Is it easy to lay a cow on its side?

Immediately a reasonable question arises - why lay the cow on its side, if this beast stays on its feet and feels good in this position? The answer is given by veterinarians. The scourge of modern animal husbandry - diseases of the hoofs of cattle, which arise because of the stall. Cows do not have enough exercise, so hoof diseases begin that will have grave consequences. It is more convenient to handle and treat hoofs using a special device that allows you to lay the cow on its side and carry out all the necessary surgical procedures. But how to do this if the weight of a good cow is half a ton or more, and there is no particular desire to lie on its side? It didn’t do without original ideas, that's why anyone is interested - I ask for cat.

Immediately a reasonable question arises - why lay the cow on its side, if this beast stays on its feet and feels good in this position? The answer is given by veterinarians. The scourge of modern animal husbandry - diseases of the hoofs of cattle, which arise because of the stall. Cows do not have enough exercise, so hoof diseases begin that will have grave consequences. It is more convenient to handle and treat hoofs using a special device that allows you to lay the cow on its side and carry out all the necessary surgical procedures. But how to do this if the weight of a good cow is half a ton or more, and there is no particular desire to lie on its side? It didn’t do without original ideas, that's why anyone is interested - I ask for cat.A little more about the problem ...

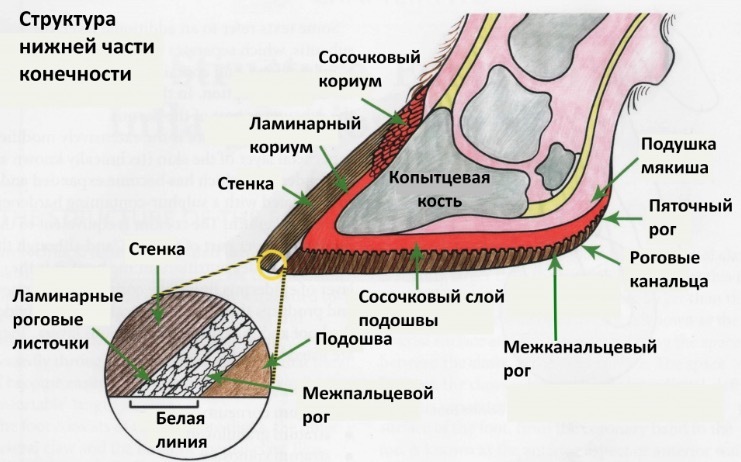

As it is reliably known, a cow has four legs, which are quite difficult to build. Nature laid down that a cow must wander a lot. This is called exercise.

During exercise, a cow evenly wears its hooves, trains its joints and feels good. In the industrial content of the cows lack of physical activity, the natural mechanism is broken, the hoof does not wear out at the proper level and diseases of the hoof occur, which can lead to serious problems.

Such pretty often. The picture is not pleasant!

In addition to the sharp drop in milk yield, damage can occur that lead to lameness and even death of the animal. Therefore, the hooves must be treated for prophylactic purposes and the treatment of already damaged limbs. This is especially true for expensive elite species of livestock, when the cost of a cow can reach hundreds of thousands of rubles for the beast.

High-speed OCD

Surprisingly, there are still people who can do something quickly enough. So in this case, I ended up visiting a company that is engaged in engineering new technology. The main task of the company is to develop and make a prototype of an industrial device in the shortest possible time. This work is called the experimental design development (OCD). This OCD was performed only 90 (!) Days. From the idea, prototyping, discussion over a glass of cognac of the future piece of iron, drawing up draft design documentation, sending to pilot production and starting tests. But it all starts with a technical specification (TZ), which is agreed with the customer. At the same time, the terms of reference should be drawn up especially carefully (it is better to issue it in accordance with GOST R 15.201-2000. The system for developing and putting products into production).

The preparation of the TOR is one of the most important starting stages of OCD. The technical task discusses all technical issues that are described in as much detail as possible. I even have an idea to describe in a separate article the peculiarities of drawing up TK for such devices, but this is still beyond the scope of this publication. A feature of the team that made this project is the presence of a technical artist who drew the “concept” of the future device.

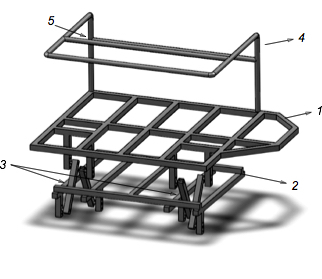

It is not necessary for the end device to look like this “concept”. The task is different - designers and developers should visualize the device, present what they need to do as much as possible. So, the surgical table on which the cow should be located, which is necessary to be put on this table, is being transported on a car trailer. The cow needs to be securely fastened and safely turned on its side. In this case, too, the hoof must be securely fastened. The device must withstand a large weight of the animal and, in the future, be as robotic as possible.

In the design of the device should be used hydraulic actuators of the node turning the table, as it is donefrom foreign competitors. But laying the beast on its side must be done carefully so as not to scare and injure the animal. The device is controlled by an electronic controller.

The main problem is the mechanism of turning the table from vertical to horizontal position. Requirements for such a mechanism suggested by veterinarians. The cow should be securely fastened with wide straps and moved to the side without a noticeable rise so that the cow does not feel a noticeable pressure on the belly, especially in the udder area. Thus, the design of the lifting mechanism must be original and provide a quick and reliable animal flipping.

Chebyshev mechanisms

In our age of high technology, we often forget about various amazing things that were invented by talented people in the nineteenth century. To those people, I take Pafnuti Chebyshev , a Russian mathematician and mechanic who invented hundreds of various amazing mechanisms, without any stretch . Chebyshev created walking mechanisms, presses, lever actuators. There is even a theorem, according to which, you can create a lever mechanism Chebeshev, which can describe any curve on the plane. A curve of any complexity. Imagine your signature. Let even the most ornate. So, theoretically, a lever mechanism can be created, one of the points of which will completely repeat your signature. Such a funny mathematics. Of course, such a mechanism will be very complicated, but all the same. Chebyshev mechanisms are promising to use in robotics, mechanics and other areas where a simple and reliable drive or movement of cargo is required. There is a wonderful video where you can learn more about Chebeshev mechanisms.

In our age of high technology, we often forget about various amazing things that were invented by talented people in the nineteenth century. To those people, I take Pafnuti Chebyshev , a Russian mathematician and mechanic who invented hundreds of various amazing mechanisms, without any stretch . Chebyshev created walking mechanisms, presses, lever actuators. There is even a theorem, according to which, you can create a lever mechanism Chebeshev, which can describe any curve on the plane. A curve of any complexity. Imagine your signature. Let even the most ornate. So, theoretically, a lever mechanism can be created, one of the points of which will completely repeat your signature. Such a funny mathematics. Of course, such a mechanism will be very complicated, but all the same. Chebyshev mechanisms are promising to use in robotics, mechanics and other areas where a simple and reliable drive or movement of cargo is required. There is a wonderful video where you can learn more about Chebeshev mechanisms.

Let's return to the surgical table for cows. In the design of the table was also used one of the mechanisms of Chebyshev.

The blue line is the plane of attachment of the table. Thus, the table does not rise in height, almost immediately goes into the horizontal plane and very quickly, which allows you to lay the cow on the side without much difficulty and stress for the animal. Since there is no rise in height, the load on the udder is minimal, which is also very important. After prototyping, the design of the coup mechanism is born, which is sent to pilot production.

The bases of the Chebyshev mechanisms 3 are mounted on the subframe 2 and are connected with the plane of the table 1 . The device has a limiting animal split 4 and the place of the cow attachment mechanism with wide straps 5 . The movement of the device carries a hydraulic piston. The device as a whole is mounted on a trailer for transportation. Very comfortably. You can handle hooves and treat animals on farms that can be located far from each other or belong to different owners. Then, using such a device, you can provide hoof treatment services, which in itself is quite an interesting niche for business.

Of course, the tests showed some design flaws, which always happens.

It was interesting for me to visit these wonderful guys who are engaged in “iron” OCD, especially in our not easy times.

Have a nice day, everyone!