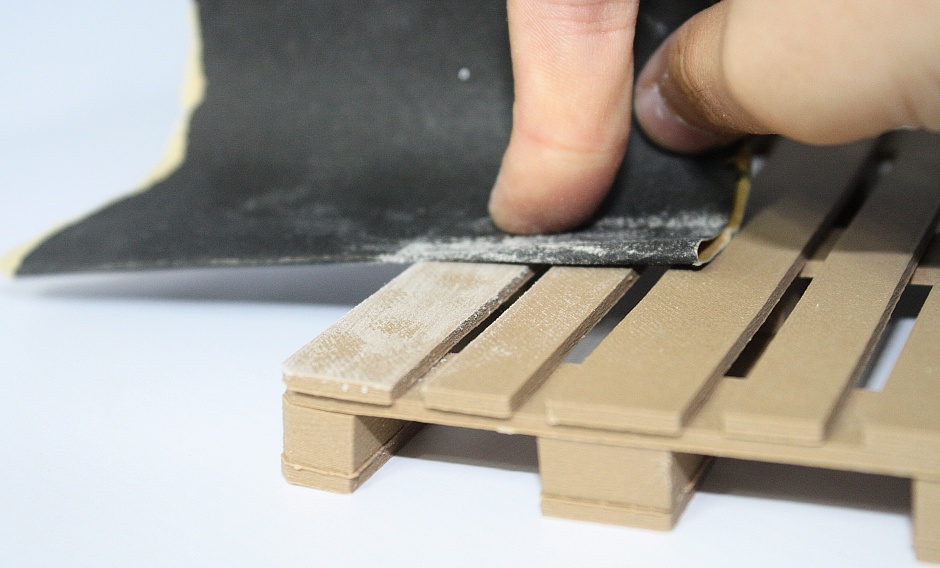

Products from FiberWood perfectly sand and processed.

Results

The most important advantage of FiberWoodot Fiber Force is that, unlike other similar materials with which we printed, the risk of nozzle clogging is minimized. And all thanks to the optimal (small) content of wood dust. This decorative plastic did not give us trouble and showed itself well when printing. Although Fiber Wood is a PLA plastic base, it is perfectly skinned, cut and processed. This turned out to be a nice plus.

It is great for creating decorative elements, art objects or everyday objects under the tree.

Subscribe to our groups on Facebook, VK and YouTube to keep up with the latest events =)

→ VKontakte

→ YouTube

The team of the company Color World